BlackJack BJTJ-1000 User manual

Please read and understand all instructions

before use. Retain this manual for future reference.

USER MANUAL

Black Jack™ Trailer Jack

1,600kg 12V DC

P/N: BJTJ-1000

www.blackjacktrailerjacks.com.au

3

USER MANUAL

1,600 KG 12V DC A-Frame Black Jack Trailer Jack™ User Manual V2.6 ©

CONTENTS

1. Specications 4

2. Introduction 4

3. Safety 5

4. Hazard Denitions 5

5. Work Area 5

6. Personal Precautions 6

7. Specic Safety Precautions 6

8. Electrical Safety 7

9. Identication Key 8

10. Assembly & Installation 8

11. Adjust The Bubble Level 9

12. Operation 10

13. Unhitching The Trailer 10

14. Hitching The Trailer 11

15. Manual Override 11

16. Care & Maintenance 12

17. Lubrication 12

18. Troubleshooting 13

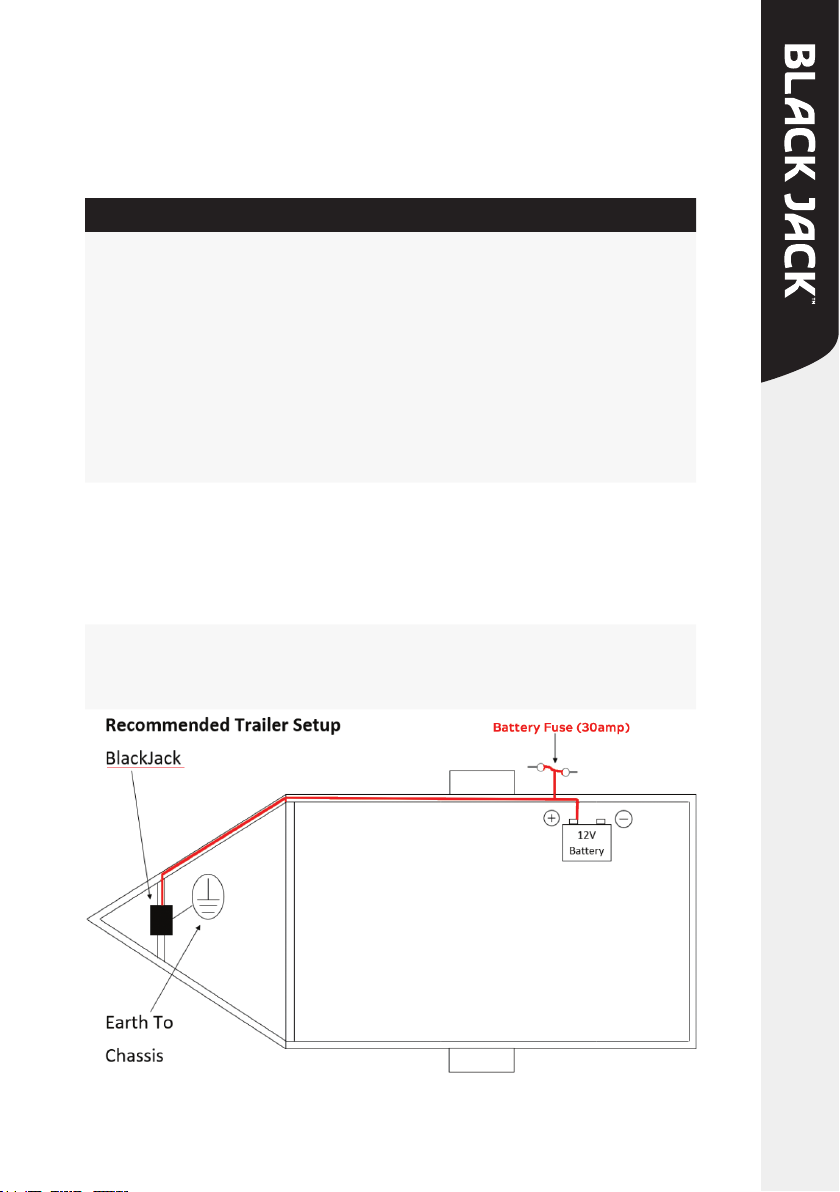

19. Wiring Diagram 13

20. Intellectual Property 14

21. Compliance 15

4

USER MANUAL

1,600 KG 12V DC A-Frame Black Jack Trailer Jack™ User Manual V2.6 ©

1. SPECIFICATIONS

Maximum Load Capacity 1600 kg

Height Range 356mm (254 to 609mm from mounting point.

