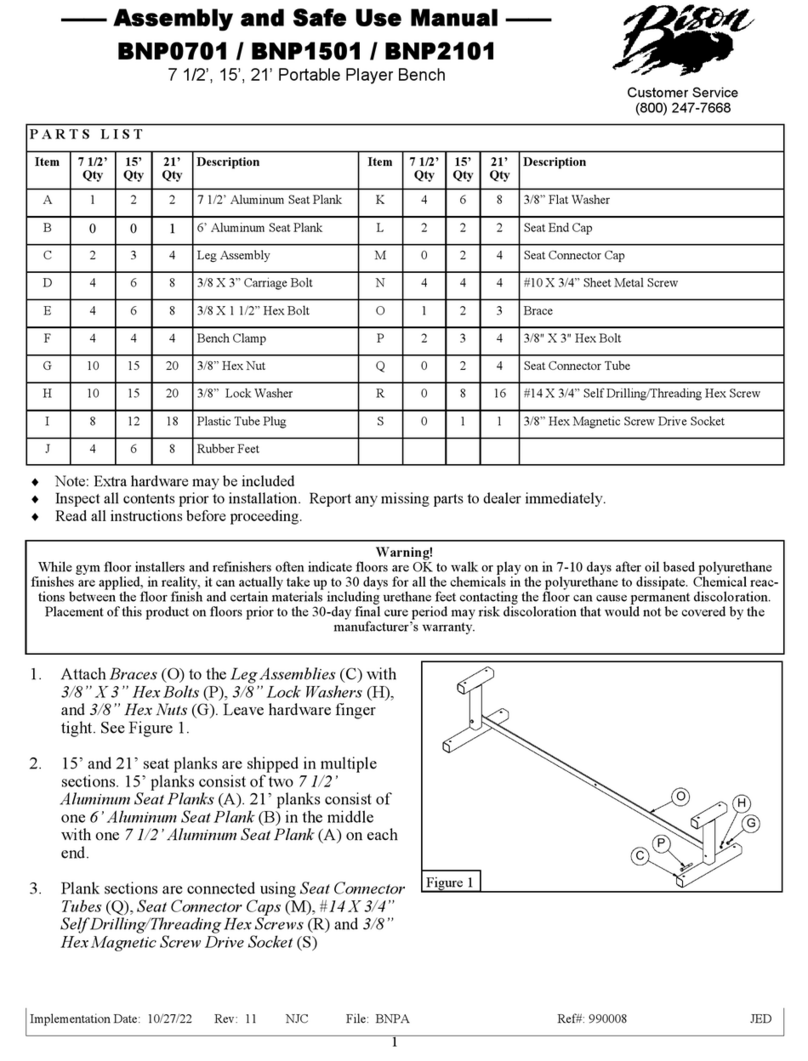

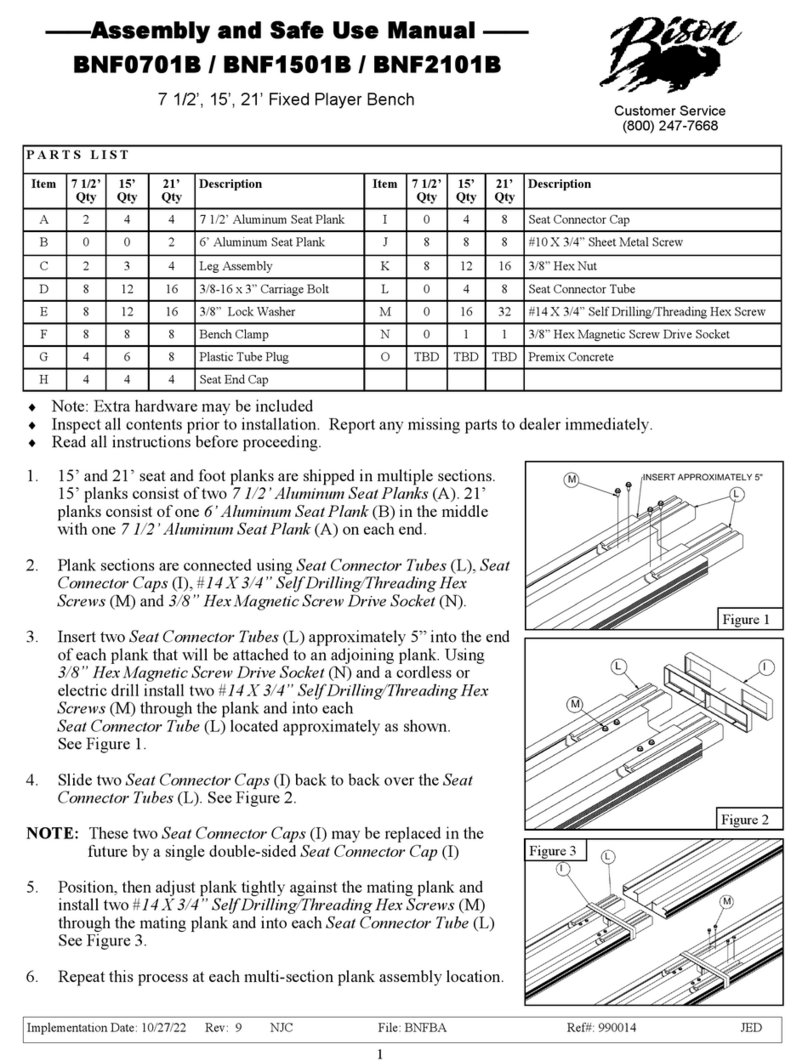

Bison BNF0701 Quick guide

Other Bison Indoor Furnishing manuals

Popular Indoor Furnishing manuals by other brands

Mocka

Mocka Claremont Bedside Table Assembly instructions

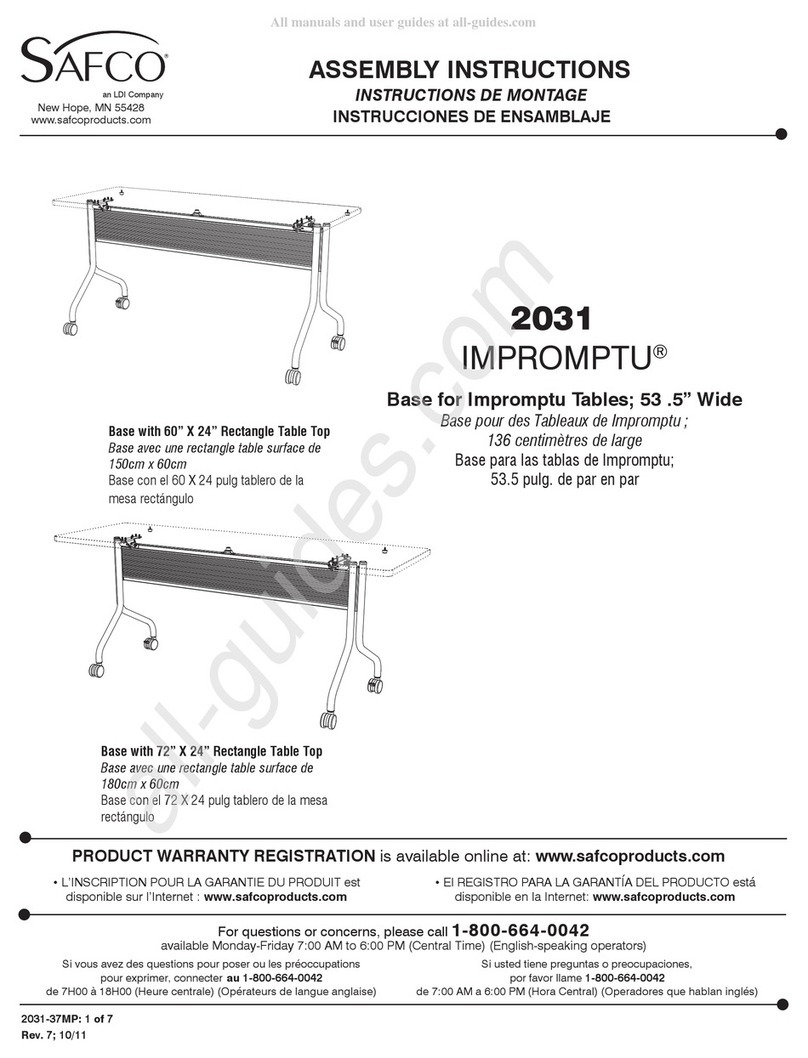

LDI

LDI Safco Impromptu 2031 Assembly instructions

