Bison BNF0701B Quick guide

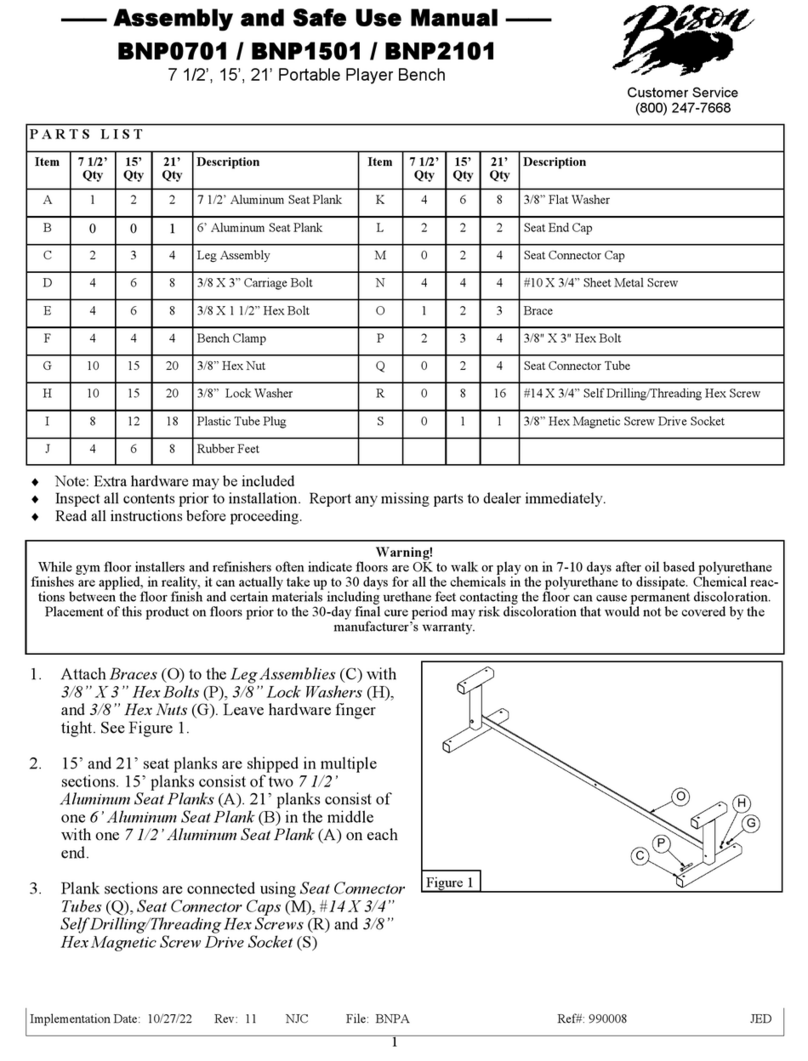

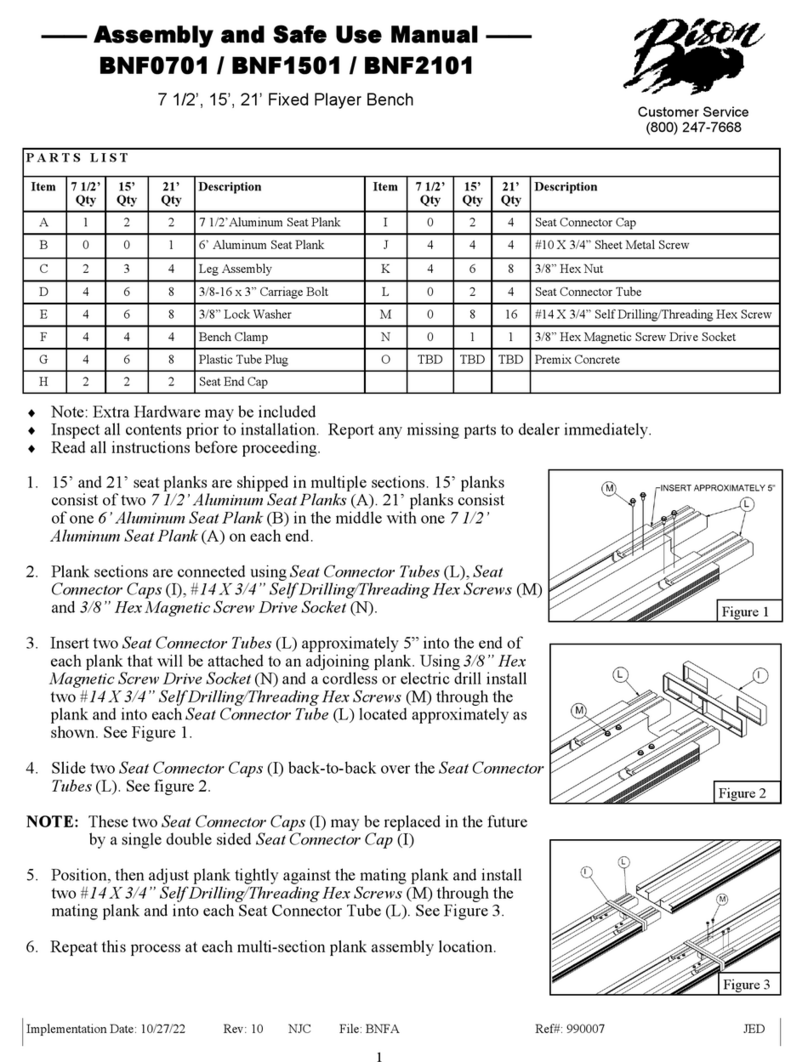

Other Bison Indoor Furnishing manuals

Popular Indoor Furnishing manuals by other brands

DS Produkte

DS Produkte 01128 instructions

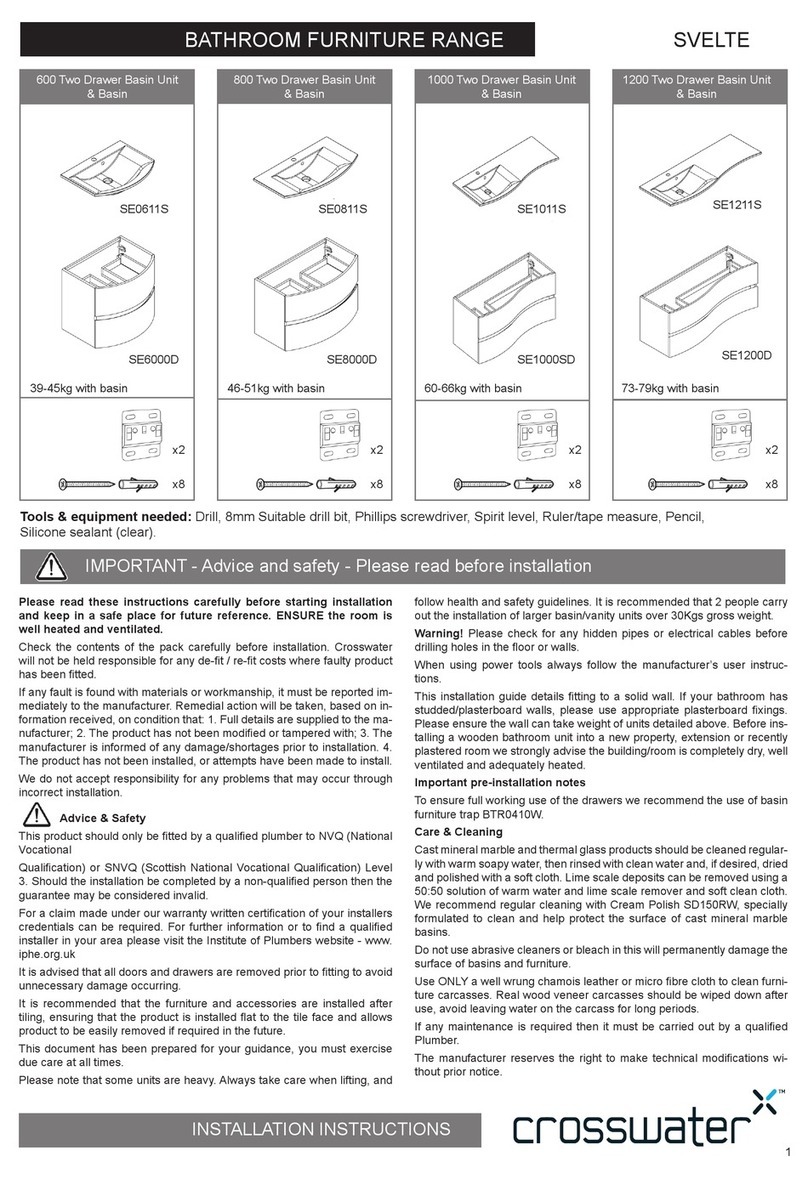

Crosswater

