BITREK BI FLSensor User manual

DYSCOVI SYSTEMS RPE LIMITED

Company code 16303375, account №260075014037759

In “UKREXIMBANK” in Kyiv

MFI 380333, tax number 163033726585

95-S Vidradniy avenue, Kyiv, Ukraine, 03061. Phone +38044 507 02 07. Fax +38044 507 02 02. www.bitrek.com.ua, sales@bitrek.com.ua

FUEL GAUGE

BI FLSENSOR

USER MANUAL

Version 2018.04.1

2

Content

FUEL GAUGE SCOPE, PURPOSE AND OPERATION PRINCIPLE .......................3

Purpose..........................................................................................3

Operation principle ..........................................................................3

GAUGE CONFIGURATION AND CALIBRATION.............................................4

Introduction....................................................................................4

Connection .....................................................................................4

Configurator description ...................................................................5

Configurator operation procedure ......................................................6

Calibration......................................................................................8

INSTALLATION AND GAGING...................................................................8

Preparation for installation................................................................8

Clipping .........................................................................................9

Installation .....................................................................................9

Gaging ......................................................................................... 10

Sealing ........................................................................................ 10

CONNECTION TO TRACKER ................................................................... 11

ADDITIONAL INFORMATION .................................................................. 14

Transportation and storage............................................................. 14

Storage........................................................................................ 14

Operating conditions...................................................................... 14

Manufacturer warranty................................................................... 15

Appendix A ......................................................................................... 16

BITREK TRACKERTM CONFIGURATION .............................................. 16

Appendix B ......................................................................................... 19

Mounting of female-threaded rivets ................................................. 19

Appendix C ......................................................................................... 21

How to fix the fuel gauge to the tank ............................................... 21

3

FUEL GAUGE SCOPE, PURPOSE AND OPERATION

PRINCIPLE

Purpose

The fuel gauge BI FLSensor (hereinafter referred to as the FG,

gauge) is designed for continuous fuel level measurement in stationary

tanks or tanks of moving objects, and transfer the information to the GPS

monitoring system.

Operation principle

BI FLSensor operates on the capacitive principle, based on the

property of a capacitor to change its capacity according to the change of

the fuel composition and level in the measuring probe of the gauge.

Technical specifications

Parameter

Specifications

Supply voltage

8-36 V

Current consumption

Up to 100 mA

Built-in galvanic isolation

Transformer

Power protection

ISO 7637-2, GOST28751-

90

Built-in temperature sensor

+

Measurement error:

at temperature from -20° to

+80°С

±0,7 %

at temperature from -40° to -

20°С

±0,9 %

Temperature measuring range

-40.... + 125 °С

Temperature measuring range

error

±2 °С

Interface

RS-485

Data transmission rate

19200 Mbit/s

Admissible data transmission rate

1200/2400/4800/9600/384

00/57600/115200 Mbit/s

Date filtration type

Kalman filter

4

Parameter

Specifications

Measured fluids

Diesel fuel, Petrol,

Kerosene, Engine Oil

Cable length

7 000 mm / optional

Standard probe length

750 mm / optional

Housing protection class

IP-67

Connection socket ingress

protection rating

IP-67

Housing material

PA6(glass fiber polyamide)

Operating temperatures range

-40...+80 °С

Weight sensor equipment

920 g

Diameter of the measure probe

neck

35 mm

Size of the head of fuel gauge

(with the neck)

61.7x62x32(51) mm

GAUGE CONFIGURATION AND CALIBRATION

Introduction

Software BI FLSensor Configurator (hereinafter referred to as

the Configurator) is purposed for configuration, calibration and

diagnostics of capacitance fuel gauges.

You can receive the configurator in the Technical Support Service of

BITREK™ upon request.

Configurator provides an opportunity to perform the necessary

operations for the implementation of fuel gauges BI FLSensor in

transport GPS-monitoring systems: setting the level of an empty tank,

selection of the network address, setting the level of filtering data, fuel

level change tracking in real time.

