1

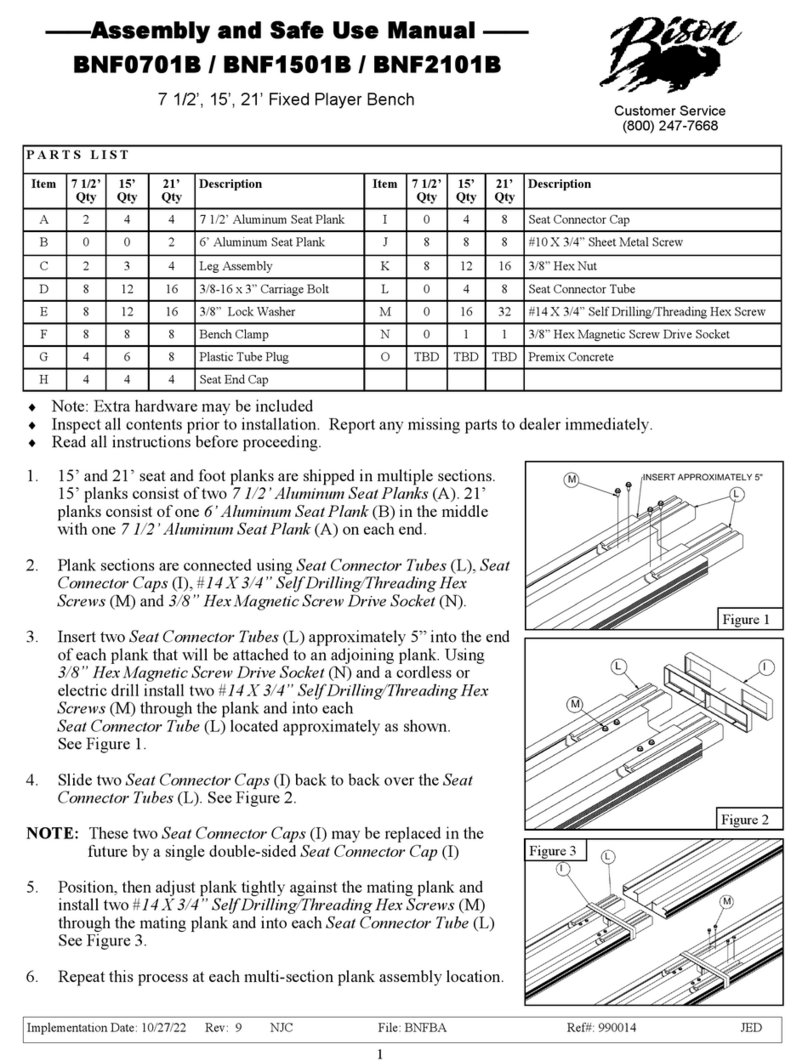

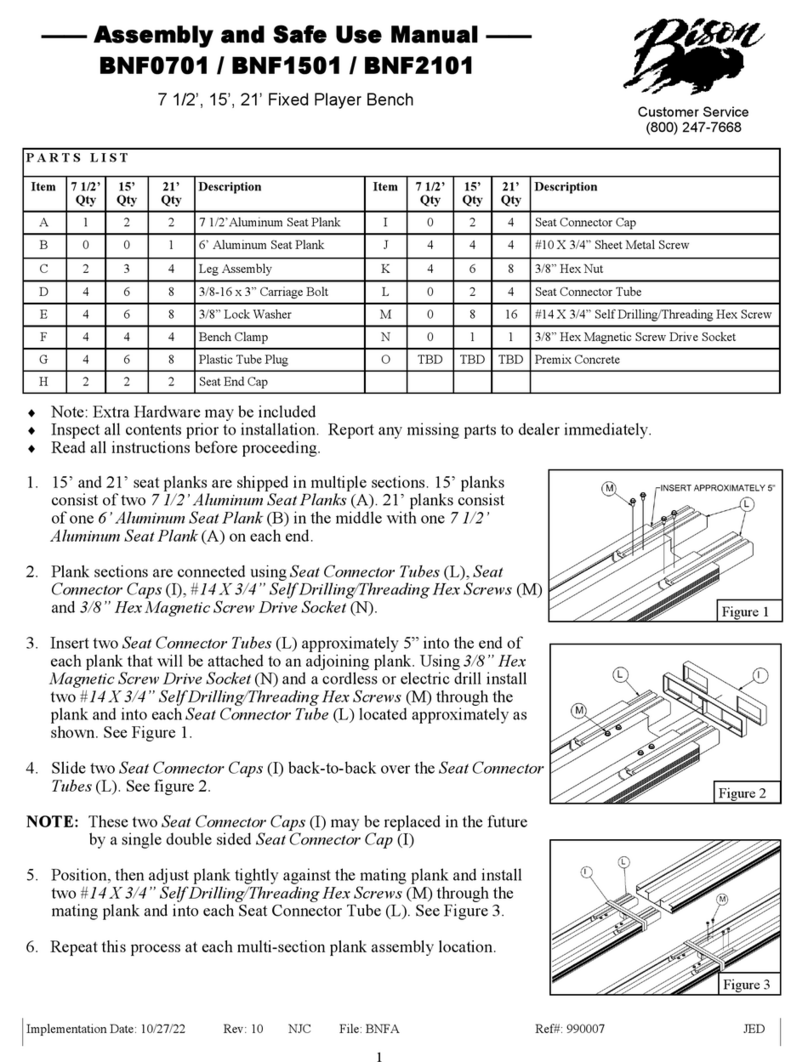

P A R T S L I S T

Item 7 1/2’

Qty

15’

Qty

21’

Qty

Description Item 7 1/2’

Qty

15’

Qty

21’

Qty

Description

A1227 1/2’ Aluminum Seat Plank K4683/8” Flat Washer

B0016’ Aluminum Seat Plank L222Seat End Cap

C234Leg Assembly M024Seat Connector Cap

D4683/8 X 3” Carriage Bolt N444#10 X 3/4” Sheet Metal Screw

E4683/8 X 1 1/2” Hex Bolt O123Brace

F444Bench Clamp P2343/8" X 3" Hex Bolt

G10 15 20 3/8” Hex Nut Q024Seat Connector Tube

H10 15 20 3/8” Lock Washer R0816 #14 X 3/4” Self Drilling/Threading Hex Screw

I812 18 Plastic Tube Plug S0113/8” Hex Magnetic Screw Drive Socket

J468Rubber Feet

Note: Extra hardware may be included

Inspect all contents prior to installation. Report any missing parts to dealer immediately.

Read all instructions before proceeding.

Implementation Date: 10/27/22 Rev: 11 NJC File: BNPA Ref#: 990008 JED

Customer Service

(800) 247-7668

—— Assembly and Safe Use Manual ——

BNP0701 / BNP1501 / BNP2101

7 1/2’, 15’, 21’ Portable Player Bench

Warning!