Crosswater SVELTE 600 Series installation instructions

Home Decorators Collection

Home Decorators Collection B272-QM079 Use and care guide

CANARMNA

CANARMNA HUTTON 203494-04TZ Assembly instruction

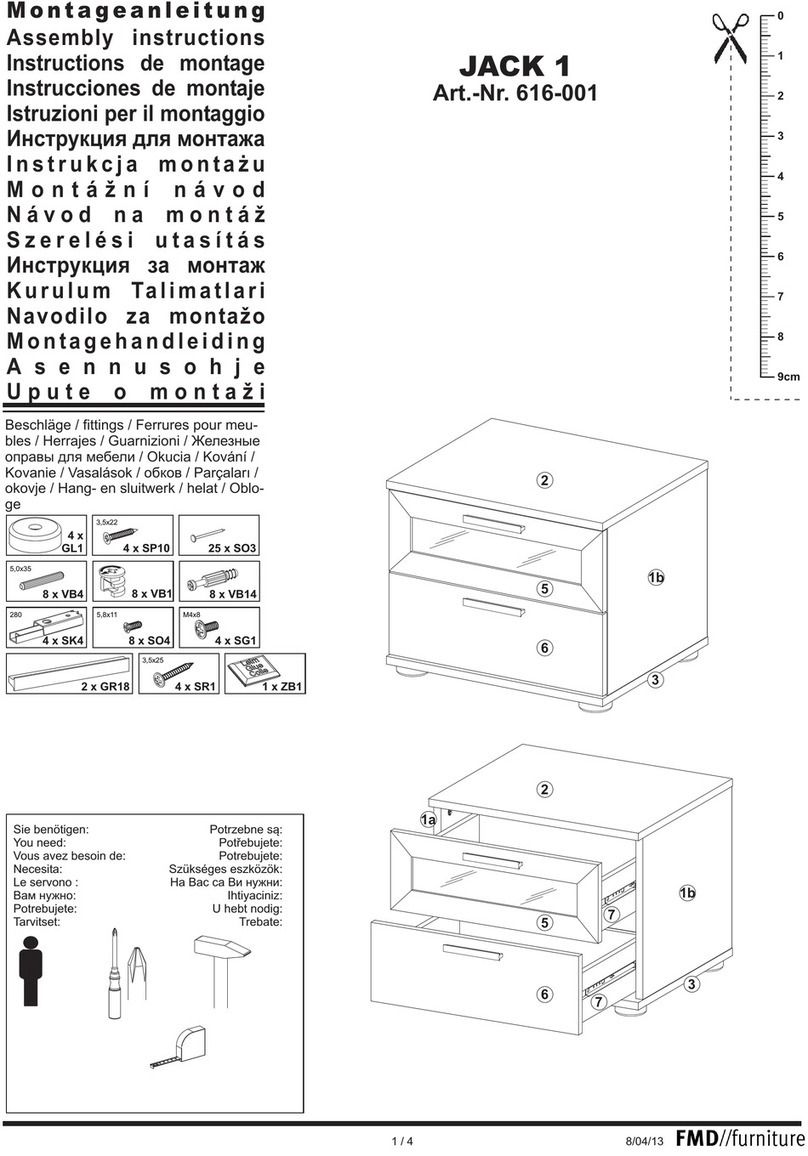

FMD Furniture

FMD Furniture JACK 1 616-001 Assembly instructions

Walker Edison

