INSTRUCTIONS : PR-2000-UD Cod : DYN 07.01.10

Date : 20/10/2020 Revision : 10

2

INSTRUCTIONS FOR USE AND MAINTENANCE

_____________________________________________________

1GENERALINSTRUCTIONS..................................................................................................................................3

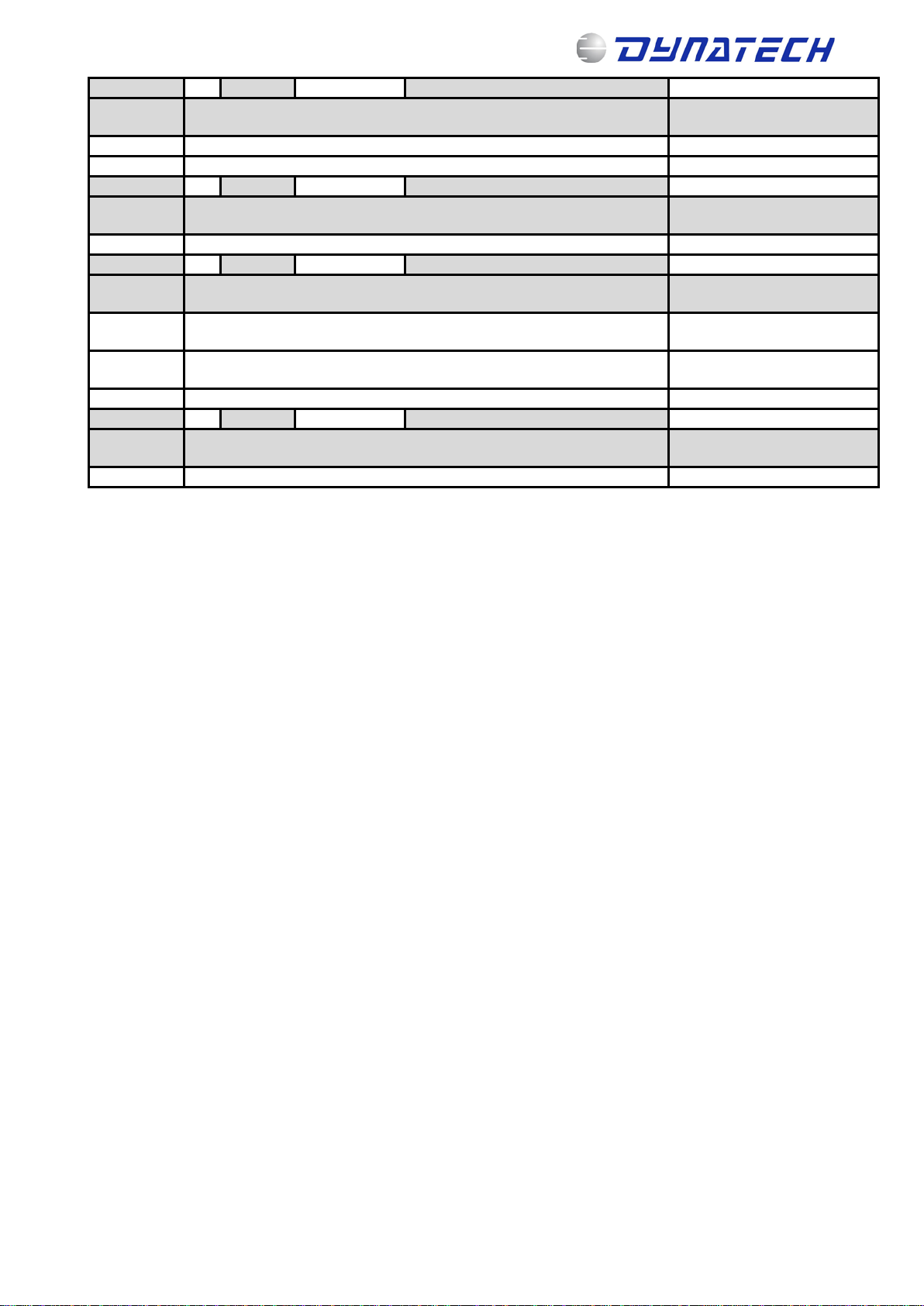

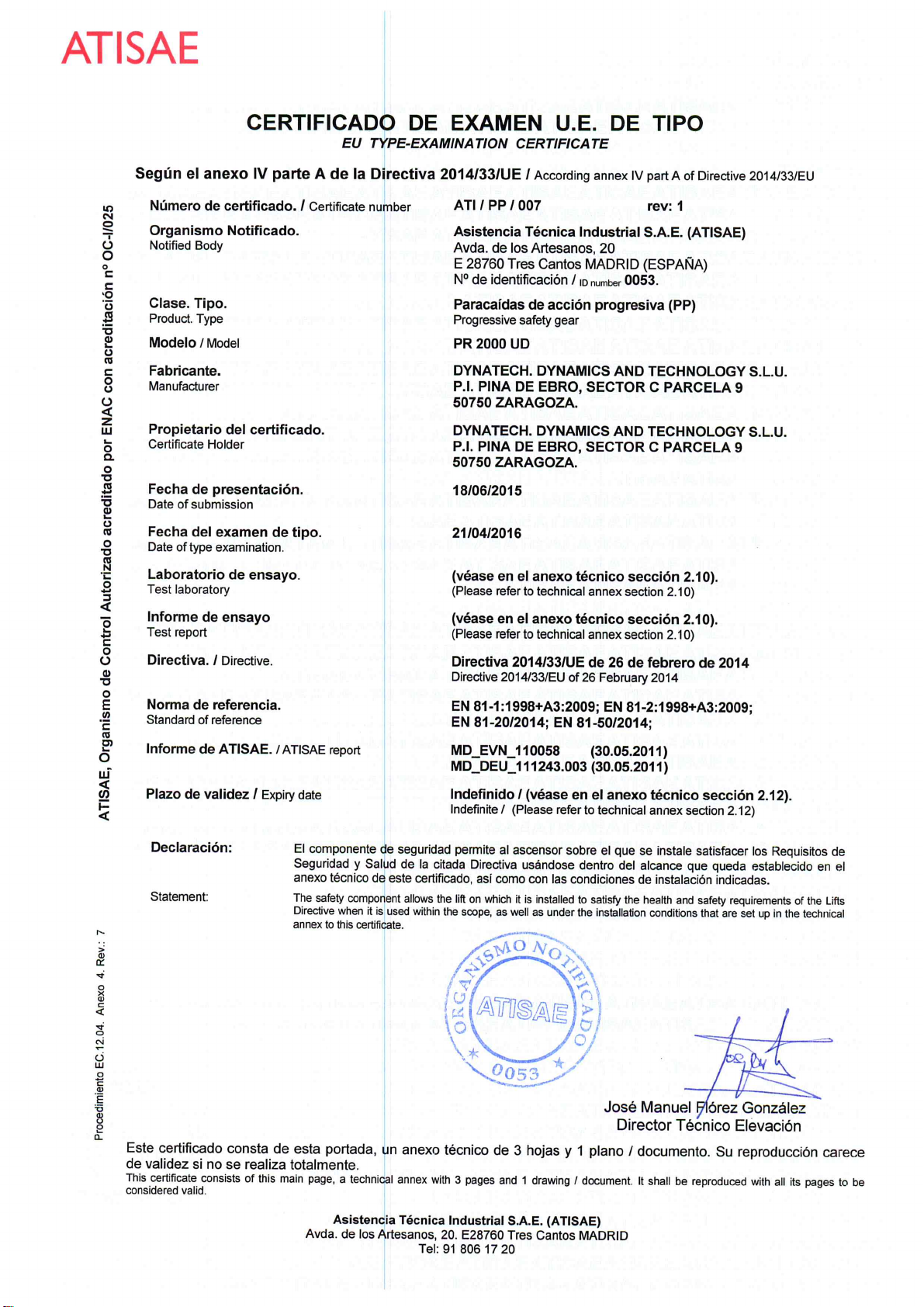

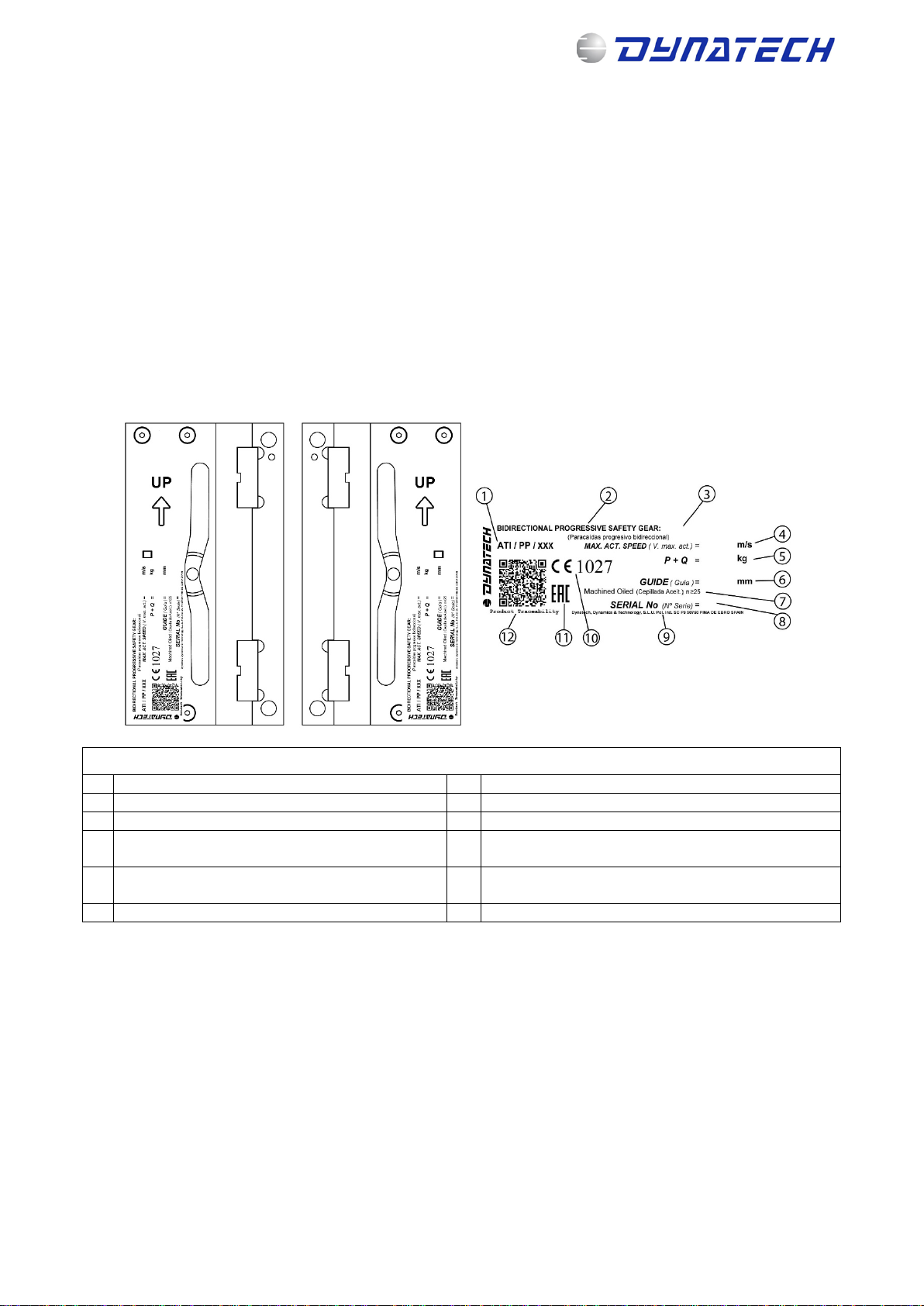

2SAFETYGEARIDENTIFICATIONANDCHARACTERISATION..................................................................................3

2.1IDENTIFICATION..................................................................................................................................................3