While gym floor installers and refinishers often indicate floors are OK to walk or play on in 7-10 days after oil based polyurethane

finishes are applied, in reality, it can actually take up to 30 days for all the chemicals in the polyurethane to dissipate. Chemical reac-

tions between the floor finish and certain materials including urethane feet contacting the floor can cause permanent discoloration.

Placement of this product on floors prior to the 30-day final cure period may risk discoloration that would not be covered by the

manufacturer’s warranty.

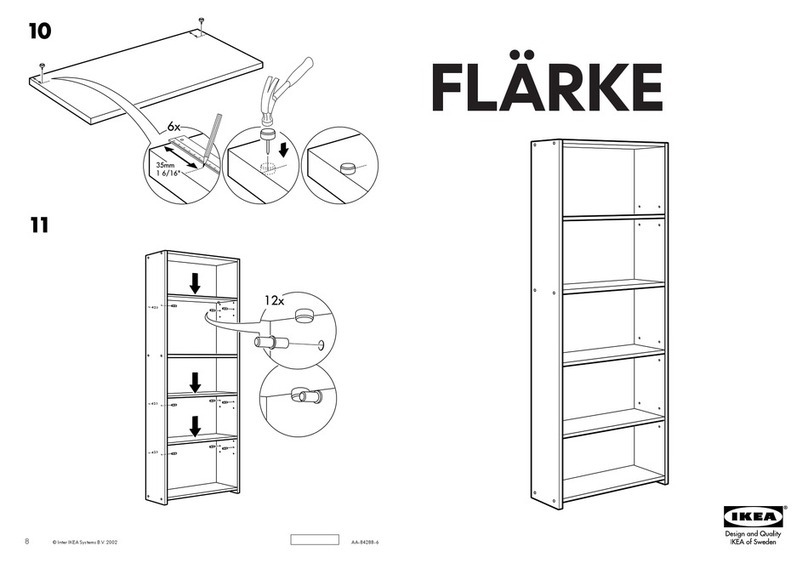

1. Attach Braces (O) to the Leg Assemblies (C) with

3/8” X 3” Hex Bolts (P), 3/8” Lock Washers (H),

and 3/8” Hex Nuts (G). Leave hardware finger

tight. See Figure 1.

2. 15’ and 21’ seat planks are shipped in multiple

sections. 15’ planks consist of two 7 1/2’

Aluminum Seat Planks (A). 21’ planks consist of

one 6’ Aluminum Seat Plank (B) in the middle

with one 7 1/2’ Aluminum Seat Plank (A) on each

end.

3. Plank sections are connected using Seat Connector

Tubes (Q), Seat Connector Caps (M), #14 X 3/4”

Self Drilling/Threading Hex Screws (R) and 3/8”

Hex Magnetic Screw Drive Socket (S)

Figure 1