Walker Edison BR52DAP6D Assembly instruction

Cooper Lighting

Cooper Lighting Interior Wall Luminaire 673 Specification sheet

Dorel Living

Dorel Living BELMONT DA1026P-18 Instruction booklet

DTY

DTY INDOOR LIVING Cortez IF-1060 quick start guide

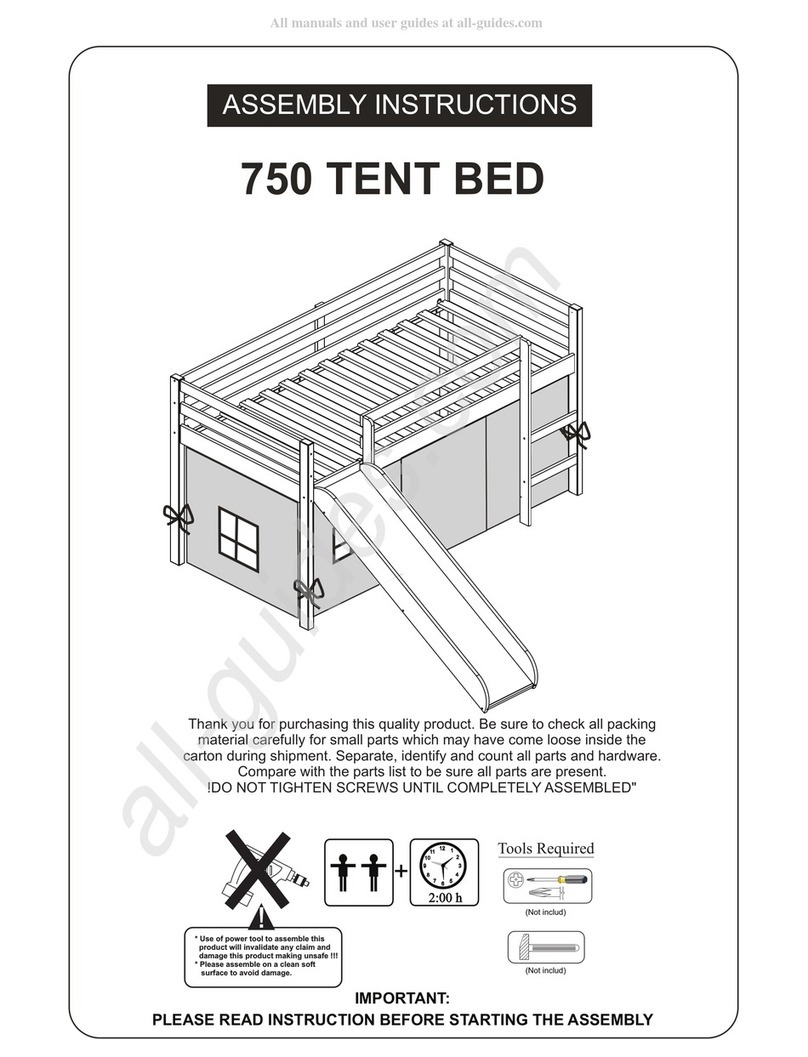

Donco

Donco 750 TENT BED Assembly instructions

