BLN nobel G5 User manual

G5 Weighing Instrument

Program version 2.0.1

Technical Manual

PM Legal for trade EN 45501, OIML 76-1

CONTENTS

1. Introduction........................................................ 1-1

General...............................................................1-1

Maintenance.......................................................1-2

Safety information............................................... 1-2

Technical data ....................................................1-3

Ordering information...........................................1-6

2. Installation.......................................................... 2-1

Mechanical installation ....................................... 2-1

Electrical installation...........................................2-2

Connection of cable shields................................ 2-2

Profibus-DP Fieldbus Adaptor............................2-7

DeviceNet Fieldbus Adaptor...............................2-9

ControlNet Fieldbus Adaptor..............................2-11

Front panel.......................................................... 2-12

3. Set-up.................................................................. 3-1

General...............................................................3-1

How to connect a PC to the instrument..............3-2

Menu system ......................................................3-2

Menu structure....................................................3-4

Parameters.........................................................3-6

4. Calibration.......................................................... 4-1

General...............................................................4-1

Common parameters..........................................4-2

Data sheet calibration.........................................4-4

Table calibration ................................................. 4-5

Deadweight calibration ....................................... 4-5

5. Operation............................................................ 5-1

General...............................................................5-1

Power-up sequence............................................ 5-1

Status LEDs........................................................5-1

Display at normal operation................................5-2

Security locks......................................................5-3

Taring.................................................................. 5-4

Gross/Net operation ...........................................5-5

Zero setting.........................................................5-5

Zero-tracking/Automatic zero setting..................5-6

Motion.................................................................5-6

Weight printing....................................................5-7

Long-term Data Store......................................... 5-10

Main Menu..........................................................5-12

Level supervision................................................5-14

Setpoint function.................................................5-15

Digital inputs and outputs ................................... 5-15

Analog output...................................................... 5-15

Filter function......................................................5-16

6. Communication..................................................6-1

General ...............................................................6-1

Serial interface....................................................6-1

Modbus RTU Slave.............................................6-1

Modbus TCP Slave.............................................6-2

FTP Server..........................................................6-3

Modbus protocol..................................................6-3

Fieldbus interface................................................6-24

Fieldbus Data Definitions....................................6-25

7. Remote Access ..................................................7-1

General ...............................................................7-1

Browser requirements.........................................7-1

Using the Remote Access...................................7-2

Security...............................................................7-2

Remote Access Login and Logout......................7-3

Remote / Local Access .......................................7-5

8. Maintenance........................................................8-1

General ...............................................................8-1

File Handling .......................................................8-1

Create Backup ....................................................8-1

Restore Backup...................................................8-1

Set Default ..........................................................8-1

Instrument Restart...............................................8-1

Program upgrade................................................8-2

9. Adaptation for legal weighing...........................9-1

General ...............................................................9-1

Non-Automatic Weighing Instrument..................9-1

Settings affecting legal functions ........................9-5

Parameters not protected by Legal Lock............9-11

Discontinuous Totalizing automatic Weighing ....9-11

Automatic Catchweighing Instrument .................9-12

Labels for legal weighing ....................................9-13

10. Troubleshooting...............................................10-1

General ...............................................................10-1

Error codes..........................................................10-1

Warnings.............................................................10-1

Technical Manual

PRECAUTIONS

READ this manual BEFORE operating or servicing this instrument. FOLLOW these

instructions carefully. SAVE this manual for future reference.

INTENDED USE

The G5 Instrument family are measuring and control devices intended for industrial

systems. Its basic function is to convert the signals from transducers to useful

information. Transducer excitation is included as well as parameter controlled signal

processing, indication of output levels, error supervision and operation of optional

external equipment. The instrument supports several types of communication

interfaces.

INSTRUMENT INSULATION AND GROUNDING

The cable connector for mains power supply should include protective grounding for

safety. The cable for 24VDC power supply (screw terminal connector) should include a

ground connected to terminal GND.

The input groups of the instrument are insulated from each other by functional

insulation. Terminals intended for connection of cable shields are connected to the

protective ground of the mains or GND terminal of 24VDC input but must not be

considered as protective grounding. Shield connection of load cell input is not

connected to mains protective ground or 24VDC GND terminal.

Change description

Revision 0: First release of this document.

!

WARNING

Only permit qualified personnel to install and service this instrument.

Exercise care when making checks, tests and adjustments that must be

made with power on. Failing to observe these precautions can result in

bodily harm.

DO NOT allow untrained personnel to operate, clean, inspect, maintain,

service, or tamper with this instrument.

