Black Magic Clutches DEFIANT X User manual

*** When disassembling the Defiant X Clutch Assembly for installation, make sure not lose the small

washer/shims from between the cover and flywheel. In addition to the large spacers there are

additional shims at each bolt/stud. These should be kept in place as the cover assembly has had the ring

height already set when purchasing a new compete unit or after coming back from servicing.

Ring Height

- Base/Standard ring height should be 1.725” (Pictured)

This is measured by using the tip of a set of dial calipers to measure through the hole in the

cover from the face of the cover down to the pressure plate.

- Ring Height can be adjusted by shimming between the cover and flywheel.

- This will change as the disc wears. We don’t recommend re-shimming to reset lever height until at

least a .030” change (.030” wear off the disc). The levers will move upward towards the bearing as the

ring height changes. You will lose approximately 12 lbs of base pressure with every .010” of disc

wear/ring height change.

Lever Height

- Standard Lever Height is set and measure two ways. Either from the tip of the lever to a straight

edge, or by measuring the gap between top of lever and the bottom edge of the cover. (Both

Pictured Below) There should never be more than a .007” variance in all three levers so that the

throwout bearing makes even contact and will ensure the same air gap at all three lever lug

locations around the full diameter of the clutch surface.

When Measuring to the lever tip with a straight edge,

place straight edge flat across the cover surface.

When Measuring this way levers can be set from .650 - .700”

When Measuring to the gap between lever and cover

When Measuring this way levers can be set from .280” - .330”

Adjusting Lever Height

- The Defiant utilizes precision machined yokes, that have minimal variance in overall height. As it

is rarely needed to adjust lever height except after a rebuild/servicing we have returned to the

shim style method of adjusting to give the cover a flat profile across the top. By using flat shim

stock we can adjust the lever height up or down. The shims are placed between the yoke and

bottom of the cover at each lever location. The Defiant X features Dyno tested and designed levers

that allow the use of conventional counter weight with specific applied pressure information

(provided below), with the added feature of “In-Board” counter weight holes located inside the

cover closer to the throwout bearing. In addition to lever height controlling the applied pressure

rate of the levers, we can control this much more effectively by utilizing in-board counter weight.

We work directly with customer’s choosing to use this feature. Mot commonly used in lower

hp/weight combinations with higher rpm.

Disc Options

- New units will feature either a .330” or .380” thick disc. This is selected at the time of order to

work with clearance options and overall use of the clutch.

- Most standard built units will come with a standard 5135 type compound.

- We work with customers on their specific combination on each clutch and in some cases suggest

a different disc material to lessen friction coefficient and allow for the use of more applied

pressure through base and counter weight offering a larger tuning window.

Common Disc Materials

5135 – Most Aggressive Compound

5050 – Medium (We rarely use this in drag racing)

5191 – Least Aggressive

Additional Black Magic Compound Options

BMC-850 - Approximately 15% Less Friction Coefficient as 5191,

Better Door Car Compound on Lower HP

BMC-PS1 – Approximately 7% less friction coefficient than standard 5191

Sintered Bronze – Approximately in the middle of 5135 and 5191, however will increase friction

coefficient as it sees an increase in temperature.

The disc should always be placed with the raised part of the hub towards the transmission and away

from the flywheel s seen below.

Specifications and Design Information

Spring Information / Base Pressure

- Free Length: 2.08”

- Rate of Pressure: 208 lbs per Inch or 52 lbs per 1/4 Inch

- Base Sheet Provided at 1/4 turn increments

- Maximum Turns: 7 Turns

- 360 lbs Total Pressure at Zero Turns (Standard 1.725” Ring Height)

- Cover to Flywheel Bolt/Stud Torque should be “snug” or approximately 30 ft/lbs

*** We don’t recommend more than 6.5 turns. If the adjuster backs completely out

of the aluminum adjusters the unit must be taken apart and the adjusters must be

rethreaded into the cups. Running the clutch with them fully backed out of the cups,

it will damage them.

Clockwise Removes Base / Counter Clockwise Adds Base.

To start turn all the way clockwise until fully loose.

Turn Counter Clockwise until you start to feel slight resistance. Start counting from there.

Counter Weight

- 1/4 Inch holes are located to the outside of the clutch unit to add counter weight.

- There are also “in-board” counter weight holes on the inside of the lever (towards the hub)

These holes can be used to slow the rate of applied pressure, but we recommend

consulting with Cale Aronson for exact tuning information.

