blondal Kalla 2 User manual

Table of contents

Popular Water Filtration System manuals by other brands

ProMinent

ProMinent CHLORINSITU IIa Assembly and operating instructions

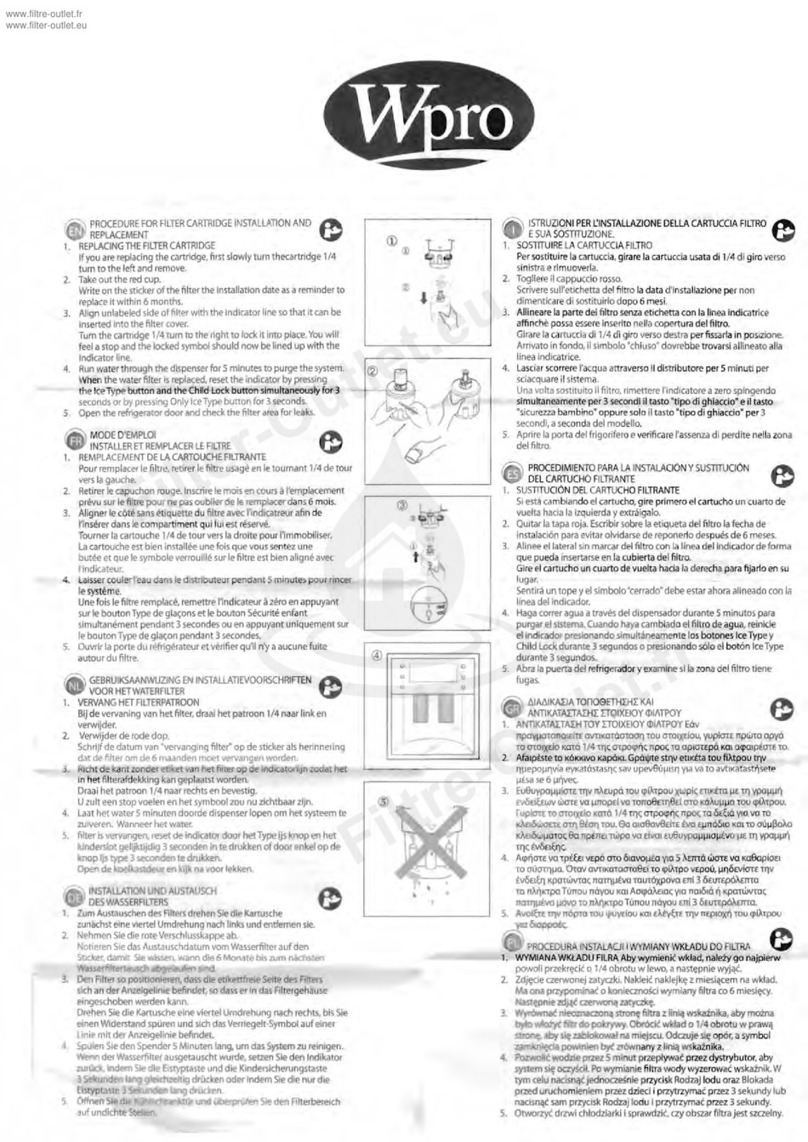

wpro

wpro APP100 Procedure for installation and replacement

Prime

Prime PRIME 501-SV user manual

Foxx

Foxx GALAZY 2000 Installation & operation manual

Hamilton Beach

Hamilton Beach AquaFusion 87325 Replacement

Hague Quality Water

Hague Quality Water WaterMax H6000 Owner's manual and installation guide

Filtech

Filtech DP 200 Use and maintenance manual

Pentair

Pentair freshpoint F1000-DFB instruction manual

Rainman

Rainman Electric Operation manual

Greiner Vibrograf

Greiner Vibrograf ACS 900 Manual and instruction

Kohler

Kohler CLARITY Instructions and care

Atlantic Ultraviolet

Atlantic Ultraviolet Eco-Logic Operation manual

Oase

Oase Biotec 30 manual

Pentair

Pentair Fleck 5812 SXT user guide

Clean Water Systems

Clean Water Systems Fleck 9100 Installation & start?up guide

CALEFFI

CALEFFI DISCAL NA551 Series Installation, commissioning and servicing instructions

Siemens

Siemens FDCL221 manual

Ispring

Ispring CU-A4 Installation instructions & operating manual