G5 Weighing Instrument

1-1

1. Introduction

General

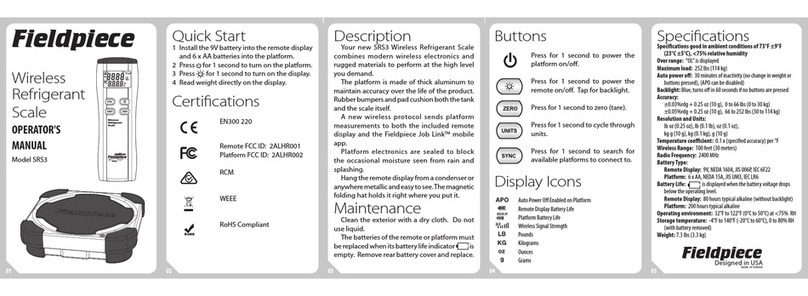

The G5 PM Indicator is a high performance single-channel weight indicator (PM model,

panel mounted) intended for industrial systems.

The basic function is to convert the signals from strain gauge transducers to useful

weight information. Transducer excitation is included as well as parameter controlled

signal processing, indication of output levels, error supervision and operation of

optional external equipment.

As long as the error supervision detects no error, a signal called ‘In process’ is then

present but if an error is detected, ‘In process’ will be off and a specific error

message will be displayed. ‘In process’ can be set to control any digital output. Note

that there are weighing channel specific and instrument specific error detection.

All functions in the G5 Instrument are controlled by set-up parameters. Setting of

parameter values can be done from the PM front panel. Maintenance functions can be

accessed locally or remotely.

It is possible to load new software into the instrument using a SD-Card.

The instrument has 4 level supervising functions and 4 set-point functions.

Power supply

The G5-PM (panel mount indicator) is available as 24 VDC model. All input and output

signals are galvanically isolated from the power supply.

Strain gauge input

Both excitation voltage and the output signal from the transducer are measured at the

transducer to avoid influence from voltage drop in the connection cable. Excitation to the

transducer, from the G5 Instrument is provided over separate wires.

A shielded 6-wire cable must be used to connect a distant transducer to the instrument.

The analog signals from the transducer are converted to digital form and filtered to give

an internal transducer signal with high resolution.

The transducer excitation and signal values are combined to form an internal

transducer signal, representing the load on the transducer. Influenced by calibration

data, this signal is converted to a digital measurement value, the weight value, which

can be presented at the local display window and at external equipment.

Communication

The instrument utilizes the serial interface, Ethernet and a fieldbus interface for

communication with control system or computer. The serial interface consists of a RS-

485/RS-422 connection that can be used with 2- or 4-wire connection.

Weight values, level status, error status etc. can be collected and commands given

through the communication interfaces. G5 Instruments can be controlled from a master

computer or PLC using the serial interface, Ethernet interface, field bus interface or

digital I/O.

Modbus RTU protocol is used for the serial interfaces, Modbus TCP and EtherNet/IP

for the Ethernet connection. Optional fieldbus interface for Profibus, DeviceNet or

ControlNet can be used.

Technical Manual

1-2

The serial port can also be used to connect a printer for printing of weight or for

showing weight on an external display unit.

Maintenance

The G5 instrument needs no maintenance, performed by the end-user. Any service

or repair work must be performed by qualified personnel.

Contact your supplier.

Cleaning

Before cleaning the G5, disconnect the power connection to the instrument. Use a soft

cloth to clean the exterior of the instrument. For cleaning the instrument front panel, a

soft, damp, cloth may be used.

Safety information

Utilization.

The instrument may only be utilized for the measurement and control functions,

described in this Technical Manual. It is especially important to adhere to the load limits

of the input/output connectors. We accept no responsibility for any damage arising from

improper operation.

Any changes to the instrument, which causes any function changes, may only be

carried out by the manufacturer or after discussion with and permission by the

manufacturer.

If G5 is used in a manner not specified, the protection provided may be impaired.

Meaning of symbols used in this manual

Direct current.

Alternating current.

!

Caution, risk of danger. Documentation needs to be consulted.

G5 Weighing Instrument

1-3

Technical data

Enclosure

types PM - Panel mount

Enclosure

design Plastic, PC

Dimensions WxHxD 226x126x100 mm

(8.9”x5.0”x3.9”)

Depth behind front 100 mm (3.9”)

Front panel depth 14 mm (0.55”)

Depth not including connectors, screw terminals or cables

Panel cut out WxH 186 ±1 x 91 ±1 mm

Display Color TFT LCD screen with backlighting, 4.3” 480x272 pixels

Keyboard 31 membrane keys

Temperature

range Legal for trade: -10 to +40 °C

Rated performance: -10 to +55 °C

Storage: -25 to +85 °C

Relative

humidity Max. 85% up to 40°C, decreasing linear to 50% at 55°C.

Non-condensing

Rated

pollution Pollution degree 2

Protection IP65 (panel), indoor use

Altitude Up to 2000 m

EMC, RF CE (Industrial)

Serial interface

RS485 For process data and control or printout data to a connected printer.