- Attached is an Applied Pressure Sheet showing the applied pressure in Lbs, over every 100

rpm.

** Loctite should never be used on counter weight!!

Installation Notes:

When you receive a Defiant Assembly new or rebuilt from Black Magic Clutches, your ring height and

lever height will already be set. Simply remove the cover from the flywheel, install the flywheel onto

your crankshaft. Be careful to keep all shims located on the studs/bolts in place as this is what is used

to set your “Ring Height”. After installing your flywheel, reinstall your disc and cover assembly. Using

an alignment tool center the disc on the flywheel/pressure plate surface and install the nuts on the

studs/bolts. Evenly draw the cover down and if torqueing apply approximately 30 ft/lbs on cover nuts.

Upon receiving your clutch, get in touch with us for a starting point and any general procedure

questions!

** It’s easier to install with no turns of base as it will have the least pressure. Add base

pressure after installation.

Throwout Bearing: You should run a wide, flat faced bearing that covers the lever tips completely. If

needed, contact us for bearing options.

Free Travel: This is the distance between the throwout bearing and levers when clutch pedal is in the

up/non-engaged position. There should be .200” - .250” free travel between you throwout bearing

and levers. We recommend a stiff return spring to keep bearing way from levers. Bearing to lever

contact can reduce applied pressure and cause damage to the levers as well as premature wear and

excessive slippage.

Air Gap: This is the amount of clearance between the disc and either heat shield when the clutch is

depressed. Generally measured with a feeler gauge. We recommend between .045” minimum and

.075” maximum. You should have an adjustable positive/solid clutch pedal stop to set this properly.

This should be checked regularly as wear of the disc will effect it. Heat also will cause a variance as the

materials expand.

Two Step: Your two step/launch rev limiter should be set to turn on/off at the point the bearing

comes in contact with the levers and should stay on throughout the travel of the clutch cycle. Do not

tie this function to your line-lock.