The BI FLSensor Configurator software can be installed on PC or

laptops based on the Windows operation system.

To connect FG to computer you should have ad hoc adapter BI

FLSensor Programmer to connect it to the USB port.

If you have any question about the installation or operation of the

fuel gauges BI FLSensor or the software BI FLSensor Configurator, please

contact your equipment supplier or the technical support of BITREK ТМ.

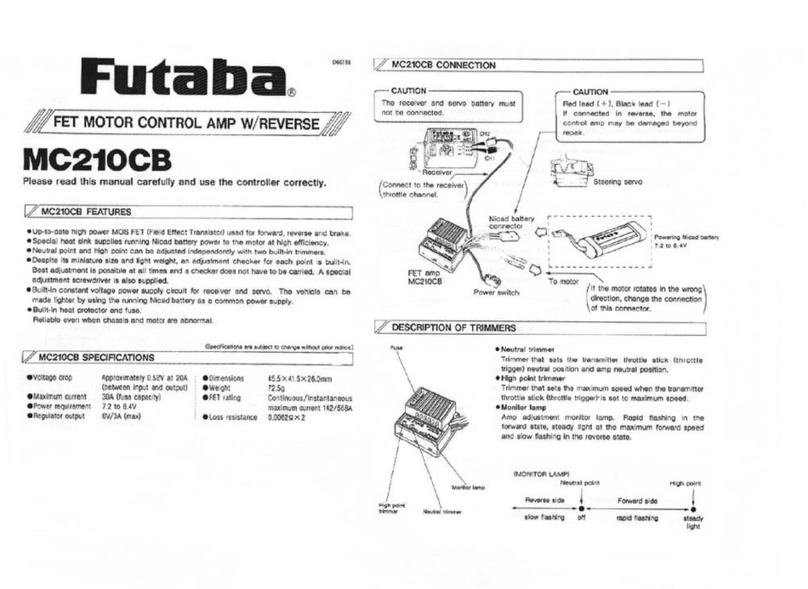

Connection

The fuel gauge BI FLSensor is connected to the computer by

inserting the BI FLSensor Programmer unit to any USB port using a

USB cable (USB-A -USB-B).

5

When the drivers are installed, connect the BI FLSensor gauge to

the configurator (the driver is installed automatically or is available

through the link http://www.ftdichip.com/Drivers/VCP.htm or in the

software directory).

Release the slide

by clicking on

the socket

connector

Keep the connector

pressed and close the

slide

switched off

switched on

The power is supplied to the gauge from computer through the BI

FLSensor Programmer configurator unit; therefore, it is not necessary

to connect the gauge to a power source separately.

Configurator description

The BI FLSensor Configurator software (hereinafter referred to

as the Configurator) is designed for configure the BI FLSensor fuel gauge

and gage the fuel tank.

The main window of the Configurator is shown below:

6

Configurator operation procedure

1

Connect the fuel gauge to a USB port of your computer using a

programmer. Run the Configurator. Select the port name from the

drop down list in the cell "COM port"

2

If the COM port in absent in the list, use the "update" button

3

Press the button for connecting to the COM port

If the configurator is connected successfully to the COM port, the

connection button looks like , and "Gauge is connected"

text will appear in the status line.

When the link is broken, the connection button looks like again,

and "Gauge is disconnected" will appear in the status line.

4

If the Configurator is connected successfully to the fuel gauge, it

switches to a mode shifts to the gauge periodic polling actions

mode. The polling time can be changed using the properly cell in

the Settings tab and the button to the right of the cell.

7

5

During the periodic polling actions, the Configurator receives three

parameters from gauge, i.e., temperature, frequency, and fuel

level. They are visualized in the respective cells and are not

available for editing.

6

First step for setting up the FG. Specify the FG network address in

the appropriate cell and apply the changes using the button

to the right of the cell.

7

Second step for setting up the FG. Specify the level corresponding

to the empty tank.