Isolated by operational insulation

Protocol Modbus RTU, ASCII serial printer

Baud rate Up to 115 kbaud

Cable ratings

Cable rated min 80°C when ambient temperature > 45°C

Cable rated min 70°C when ambient temp. < 45°C and > 35°C

Fieldbus For process data and control (optional)

Technical Manual

1-4

Types Profibus, DeviceNet or ControlNet

USB Version 2.0

USB Memory USB type for PC

For backup and restore of set-up parameters. Operational insulation,

max 500mA output.

SD-Card Micro SD, Micro SDHC types.

Ethernet 10/100BASE-T. For process data, control, file transfer and remote

access.

Protocols Modbus TCP, FTP, http.

RJ45 Indications Orange LED: 100 Mbit/s. Yellow LED: Receiving/Transmitting.

Power supply DC

PM DC model 24 V ±15% including fluctuations, 15W

Impulse withstand (overvoltage) category I of IEC 60364-4-443.

Cable ratings

Cable rated min 80°C when ambient temperature > 45°C.

Cable rated min 70°C when ambient temp. < 45°C and > 35°C.

Load cell input Operational insulation

Excitation voltage: Nominal 10 V. Below is actual excitation shown with 350 ohm load

cells.

1 LC => 9.72V, 2 LC => 9.46V, 3 LC => 9.21V, 4 LC => 8.97V,

5 LC => 8.75V, 6 LC => 8.54V, 7 LC => 8.33V, 8 LC => 8.14V,

Sense voltage Min 1.2V, max 10V. Sense common mode must be within +-0.5V

relative terminal 26 in the load cell input connector.

Max load Maximum 8 (350 ohm)

A/D conversion: 2.4 kHz, 16 000000 units (24 bits)

Input range +/- 3 mV/V

Update rate: 300 weight updates per second

Sensitivity: 0.1 µV

Zero drift: <10 nV/V/K

Span drift: <2 ppm/K

Digital I/O

4 inputs 24 V ±15%, 5 mA from external power supply, isolated by

operational insulation and with common return

4 outputs 24 V ±15%, max 100 mA from external power supply, isolated by

operational insulation and with common return

Cable ratings Cable rated min 80°C when ambient temperature > 45°C

Cable rated min 70°C when ambient temp. < 45°C and > 35°C

Analog output

Resolution 65000 units, 16 bits

Voltage output 0 – 10 V, -10 – 10 V, > 1 kohm load

G5 Weighing Instrument

1-5

Current output 4 – 20 mA, 0 – 20 mA, -12 – 20 mA, -20 – 20 mA,

< 500 ohm load. Current source, i.e. no external power supply

needed.

Update rate 300 Hz

Filter Weight filter + extra smoothing filter (on/off via set-up)

Fieldbus ProfibusDP, DeviceNet and ControlNet.

Fieldbus

data 16 bytes from fieldbus to instrument.

80 bytes from instrument to fieldbus.

See chapter ‘Communication’ section ‘Fieldbus communication interface’ for

details on fieldbus data mapping.

Settings All fieldbus settings are done with setup parameters in the instrument. No

settings are done on the module itself.

Mounting The fieldbus adaptor is mounted in the fieldbus slot with LED’s and connector

accessible.

Remove the plastic cover from the fieldbus slot. Insert the adaptor very

carefully and make absolutely sure that the adaptor slides correctly into the

guides in the connector on the PCB. Tighten the two fastening screws at the

adaptor front and check that the two securing hooks locks into the PCB.

Module

type Profibus-DP DeviceNet ControlNet

Connector Profibus 9-pin, female

D-sub (DB9F) 5 pin male connector. BNC.

Baud rate 9.6 kbps – 12 Mbps or

Auto set by parameter 125, 250, 500 kbps or

Auto set by parameter. Fixed 5 Mbit/s.

Address 1 – 125,

set by parameter 0 – 63,

set by parameter 1 – 99, set by parameter

Bus

Supply

Voltage

According to DeviceNet

(Node) specification:

nominal 24 VDC,

range 11 – 25 VDC.

