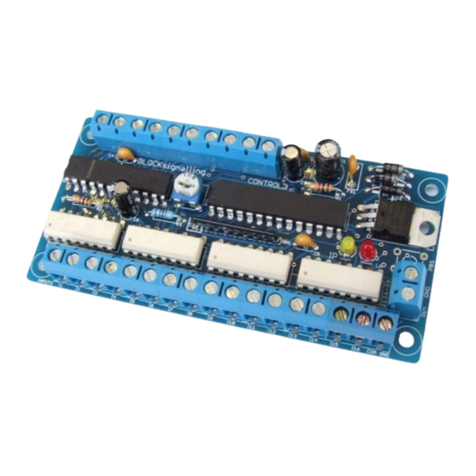

BLOCKsignalling SAS2-BR User manual

DC SHUTTLE WITH STATION STOP

AND ACCELERATION SAS2-BR

The BLOCKsignalling SAS2-BR is a self-contained DC throttle, designed to operate

a single loco along a section of track. Upon reaching the end of the track, the loco

will decelerate to a standstill, wait for a period, then accelerate in reverse. It will run

to the other end of the track and then decelerate to a standstill, wait again, and then

accelerate off forwards.

Runs a DC equipped loco back and forth along a single section of track

Optional station stop function brings the train to rest at a station

Realistic acceleration and deceleration

Quick and easy to connect and set-up

For a long while simple shuttles have been available to model rail enthusiasts to

operate DC locos back and forth along a single section of track. We had wanted to

add further realism by controlling acceleration and deceleration, allowing the option

Page 2 of 19

BLOCKsignalling www.blocksignalling.co.uk

of station stops and so on.

To fill this gap, we have designed the SAS2-BR. This module is a self-contained DC

throttle, designed to operate a single loco along a section of track. Upon reaching

the end of the track, the loco will decelerate to a standstill, wait for a period, then

accelerate in reverse. It will run to the other end of the track and then decelerate to

a standstill, wait again, and then accelerate off forwards.

This action would be appropriate to single line with one train and two terminus

stations.

There is also the option to add one or more intermediate stations. In this case, as

the train enters the vicinity of the station, it automatically slows to a standstill, waits a

set time at the station and then sets off again. There can be any number of such

stations on the single line.

Many programming options are catered for; to control the waiting times, speed, and

randomness of stopping times, etc.

Page 3 of 19

BLOCKsignalling www.blocksignalling.co.uk

Power Supply

The controller is designed for use with a 12V DC plug-top type power supply with a

2.1mm jack connector (centre positive).

Alternatively, the power supply can be connected to the IN1 and IN2 terminals.

If a DC power supply is connected with incorrect polarity no damage will occur, but

the module will not operate.

The module will not be damaged by reverse polarity, being connected to AC rather

than DC, or input voltage up to 35V DC or 25V AC.

Normal traction current is below 0.2A for N gauge and 0.3A for OO and HO gauges

for the speeds shuttle trains are normally operated at.

The module can provide up to 0.5A of traction current, and a power supply with a

minimum output of 0.5A is recommended for Z and N gauges, 1A for OO and HO.

The output is protected against short-circuits.

Do not use the auxiliary terminals on the back of a train controller as the module

may operate unpredictably and could be damaged. These outputs are often

unsuitable as they are designated as a fairly basic power outputs for accessories

such as points motors and may not be smooth or stable.

BLOCK

signalling

Alternative Power Supply Arrangements

(use one only)

REV1

S

REV2

COM

OUT2

OUT1

IN2

IN1

POWER

JACK

12V DC

POWER PACK

+12V

GND

Centre Pin Positive

Page 4 of 19

BLOCKsignalling www.blocksignalling.co.uk

Speed Setting & Waiting Time Adjustment

The locomotive top speed is set by the SPEED adjustment on the module.

Generally the midway position shown in the image below will be a suitable starting

point.

The waiting times are programmed separately for the two ends and the station stop.

These waiting times can only be adjusted by the TIME adjustment on the module if

these individual settings for the waiting time are programmed to a value of 1 (see

later).

Emergency Stop

If you want to stop the train, either in an emergency, or perhaps to re-rail or change a

loco, press the button on the PCB. Track power will be removed and the train will

immediately come to a standstill.

The led on the PCB will flash 0.5seconds on/ 0.5seconds off.

To re-power the train, press and hold the PCB button for 1 second and then release.

BLOCK

signalling

TIME ADJUSTMENT

10mins

MIN

90sec

30sec 6mins

Fine Control Coarse Control

SPEED ADJUSTMENT

100%

MIN

50%

20% 80%

Page 5 of 19

BLOCKsignalling www.blocksignalling.co.uk

Programming Procedure

The module is programmable, and many of the settings can be adjusted to suit.