Home Decorators Collection

Home Decorators Collection WYNDOVER GC-41101-AAT Use and care guide

RiverRidge

RiverRidge Somerset 06-039 Assembly instructions

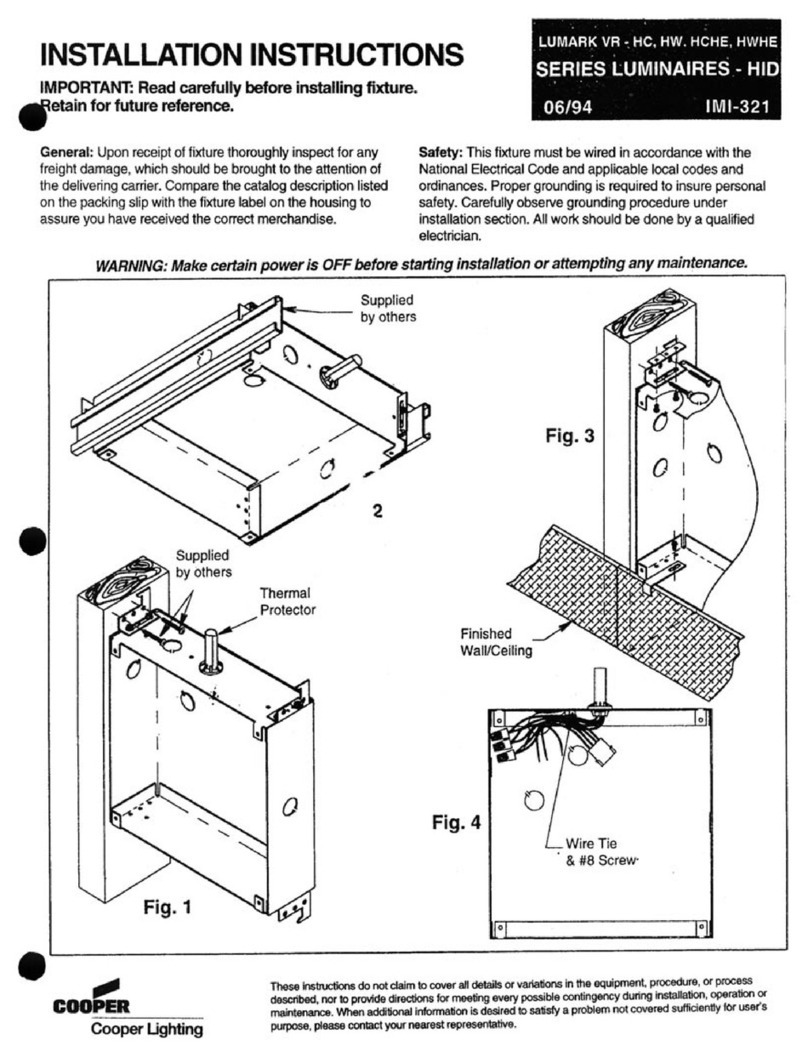

Cooper Lighting

Cooper Lighting IMI-321 installation instructions

Dorel Home Products

Dorel Home Products 4234019WE Instruction booklet

