7

i) Always call a skilled electrician or your distributor when you have questions about the safety of the

electrical components.

j) Work on electrical equipment or operating materials may only be undertaken by a skilled electrician or by

trained persons under the guidance and supervision of a skilled electrician as well as in accordance with

the electrical engineering regulations.

k) Always use tools that are insulated against voltages.

l) Do not abuse the cord. Never use the cord for carrying, pulling or unplugging the machine. Keep cord

away from heat, oil, sharp edges or moving parts. Damaged or entangled cords increase the risk of

electric shock.

m) Be careful with water on the treated surface. Electrical cables must not come into contact with water.

n) During a long standstill of the machine, pull out the main plug and cover it with plastic foil.

o) If the machine is to be operated using power from a generator, the generator must be operated in

accordance with the current legal regulations and directives in force. (this applies to the protective earth

conductor in particular) in order to ensure that all safety devices are functioning and to eliminate possible

damage to electrical components.

3.3 Personal safety

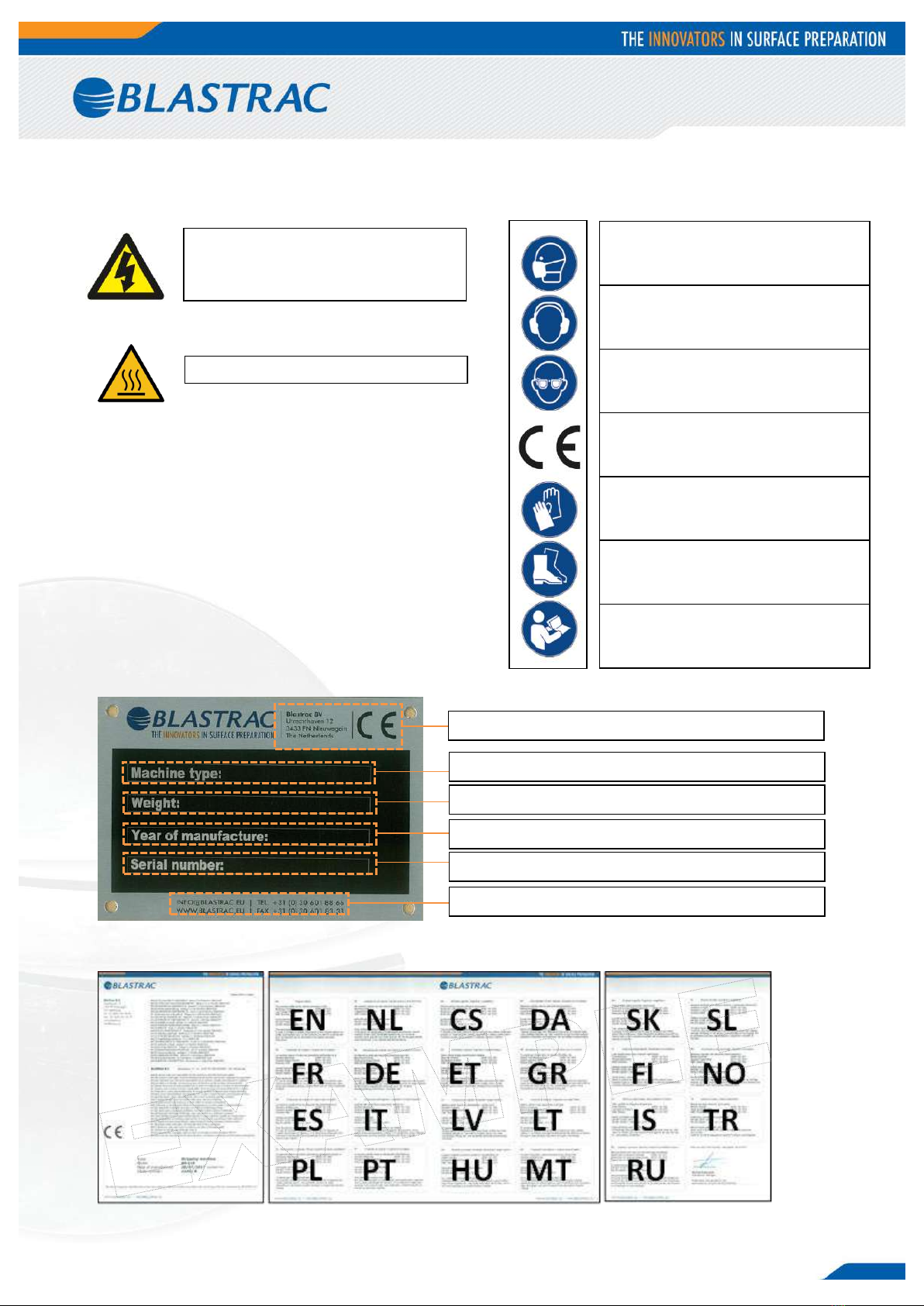

a) Always wear Personal Protective Equipment while working with the machine.

-Dust mask class FFP3 or higher

-Ear protection

-Safety glasses with lateral protection

-Protecting gloves

-Safety shoes

b) Dress properly. Do not wear loose clothing or jewellery. Keep your hair, clothing and gloves away from

moving parts.

c) Stay alert, watch what you are doing and use common sense when operating the machine.

d) Always seek professional medical attention immediately in case of injury.

e) All persons surrounding the machine should wear Personal Protective Equipment.