8

We recommended that you set a low level of data filtering before

starting the gaging procedure.

9

Within the process of gaging, the data are constantly changing.

Use parameters to stabilize the readings for convenience in

processing these data. Specify the number of positions to assess

stabilization (default value is 10) and the stabilization deviation

(default value is 5). If in the last ten positions the difference

between the minimum and maximum values is not more than 5,

the readings will be considered stabilized.

10

Use the properly button to restore the factory settings of the

gauge.

During the gaging, switch to the Gauge gaging tab. In addition, the

configurator window will be as shown below:

11

Changing of fuel gauge readings in real time mode can be

conveniently monitored using the time schedule of temperature

and level. Remove data of the graph using the button

8

12

The gaging table can be filled during the process of gaging. The

first column contains the fuel level value, and the second column

contains the appropriate fuel volume (litres). Using the button

, the data can be manually entered to the table, and the

existing entries can be edited or deleted. The data in the table are

automatically sorted in level values ascending order.

13

The gaging curve is available to analyse using the graph on the

tab "Schedule of gaging table".

14

In addition, the data to the gaging table can be entered directly

from the Field of current values. To do this, specify either the

volume of fuel in the tank at the current level (cell "Current

volume, litres"), or the volume of last filling (cell "Recent filling,

litres"). You can use only one way and only one of two cells will be

active.

15

Use the button to enter the data from the Current values field

to the gaging table. If the data are not stabilized (see clause 9),

the button will be yellow. If the data are stabilized, the button will

be green.

16

When the gaging process is ended, the gaging table can be saved

to a text file by pressing the button .

We also recommend that you set the level of data filtering (see

clause 8) according to the vehicle operation mode.

Press the button (disconnection from the COM port) to stop

properly the operation with a gauge, (see clause 3).

Calibration

You may calibrate only after cutting the measure probe to required

length.

Do not immerse the gauge within the measured liquid prior to

calibration. By all means, set 500 in the Set a value of an empty tank

field.

INSTALLATION AND GAGING

Preparation for installation

Switch off the vehicle power supply.

Before installation, the tanks for flammable substances shall be

emptied and cleaned by steaming. If possible, clean to remove

accumulated sediment and debris.

Select a place as close as possible to the geometric centre of the

top of the tank (at the intersection of two diagonals). In addition, when

9

you select the place for gauge mounting, it is necessary to consider the

fasteners, frames, and internal baffles of the tank.

If the tank is specially shaped and has two upper levels or overflow

holes, we recommend that you install 2 fuel gauges to eliminate the

deadzones of measuring.

Clipping

To trim the sensor you need to do the following steps:

Unscrew the clamping screws on the sides of the plastic cap at

the bottom of the sensor;

Remove the plastic cap;

Measure the height of the tank and cut the probe. We

recommend making it shorter by 15-20 mm than the tank height;

Clean the cut edge from the metallic facings and burrs;

Fasten the plastic tip on the cut edge of the measuring tube;

Clamp the fixing screws on the sides of the cap.

Installation

Make a hole of small diameter in the preliminary prepared tank in

the selected place, and use a thin rod to check the presence of obstacles,

walls, humps and compression marks on the bottom.

Extend the hole to the diameter of the probe - 35 mm - using

crown milling tool or stepped drills. At the same time, make sure that the

facings and debris clog the tank to the minimum degree as possible.

Place the gauge into the hole and mark 4 points for the fastener.

Before installing the gauge, lubricate the rubber gasket on with

gas-oil resistant sealant in the marked slot and making sure that the

sealant does not come within the hole in the bottom of the gauge head.

If the gauge is fastened with rivets, it is necessary to make 7

mm diameter holes for special threaded rivets. If the gauge is fixed with

self-driving screws, they are screwed directly into the tank using a

screwdriver or a tipped drill. Detailed description of a fastener is provided

in Appendix C.

Fasteners (self-driving screws or rivets) shall be fixed to the

holes on the diagonal sides of the gauge head for the subsequent sealing.