Excluding Drop Leg Height)

Stroke Length Max stroke length including drop leg 22” (560mm)

Drop Leg Height Up to 203mm

Foot Plate Removable 133mm diameter foot plate

Handle Manual crank override

Ratio 5:1 (manual crank handle)

Tube Diameter 62mm outer Dimension

Construction Steel tubes and plate and polypropylene cover

Motor Type Sealed brushless motor

Finish Powder coat tube, zinc plated inner and drop tubes

Overall Dimensions H 781 x W 216 x D 140mm

Voltage Rating 12V DC

Circuit Protection Circuit Breaker 30amp Short Stop, Auto resettable

ignition protected

Current Rating Maximum 28A (Extended), 6A (Retracted)

IP Rating IP 56

2. INTRODUCTION

The 1,600 kg 12V DC A-Frame Black Jack Trailer Jack is rated to support up to

1,800kg trailer tongue weight. The jack is predrilled to t with the Patented Black

Jack Clamp so that it can be tted to any A-frame trailer.

The Black Jack features an LED light to illuminate the hitch area at night and a built-

in leveling gauge.

5

USER MANUAL

1,600 KG 12V DC A-Frame Black Jack Trailer Jack™ User Manual V2.6 ©

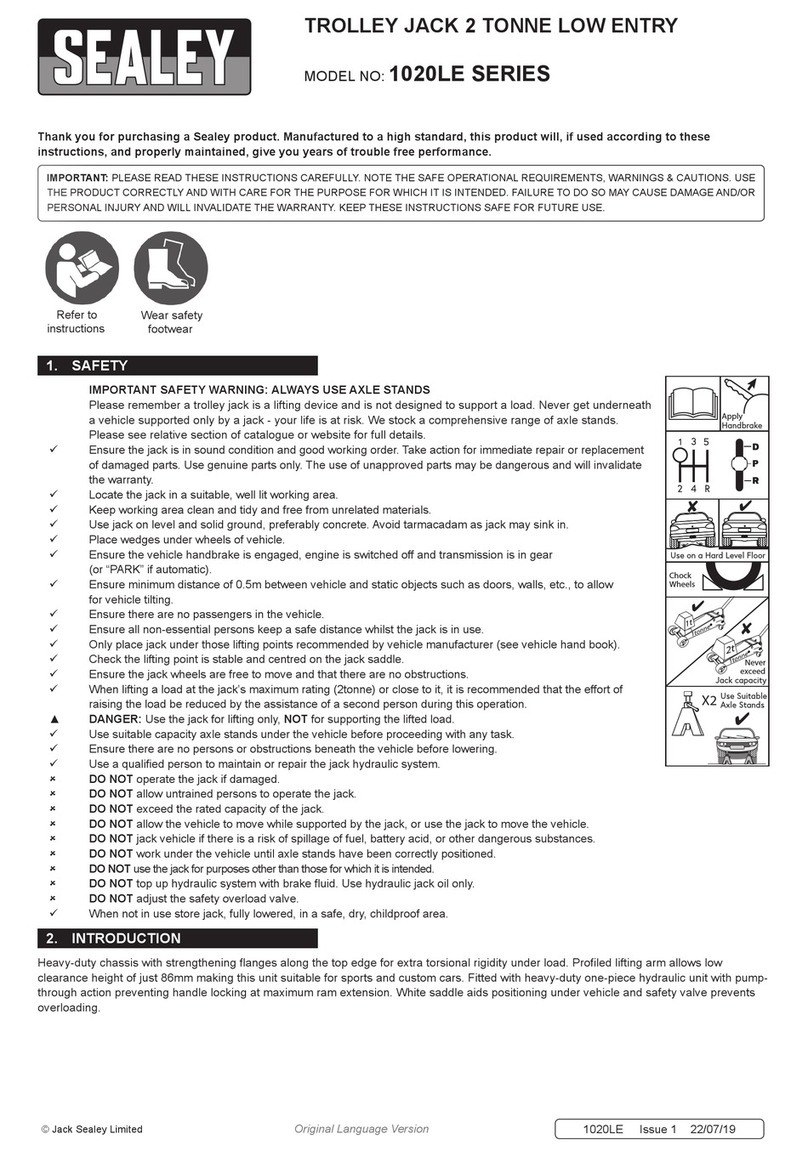

3. SAFETY

WARNING! Read and understand all instructions before using this device. The

operator must follow basic precautions to reduce the risk of personal injury and/or

damage to the equipment.