Technical Manual

1-6

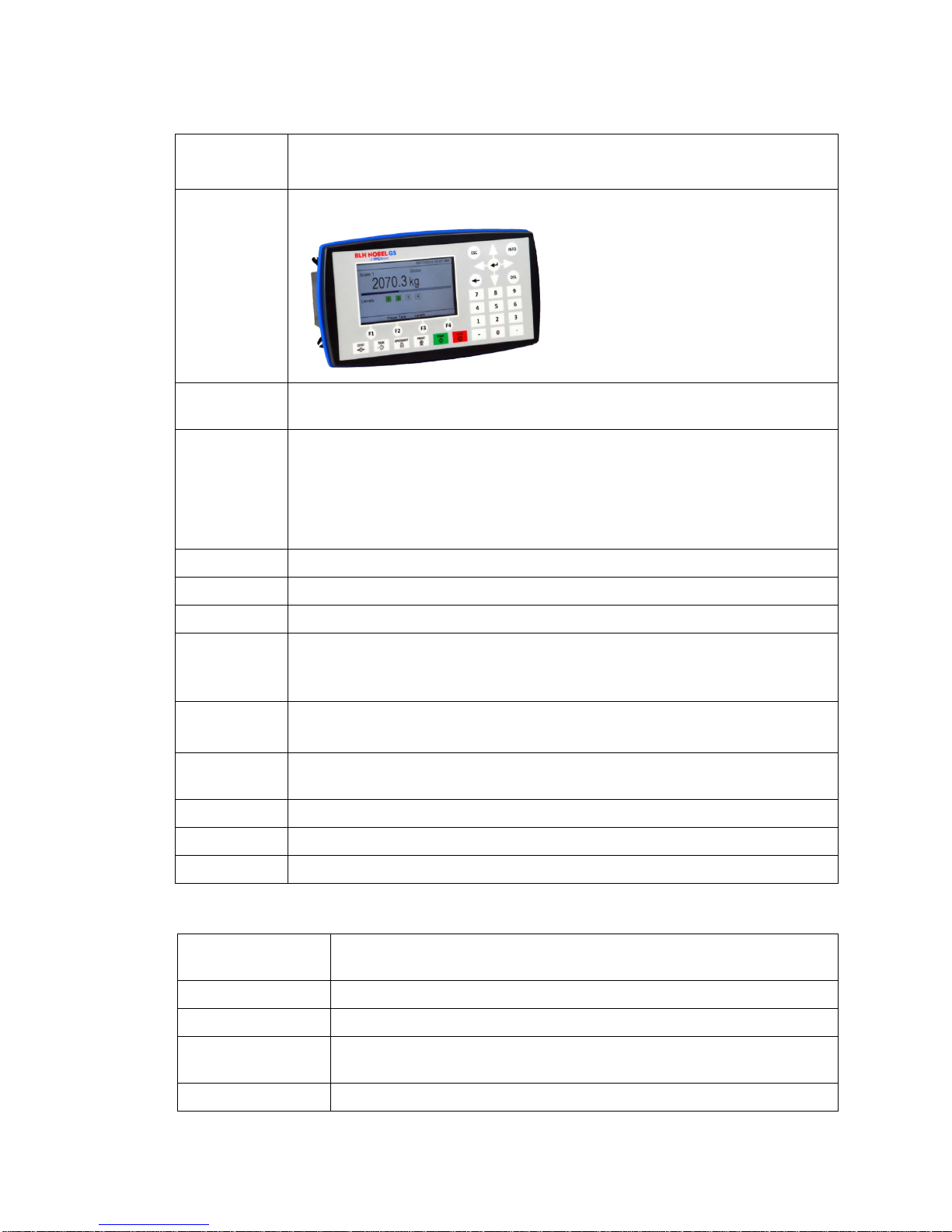

Ordering information

PM model, single channel weighing, 24VDC supply

Denomination: G5-PM-S-DC-S

P/N: 110860 (ordering number).

If an (optional) fieldbus module is needed it must be ordered together with the

instrument. Ordering numbers are shown below. If multiple instruments and/or fieldbus

modules are purchased in the same order it must be clearly specified which module

should be mounted in which instrument.

Optional ProfibusDP fieldbus module

P/N: 110559 (ordering number).

Optional DeviceNet fieldbus module

P/N: 110560 (ordering number).

Optional ControlNet fieldbus module

P/N: 110838 (ordering number).

Example showing product information

and installed option(s).

Label shows:

G5-PM-S-DC-S=> G5, Panel Mount, Single load cell, DC power, Special program.

P/N 110860 => Part Number 110860 = Legal for trade

S/N 16-0199 => Serial Number, first two figures is year

HW v2 => Hardware version 2

Serial Number, Hardware version and Software version can also be found by pushing

INFO-key/Main Menu/System Information.

G5 Weighing Instrument

2-1

2. Installation

Mechanical installation

See chapter Introduction – Technical data for references to PM mechanical

measures: outer extents and body extents.

The safety of any system incorporating the equipment is the responsibility of the

integrator of the system.

Allow at least 20 mm free space around the instrument for ventilation.

PM type instrument:

In an enclosed plastic bag there are four M5x30 hexagon socket head screws and four

fastening brackets.

1. Insert the instrument in the panel cutout.

91mm +-1mm

3.58" +-0.04"

186mm +-1mm

7.32" +-0.04"

4x R max 5 mm

4x R max 0.2"

2. Place a bracket in the corner recession of the rear of the instrument and use the

M5 screw to secure it without tightening it.

3. Place the remaining three brackets and secure each with M5 screws. Tighten the

screws until the brackets start to press against the inside of the panel.

4. Make sure the tip of the brackets is resting against the panel on which the

instrument is mounted and not on the instrument plastic front. This might happen if

the cutout is large.

5. Check that the instrument is positioned

so that the blue front sealing is not

visible through the cutout which might

compromise the sealing properties.