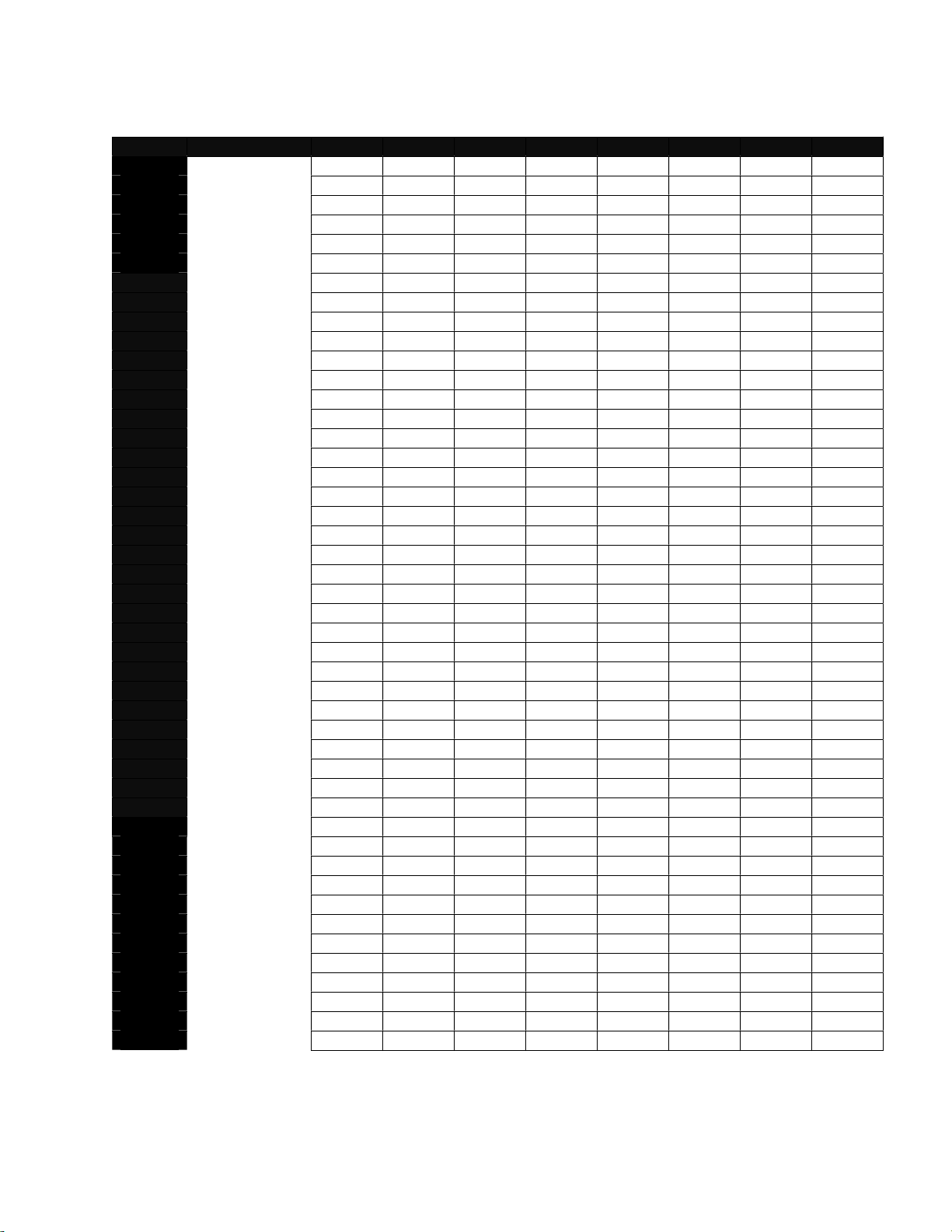

Defiant X 10.00” 3 Lever Applied Counter Weight Pressure

GRAMS

lb per gram

15

18

21

24

27

30

33

36

3500

8.1 121.7 146.0 170.3 194.6 219.0 243.3 267.6 292.0

3600

9.1 135.9 163.1 190.3 217.4 244.6 271.8 299.0 326.2

3700

10.0 150.2 180.2 210.2 240.2 270.3 300.3 330.3 360.4

3800

11.0 164.4 197.3 230.2 263.0 295.9 328.8 361.7 394.6

3900

11.9 178.4 214.0 249.7 285.4 321.0 356.7 392.4 428.0

4000

12.8 192.2 230.6 269.0 307.4 345.9 384.3 422.7 461.2

4100

13.7 205.8 247.0 288.1 329.3 370.4 411.6 452.8 493.9

4200

14.6 219.2 263.0 306.8 350.6 394.5 438.3 482.1 526.0

4300

15.4 230.9 277.0 323.2 369.4 415.5 461.7 507.9 554.0

4400

16.3 243.9 292.7 341.5 390.2 439.0 487.8 536.6 585.4

4500

17.1 256.5 307.8 359.1 410.4 461.7 513.0 564.3 615.6

4600

18.2 272.7 327.2 381.8 436.3 490.9 545.4 599.9 654.5

4700

18.9 283.2 339.8 396.5 453.1 509.8 566.4 623.0 679.7

4800

19.8 296.7 356.0 415.4 474.7 534.1 593.4 652.7 712.1

4900

20.9 313.2 375.8 438.5 501.1 563.8 626.4 689.0 751.7

5000

21.5 322.7 387.2 451.7 516.2 580.8 645.3 709.8 774.4

5100

22.5 336.8 404.1 471.5 538.8 606.2 673.5 740.9 808.2

5200

23.4 351.5 421.7 492.0 562.3 632.6 702.9 773.2 843.5

5300

24.5 366.9 440.3 513.7 587.0 660.4 733.8 807.2 880.6

5400

25.4 380.3 456.3 532.4 608.4 684.5 760.5 836.6 912.6

5500

26.3 394.8 473.8 552.7 631.7 710.6 789.6 868.6 947.5

5600

27.1 407.1 488.5 569.9 651.4 732.8 814.2 895.6 977.0

5700

28.2 422.9 507.4 592.0 676.6 761.1 845.7 930.3 1014.8