Keep this manual for safety warnings, precautions, operating or inspection and

maintenance instructions.

4. HAZARD DEFINITIONS

Please familiarise yourself with the hazard notices found in this manual. A notice

is an alert that there is a possibility of property damage, injury, or death if certain

instructions are not followed.

DANGER!

This notice indicates an immediate and specic hazard that will result in severe

personal injury or death if the proper precautions are not taken.

WARNING!

This notice indicates a specic hazard or unsafe practice that could result in severe

personal injury or death if the proper precautions are not taken.

CAUTION!

This notice indicates a potentially hazardous situation that may result in minor or

moderate injury if proper practices are not taken.

NOTICE!

This notice indicates that a specic hazard or unsafe practice will result in equipment

or property damage, but not personal injury.

5. WORK AREA

Operate in a safe work environment. Keep your work area clean, well-lit, and free of

distractions. Keep anyone not wearing the appropriate safety equipment away from

the work area.

Store unused devices properly in a safe and dry location to prevent rust or damage.

Lock devices away and keep out of the reach of children.

Do not install or use in the presence of ammable gases, dust, or liquids.

6

USER MANUAL

1,600 KG 12V DC A-Frame Black Jack Trailer Jack™ User Manual V2.6 ©

6. PERSONAL PRECAUTIONS

Control the device, personal movement, and the work environment to avoid personal

injury or damage to device.

Do not operate any device when tired or under the inuence of drugs, alcohol, or

medications.

Avoid wearing clothes or jewelry that can become entangled with the moving parts of

a device. Keep long hair covered or bound.

Do not overreach when operating a device. Proper footing and balance enable better

control in unexpected situations.

7. SPECIFIC SAFETY PRECAUTIONS

WARNING! DO NOT let comfort or familiarity with product (gained from repeated use)

replace strict adherence to the device safety rules. If you use this device unsafely or

incorrectly, you can suffer serious personal injury.

Use the correct device for the job. This device was designed for a specic function.

Do not modify or alter this device or use it for an unintended purpose.

Do not attempt to lift more than the 1,800 kg maximum lifting capacity of this jack.

Always place the jack on a hard, level surface capable of supporting the load. Allow

enough clearance around the jack and the load for movement.

Never place any part of your body beneath the trailer that is supported by the jack.

A jack failure or shifting of the trailer may cause it to collapse and cause a serious

injury or death.

Keep your limbs and body away from any pinch or shearing points while using the

jack. Failure to do so may result in a serious injury.

Inspect the jack before each use. DO NOT use if bent, broken, cracked or otherwise

damaged, if any suspect parts are noticed or it has been subjected to a sudden or

unexpected load (shock loading).

Ensure that all applicable pins, bolts, and nuts are rmly tightened before using.

Do not allow untrained persons to operate the jack.

Secure the load, trailer, and vehicle by chocking all the wheels before using.

Do not place your hands between moving components.

7

USER MANUAL

1,600 KG 12V DC A-Frame Black Jack Trailer Jack™ User Manual V2.6 ©

Use only with accessories rated to handle the forces exerted by the device during

operation. Other accessories may break and forcefully launch pieces.

Once the load is lifted to the desired height, support the load with jack stands to

prevent injury should the jack fail. Do not work under a load that is supported only by

a jack.

Ensure that there are no obstructions under the load and that the area is clear before

lowering it.

Ensure that the lock pin is properly inserted through the inner and outer tubes, and

that there is no load on the trailer before using the manual drop leg extension.

Do not adjust the drop foot while there is a load on the jack.

8. ELECTRICAL SAFETY

Disconnect device from power source before cleaning, servicing, changing parts/

accessories or when not in use

Protect yourself against electric shocks when working on electrical equipment.