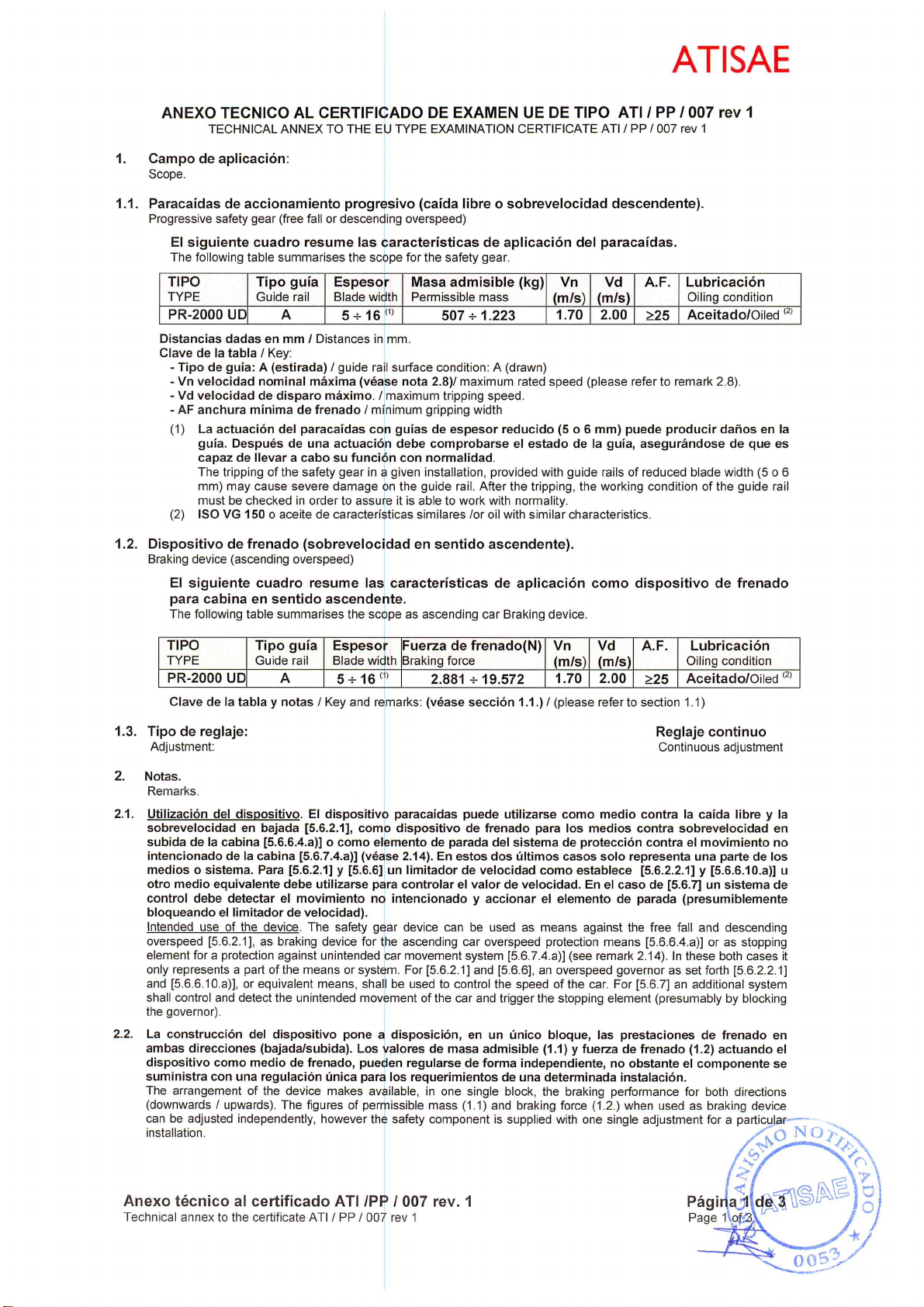

2.2SAFETYGEAR’SFEATURESANDUSE....................................................................................................................3

2.3RANGEOFUSE....................................................................................................................................................3

3INSTALLATIONANDADJUSTMENT....................................................................................................................4

