Blake Water Solutions MOD-EMU-BWS User manual

Operaon & Installaon Instrucons

EQUIPMENT MODULES

Table of Contents

Emulator Module .............................................. 1

Remote Alarm Module ...................................... 2

4-20 mA Module................................................ 3

Solonoid Module ............................................... 4

Water Quality Monitor Module......................... 8

1|Page

EMULATOR MODULE

MODEL # MOD-EMU-BWS

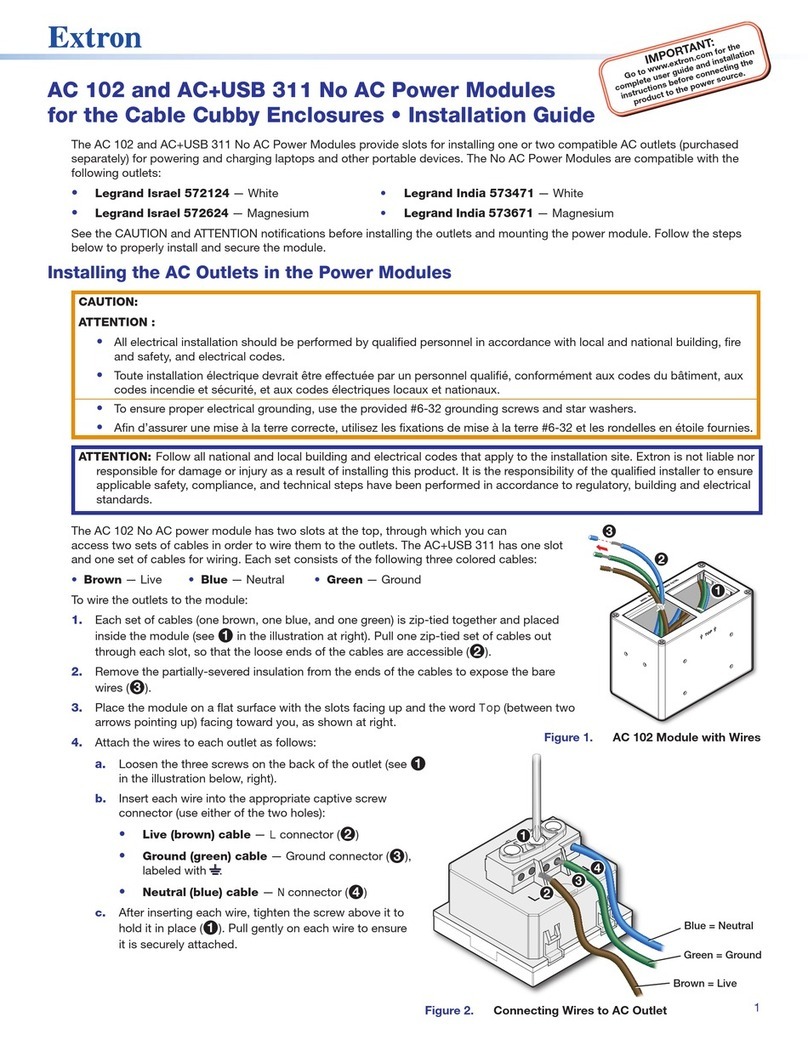

The Emulator module comes with a male

IEP connecon (Innite Expandability

Port). Prior to start-up, rst ensure all the

toggle switches for the “Module Alarms”

and “Lamp Alarm” are in the OFF (toggle

up) posion. Plug the Emulator connector

into the IEP on the BLAKE/HO controller,

then plug in the controller power cord.

To Emulate a parcular module failure,

toggle the corresponding switch to the

ON (toggle down) posion. The alarm can

be cleared by returning the switch to its

OFF (toggle up) posion. The device also

can emulate the UV intensity reported by

a UV sensor module. Turning the right “UV” knob in the clockwise direcon will increase the

intensity, while turning it counterclockwise will decrease the intensity. Please note that to see

all the capabilies of the sensor, you will need to cycle the intensity through the range of 49

through 66 %. The “Days Remaining” cycle can also be adjusted by turning the le “Days” knob.