3.4 Machine safety general

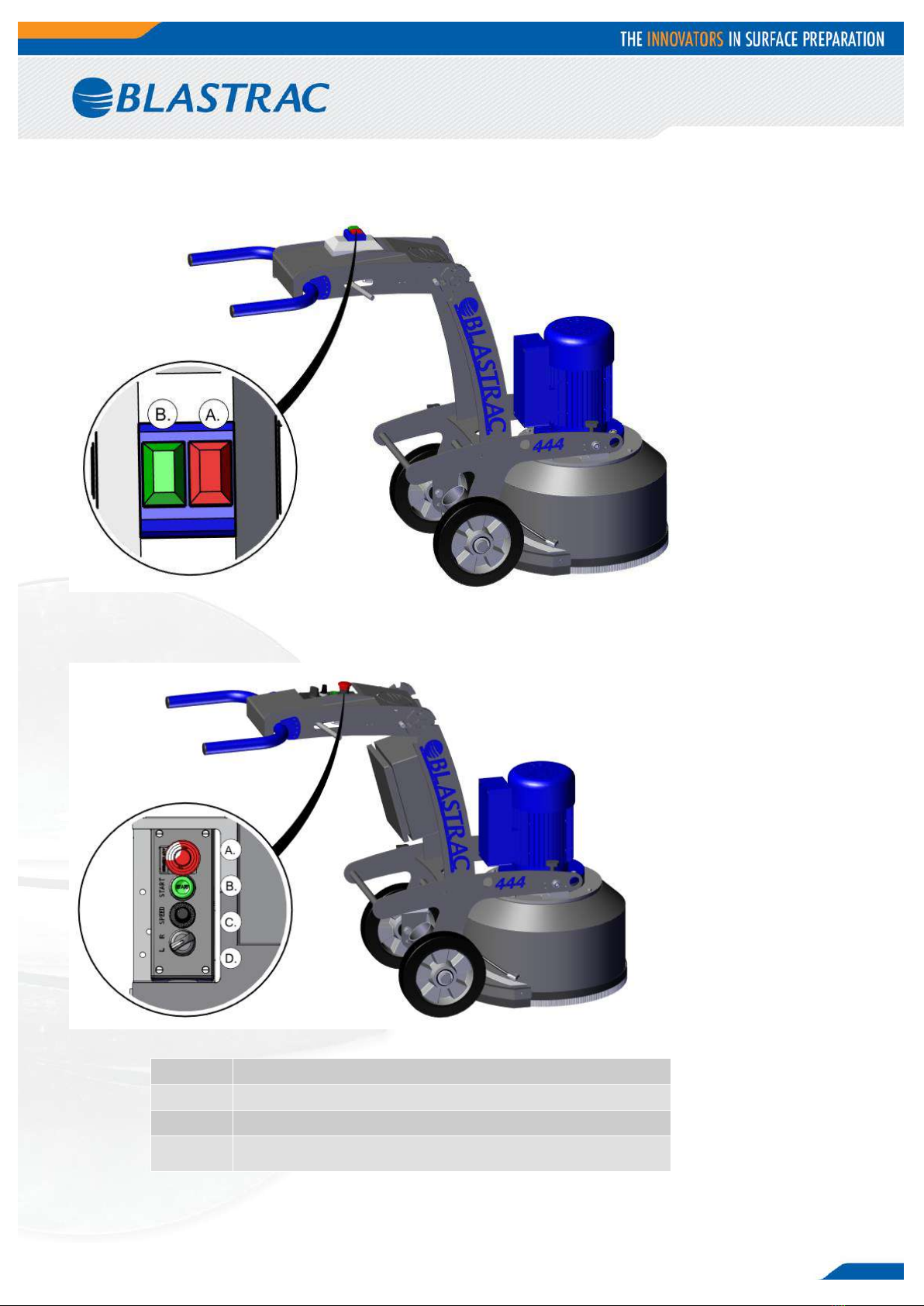

a) Safety functions and operating functions must work correct.

b) No loose bolts and nuts permitted.

c) Never operate machine without the guards and/or safety devices in place.

d) Never change anything on the safety devices on the machine!

e) The machine, specially the handle grips must be free of fats/oils and has to be dry.

f) If the length of the brushes is, due to wear, less than 5mm or they are extremely deformed, the brushes

have to be replaced. Check the Service Manual for the order numbers.

g) All repair work has to be done by qualified Blastrac personnel, this guarantees a safe and reliable

machine.

h) Always use original Blastrac spare parts, grinding discs, grinding wings and polishing pads. This

will ensure the best performance. Only original parts meet the factory specifications and quality.

Otherwise Blastrac BV cannot guarantee the safety of the machine.

The part numbers can be found in the Service Manual.

i) If safety-critical changes occur to the machine or its working method, the machine must be shut down

immediately! The cause of the fault must be established, and rectified.

j) In the event of operational malfunctions the machine must be shut down immediately and secured!

k) Do not use the unit when it is damaged.

l) Do not open or remove protective guards while driving gears are running.

m) Do not stand on the machine. Do not add extra weight on the machine.

n) Do not place anything on the grinding motor. Make sure that the motor has enough airflow to cool.

3.5 Maintenance safety

a) Pull out the main plug before starting inspections and repairing on the machine. Press the Emergency

shutdown button.

b) Wait for standstill of all drives before any inspections, adjustments and/or maintenance work is started.

c) Block the machine in stable position before doing any maintenance work.

d) Failures due to inadequate or incorrect maintenance may generate very high repair costs and long

standstill periods of the machine. Regular maintenance therefore is imperative.

e) Operational safety and service life of the machine depends, among other things, on proper maintenance.

f) Prevent premature wear by keeping the machine as dust free as possible. Clean the machine for this

reason regularly with a dust collector and non-aggressive materials, especially the upper drive. Never use

a high pressure water cleaner to clean the machine.