5800

29.1 436.7 524.0 611.3 698.6 786.0 873.3 960.6 1048.0

5900

30.3 455.0 545.9 636.9 727.9 818.9 909.9 1000.9 1091.9

6000

31.1 466.4 559.6 652.9 746.2 839.4 932.7 1026.0 1119.2

6100

32.1 480.9 577.1 673.3 769.4 865.6 961.8 1058.0 1154.2

6200

33.4 500.4 600.5 700.6 800.6 900.7 1000.8 1100.9 1201.0

6300

35.0 525.6 630.7 735.8 841.0 946.1 1051.2 1156.3 1261.4

6400

36.0 540.2 648.2 756.2 864.2 972.3 1080.3 1188.3 1296.4

6500

37.5 562.1 674.5 786.9 899.3 1011.7 1124.1 1236.5 1348.9

6600

39.2 587.3 704.7 822.2 939.6 1057.1 1174.5 1292.0 1409.4

6700

40.2 602.7 723.2 843.8 964.3 1084.9 1205.4 1325.9 1446.5

6800

41.3 619.7 743.6 867.5 991.4 1115.4 1239.3 1363.2 1487.2

6900

43.1 646.1 775.3 904.5 1033.7 1162.9 1292.1 1421.3 1550.5

7000

44.8 672.3 806.8 941.2 1075.7 1210.1 1344.6 1479.1 1613.5

7100

46.5 697.1 836.5 975.9 1115.3 1254.7 1394.1 1533.5 1672.9

7200

48.4 726.0 871.2 1016.4 1161.6 1306.8 1452.0 1597.2 1742.4

7300

50.1 751.4 901.6 1051.9 1202.2 1352.4 1502.7 1653.0 1803.2

7400

52.0 779.7 935.6 1091.6 1247.5 1403.5 1559.4 1715.3 1871.3

7500

53.8 806.6 967.9 1129.2 1290.5 1451.8 1613.1 1774.4 1935.7

7600

55.6 833.7 1000.4 1167.2 1333.9 1500.7 1667.4 1834.1 2000.9

7700

57.3 858.9 1030.7 1202.5 1374.2 1546.0 1717.8 1889.6 2061.4

7800

59.1 886.7 1064.0 1241.3 1418.6 1596.0 1773.3 1950.6 2128.0

7900

60.8 911.9 1094.2 1276.6 1459.0 1641.3 1823.7 2006.1 2188.4

8000

62.7 940.1 1128.1 1316.1 1504.1 1692.1 1880.1 2068.1 2256.1

Applied Base Pressure (Per 1/4 Turn)