6. When the instrument is properly

positioned tighten the screws 2 – 3

turns. Do not overtighten. Note that the

brackets are flexible.

7. Provide support for the cables to avoid

that strain is applied to the connectors.

Mounting bracket on

the panel mount model

Technical Manual

2-2

Electrical installation

The field wiring of the instrument shall be suitable to the environment

(e.g. chemically) in the end-user application.

Mains cables shall be separated and routed away from SELV or

SELV-E field wiring.

Field wiring installation shall comply with any national regulations, hereunder National

Electrical Code (NEC) for US and/or Canadian Electrical Code for Canada.

•A switch or circuit-breaker shall be included in the building installation.

•The switch shall be in close proximity to the equipment and

within easy reach of the operator

•The switch shall be marked as the disconnecting device for the equipment.

•The equipment switch or circuit-breaker employed as disconnecting device shall

comply with relevant requirements of IEC 60947-1 and IEC 60947-3.

The power supply for the instruments is an external DC source for

G5-PM-S-DC-W

For electrical installation with DC supply, see section DC Supply.

The voltage levels on connectors shall not exceed hazardous voltage levels of 30

Vrms, 42.4 Vpeak or 60 Vdc under normal conditions. In wet locations

these voltage levels shall not exceed 16 Vrms, 22.6 Vpeak or 35 Vdc.

This applies to all accessible parts.

Connection of cable shields

Shielded cables should be used to avoid EMI on the measurement signals or from

entering the instrument. Shields should be grounded in one point of the cable. Avoid

grounding via long and thin leads which will impair the shielding ability of the cable. The

preferable point of grounding is when the cable enters the metal cabinet housing the

instrument. There are a few ways of grounding the cable shield:

1. The absolutely best way of grounding the shield is by using EMI cable glands that

will provide a seamless protection against EMI.

2. Connect the shield to a ground strip inside the cabinet close to the entry point.

3. Connect the shield to a ground terminal inside the cabinet. Always keep the shield

all the way to the instrument.

The following applies to HW version 2 or later. See the System Information menu to

find out the actual HW version of the instrument. The shield of the load cell cable can

also be connected at terminal 26 to achieve best possible noise immunity of the LC

WARNING

Make sure that that the power to the instrument is turned off before

any connections are connected to or disconnected from the

instrument.

Remove connector from instrument when tightening or loosening

screw terminal screws.

!

!

!

G5 Weighing Instrument

2-3

input. Note that terminal 26 is not the grounding point of the load cell cable but it will

extend the shield into the ground plane of the input circuit. Terminal 26 is not

connected to the ground of the instrument.

Communication

External computing devices connected to the communication interfaces of the

instrument have to comply with the standard, UL 60950.

RS422/RS485

The serial communication is made for 2-wire or 4-wire with common 0 V. This is a

SELV/SELV-E circuit.

It can be used for serial communication to computer/PLC (Modbus RTU) or a printer.

Connections are made to terminals 1 – 5. Shielded cable must be used. Shield can be

connected to terminal 6 unless grounded in other point.

The communication lines must be terminated in both ends. Termination switches are