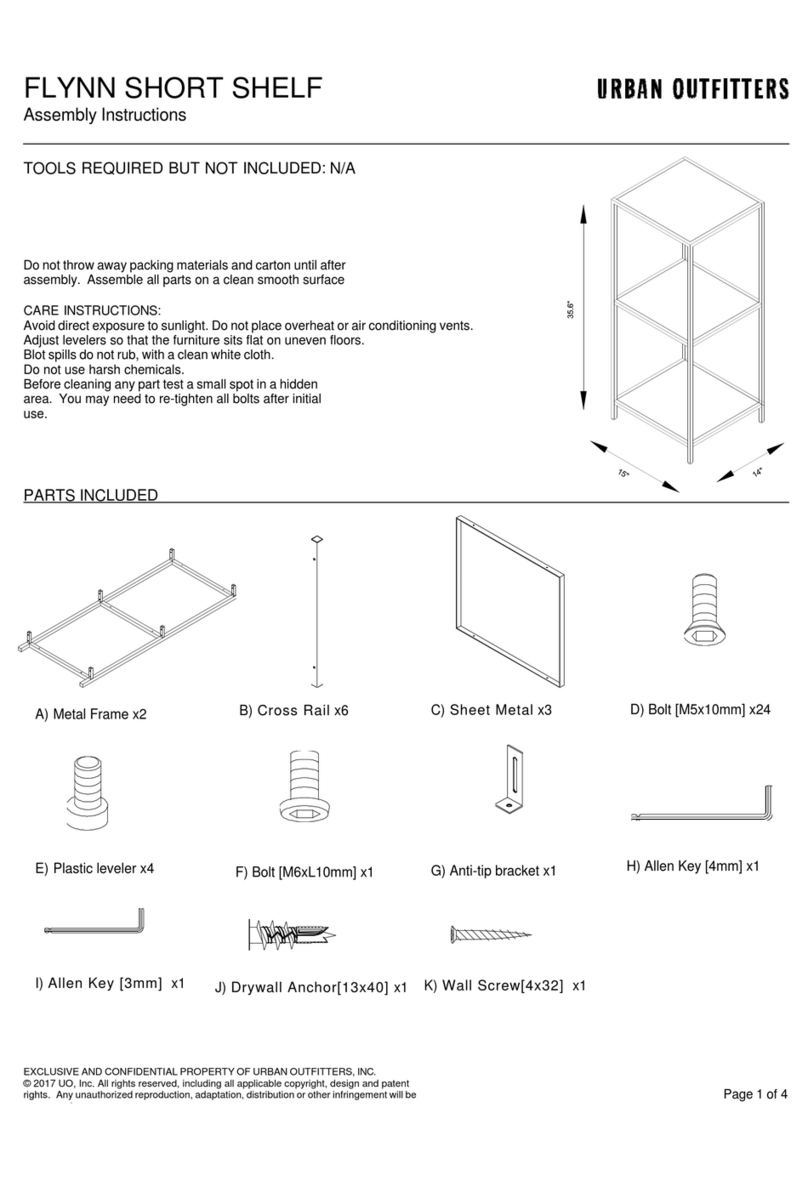

URBAN OUTFITTERS

URBAN OUTFITTERS FLYNN SHORT SHELF Assembly instructions

Uplift Desk

Uplift Desk V2 manual

Sunnydaze Decor

Sunnydaze Decor MERANTI FRN-893 Assembly instructions

Safavieh Furniture

Safavieh Furniture Lucas AMH6501A quick start guide