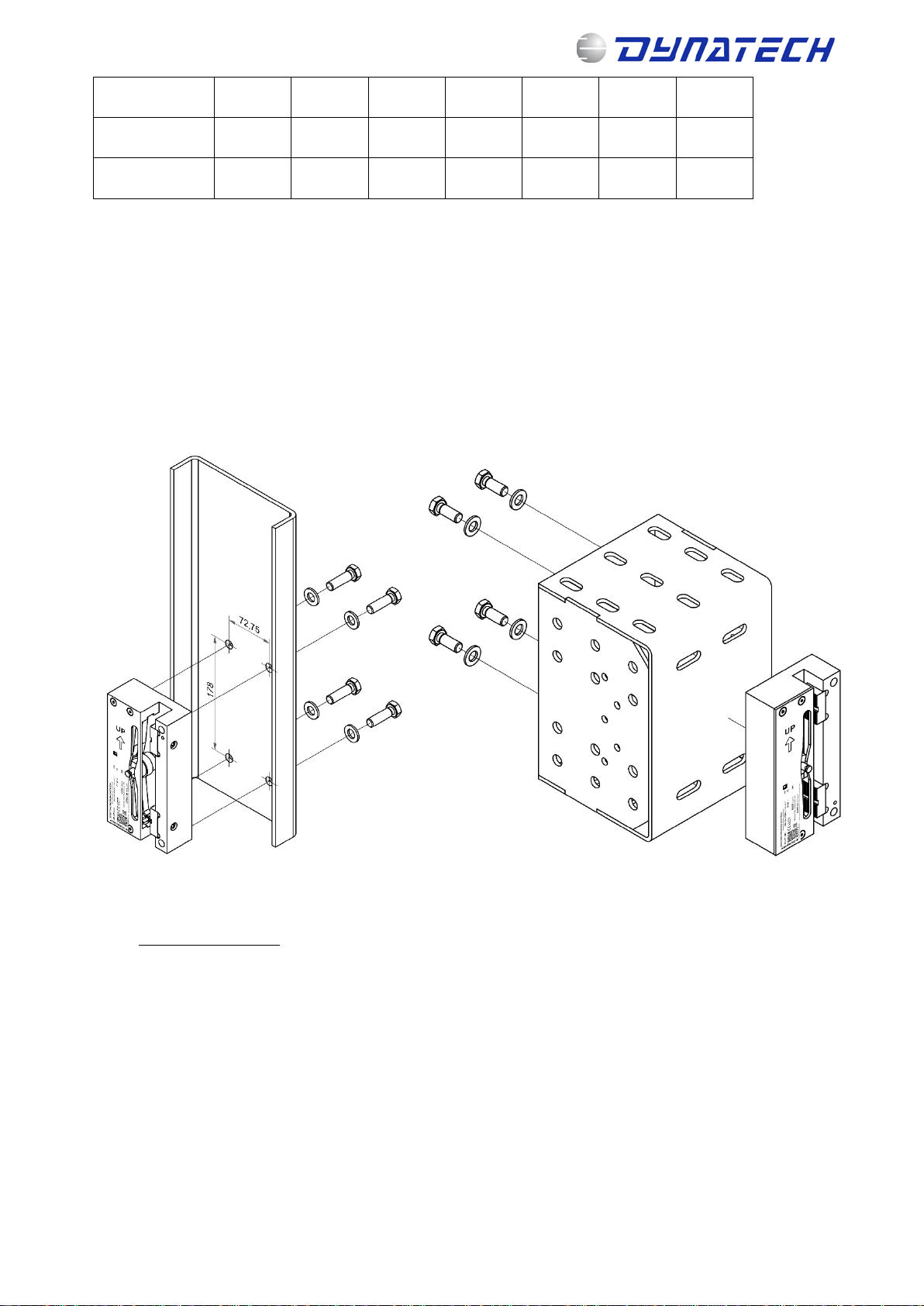

3.1ASSEMBLYONTHEFRAME..................................................................................................................................4

3.2SAFETYGEARADJUSTMENT................................................................................................................................6

3.3COUPLINGTHEDRIVINGBAR..............................................................................................................................6

3.3.1USINGDYNATECH’ST‐3DRIVINGBAR........................................................................................................6

4INSPECTIONSANDMAINTENANCE....................................................................................................................7

4.1CHECKINGTHESAFETYGEARS............................................................................................................................7

4.2PRECAUTIONS.....................................................................................................................................................8

4.3MAINTENANCE....................................................................................................................................................8

4.3.1LISTOFMAINTENANCEOPERATIONS.........................................................................................................8

4.3.2CORROSION.................................................................................................................................................8

4.4STORAGEANDSERVICELIFE................................................................................................................................8

5UCM................................................................................................................................................................9