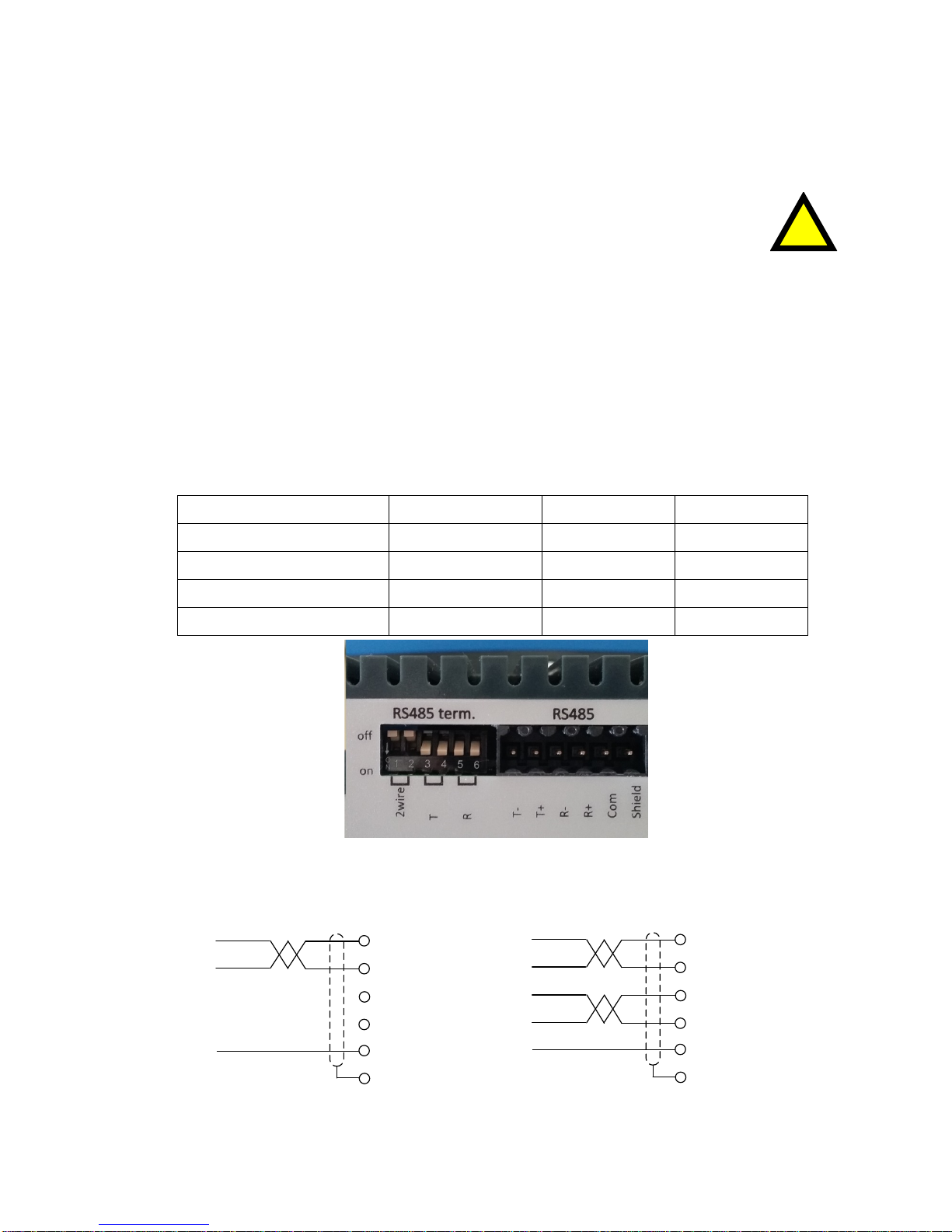

set as shown in the table below:

DIP switch settings

2wire DIP-switches T DIP-switches R DIP-switches

2-wire with termination ON (x2) ON (x2) OFF (x2)

4-wire with termination OFF (x2) ON (x2) ON (x2)

2-wire without termination ON (x2) OFF (x2) OFF (x2)

4-wire without termination OFF (x2) OFF (x2) OFF (x2)

Example of DIP-switch settings.

4-wire with termination

!

1. Tx-

2. Tx+

3. Rx-

4. Rx+

5. Com

6. Shield

1. Tx-

2. Tx+

3. Rx-

4. Rx+

5. Com

6. Shield

RS485, 2-wire RS422, 4-wire

Technical Manual

2-4

Field Bus

Slot for optional Fieldbus interface. Profibus DP-V1, DeviceNet and ControlNet are

available. See section Profibus-DP Fieldbus Adaptor or DeviceNet Fieldbus Adaptor or

ControlNet Fieldbus Adaptor later in this chapter for details.

USB

The USB connector is intended for USB memory only. This port has operational

insulation (from HW version 2). It should be considered as a SELV/SELV-E circuit.

USB Hub is not supported.

Ethernet

This is a SELV circuit. Use a category 5 cable to connect to a PC (point to point

connection) or to connect to other equipment through a switch, hub or router. Use an

electrically isolating network device if the instrument is being connected to the public

network.