10

Extend and securely tight the corrugated cable along the body of

the vehicle to the place of installation of the GPS-tracker.

Gaging

Gaging of the fuel tank is required to reveal the conformity of the

value received from the gauge with the actual volume of fuel in the fuel

tank.

Tank gaging is a unit-dose filling of fuel into the tank from empty to

full state. Measurement is carried out with a certain filling step, recording

the gauge readings in the gaging table. The tank shape determines

dependence on the level of the fuel volume and it is unique for each

vehicle.

Gaging process recommendations:

Before gaging start, the gauge shall be calibrated in accordance

with the instructions.

We recommend that you perform the gaging procedure at a

constant temperature (+20 °C).

The liquid used for gaging shall be the same as within operation

of the fuel gauge.

Place the vehicle or tank (if removable) horizontally and do not

change its position during the entire process.

The procedure can be performed for each vehicle separately.

Measured liquid shall not contain any impurities, sludge, dirt and

debris.

Gaging shall be carried out in portions of not more than 10% of

the total volume of the tank (the lower portion of the filling ensures more

accurate indications of the system).

After each filling of liquid in the tank, wait until level stabilization,

then record the gauge readings in the table.

Avoid impacts on the tank, which can cause vibration, shaking or

change of the tank shape.

Sealing

Sealing procedure is performed to protect

the device against outside interference during its

operation. The standard equipment consist of 600

mm wire for sealing and 2 seals. If you want to

seal the gauge head, extend the wire through the

11

hole on the fastener of corrugated item, then to the holes in the screw

heads (located on the diagonal) and through the second hole on the

fastener of the corrugated item. Extend both ends of the wire through

reach-through holes, turn the seal clockwise against stop. Break off the

tail piece used for the sealing.Cut the excess wire with the tool.

To seal the connecting group, extend the wire through the sealing

holes of the corrugated holder on both sides of the connection (from the

side of the fuel gauge and from the cable connected to the tracker). Then

perform seal tightening up on the wire.

Do not forget to record the serial numbers of the seals specified on

the front side.

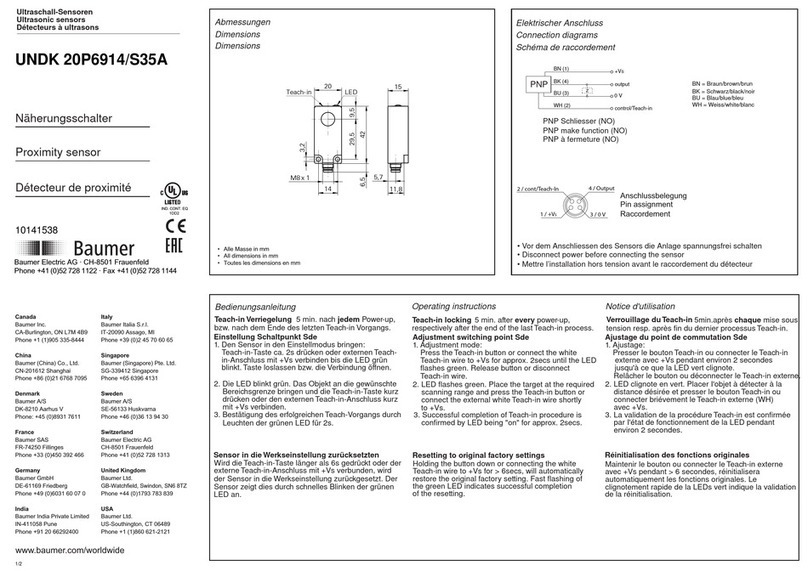

CONNECTION TO TRACKER

The fuel gauge equipment includes a connection cable for the data

reading device, one side of the cable contains is a connector (to connect

directly to fuel gauge BI FLSensor itself), on the other side it contains the

cut end with 5 wires, which is connected to a data reading and

processing device. Purpose of conductors is specified in Table 4.1.

