2

CONTENTS

Delivery set ............................................................................................................................................................................................................................................ 7

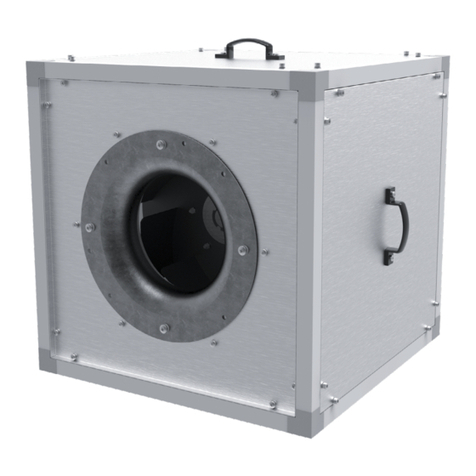

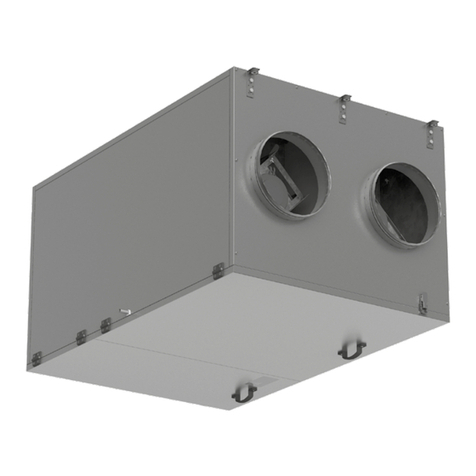

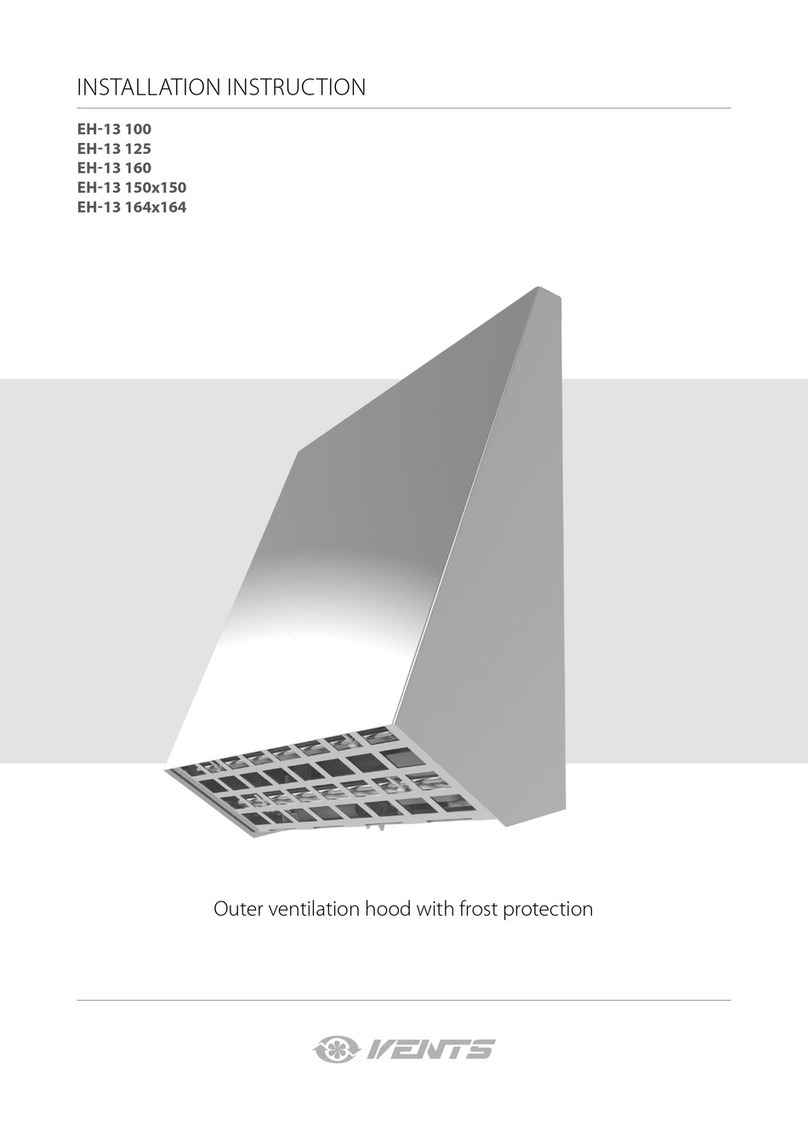

Brief description ................................................................................................................................................................................................................................ 7

Operation guidelines ...................................................................................................................................................................................................................... 8

Designation key................................................................................................................................................................................................................................... 8

Installation and set-up..................................................................................................................................................................................................................... 9

Connection to power mains ...................................................................................................................................................................................................... 13

Electronics operation algorithm ............................................................................................................................................................................................... 14

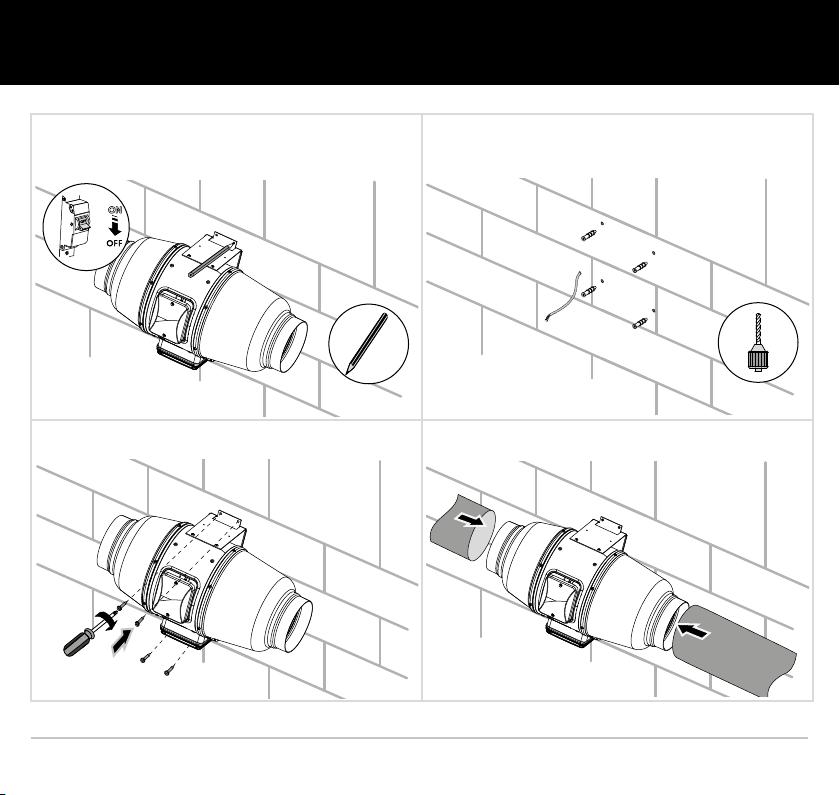

Technical maintenance ................................................................................................................................................................................................................. 15

Troubleshooting.................................................................................................................................................................................................................................. 16

Storage and transportation regulations............................................................................................................................................................................... 16

Manufacturer’s warranty................................................................................................................................................................................................................ 17