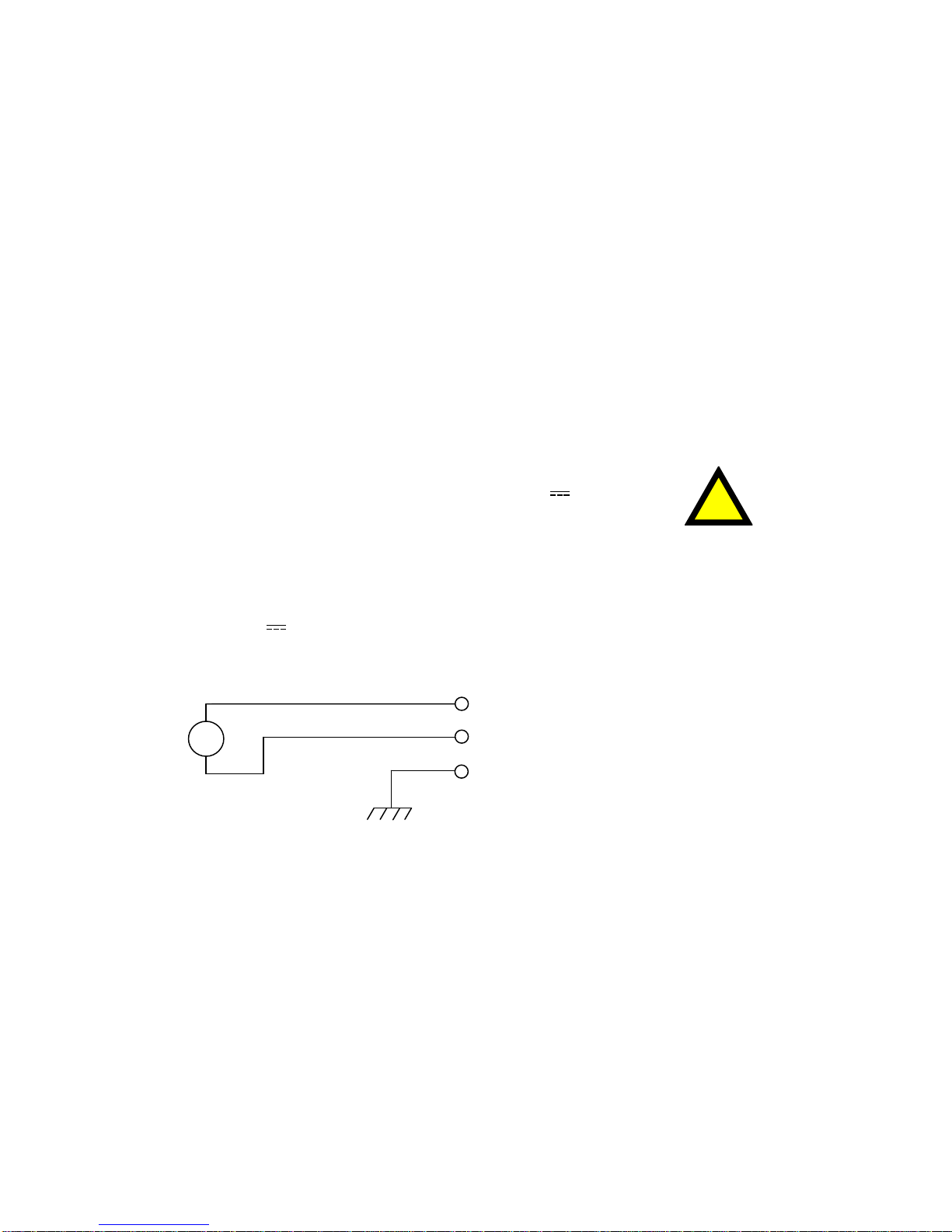

DC supply

The output of the external DC source must be rated 24 V , ±15%

including fluctuations, min. 15 W. The DC source must provide Double

Insulation between Mains parts and 24 V SELV or SELV-E Circuit, and a

limited-energy circuit (maximum available current of 8 A). For the US

market this energy limit can be achieved with an ANSI/UL248-14 fuse rated 5A. For

other markets an IEC 60127 T type fuse rated 4A may also be used.

24 VDC power is connected to terminals 19, 20 and 21. The G5 instrument should be

powered by 24 V , connected according to the diagram below. To achieve functional

grounding, terminal 21 should be connected to ground.

See Technical data for input voltage ratings.

19. +24 VDC

20. 0V

+

-21. PE

+24 VDC

power supply

!

G5 Weighing Instrument

2-5

Load cell connection

Terminals 22 – 29, transducer connection and cabling should be handled with great

care to achieve good measurement of data. Transducer integrated cables may not be

shortened.

4-wire connection can be used if the transducer integrated cable is long enough to

be connected directly to a transducer input. With a 4-wire connection Sense+ must

be connected to Exc+ and Sense- must be connected to Exc-.

6-wire connection should be used if the integrated cable must be lengthened

or if several transducers should be connected to one transducer input.

The transducer input is insulated by operational insulation and the shield should be

connected to the most convenient ground/earth point. This can be the junction box

when using multiple transducers, at the cable entry to the enclosure where the G5 is

mounted or at the barrier ground when using Ex zener barriers.

Shield can be connected to terminal 26 if the instrument is of HW version 2 or later.

On the transducer cable next to the terminals 22-29 shall two STAR-TEC Snap

Ferrite with safety key technology, part number 74271112 from Wurth or equal be

placed.

In the junction box SL-4 from BLH Nobel all necessary terminals and

interconnections are provided.

29. TEDS+ (NC)

22. Exc+

23. Sense+

24. Exc-

25. Sense-

26. TEDS- (NC)

27. Sign+

28. Sign-

E+

E-

S+S-

Junction box

Connection of transducer(s)

NOTE! Transducer cables must be routed at least 200 mm away from

230/400 V, 50/60 Hz power cables. By cables with other frequencies or

high power, an even wider distance is preferable.

Technical Manual

2-6

Solid state relay outputs

Digital outputs use terminals 7 to 10 with terminal 11 (OCom) as the common

connection. Four digital outputs are provided with contact rating given in Technical

data. External 24 VDC power supply must be used. Note that either the positive or the

negative pole of the voltage source (24 V ) can be connected to OCom (11).

