Function description and application examples

10

02.00 | FMS | Assembly and Operating Manual | en | 389074

4 Function description and application examples

4.1 Functional description

The FMS force measuring system allows you to measure forces

that act on the base jaw in the direction of the jaw movement. The

force must act centrally on the force measuring adapter.

Depending on the application, one to three active (equipped with

sensor systems) FMS-ZBA intermediate jaws are needed. The

remaining base jaws contain the passive FMS-ZBP intermediate

jaws (without sensor systems). Alternatively, the fingers can be

manufactured accordingly.

For each active intermediate jaw FMS-ZBA, an electronic processor

FMS-A1 is required for the evaluation, as well as a connection cable

FMS-AK for connecting the electronic processor with a power supply

unit and a force/torque sensor system controller (e.g. a PLC).

The active intermediate jaw is made to be deformed specifically in

the micron range. This deformation is detected by an integrated

DMS. Furthermore, the intermediate jaw is made in such a way

that a moment or force from a different direction only slightly

changes the measured value. It is therefore generally only the

gripping forces which are measured.

By means of the force/torque sensor system controller, the DMS

small signal is amplified and output to a voltage level proportional

to the gripping force.

When this is done, a positive value indicates a force acting from

the center of the gripper on the finger (e.g., a workpiece between

the gripper fingers), while a negative value indicates an external

force on the gripper fingers (e.g. reaching into a bore hole).

The output voltage level has a linear relationship to the occurring

force. However, only a change in force will be detected and not an

absolute force.

This means that when measuring, the force/torque sensor system

controller has to be reset to zero before gripping (button on the

force/torque sensor system controller or digital signal). After that,

gripping ought to be started immediately and the output

measured value ought to be evaluated.

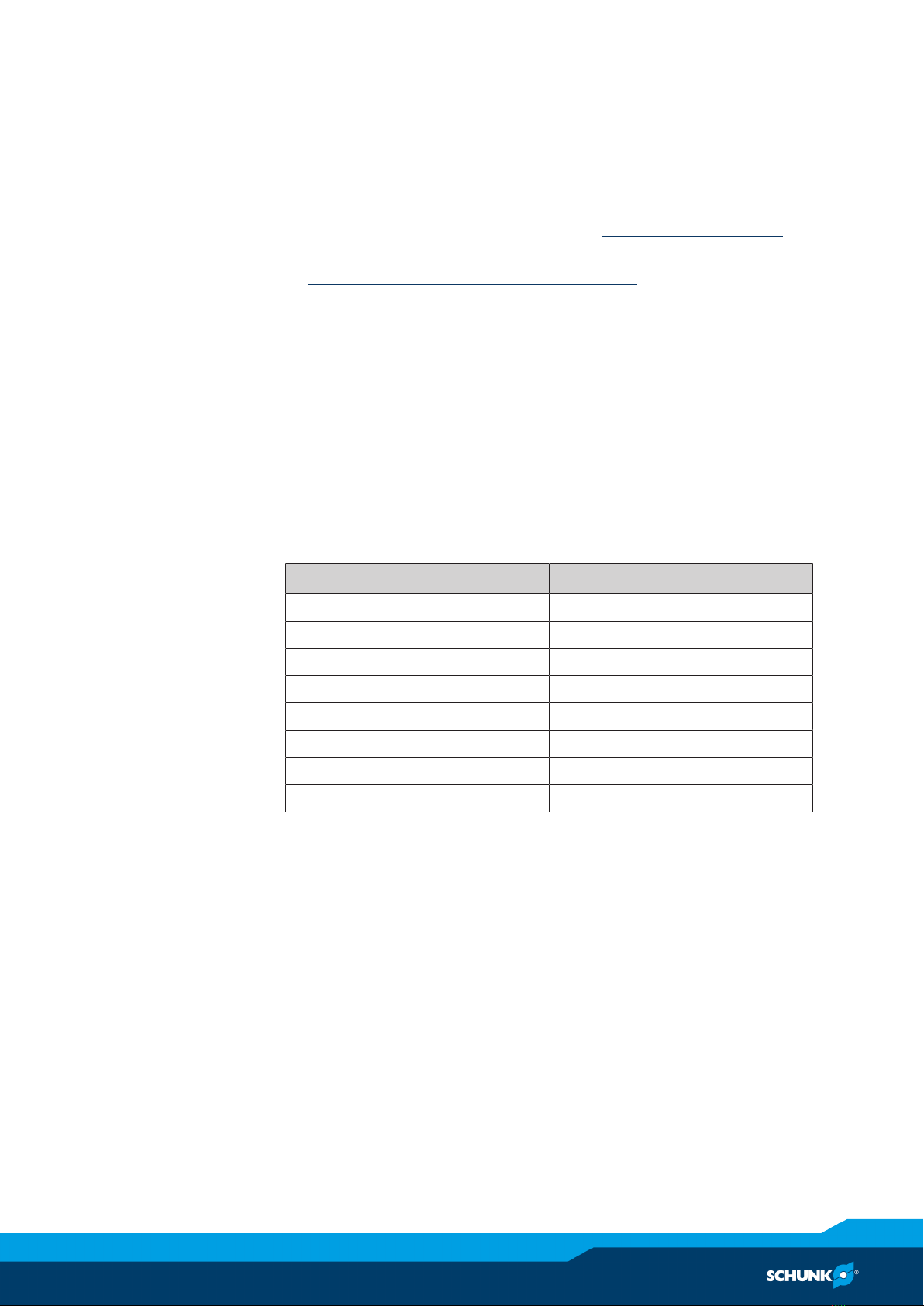

To convert the measured value into a force, the factor included in

the data sheet and the value of the base gradient is required.

Since the pitch m is a function of the finger length, the distance

from which the gripping takes place is inserted into the formula

which has been provided by the factory. The distance is the length

between the base jaws of the gripper and the gripping point. The

result of this calculation is the gradient factor for the

corresponding finger length.