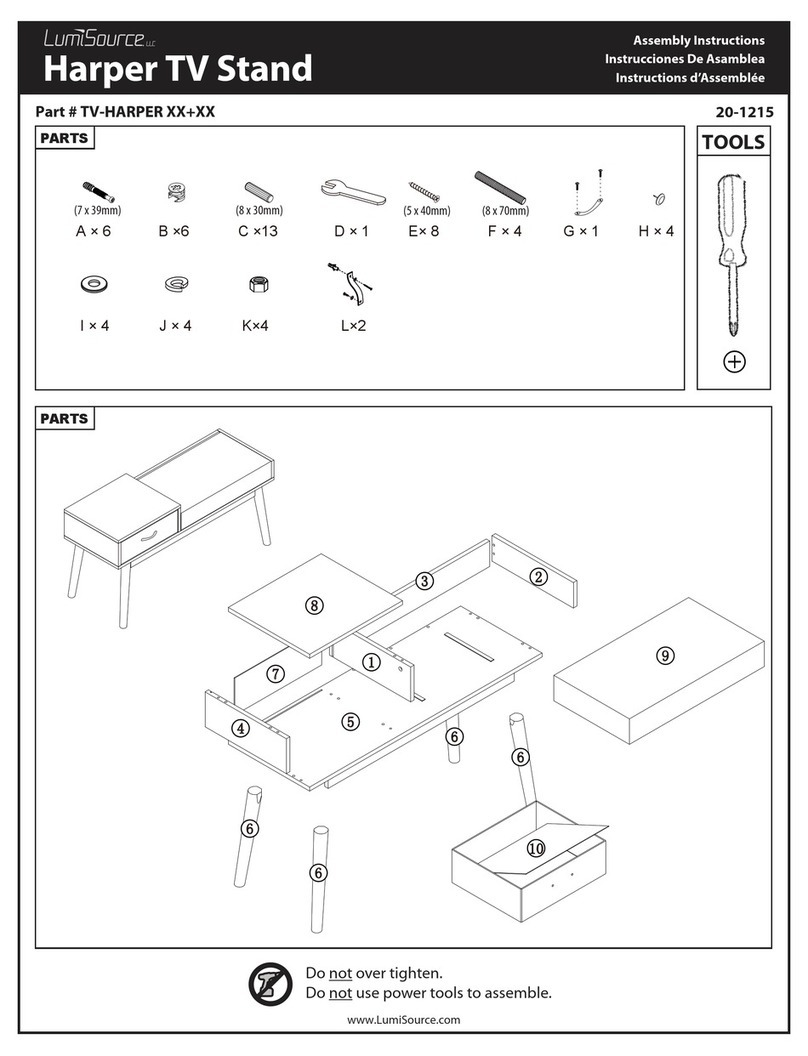

LumiSource

LumiSource TV-HARPER Series Assembly instructions

Crate&Barrel

Crate&Barrel Small Space Bunk Bed Assembly instructions

Dorel Home Products

Dorel Home Products 4120139WE manual

Coolaroo

Coolaroo AutoSun Custom Made instruction manual

Songmics

Songmics VASAGLE LWS031 manual

Forte

Forte CTGV531 Assembling Instruction

Sauder