Programming is performed holding down the Push Button on the module when

switching on the power.

Full details of the programming procedure and options available are given later.

BLOCK

signalling

PUSH-BUTTON

RED LED

POWER

SUPPLY

+

_

Page 6 of 19

BLOCKsignalling www.blocksignalling.co.uk

Connecting the Unit

The track is divided up into a minimum of three sections, the main section and two

ends.

The ends are formed by isolating the right-hand rail by using an insulated rail joiner,

or by cutting the rail with a dremel or hacksaw. Fill any remaining gaps caused by

cutting with epoxy glue to ensure smooth running. This is not necessary at the

testing stage, but will ensure the final running is smooth.

The right-hand rail is relative to the forwards direction of the locomotive.

The length of the end sections of the track should be sized to allow for the loco to

enter, be detected and to stop. Carriages with lights which draw power from the rails

will be detected if they draw more than 4mA.

BLOCK

signalling

Terminal Arrangement

REV1

S

REV2

COM

OUT2

OUT1

IN2

IN1

POWER

JACK

Page 7 of 19

BLOCKsignalling www.blocksignalling.co.uk

If the station stop function is being used, then form isolated sections for each station.

These will need to extend either side of the platform, to allow time for the train to

decelerate.

BLOCK

signalling

STOP –WAIT

REVERSE SPEED1 STOP –WAIT

REVERSE

BLOCKsignalling Shuttle

TRACK BREAK TRACK BREAK

POWER

SUPPLY

+

_

CARE

DO NOT CONNECT TO

TERMINALS ON

CONTROLLER (SEE TEXT)

BLOCK

signalling

STATION

STOP –WAIT

REVERSE CRUISE STATION STOP CRUISE STOP –WAIT

REVERSE

BLOCKsignalling Shuttle

TRACK BREAK TRACK BREAK TRACK BREAK TRACK BREAK

POWER

SUPPLY

_+

CARE

DO NOT CONNECT TO

TERMINALS ON

CONTROLLER (SEE TEXT)

Page 8 of 19

BLOCKsignalling www.blocksignalling.co.uk

Program Flow Diagram

As mentioned above, there are a number of memory locations which can

programmed with different values to change the operation of the module.

Before starting, it is a good idea to write down the memory locations and the values

you are going to set them to.

Programming is performed by holding down the Push Button when switching on the

power. The red led on the PCB flashes at 1 second intervals.

When the required number of flashes is seen for the memory you want to change,

the button is released to select the memory. At this point the led comes on for five

seconds to confirm. Wait until it goes out.

The led then starts flashing again, and this time the button needs to be pressed to

store the value you want the memory to be set to.

After pressing the button, the led flashes 10 times rapidly, and the module starts

operating.

Repeat the process for the any other changes you want to make.

If you make a mistake selecting the memory location or setting the value, you may

want to perform a factory reset to return the module to its default settings.

See the following page for the options available.

Factory Reset

Resetting back to factory settings will allow the module to restart with known settings

and is useful if there may have been a mistake made in programming.

To reset the module back to factory settings, switch off the power to the module and

hold down the Push Button. Apply the power and continue holding the push button

until 1 flash of the led is seen. At this point, release the button. You will see a long

flash of five seconds.

The led will begin flashing again. When you have seen 1 flash, press the button. You

will see a long flash of five seconds and then 10 rapid flashes.

The reset procedure is then complete and the module will restart with factory

settings.

If you make a mistake programming, simply repeat the process.

Page 9 of 19

BLOCKsignalling www.blocksignalling.co.uk

Page 10 of 19

BLOCKsignalling www.blocksignalling.co.uk

Programming Options

East End Waiting Duration (option 3)

Sets the waiting time when the train arrives at the track section connected to the

REV2 terminal.

It a setting of 1 is used, then the waiting time will be set by the TIME adjustment on

the module.

Minimum setting 2 seconds.

Maximum setting 255 seconds.

Default setting (after factory reset) 5 seconds.

After the waiting time, the train departs in reverse.

West End Waiting Duration (option 4)

Sets the waiting time when the train arrives at the track section connected to the

REV1 terminal.

It a setting of 1 is used, then the waiting time will be set by the TIME adjustment on

the module.

Minimum setting 2 seconds.

Maximum setting 255 seconds.

Default setting (after factory reset) 10 seconds.

After the waiting time, the train departs forwards.

Station Stop Duration (option 5)

Sets the waiting time when the train arrives at the track section connected to the S

terminal.

It a setting of 1 is used, then the waiting time will be set by the TIME adjustment on

the module.

Minimum setting 2 seconds.

Page 11 of 19

BLOCKsignalling www.blocksignalling.co.uk

Maximum setting 255 seconds.