Table 4.1. Purpose of conductors

BI FLSensor

Connected equipment

No.

Wire

colour

Purpose

BI910/BI920

BI810/BI820

1

Yellow

A

Green/Red

B7

Orange

А

2

Green

B

Green/Black

C7

Green

B

3

Brown

Signal

GND

Black

С1/С8

Black

GND

4

White

+VCC

Yellow

B8

Yellow

+Vout

5

Grey

Power

GND

Black

С1/С8

Black

GND

6

Not

applied

-

-

-

-

-

Different issues can be solved depending on organization of the fuel

gauge connection to the in vehicle network and GPS-tracker.

The diagrams below contain the circuit examples:

(1) before the battery disconnect switch

(2) after the battery disconnect switch

12

Each of the above switching circuits has its own application.

The scheme (1) is applied for continuous monitoring of the vehicle.

The limitation of this scheme is a constant discharge of the car battery. If

the car battery is used for a long time without recharging, it can be

completely discharged

The scheme (1) is applied for monitoring of the vehicle and fuel

consumption only at battery disconnect switch on. When the battery

disconnect switch is off, the tracker and the fuel gauge will be

disconnected from the power supply.

Scheme (1).

13

Scheme (2).

Contact arrangement on the tracker:

BI 910 TREK / BI 920 TREK

14

BI 810 TREK / BI 820 TREK

ADDITIONAL INFORMATION

Transportation and storage

Climatic conditions of gauges transportation:

ambient temperature -50... + 40 °C

relative humidity 98% at temperature of +25 °C

The air area should not contain acids, alkali and other aggressive

impurities.

Storage

The gauges shall be stored in the manufacturer's packaging, in

closed spaces with natural ventilation, without artificially controlled

climatic conditions, without heating. Storing of gauges without packaging

is not allowed. It is forbidden to store the gauges in the same premise

with substances causing metal corrosion and substances with aggressive

impurities.

Operating conditions

The gauge shall be used for units with a successful fuel supply

system.

The marking for mounting of the gauge assembly shall conform to

mounting holes.

The gauge shall be protected from corrosive environment,

electromagnetic field, as well as mechanical and environmental stresses

that exceed the parameters indicated in the specification to prevent from

failure.

Do not connect the gauge to the devices with interface that does

not meet the characteristics specified in the passport.

15

Unpack the gauge only after keeping it under normal conditions for

at least 2 hours.

It is necessary to perform an external inspection of the gauge prior

to commissioning. If there are detected any mechanical damages (cracks,

shears, dishes), further installation is not allowed.

Only the personnel familiar with the device, operation principle and

instructions specified in the technical specification of the gauge may

perform the installation of the gauge.

Manufacturer warranty

The manufacturer guarantees the serviceability of the gauge under

keeping of service rules such as conditions of storage, transportation and

operation, as well as Instructions for use.

Warranty period of gauge use is 12 months from the manufacture

date.

Warranty does not cover a gauge with defects (cracks, shears,

dishes, shock marks, contamination of the measurement chamber or

tank) occurring due to the fault of the user, when there is a violation of

use, storage and transportation conditions.

16

Appendix A

BITREK TRACKERTM CONFIGURATION

Proper operation of devices requires proper configuration of the

necessary parameters. There are some examples of fuel gauge

configuration (see tables below).

Note: The fuel gauge contains an internal intelligent filter based on

Kalman filter.