Sauder Steel River 423976 Instruction booklet

FILCAR

FILCAR Linea 670 AT-C2-R067 Assembly instructions

Teulat

Teulat Doric 14951 TE Assembly instructions

Amart Furniture

Amart Furniture BROOKHAVEN 72570 Assembly instruction

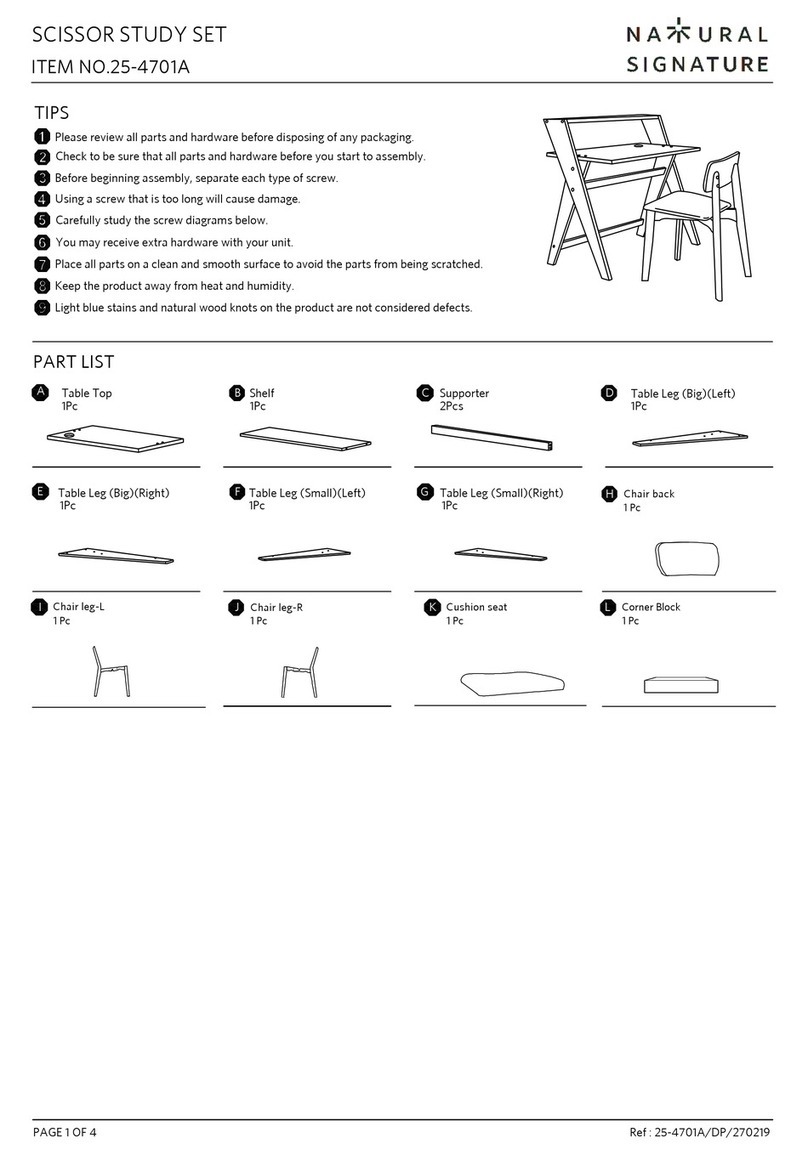

Natural Signature

Natural Signature 25-4701A quick start guide

Hillsdale Furniture