Default setting (after factory reset) 5 seconds.

After the waiting time, the train departs in same direction as it arrived.

Speed Control (option 6)

Sets whether the train stops and starts using the acceleration and deceleration

settings, or simply starts and stops with full power immediately applied and removed.

1=starts and stops with full power immediately applied and removed.

2=gradual acceleration and deceleration.

Rate of Acceleration (option 7)

Sets rate of acceleration applied.

Time in seconds for the voltage applied to the track to be raised from OFF up to the

maximum set by the adjuster on the board.

A higher value results in slower acceleration.

Note: the smoothness of the acceleration is highly dependent on the model and the

amount of friction present. Sometimes a longer acceleration time will be required, as

the model will not move during the initial application of voltage to the track.

Minimum setting 1 second.

Maximum setting 20 seconds.

Default setting (after factory reset) 6 seconds.

Rate of Deceleration (option 8)

Sets rate of deceleration applied.

Numerical value is the time in seconds for the voltage applied to the track to be

lowered from the maximum set by the adjuster on the board to OFF.

Minimum setting 1 second.

Page 12 of 19

BLOCKsignalling www.blocksignalling.co.uk

Maximum setting 20seconds.

Default setting (after factory reset) 2 seconds.

East End Delay (option 9)

Sets whether the waiting time when the train arrives at the track section connected to

the REV2 terminal is fixed or randomised.

When randomised, the waiting time varies between 25% and 100% of the set waiting

time.

1=fixed

2=randomised

When set to randomised, the variations in delay will only be obvious for longer

waiting times (greater than 30 seconds or so).

West End Delay (option 10)

Sets whether the waiting time when the train arrives at the track section connected to

the REV1 terminal is fixed or randomised.

When randomised, the waiting time varies between 25% and 100% of the set waiting

time.

1=fixed

2=randomised

When set to randomised, the variations in delay will only be obvious for longer

waiting times (greater than 30 seconds or so).

Station Delay (option 11)

Sets whether the waiting time when the train arrives at the track section connected to

the S terminal is fixed or randomised.

When randomised, the waiting time varies between 25% and 100% of the set waiting

time.

Page 13 of 19

BLOCKsignalling www.blocksignalling.co.uk

1=fixed

2=randomised

When set to randomised, the variations in delay will only be obvious for longer

waiting times (greater than 30 seconds or so).

Maintenance Mode (option 25)

When set to 1, displays the software version of the module by flashing the led on

module to signal a group of four digits.

The power must be removed to reset the module.

Page 14 of 19

BLOCKsignalling www.blocksignalling.co.uk

Step-by-step Connecting Up

There follows a step-by-step approach to connecting up and testing the unit. This

process can also be followed in case of the unit not functioning as expected.

1. Connect power to the module. The supply module is designed for a 12V DC

supply.

2. Switch on the power. The led on the PCB should light for 1 second, then flicker at

about 1/4 brightness.

3. Switch off the power and connect the continuous rail (the one without any breaks)

to the terminal marked OUT1. Connect the other rail to the terminal marked OUT2

and also insert a link between OUT2 and the COM terminal. Place a locomotive on

the track and switch on the power. After a few seconds, the locomotive should move

forwards. If necessary turn the SPEED adjustment on the module clockwise until the

locomotive moves. Switch off the power.

4. If you have a station section, connect it to the terminal marked S. Place a

locomotive on the track so that it will move towards the station section and switch on

the power. After a few seconds, the locomotive should move forwards. When it

reaches the station section, it should come to a stop for a few seconds then move off

again. Switch off the power.

5. Any track after the station should be connected with a link to the track before the

station, to ensure it receives power.

6. The stopping section which causes the train to switch from forwards to reverse

should be connected to terminal REV2. Place a locomotive on the track so that it will

move towards the end section and switch on the power. After a few seconds, the

locomotive should move forwards. When it reaches the end section, it should come

to a stop for a few seconds, then reverse back. Be ready to cut the power in case it

does not stop in time or does not reverse. Switch off the power.

7. Fit the final end section and connect to the REV1 terminal. Repeat the tests in full

to confirm that the train runs as expected backwards and forwards.

8. If you want to adjust any of the settings, this can now be undertaken.

Page 15 of 19

BLOCKsignalling www.blocksignalling.co.uk

Troubleshooting

Q. The locomotive does not move when the module is first switched on.

A. The locomotive should be moving forwards within 10 seconds. If not, increase the

SPEED adjustment on the module clockwise. Gently nudge the loco forwards in

case mechanical or electrical resistance is preventing it moving. If required, test the

locomotive in the same position with your DC controller to check it operates

correctly.

Q. The locomotive runs in the wrong direction when the module is first

switched on.

A. The locomotive motor may be wired incorrectly or the connections between the

module and the track wired incorrectly (reversed).

