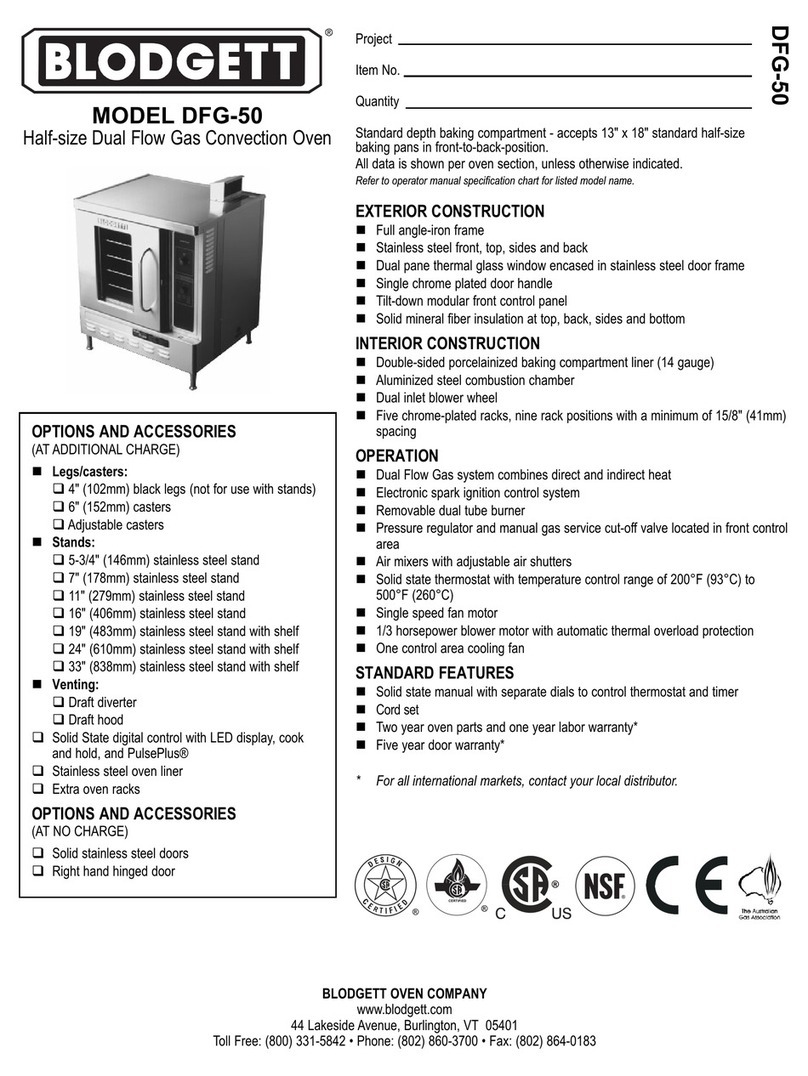

Project

Item No.

Quantity

All data is shown per oven section, unless otherwise indicated.

Refer to operator manual specification chart for listed model names.