Shielded cable/cables should be used and the shield can be connected to terminal 12 if

it’s not possible to ground it in another point.

7. Out 1

8. Out 2

9. Out 3

10. Out 4

11. OCom

+

-

12. Shield

+

-

Alternative

connection

Digital inputs

Digital inputs use terminals 13 to 16 with terminal 17 (ICom) as the common

connection. Four digital inputs are provided, with functions that can be set in the G5

set-up. External 24 VDC power supply must be used. Note that either the positive or

the negative pole of the voltage source (24 V ) can be connected to ICom (17).

Shielded cable/cables should be used and the shield can be connected to terminal 18 if

it’s not possible to ground it in another point.

13. In 1

14. In 2

15. In 3

16. In 4

17. ICom

+

-

18. Shield

+

-

Alternative

connection

Analog input and analog output

Terminals 38 (Vi) and 39 (Comi) are used for the +-10V auxiliary analog

input of the instrument. The analog output is connected to terminals 41

(Como and output signal to terminal 42 (Vo1/Io1). The analog output is either

voltage or current loop. Como and Comi are internally connected.

Shielded cable/cables should be used and the shield can be connected to the shield

terminal 40 if it’s not possible to ground it in another point.

38. Comi

39. Vi

40. Shield

41. Como

42. Vo1/Io1

+

-

V/A

Analog input: +-10V

Analog output:

G5 Weighing Instrument

2-7

Profibus-DP Fieldbus Adaptor

Profibus module front view

(1) Operation mode LED.

(2) Status LED.

(3) Profibus connector.

Operation mode LED

State Indication

Off Not online / No power

Green On-line, data exchange

Flashing Green On-line, clear

Flashing Red (1 flash) Parameterization error

Flashing Red (2 flashes) Profibus configuration error

Status LED

State Indication

Off No power or not initialised

Green Initialised

Flashing Green Initialised, diagnostic event(s) present

Red Exception error

OP ST

PROFIBUS DP-V1

(1) (2)

(3)

Technical Manual

2-8

Profibus connector (DB9F)

Pin Signal Description

1 - -

2 - -

3 B line Positive RxD/TxD, RS485 level

4 RTS Request to send

5 GND Bus Ground (isolated)

6 + 5V Bus Output +5V termination power (isolated)

7 - -

8 A line Negative RxD/TxD, RS485 level

9 - -

Housing Cable shield Functional ground internally connected to the

module protective ground via cable shield

filters according to the Profibus standard.

For connection of the adaptor to the Profibus master, use a Profibus standard cable

and connector according to the diagram below.

8. A-Line

3. B-Line

Shield

For reliable fieldbus function, line termination must be arranged in both ends of the

transmission line. For a G5 instrument, at the end of the cable, a connector with line

termination should be used. For all other G5 Instruments, connection without line

termination should be used.

For configuration of the adaptor, a GSD file (VISH0F83.GSD) is available and should

be installed in the master.

Select the 8 words output module + 2 x 16 words input modules + one 8 words input

module. This will give 16 bytes of output data and 80 bytes of input data. The PLC set-

up should match this exactly including the order of the input modules.

G5 Weighing Instrument

2-9

DeviceNet Fieldbus Adaptor

DeviceNet module front view

(1) Network Status LED.

(2) Module Status LED.

(3) DeviceNet connector.

Network Status LED

State Indication

Off Not online / No power

Green On-line, one or more connections are established

Flashing Green (1 Hz) On-line, no connections established

Red Critical link failure

Flashing Red (1 Hz) One or more connections time out

Alternating Red/Green Self-test

Module Status LED

State Indication

Off No power

Green Operating in normal condition

Flashing Green (1 Hz) Missing or incomplete configuration

Red Unrecoverable fault(s)

Flashing Red (1 Hz) Recoverable fault(s)

Alternating Red/Green Self-test

NS MS

DeviceNet

(1) (2)

(3)

(Pin 1)

Technical Manual

2-10

DeviceNet connector

Pin Signal Description

1 V- Negative bus supply voltage

2 CAN L CAN low bus line

3 Shield Cable shield, functional ground.

4 CAN H CAN high bus line

5 V+ Positive bus supply voltage

For connection of the adaptor to the DeviceNet master, use a standard cable for

DeviceNet or similar shielded cable with twisted pairs and a connector according to the

diagram below. The bus supply voltage shall be 11 – 25 VDC.

2. CAN L

4. CAN H

1. V-

5. V+

3. Shield

For reliable fieldbus function, line termination must be arranged in both ends of the

transmission line. For a G5 Instrument placed at the end of the line, terminate line by

placing a 121-ohm resistor between CAN L (pin 2) and CAN H (pin 4).

For configuration of the adaptor an EDS file is supplied with the instrument that should

be installed in the master. Note that the EDS file is a generic type supplied by the

module manufacturer. The file doesn’t contain any reference to the G5 Instrument or to

BLH Nobel.

Table of contents