Avoid body contact with grounded surfaces. There is an increased chance of

electrical shocks if your body is grounded.

Do not expose device to rain or wet conditions. Water entering a power device will

increase the risk of electric shock.

Do not disconnect the leads in place of using the ON/OFF switch on the device. This

will prevent an accidental startup when the leads are connected to the power supply.

Do not alter any parts of the device or accessories. All parts and accessories are

designed with built-in-safety features that may be compromised if altered.

Make certain the power source conforms to requirements of your equipment (see

Specications).

Do not operate this device if the leads are frayed or damaged as an electric shock or

surge may occur, resulting in personal injury or property damage.

Inspect the leads for cracks, fraying or other faults in the insulation before each use.

Discontinue use if the leads feel more than comfortably warm while operating the

device.

Keep all connections dry and off the ground to reduce the risk of electric shock. Do

not touch the leads with wet hands.

8

USER MANUAL

1,600 KG 12V DC A-Frame Black Jack Trailer Jack™ User Manual V2.6 ©

Keep the leads away from heat, oil, sharp edges or moving parts.

Place the leads in a position that prevents them from encountering the device.

Keep any ignition source, such as ames, sparks, or embers away from the battery.

Avoid contact with batteries as they contain sulfuric acid. The acid is corrosive and

can cause skin burns.

Install caps over the battery terminals to prevent accidental contact. Discharged

batteries may still carry charges and cause electric shock upon contact.

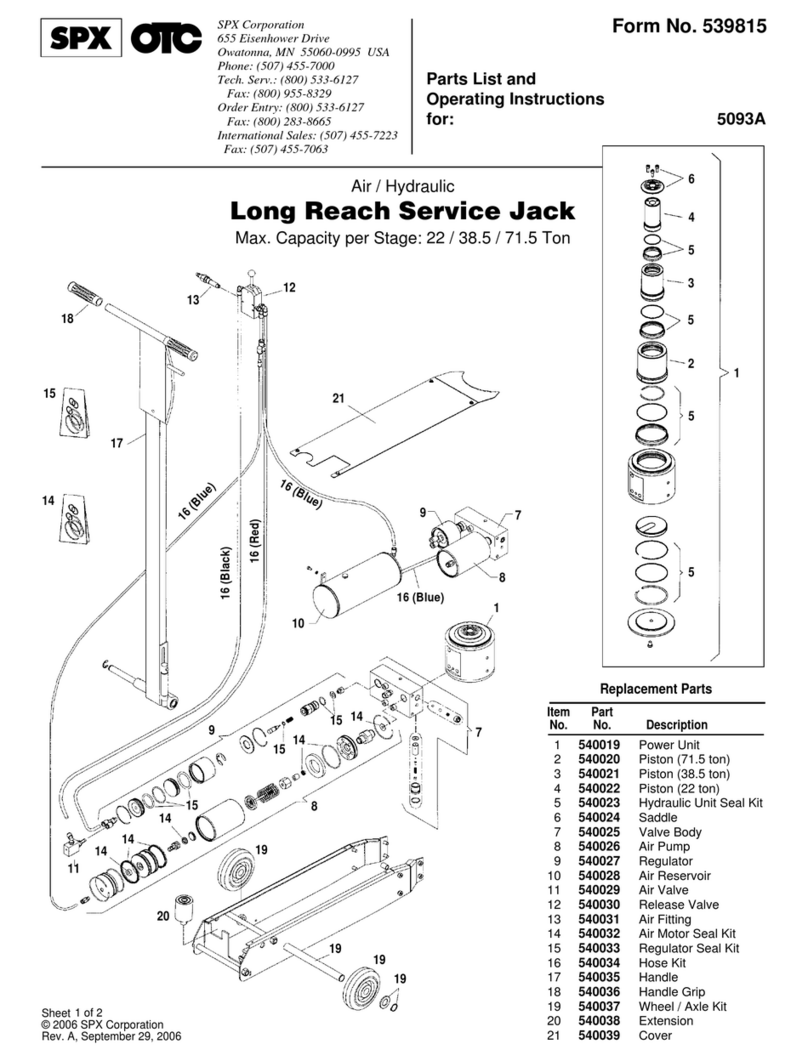

9. IDENTIFICATION KEY

Letter references are in parenthesis (A) refer to the included Identication Key.