Emulation Module

Module Alarms

Closed Open

Days UV

Sensor Solenoid 4-20 LampRemote Alarm

Solenoid Status

MOD-EMU-BWS

4-20 mA module

BWS5/BWS6

Series controllers

BWS5-C/6-C

Series controllers

IEP

connecon

IEP

connecon

2|Page

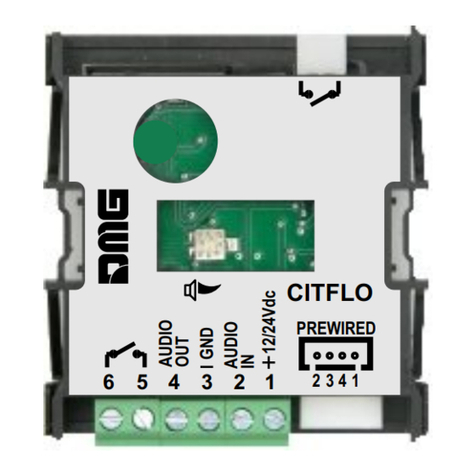

REMOTE ALARM MODULE

MODEL # MOD-RAM-BWS

The Remote Alarm module comes with both a male and female IEP connecon (Innite

Expandability Port). To iniate the module simply plug the male plug into the IEP on the

Standard or High Output controller, or into any other BLAKE module that contains an IEP

(sensor, 4-20 mA module, solenoid module, etc.) and then restart the system.

The Remote Alarm module is a pair of dry contacts and can be used to connect the controller

to a PLC based system, an alarm buzzer (or light), or an “OK” light. The Maximum contact rang

is 30V / 1A. If your device draws more current, please use the module to switch a relay with

contacts rated for the device you wish to use.

Sensor IEP

Installaon

IEP

connecon

BWS5/BWS6

Series controllers

BWS5-C/6-C

Series controllers

IEP

connecon

IEP

connecon

“OK”

Light

Customer

Power Supply

Maximum 30V

“FAIL” Light/Buzzer

Autodialer

Customer

Power Supply

Maximum 30V

remote alarm module

MOD-RAM-BWS

1A MAX

Com OKFault

remote alarm module

MOD-RAM-BWS

1A MAX

Com OKFault

3|Page

4-20 mA MODULE

MODEL # MOD-420-BWS

The 4-20 mA module comes with both a male and female IEP connecon (Innite Expandability

Port). To iniate the module simply plug the male plug into the IEP on the controller, or into

any other BLAKE module that contains an IEP (sensor, remote alarm, solenoid module, etc.)

Connect “LOOP” Connecons as follows:

Sensor IEP

Installaon

IEP

connecon

BWS5/BWS6

Series controllers

BWS5-C/6-C

Series controllers

IEP

connecon

IEP

connecon

LOOP Specifications

Power Supply: Min 5 volts

Max 30 volts

Power Supply

PLC

or

Data Logger

4-20 mA module

MOD-420-BWS

4|Page

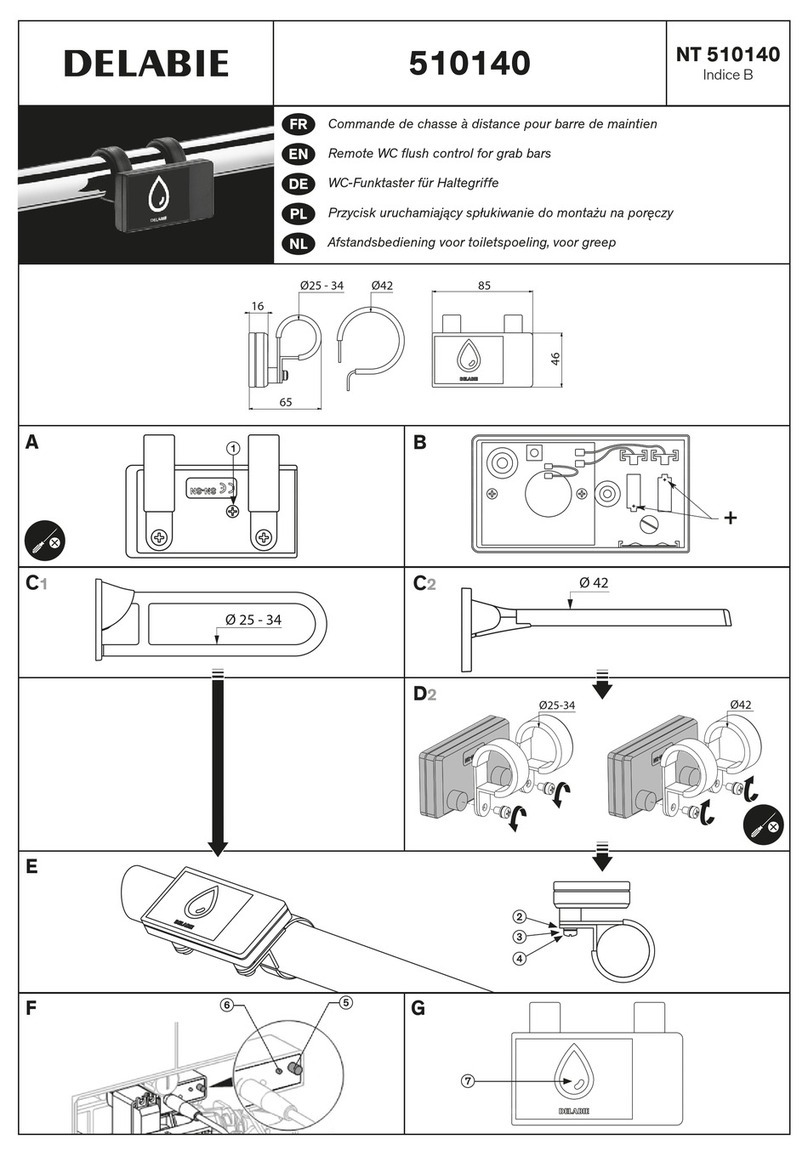

SOLENOID MODULE

MODEL # MOD-SOL1-BWS

The Solenoid Module is designed to connect a

NORMALLY CLOSED line voltage solenoid valve to the

controller. It is possible to us a 12V or 24V normally

closed solenoid by replacing the AC power cord.

Note that the maximum contact rang is 240VAC

(50-60Hz) / 30VDC / 2A.

LOCATION

Step 1) Find a suitable locaon on the wall for the

solenoid module. The module must be installed close

enough to the controller, or the UV sensor to be able

to plug in the male IEP connector. The module must

also be installed close enough to the actual solenoid

valve and this distance will be dependent on the cord

length of the parcular solenoid valve that is used.

Step 2) Pick a locaon for the solenoid valve and install as per the manufacturer’s direcons.

The solenoid module requires bare leads, so if the solenoid cable has a plug aached, remove

the plug and strip the wires to a suitable length.

INSTALLATION

Step 1) Make sure the solenoid valve cable is NOT plugged into the electrical outlet. Insert

the solenoid valve cable through the center hole of the middle strain relief. Connect the three

electrical wires to the terminal block that is marked “SOLENOID” (see Fig. 1). Connect the

ground wire in the posion marked “GND”, the line voltage wire in the posion marked “L1”

and the neutral wire in the posion marked “N”. Typical wire colour conguraons are marked

directly on the circuit board to the le of the SOLENOID terminal block to aid in this process

(see Fig.2) If you are unsure of the correct wiring conguraon for you parcular solenoid

valve, please contact an approved electrical contractor. Once all the line voltage connecons

have been made, ghten the strain relief nut to secure the cable to the solenoid module.

