STL3500

7

II) INTRODUCTION

CAUTION

This instruction manual has been prepared for professional workshop personnel used to working with lifts, as well as for

the technicians who are in charge of the lift’s installation and maintenance.

This manual is an important part of the lift and must be kept where it is easily accessible for consultation and we

recommend particular attention in reading the chapter on safety.

All operations of the lift must be carried out by skilled and authorised personnel, especially operations of transportation,

assembly, installation, maintenance, overhaul, moving, dismantling, etc… The manufacturer cannot be held responsible

for damages to persons, vehicles or objects caused by improper use of the lift.

The lift model STL3500 has been designed and built according to:

-European Directives 2006/42/CE

-European Standard EN1493-2010

III) PACKING, TRANSPORT AND STORAGE

CAUTION

Any action involving the operation, transportation or unpacking of the equipment must ONLY be performed by trained

personnel with a proper knowledge of the lift and of the contents of this operating manual.

LIFTING AND MOVING THE PACKING

The lift is delivered assembled and packaged as follows:

N° 1 platform complete with base, scissors, positioned on 2 wooden blocks, wrapped in pluriball plastic and closed with

metal clips and relative seals.

N° 1 carton containing the control unit wrapped in plastic sheet and the kit of hoses/cables for the electrical, hydraulic

and pneumatic connection.

N° 1 carton with lifting system.

DIMENSIONS

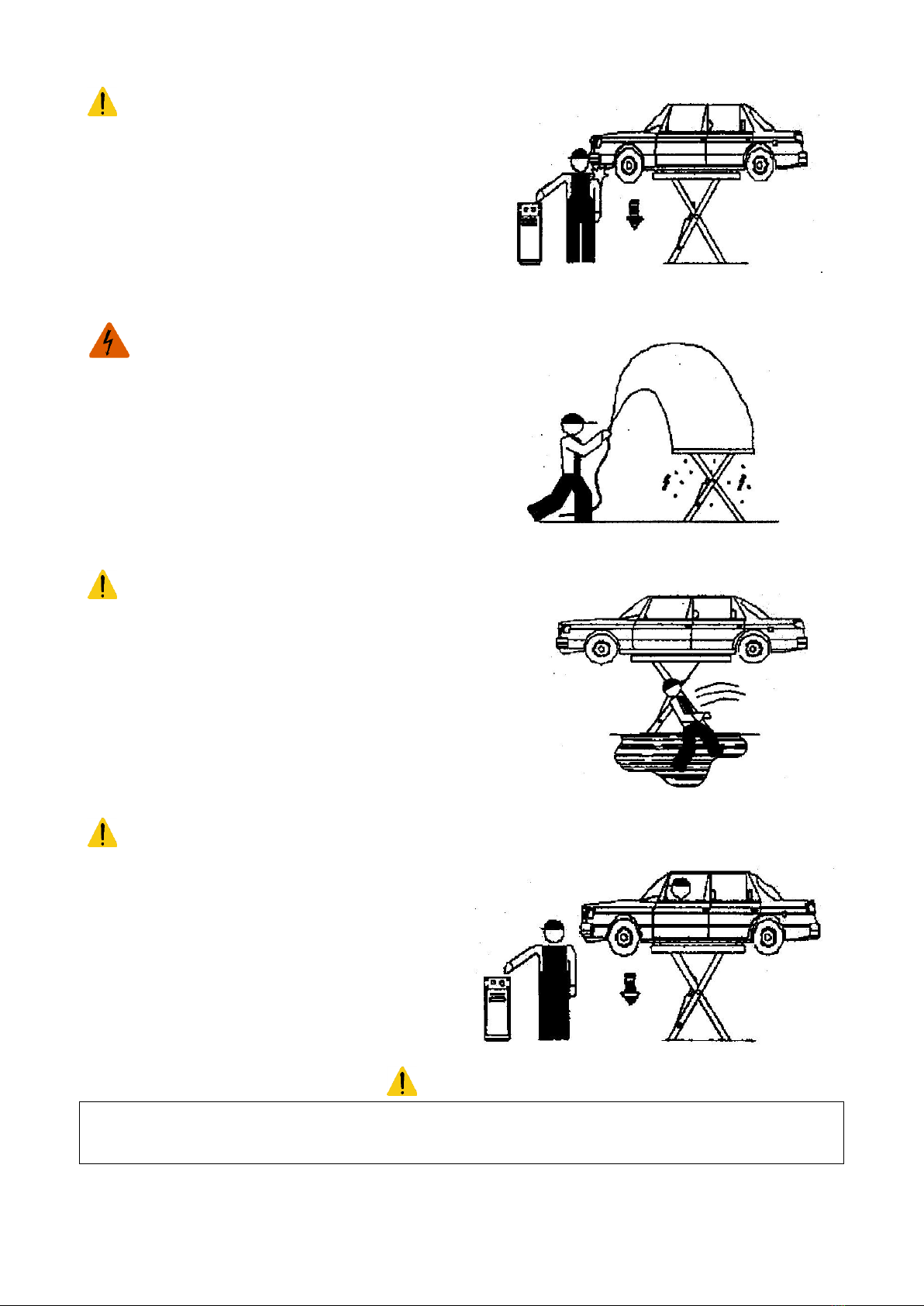

The packed lift must be lifted and moved with the help of a fork lift or a crane of adequate capacity.

STORAGE

The packed lift must always be placed in a covered area at a temperature between -10°C and +40°C and must not be

exposed to direct sunlight.

PACKING

Make sure the equipment has not been damaged during transport, and that all the components mentioned in the packing

list are physically present.

Any damage and / or missing parts must be immediately reported to the deliverer and subsequently reported and

documented to the manufacturer.