The Black Jack Trailer Jack also comes with the Black Jack Clamp (Patent Pending

NO 20200902039) and the Black Jack All Weather Cover.

10. ASSEMBLY & INSTALLATION

1. Attach and secure the trailer’s coupler to the tow vehicle’s hitch. Chock the

wheels of the trailer and vehicle. Also apply the vehicle’s parking brake.

2. Slide the tube (D) into the Black Jack Mounting Bracket hole. Guide the foot

plate into the jack’s leg (E). Ensure the groove in the leg is aligned with the one

on the foot plate. Do not insert the lock pin (K).

9

USER MANUAL

1,600 KG 12V DC A-Frame Black Jack Trailer Jack™ User Manual V2.6 ©

3. Position the jack to face the towing vehicle or the side. The design of the vehicle

may impair the use of the manual crank (L) based on the jack’s orientation.

4. Slide a 3/8 in. star washer (M) between the mounting plate and frame at each

bolt hole.

5. Slide a 3/8-16 in. lock washer onto each of the three 3/8-16 in. bolts, then insert

the bolts through the mounting plate, the star washers and A-frame.

6. Secure each bolt with a 3/8-16 in. hex nut. Tighten the bolts with a torque

wrench to between 15 to 20 ft-lb.

7. Use the Earth cable provided to connect from one of the three bolt positions

on the Black Jack Mounting Plate. Ensure the Star Washers provide has clean

contact to bare metal. Sanding back this point can also improve this metal

on metal contact. Once this has been created attached the other end to your

chassis rail. Pre-drill and use the Tek Screw provided to connect the earth

cable. Remove the foot plate (F) and position it below the hole in the Black Jack

Mounting Bracket.

8. Unravel the black wire and lay it out along the A-frame to the battery. Secure

the wire with cable ties. Position the cable in a way to protect it from damage if

possible. Connect the wire lead to the battery’s positive terminal (+).

9. Press the extend/retract switch (H) to test that the connection is correct, and

the jack is working. Also press the LED ON/OFF Switch (C) to conrm the light is

working.

10. Push the foot plate up fully and insert the lock pin (K) and retract the jack.

11. ADJUST THE BUBBLE LEVEL

The bubble level will require a one-time adjustment once the jack is installed. The

trailer must not be hitched to a towing vehicle during the leveling.

1. The bubble level will require a one-time adjustment once the jack is installed.

The trailer must not be hitched to a towing vehicle during the leveling.Chock the

trailer’s wheels to prevent them from rolling.

2. Extend the foot plate (F) and lock it into place with the lock pin (K).

3. Follow either a. orb. based on your situation:

4. Uncouple the trailer’s hitch receiver from the tow vehicle, but do not remove it

yet.

5. Leave jack stands supporting the A-frame in place.

10

USER MANUAL

1,600 KG 12V DC A-Frame Black Jack Trailer Jack™ User Manual V2.6 ©

6. Remove the bubble level (H) from the housing. Retain the three screws.

7. Place the bubble level on a at surface of the trailer. Ensure it will not fall off

during the leveling process.

8. Lower the levelling jacks on the trailer (if equipped with them).

9. Extend the jack until it clears the hitch or the jack stands. Move the jack stands

aside if necessary.

10. Raise or lower the trailer jack until the bubble level indicates the trailer is

horizontal and centered.

11. Place the bubble level back into the housing so it remains centered.

12. Screw all three retaining screws back into the cover. Adjust each screw until

they are tight, and the bubble is centered.

13. The adjustment is complete. You may wish to raise the jack enough to allow the

jack stands to be moved back into place. Once they are in position, retract the

jack fully.

12. OPERATION

WARNING! Never apply horizontal force against the jack. The load may shift and

cause the jack to fail, creating a dangerous situation for the user or bystanders.

This unit has a built-in circuit breaker which automatically trips and resets.

Press the light switch (C) to turn on the LED when performing these operations in the

dark.

13. UNHITCHING THE TRAILER

Chock the trailer’s wheels to prevent rolling.