Figure 2

Wiring Colour Guide

Figure 1

Solenoid Wire Installaon

Solenoid module

MOD-SOL1-BWS

5|Page

Step 2) Plug the solenoid valve into the applicable electrical

outlet. At this stage, the funconality of the solenoid valve

can be tested by pressing the solenoid test buon located on

the upper le of the circuit board. Manually depressing (and

holding) this buon will complete the electrical circuit and will

open the normally closed solenoid valve. You should be able to

hear the acvaon of the solenoid valve at this stage to ensure

the valve is funconing properly (see Fig. 3).

Step 3) Make sure your UV controller is unplugged from the

power source. Once all these connecons have been made,

ax the male IEP plug of the solenoid module cable into the

IEP port on the controller, or any other available IEP port such

as the UV sensor, 4-20 mA module or remote alarm module. It

does not maer which IEP port any module is aached to, as

long as they are aached.

Figure 3

Solenoid Test Buon

OPERATION

Step 1) Plug the controller into the power source and make sure the solenoid module is

acvated on the controller. During the start-up sequence, the SOLENOID MODULE screen will

indicate a “inialized” when the module is acvated properly (see Fig. 4).

Figure 4

Solenoid

Acvaon

Screens

Sensor IEP

Installaon

IEP

connecon

BWS5/BWS6

Series controllers

BWS5-C/6-C

Series controllers

IEP

connecon

IEP

connecon

6|Page

Step 2) The controller will only nofy you when there is a failure

mode whereby the solenoid module (and connected solenoid valve)

will be acvated. On the BWS5 system, the solenoid module will be

acvated (shung o the ow of water) upon LAMP FAILURE (see

Fig. 5). To remedy this, replace the UV lamp and restart the system as

per the direcons outlined in the Owner’s Manual.

Step 3) On the BWS6 system where a UV sensor is installed, the solenoid

module will be acvated (shung o the ow of water) upon a LOW

UV condion (less than 50%) (see Fig. 6). To remedy this, you will need

to address the reason for this low UV condion which may be due to a

dirty UV sensor and quartz sleeve, a lamp that is not eming enough

UV energy, or a change in the water quality. Please refer to the UV

systems Owner’s Manual for correcve acon procedures.

Figure 5

LAMP FAILURE Screen

Step 4) To determine what posion the solenoid valve is currently in, the solenoid module

incorporates three lights on the circuit board (see Fig. 7). When the solenoid is in the OPEN

posion a green light will appear on the circuit board beside the word “OPEN”. When the valve

is CLOSED, a red light will appear on the circuit board beside the word “CLOSED”. And when the

solenoid is in an OVERRIDE posion, an amber light will appear on the circuit board beside the

word “OVERRIDE ON”.

Figure 6

LOW UV

Screens

Figure 7

Solenoid Status

(Colour)

Boil Water Advisory: If any failure occurs on a BLAKE UV system, the water

must not be used for human consumpon unl the system is returned to a safe operaonal

mode. If the water is used for human consumpon during this period, the water must be

boiled (minimum 20 minutes at a full boil) prior to consumpon.

EMERGENCY BYPASS

In a case where the solenoid valve has been acvated (valve is closed and no water is allowed

to ow), the solenoid module has the ability to bypass the solenoid valve in case of an

emergency need of water. To iniate this bypass, depress the buon labeled “OVERRIDE”

located in the lower le poron of the circuit board (see Fig. 8)

7|Page

Figure 8

Solenoid Bypass

Buon

Once this buon has been pressed, the system will remain in this

override mode regardless of whether or not the condion causing the

solenoid acvaon has been remedied or not. To reset the system,

the power to the controller must be shut o and restarted. While

in this override mode the controller will intermiently display a red

“SOLENOID OVERRIDE” screen (see Fig. 9).

