Operating Instructions Manual BMG-2500 MULTI GRINDER

6

JANUARY 2005 © International Surface Preparation Group, Inc.

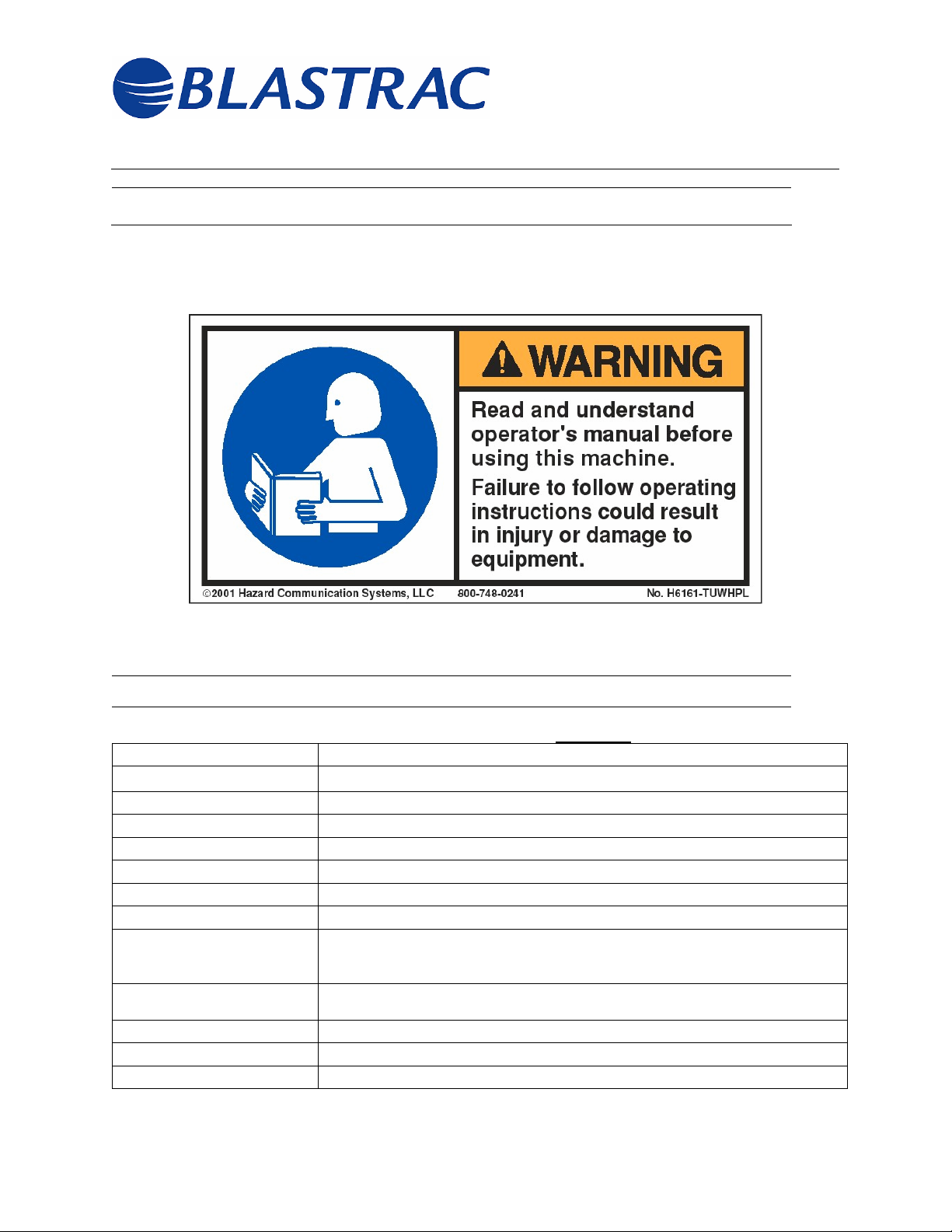

Connect power cord to power source and power cable extensions with approved plugs and with

machine power switch turned off. If cord is damaged, disconnect power and repair immediately.

4.18 DO NOT OVEREACH. Keep proper footing and balance at all times.

4.19 DO MAINTAIN MACHINE WITH CARE. Keep machine clean and use sharp cutters or diamond

plugs that are in good condition. Keep handles dry, clean and free from oil and grease. Follow

instructions for lubricating and changing accessories or tools.

4.20 DO DISCONNECT MACHINE FROM POWER SOURCE. When not in use, before servicing and

when changing cutters or plugs, always disconnect power cord from power source.

4.21 DO AVOID UNINTENTIONAL STARTING. Do not carry or transport machine with finger or hand

on the power switch while power cord is connected to power source.

4.22 DO NOT LEAVE MACHINE RUNNING UNATTENDED. TURN POWER OFF. Always have full

control of the machine until all machine components have come to a complete stop.

4.23 DO REMOVE ADJUSTING WRENCHES AND TOOLS. Check to see that wrenches and tools, or

any other loose objects are removed from machine before turning it on.

4.24 DO STAY ALERT. Watch what you are doing. Use common sense. Do not operate machine

when you are not fully alert.

4.25 DO NOT USE DRUGS, ALCOHOL, MEDICATION. Do not operate machine while under the

influence of drugs, alcohol, or any medication.