BLODGETT COMBI

www.blodgett.com

44 Lakeside Avenue, Burlington, VT 05401

Phone: (802) 658-6600 • Fax: (802) 864-0183

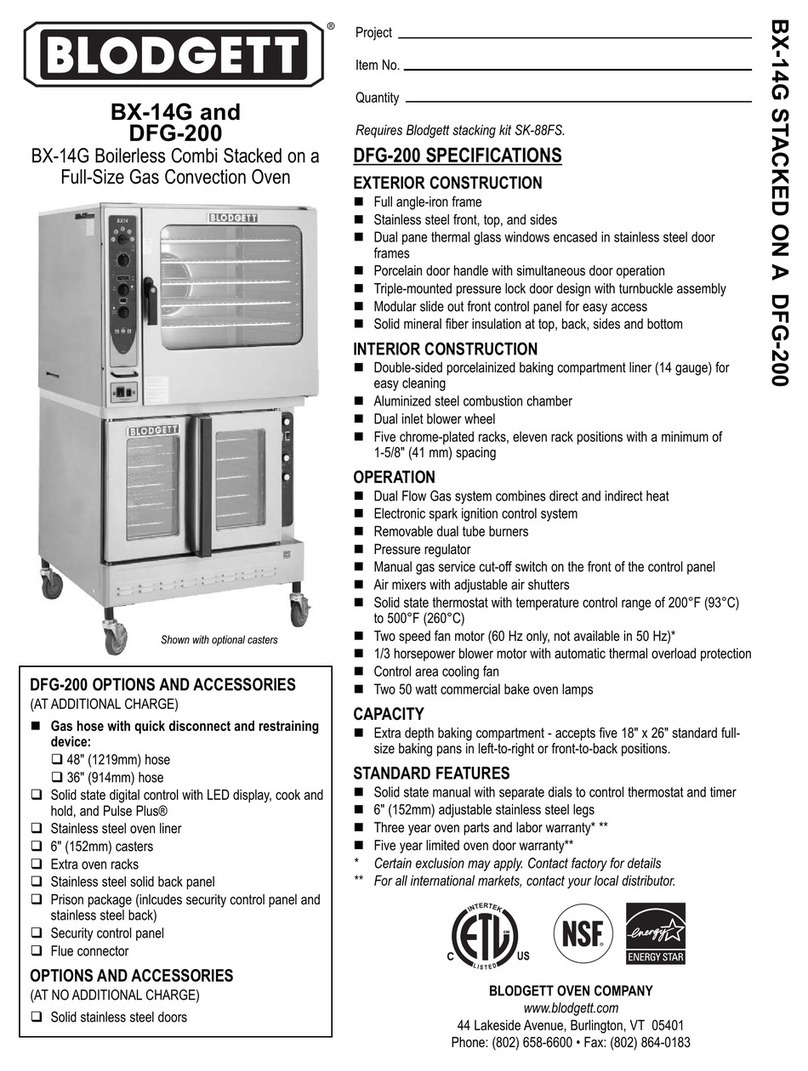

EXTERIOR CONSTRUCTION

Stainless steel top, front, sides and right hand door hinge

Single pane tempered viewing window

Door mounted condensate trough

Well protected control panel

Side mount, easily adjustable door hinges

Roll out control panel exposes most serviceable parts

Modular controls allow for field upgrade to digital controls

INTERIOR CONSTRUCTION

Fully welded stainless steel frame

Fully insulated cooking chamber

Fixed drain bottom center of cavity

Filterless grease slinging convection fan

Easily removable stainless steel side rails

OPERATION

Standard control with four function selection switch for steam, hot air, com-

bined steam/hot air, cool down, Vario Steam® and steam on demand feature

Solid state rotary dial thermostat - range 150-500°F (66-260°C)

Motor driven 120 minute timer shuts down at elapsed time

Two speed fan

Magnetic door interlock switch shuts off oven when door is opened

Electronic ignition

Open vented system. Condenses steam and drains away by-products of the

cooking process, eliminates flavor transfer

Self contained, self-flushing steam generator separate from cooking compart-

ment for instant steam recovery when switching modes

Deliming light flashes when steam generator requires deliming

Deliming container with manual pump for storing and dispensing deliming solu-

tion. (See automatic deliming option)

CAPACITY

Fourteen 12" x 20" x 2-1/2" deep pans at 3-1/4" spacing

Seven 18" x 26" deep pans at 3-1/4" spacing

STANDARD FEATURES

Five (5) stainless steel wire shelves per section (capacity for 7)

Deliming bottle and pump assembly

Pressure spray bottle for oven cleaning

Hose and spray assembly for interior cleaning

Stacking kit and casters for double stack ovens

Two speed fan

Water pressure regulator (1 per section)

Drain kit assembly

Start-up inspection service by factory authorized service agent

One year parts and labor oven warranty*

* For all international markets, contact your local distributor.

OPTIONS AND ACCESSORIES

(AT ADDITIONAL CHARGE)

Legs

4" (101.6mm) adjustable legs

6" (152.4mm) adjustable legs

6" (152.4mm) seismic legs

25" (635mm) adjustable legs

Floor stand with rack supports

Stand Mount Casters

Semi-Automatic Deliming pump that installs directly

to the back of the unit with delivery hose and delim-

ing container

Programmable digital controls with cook and hold

and Vario Steam®

Locking control panel

Locking door hasp

Tamper proof screws

Additional stainless steel wire shelves

Core temperature probe with digital readout

Stainless steel back panel

Chicken roasting rack

Hot water/filtered water connection kit

Extended warranty

OPTIONS AND ACCESSORIES

(AT NO CHARGE)

LP gas

208/240 volt

BC-14G AND BC-142G

Single or Double

Combination-Oven/Steamer

BC-14G AND BC-142G