Q. At the end of the track the locomotive stops briefly, and then continues in

the same direction rather than changing direction.

A. When the train reaches the end of the track connected to the REV2 terminal, it will

stop then reverse. When the train reaches the end of the track connected to REV1,

it will stop then leave the section in the forward direction. Check the connection from

the track ends to the module to check they are correctly wired.

Another common cause of a loco stopping at the end and then continuing in the

forward direction is if the connections to rails have high resistance. Check closely

the connection quality at the attachment to the COMMON rail and to the EAST and

WEST connections.

Q. The train does not stop at a section.

A. The gap in the rail could be blocked by swarf or debris, or the deceleration time

could be set to too long. This is also possible if the REV1 and REV2 ends are

incorrect (reversed).

Another common cause of the locomotive not being slowed by the module is a poor

connection to the rail (poor solder joint or dirty connection).

Page 16 of 19

BLOCKsignalling www.blocksignalling.co.uk

Q. The acceleration is not very smooth.

A. The train has to overcome friction before moving off, after which the friction

reduces. For this reason, more realistic acceleration can be achieved with a longer

acceleration time. This effect is not seen when the locomotive is decelerating.

Page 17 of 19

BLOCKsignalling www.blocksignalling.co.uk

Station Stop on a Loop

The SAS2-BR can be used to provide a Station Stop on a loop.

The locomotive travels forwards around the loop, stopping each time at the station

for a delay period set by the Station Stop Duration memory location.

If you don't want the module to stop trains at the station, you can place a switch

across one of the rail gaps.

When the switch is closed, the module will not detect trains at the station and so the

trains will not be stopped.

PLATFORM

BLOCK

signalling

BLOCKsignalling Shuttle

and Station Stop

TRACK BREAK TRACK BREAK

S

COM +

_

POWER

SUPPLY

_+

Page 18 of 19

BLOCKsignalling www.blocksignalling.co.uk

Use with Reed Switches, Push Buttons, etc

Instead of using the traction current to trigger the SAS2-BR, you can use reed

switches, push buttons, etc.

This could allow the modelling of cable cars, lifts, etc, in addition of conventional

model train shuttles.

See diagram below for wiring.

You may wish to experiment with the positioning of the reed switches, and vary the

acceleration setting, to suit your model.

The motor polarity can be set by trial and error.

If reed switches are used for station stops, a switch can be placed at each end of the

platform, with the switches wired in parallel and connected to the S terminal.

Instead of locating reed switches along the centreline of the rails, it may be possible

to offset them to alter the stopping point for the train depending on direction (fixing

magnets to diagonally opposite corners of the train).

BLOCKsignalling Shuttle

REV1

COM

OUT2

OUT1

IN1

IN2

REV2

BLOCK

signalling

1k Resistor

Reed Switches, etc

Page 19 of 19

BLOCKsignalling www.blocksignalling.co.uk

Funiculars & Cable Cars

Instead of using the traction current to trigger the SAS2-BR, reed switches (as

previously said) can be used, but for funiculars or cable cars it may be difficult to find

a solution to mounting magnets.

Instead, BOD2-RLY infra-red detectors can be used.

Run initially without the cable car fixed to the rope to confirm the correct motor

direction.

It may be necessary to increase the BOD2-RLY sensitivity, or to reduce the

Deceleration rate of the SAS2-BR to ensure the cable car stops at the intended

location.

On a funicular or a cable car with two cars, position the BOD2-RLY modules to

monitor the same car at the top and bottom of the run. Alternately, mount the BOD2-

RLY modules side by side at either the top or bottom of the run.

A centre station can be wired in the same way if required, although if precision is

required for stopping, then two BOD2-RLY modules may be required looking both up

and down the run.

BLOCK

signalling

BLOCKsignalling SAS2-BR

SHUTTLE

POWER

SUPPLY

_+

BLOCKsignalling

BOD2-RLY

BLOCKsignalling

BOD2-RLY

MDRIVE

MOTOR

REV1

REV2

COM

COM NO

COMNO

BOD2-RLY POWER SUPPLY

CONNECTIONS NOT SHOWN

1k RESISTOR

1k RESISTOR

Table of contents

Other BLOCKsignalling Measuring Instrument manuals

Popular Measuring Instrument manuals by other brands

LaserLiner

LaserLiner ClimaHome-Check Plus manual

Kipp & Zonen

Kipp & Zonen LAS MkII ET System instruction manual

ITRON

ITRON Mobile Collector Lite installation guide

Mitutoyo

Mitutoyo LGF-110L-B manual

Kamstrup

Kamstrup ULTRAFLOW 54 DN15-125 Technical description

Extech Instruments

Extech Instruments FM200 user manual