You can set the following parameters for fuel gauges in the trackers

manufactured by BITREK:

1. Filtered data of fuel level:

Table. Filtered data of fuel gauge

1

network

address

2

network

address

5 network

address

6

network

address

Parameter

Value

Parameter

Description

ID 100

ID 101

ID 129

ID 130

ID at

transmission

setparam

0580

setparam

0590

setparam

0850

setparam

0860

1

Parameter

activation

setparam

0581

setparam

0591

setparam

0851

setparam

0861

0

Priority

setparam

0582

setparam

0592

setparam

0852

setparam

0862

0

Upper limit off

setparam

0583

setparam

0593

setparam

0853

setparam

0863

0

Lower limit off

setparam

0584

setparam

0594

setparam

0854

setparam

0864

3

Monitoring Mode

setparam

0585

setparam

0595

setparam

0855

setparam

0865

5

Constant of

averaging

Gauges use 2 filters (optional):

Butterworth filter (setparam 0209 0;)

Kalman filter (setparam 0209 1;)

Factor F

950

Coefficient F for Kalman filter

Factor Q

951

Coefficient Q for Kalman filter

Factor Н

952

Coefficient H for Kalman filter

Factor Rs SТОР MOTION

953

Coefficient R for Kalman filter at motion

absence

Factor Rm IN MOTION

954

Coefficient R for Kalman filter at motion

Switch filters

209

Setting of the filters switching; for filtered

fuel gauges.

(0-Butterworth filter)

(1-Kalman filter)

17

The 1-byte parameter type filter with ID = 0209 was entered to

select the used filter type; default value

When setparam value is setparam 0209 0, the Butterworth filter is

used,

For properly operation of the filter, it is desirable to set the

following data:

Kalman filter is used at the value of parameter.

setparam 0209 1;

Example of standard setting via SMS:

setparam 0950 1000000;

setparam 0951 2000000;

setparam 0952 1000000;

setparam 0953 20000000;

setparam 0954 400000000;

Value of the last valid level of fuel

setparam 0819 1;

Timeout of movement start according to the accelerometer

setparam 0284 50;

Timeout of movement stop according to the accelerometer

setparam 0285 200;

2. Transfer to the database server without fuel level filtering: Not

filtered data of fuel gauge

Table. Unfiltered data of fuel gauge

1

network

address

2

network

address

5

network

address

6

network

address

Parameter

Value

Parameter

Description

ID 112

ID 113

ID 131

ID 132

ID at transfer

setparam

0690

setparam

0700

setparam

0870

setparam

0880

1

To activate the

parameter

setparam

0691

setparam

0701

setparam

0871

setparam

0881

0

Priority

setparam

0692

setparam

0702

setparam

0872

setparam

0882

0

Upper limit off

setparam

0693

setparam

0703

setparam

0873

setparam

0883

0

Lower limit off

setparam

0694

setparam

0704

setparam

0874

setparam

0884

3

Monitoring mode

setparam

0695

setparam

0705

setparam

0875

setparam

0885

5

Constant

of averaging

18

3. Readings from the temperature sensor located in the fuel level gauge:

Table. Temperature measured by the fuel gauge

1

network

address

2

network

address

5

network

address

6

network

address

Parameter

Value

Parameter

Description

ID 102

ID 103

ID 127

ID 128

ID at transmission

setparam

0600

setparam

0610

setparam

0520

setparam

0530

1

Parameter

activation

setparam

0601

setparam

0611

setparam

0521

setparam

0531

0

Priority

setparam

0602

setparam

0612

setparam

0522

setparam

0532

0

Upper threshold

off

setparam

0603

setparam

0613

setparam

0523

setparam

0533

0

Lower threshold

off

setparam

0604

setparam

0614

setparam

0524

setparam

0534

3

Mode

of monitoring

setparam

0605

setparam

0615

setparam

0525

setparam

0535

5

Constant

of averaging

19

Appendix B

Mounting of female-threaded rivets

Select the mandrel (core) and insert the pin with locknut for the

required rivet diameter - M5.

Fix the rivet on the threaded part of the core (the core must extend

on the other side). Fix the rivet with the pin and lock the locknut on the

front sleeve.

20

Install the wound rivet into the hole, perpendicular to the surface,

and press the handle of the riveter against stop.

Remove the core of the riveter from the mounted rivet.

If the rivet is mounted incorrectly, is loose or it is difficult to screw

the fixing screw, drill out the rivet tool and adjust the lock nut of the tool

and the front sleeve according to the scheme provided below.

Table of contents