Uncouple the trailer’s hitch receiver from the towing vehicle’s hitch.

Press the extend/retract switch to extend the jack’s leg (E) until the foot plate

contacts the ground and raises the trailer off the hitch.

The fully extended leg may not reach the ground. Retract the leg until you have

enough room to extend the foot plate.

Remove the lock pin and lower the foot plate until it touches the ground.

11

USER MANUAL

1,600 KG 12V DC A-Frame Black Jack Trailer Jack™ User Manual V2.6 ©

Raise the foot plate upwards until the bolt holes in it align with the bolt hole in the

leg.

Insert the locking pin and close the clasp.

Move the towing vehicle away from the trailer’s hitch receiver.

Level the trailer by pressing the extend/retract switch to raise or lower the jack. It is

level once the bubble level is centered.

14. HITCHING THE TRAILER

Press the extend/retract switch to raise the trailer’s hitch receiver above the level of

the towing vehicle’s hitch.

Align the towing vehicle’s hitch with the trailer hitch receiver.

Press the extend/retract switch to lower the trailer hitch receiver onto the towing

vehicle hitch. Secure the hitch receiver once seated.

WARNING! The hitch receiver must be properly aligned and seated before retracting

the leg fully to prevent it from slipping off the hitch and causing an injury to yourself

or bystanders.

15. MANUAL OVERRIDE

A loss of power may require you to raise and lower the trailer using the manual crank

(L).

Remove the crank cap (G) and set aside.

Insert the manual crank onto the shaft in the housing.

Crank counterclockwise to extend the leg. Crank clockwise to retract the leg.

Follow the directions for hitching or unhitching the trailer.

Replace the crank cap when done and store the crank.

12

USER MANUAL

1,600 KG 12V DC A-Frame Black Jack Trailer Jack™ User Manual V2.6 ©

16. CARE & MAINTENANCE

Maintain the device with care. A device in good condition is ecient, easier to control

and will have fewer problems.

Inspect the device components periodically. Repair or replace damaged or worn

components. Only use identical replacement parts when servicing.

Follow instructions for lubricating and changing accessories.

Only use accessories intended for use with this device.

The jack ‘s motor is sealed and maintenance-free.

Check the wiring from time-to-time. Ensure all the connections are tight and free

from corrosion. Ensure the ground wire has a solid metal-to-metal contact with the

trailer frame.

Check the battery charge and electrolyte level as directly by the battery’s

manufacturer.

Disconnect the battery from the trailer jack if it will not require power for several

days. This will prevent the battery from discharging.

Maintain the device’s labels and name plates. These carry important information. If

unreadable or missing, contact Titan Stability Solutions Pty Ltd. for replacements.

WARNING! Only qualied service personnel should repair the device. An improperly

repaired device may present a hazard to the user and/or others.

17. LUBRICATION

Inspect and lubricate the device when required. Apply grease to the inner tube when

extended and then retract to grease the outer tube

NEVER use a penetrating oil to lubricate the device. Penetrating oil may act as a

solvent that can break down the grease and cause the device to seize up.

13

USER MANUAL

1,600 KG 12V DC A-Frame Black Jack Trailer Jack™ User Manual V2.6 ©

18. TROUBLESHOOTING

Contact Titan RV for a solution if the device does not function properly or parts are

missing. If unable to do so, have a qualied technician service the device.

Problems Possible Cause(s) Suggested Solution(s)

Motor is not

operating

Poor Ground Use the Earth cable provided to

connect from one of the three

bolt positions on the Black Jack

Mounting Plate. Ensure the Star

Washers provide has clean contact

to bare metal. Sanding back this

point can also improve this metal on

metal contact. Once this has been

created attached the other end to

your chassis rail. Pre-drill and use

the Tek Screw provided to connect

the earth cable.

No or Low voltage Check battery and electrical

connections. Power supplied must

be at least 10V DC. If the battery

is low, plug the trailer cable into

the tow vehicle, and start the tow

vehicle to provide power to the jack.

No Power from

trailer connector

Check the trailer connector has

power. Replace or repair the trailer

connectors or wiring.

