1

Safety

Principle Safety Advise

Only qualified personnel as stated by the machines instruction manual and user guidelines should operate the

machine. All machine safety guidelines and requirements are to be followed.

All company and machine safety regulations are to be followed.

The following pages describe the basic safety instructions and the safety regulations. With these safety

instructions no claim is made to the completeness.

Danger when Operating the System or Subassemblies

reCool®is constructed according to the latest state-of-the-art and the recognized safety regulations. Danger to the

operator or to others, or damage to the system or other material damage through improper handling or use can

occur. The system must only be operated:

•for the intended purpose.

•in a safe condition.

Faults which can affect safety must be eliminated immediately.

Appropriate Use

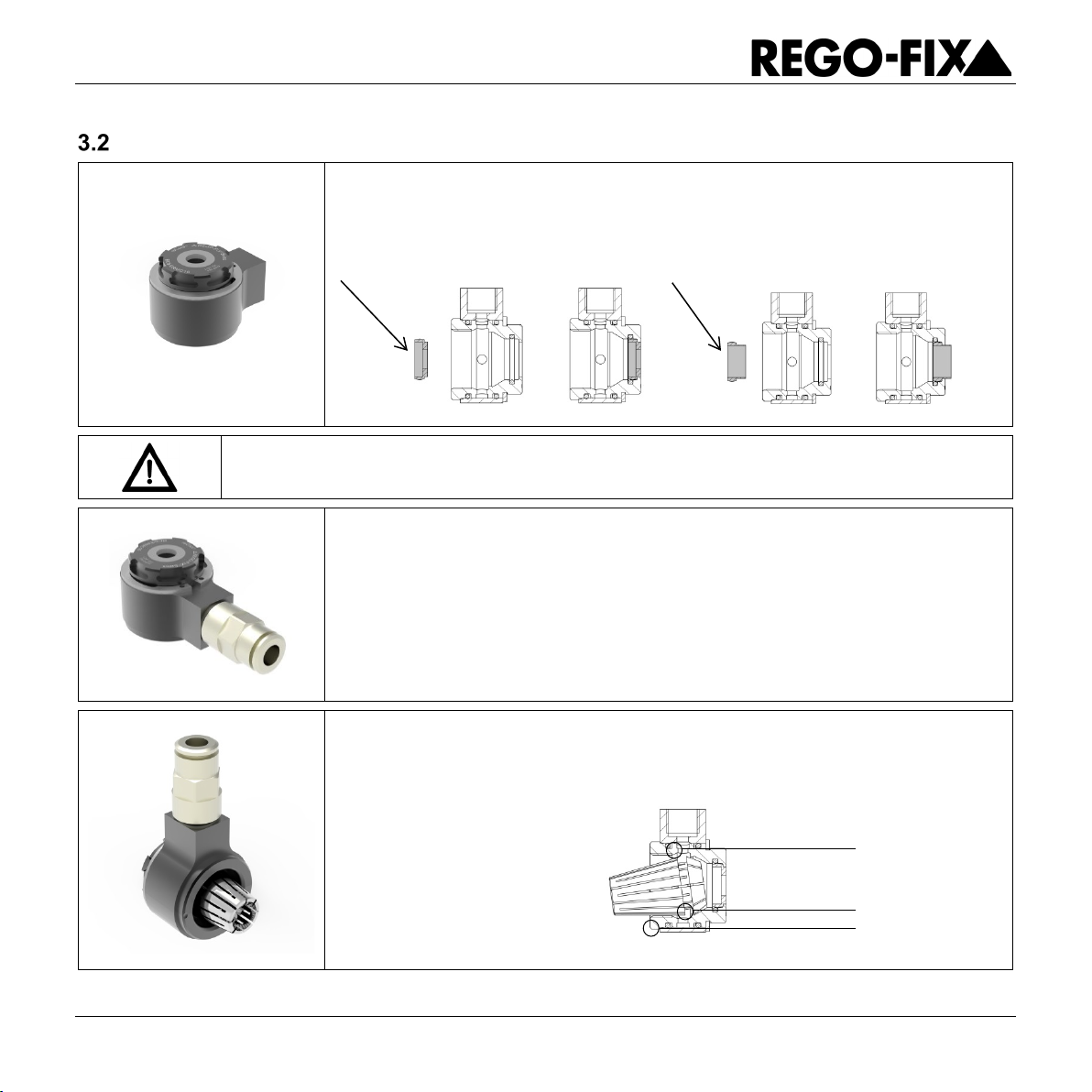

reCool®is exclusively for the clamping of tools (cutters and drills) to be used in static tools. The machine must be

equipped with external flood cooling ports (used as peripheral cooling).

All other use is considered inappropriate. Consequently, REGO-FIX does not take any responsibility for damage

caused by inappropriate use.

Appropriate use means, among other things:

•To follow all recommendations mentioned in the Operating Instructions.

•To adhere to the inspection and maintenance requirements.

Inappropriate Use

We do not take any responsibility for damages caused by inappropriate use.

Inappropriate use includes, but is not limited to:

•The use of a defective reCool®.

•Operation of reCool®static on driven tools.

•Use of coolant pipes and fittings of other manufacturers.

•Use of coolant pipes and fittings for ≤100 bar with more coolant pressure.