Figure 9

SOLENOID OVERRIDE

Screen

DISABLING EMERGENCY BYPASS

In certain regulated applicaons, the availability , and use,

of the emergency bypass feature may be in violaon of the

local, state/provincial codes. If this is the case, the bypass

feature can easily be disabled by physically removing the

bypass buon. To accomplish this, carefully use a pair of

needle nose pliers and physically remove the actual bypass

buon (marked “OVERRIDE”) from the circuit board .

Figure 10

SOLENOID FAILURE

Screen

OTHER FAILURE MODES

In the event there is an issue with the solenoid connecon from

the IEP cable to the controller, the system will register a “SOLENOID

FAILURE” screen on the controller (see Fig. 10).

CAUTION: BEFORE PERFORMING ANY

WORK ON THE SOLENOID MODULE, THE

POWER CORD MUST BE DISCONNECTED

FROM ITS POWER SOURCE (WALL PLUG).

8|Page

WATER QUALITY MONITOR MODULE

MODEL # MOD-SHERPA-BWS

The module comes with a Transmier and a Remote Display. The Transmier connects to a

standard output and high output controller and transmits the controller’s status wirelessly

to the Remote Display. Every Transmier and Remote Display is paired together and uses

encryption to create a reliable and secure communication link between the two devices. Every

Transmier supports up to ve Remote Displays. Additional Remote Displays can be purchased

and installed separately. Refer to ‘Pairing an Additional Remote Display’ for additional Remote

Display installation.

Installation

Step 1) Power o the UV system controller.

Step 2) Plug the male plug of the Transmier into the IEP (Innite Expandability Port) on

the controller, or into any other module that contains an IEP (sensor, 4-20 mA

module, solenoid module, etc.) and then restart the system Note 1.

Step 3) To Receive the UV system

controller’s status on the

Remote Display, plug the AC/

DC wall adapter into the Power

Port on the Remote Display (5V

Max) and slide the switch to

the ON position.

Back of

Remote

Display

Transmier

Remote Display

50m/164

(Note 2) Good

Caution

Alarm

Comm

Active

Water Quality

Monitor

Sensor IEP

Installaon

IEP

connecon

BWS5/BWS6

Series controllers

BWS5-C/6-C

Series controllers

IEP

connecon

IEP

connecon

9|Page

Operation

Remote Display

Status LED’s

Good

(Green) No Active Alarms.

Caution

(Yellow) Active Minor Alarm, check system for details.

Alarm

(Red) Active Major Alarm, check system for details.

Comm. LED

OFF Communication is working.

Flashing

Communication is NOT working.

Remote Display is Out-of-Range2, Transmier is disconnected

OR controller is powered o.

ON Remote Display is aempting to pair with a local

transmier in proximity.

Power

Switch

IRemote Display Powered ON

O Remote Display Powered OFF

NOTE 1: Not Compatible with MOD-RAM-BWS. The module gets detected as a “Remote Alarm”

on standard output and high output controllers during the start-up sequence.

NOTE 2: The Wireless Range can vary based on the installation environment; objects, walls

and metal obstacles can interfere and degrade the wireless signal. Best suited for residential

applications.

Pairing an Additional Remote Display

To pair an additional Remote Display to a currently installed Transmier:

Step 1) Power ON the Additional Remote Display within 5m (15) proximity to the

transmier; by simply plugging the AC/DC wall adapter into the Power Port on

the Remote Display and sliding the switch to the ON position.

Step 2) The Remote Display performs self-pairing with the local transmier. Once paired

the Communication LED on the Remote Display will turn OFF and a Status LED

will turn ON.

Step 3) Once pairing is complete, relocate the Remote Display to any location2.

Blake Equipment

4 New Park Rd East

Windsor CT 06088

1-800-353-1100

Email: [email protected]

www.blakeequip.com

PN#910406

Version Date: 06-2021

This manual suits for next models

4

Table of contents