4.26 DO CHECK FOR DAMAGED PARTS. Before any use of the machine, check for damaged parts

that should be replaced. Check for alignment of moving parts, binding of moving parts, breakage

of parts, mounting of cutter or diamond tools and any other condition that may affect machine

operation. A guard, power switch or other part that is missing or damaged should be properly

repaired or replaced by an authorized service center. Do not operate machine if power switch

does not turn machine on and off.

4.27 DO CHECK VOLTAGE. Before connecting machine to a power source, be sure the voltage

supplied is the same as that specified on the nameplate of the machine or motor. A power source

with voltage greater than that specified for the machine can result in serious injury to the user and

damage to the machine. If in doubt, do not plug in machine. Using a power source with voltage

less than the nameplate rating is also harmful to the motor.

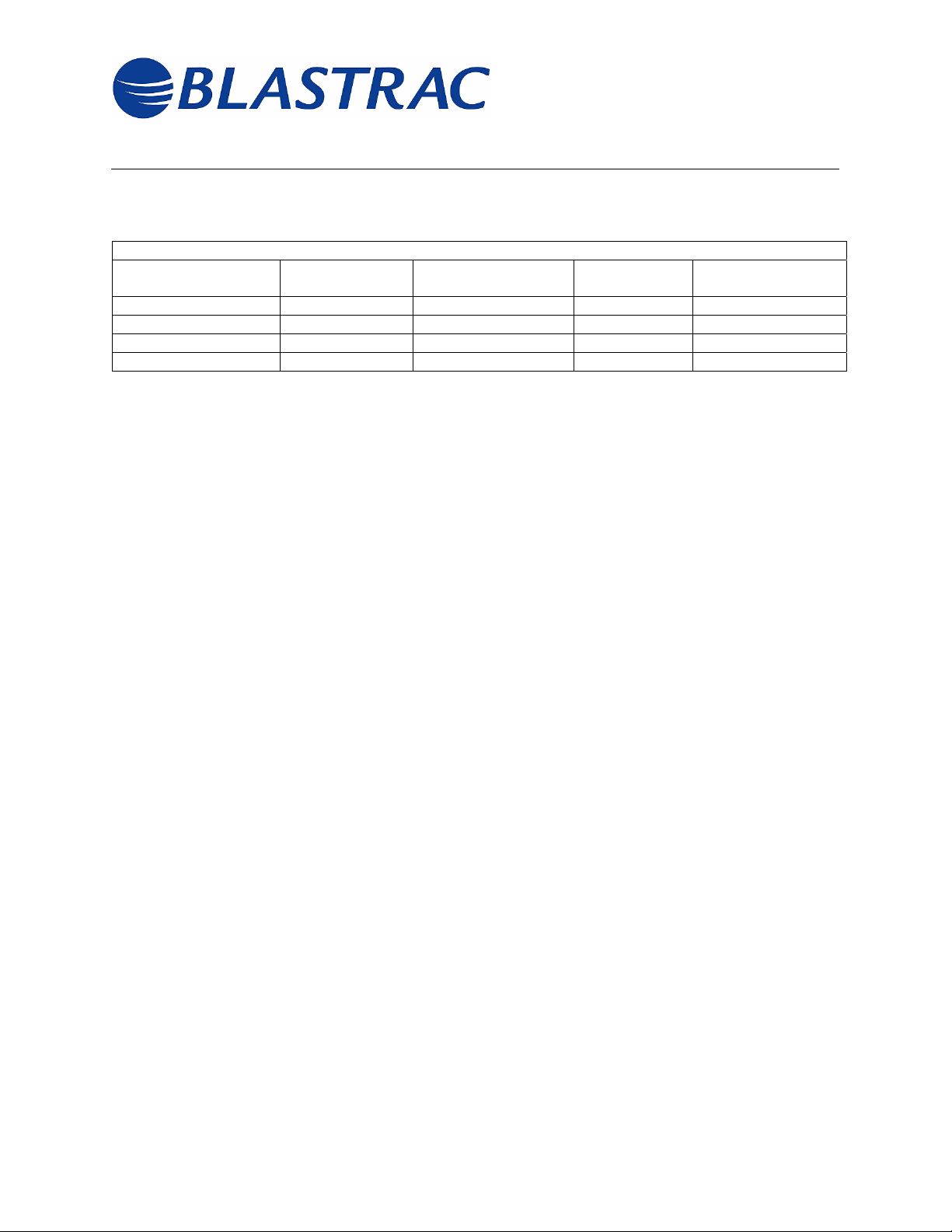

4.28 DO UNDERSTAND ELECTRICAL REQUIREMENTS FOR USING EXTENSION CORDS.

Length of extension cord should be limited to electric supply limitations and should never

exceed 100ft in length. Use only (3) three conductor cords on the single-phase machines. Make

sure that any extension cord used is in good condition. Disconnect power source and replace or

repair damaged cords and plugs before starting the machine. When using an extension cord, be

sure to use one heavy enough to carry the current the machine will draw. An undersized cord will

cause a drop in line voltage, resulting in loss of power and overheating. Table 1 shows the correct

size and type of conductor to use, depending on cord length and nameplate ampere rating. If in

doubt, use the next heavier gauge. As the gauge number decreases, the cord thickness

increases.