14

USER MANUAL

1,600 KG 12V DC A-Frame Black Jack Trailer Jack™ User Manual V2.6 ©

19. WIRING DIAGRAM

20. INTELLECTUAL PROPERTY

Registered Trademark

Black Jack Trailer Jacks™ is a registered trademark in Australia owned by Titan

Stability Solutions Pty Ltd

Patent Pending

The Black Jack Clamp is a registered patent pending in Australia (Patent Pending NO

20200902039).

Registered Design

The Black Jack Clamp is a registered design pending in Australia.

Copyright

This “Black Jack Trailer Jack™ 1,600kg 12V DC User Manual” is copyright protected

and owned by Titan Stability Solutions Pty Ltd.

Domain Name

15

USER MANUAL

1,600 KG 12V DC A-Frame Black Jack Trailer Jack™ User Manual V2.6 ©

Blackjacktrailerjacks.com.au is a registered domain name owned by Titan Stability

Solutions Pty Ltd

21. COMPLIANCE

1. EMC Compliance

The Black Jack TM is EMC approved and compliant with:

EN 61000-6-3:2007+A1:2011+AC:2012

EN IEC 61000-6-1:2019

EN IEC 61000-3-2:2019

EN 6100-3-3:2013+A1:2019

2. Australian Standards for Gas Installations in Caravans

Gas Installations in Caravans AS\NZS 5601.2.2010 & Amendment N0.1 to AS/

NZS 5601.2.2013 (Standard)

The Standard requires that an “ignition source” cannot be located within the

clearances of an exchange gas cylinder as set out in the diagram below. The

E8394

16

USER MANUAL

1,600 KG 12V DC A-Frame Black Jack Trailer Jack™ User Manual V2.6 ©

standard denes an “ignition source” as:

“A source of energy sucient to ignite a ammable mixture and includes,

but is not limited to naked ames, exposed incandescent material, electrical

welding arcs, and any electrical or mechanical equipment not suitable for use in

hazardous locations”.

The Black Jack is dened as “electrical equipment” however the standard does

not dene or provide a criterion for the term “not suitable”. However, we conrm:

A. The Black Jack contains two Single Pole 12VDC rocker switches: an LED

Light ON-OFF switch and an UP–DOWN momentary switch. Both switches

are enclosed and carry an Ingress Protection (IP) rating of 64, meaning

they are completely dust tight and water tight from splashing water.

B. The Circuit protection used in the Black Jack is dened as a 12VDC Short

Stop Automatic Resettable Circuit Breaker. Ignition Protected, IP66,

meaning they are completely dust tight and protected against powerful jets

of water. Maximum current rating of 30amps @12DVC.

C. The 12VDC motor in the Black Jack is brushless and fully encapsulated

with maximum 28-amp current draw @ 12VDC.

D. All hard-wired terminal connections are located within the plastic cover

head housing.

Based on A. to D. above, the 12 volt DC components in the Black Jack, whilst

being deemed “electrical equipment” are not considered an ignition source in

keeping with the Australian Standard’s broad denition that includes “naked

ames, welding arcs etc., that are sucient to ignite a ammable mixture”.

17

USER MANUAL

1,600 KG 12V DC A-Frame Black Jack Trailer Jack™ User Manual V2.6 ©

ABOUT BLACK JACK™

Black Jack™ Trailer Jacks is a division of Titan Stability Solutions Pty Ltd

Our range of brands include:

Gone are the days of manually winding the jockey wheel to raise or

lower the caravan or trailer.

www.blackjacktrailerjacks.com.au

The best selling Sway Control and Weight Distribution Hitches in the USA

now available in Australia.

www.swaycontrolhitches.com.au

Hydraulic auto levelling system for motorhomes, caravans,

specialty vehicles and 5th wheelers.

www.redfootlevelling.com.au

Gone are the days where you must settle for a cheap ball mount

that rusts the rst time it rains.

www.hothitches.com.au

CONTACT US

Black Jack™ Trailer Jacks is a division of Titan Stability Solutions Pty Ltd

Titan Stability Solutions Pty Ltd

Unit 5

Euro Business Park

26-34 Weippin Street

Cleveland QLD 4163

AUSTRALIA

P: +61 07 3286 1199

www.blackjacktrailerjacks.com.au

V2.6

July 2020

Other manuals for BJTJ-1000

1

Table of contents

Other BlackJack Jack manuals