Hillsdale Furniture EASTMAN ADJUSTABLE BARSTOOL 5350-830 Assembly instructions

SMITH SYSTEM

SMITH SYSTEM Flavors P-Tablet Assembly instructions

Stack-On

Stack-On GORTA-7203 Assembly

Unfinished Furniture of Wilmington

Unfinished Furniture of Wilmington WC-10 Assembly instructions

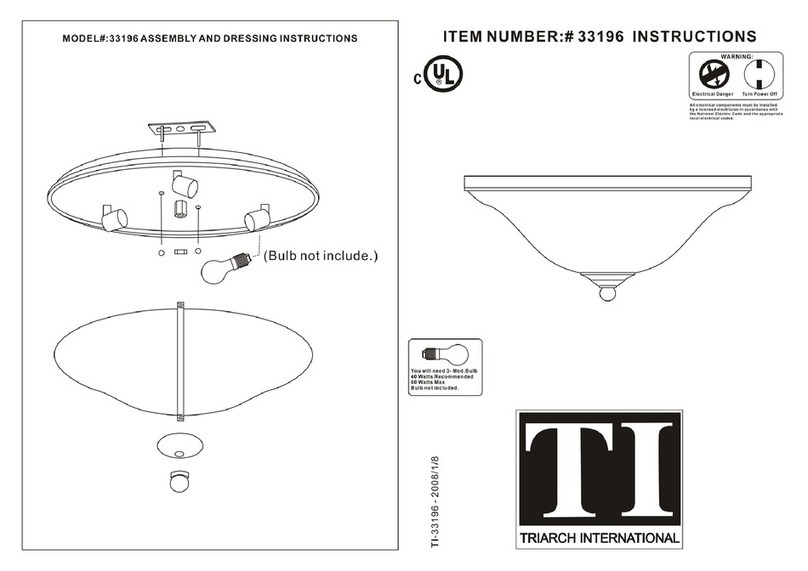

Triarch

Triarch Indoor Lighting 33196 instructions