360 Lbs at Zero Turns

Turns Pressure

Turns Pressure

0.25 368.5 3.75 627.5

0.5 387 4 646

0.75 405.5 4.25 664.5

1 424 4.5 683

1.25 442.5 4.75 701.5

1.5 461 5 720

1.75 479.5 5.25 738.5

2 498 5.5 757

2.25 516.5 5.75 775.5

2.5 535 6 794

2.75 553.5 6.25 812.5

3 572 6.5 831

3.25 590.5 6.75 849.5

3.5 609 7 868

Black Magic Clutches / Aronson Motorsports

www.blackmagicclutches.com

Cale@BlackMagicClutches.com

816-390-0852

Table of contents

Popular Industrial Equipment manuals by other brands

Bomar

Bomar Individual 720.540 DGH operating instructions

Energy Recovery

Energy Recovery PX G1300 Installation and operation manual

MARTINS Industries

MARTINS Industries MIC-AUHD-52 manual

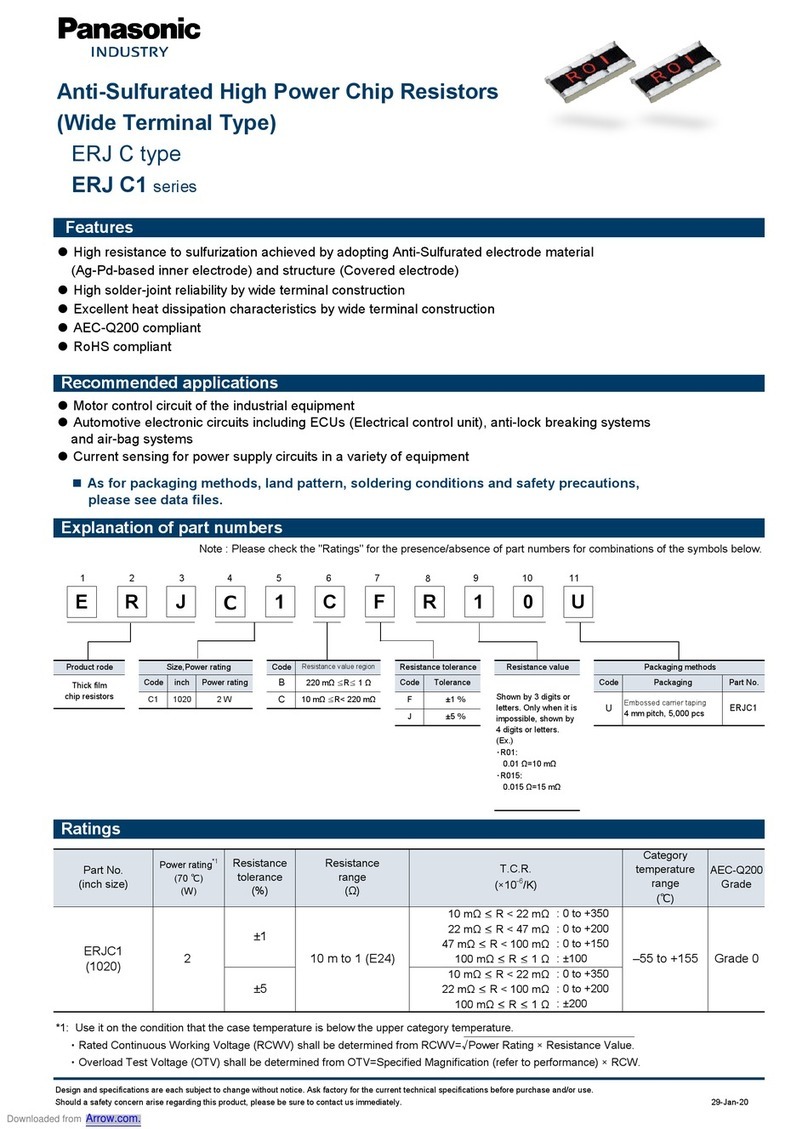

Panasonic

Panasonic ERJ C1 Series manual

ABB

ABB Power2 340-H44 Operation manual

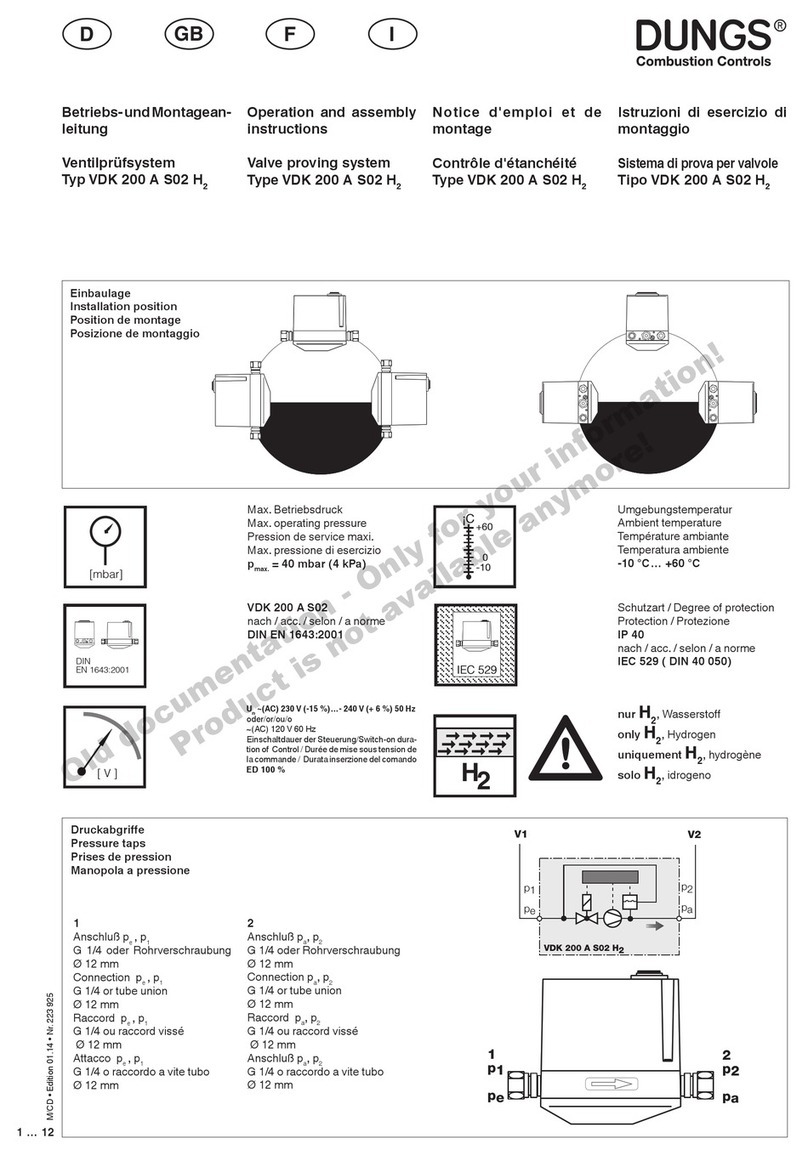

Dungs

Dungs VDK 200 A S02 H2 Operation and assembly instructions