5.1UCMSYSTEM’SPRELIMINARYDESIGN................................................................................................................9

5.2SAFETYGEARBRAKINGDISTANCECALCULATION...............................................................................................9

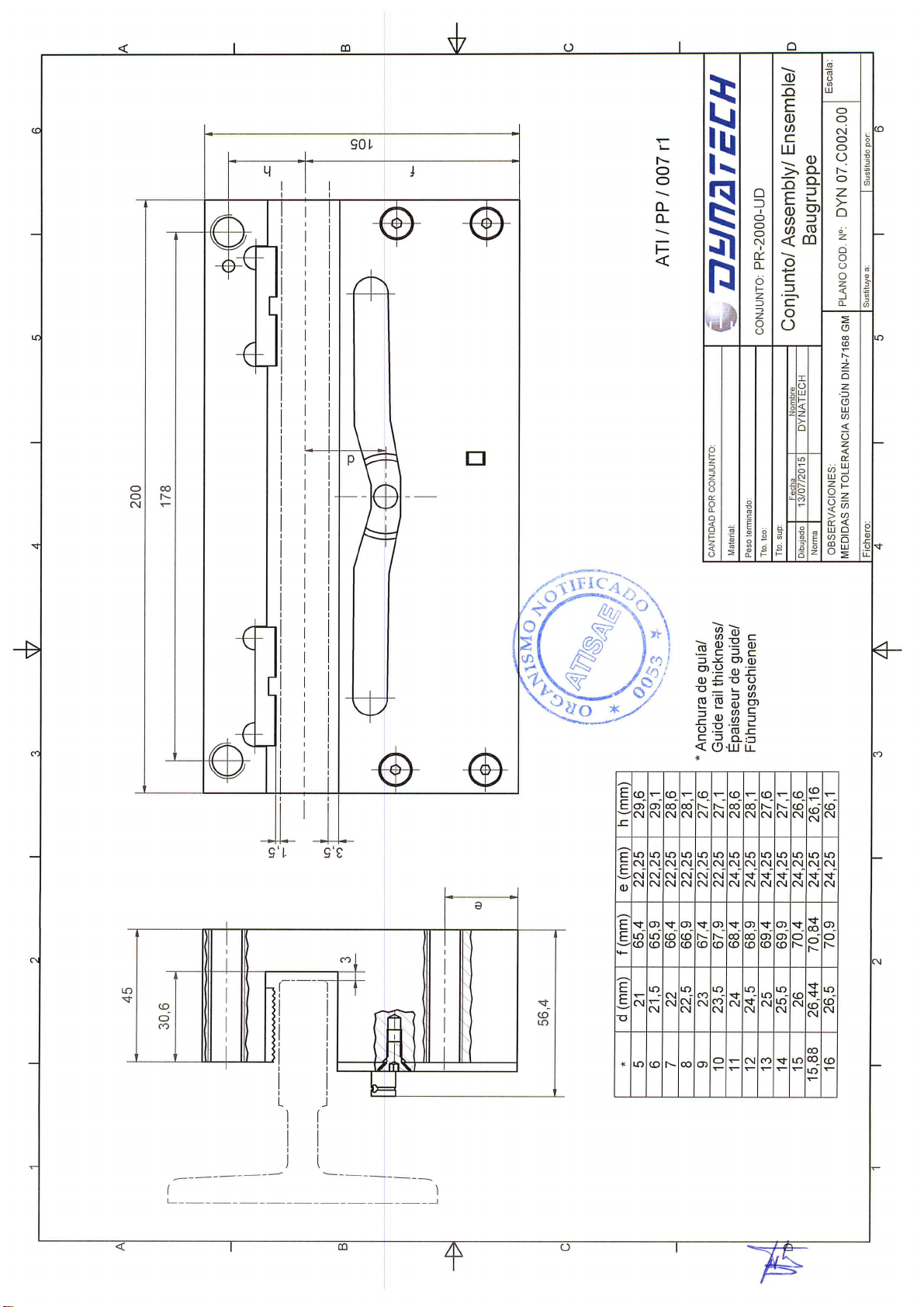

6GENERALDRAWING.........................................................................................................................................9

7ANNEXES........................................................................................................................................................10

_____________________________________________________