Using the system

This section explains how to operate the system on a regular basis, including set up, starting, stopping, and

flushing the system.

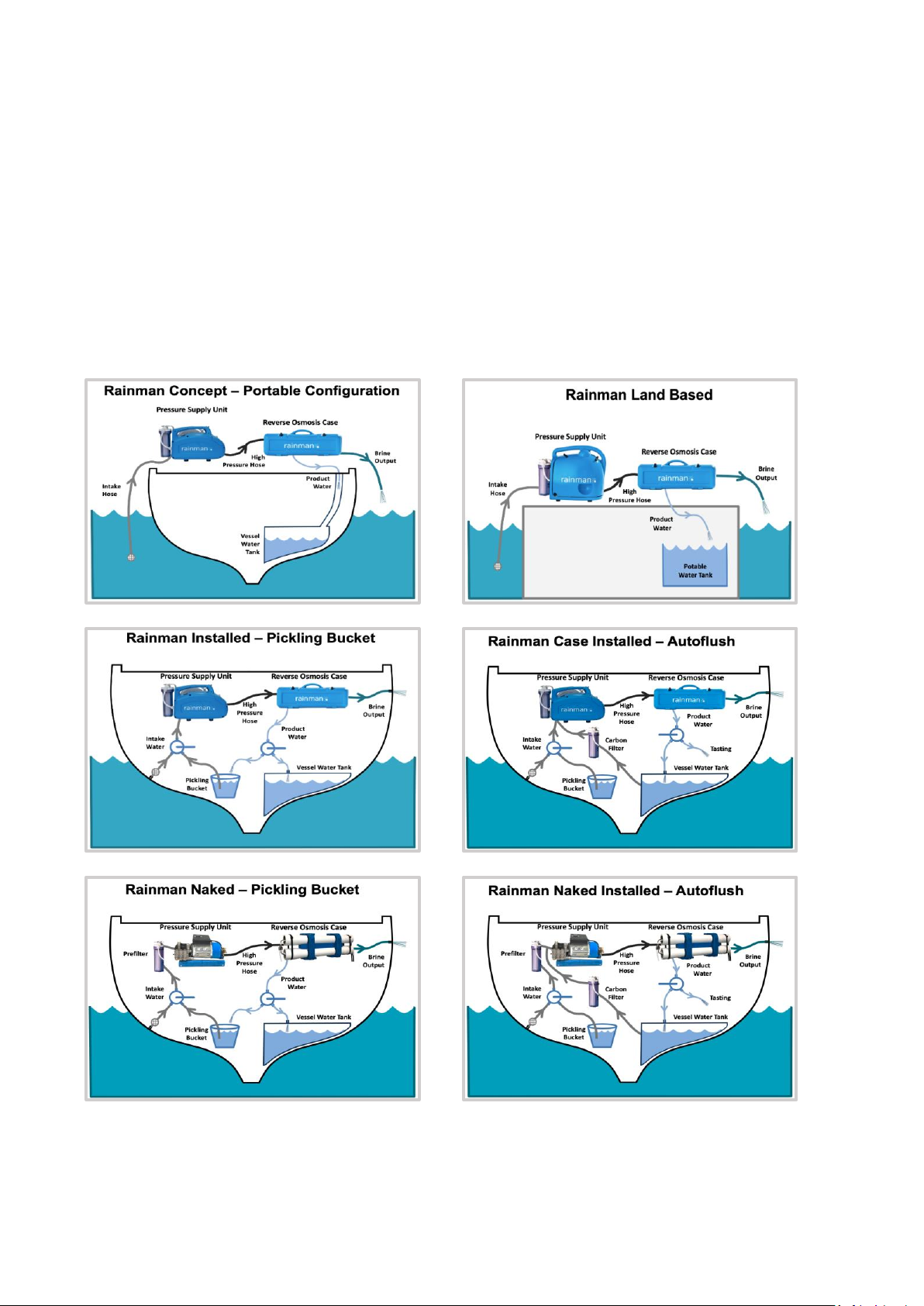

Setup - Portable

1. Place the Rainman Pressure Supply Unit (PSU) and Reverse Osmosis (RO) unit in a stable

place on the deck of your vessel. A swim platform is an ideal location.

Certain positions on some vessels will resonate causing excess noise. In this case, place the

unit on a towel or foam mat.

Make sure the PSU is no more than 2 metres (6 feet) above water level. The unit will work

best operating as close to water level as possible.

Do not use on a swim platform if there is any chance of the unit getting wet.

2. Open the RO unit. Remove and uncoil the three hoses. Remove the white travel plug from

the quick connect on the outside of the PSU. Connect the black high-pressure hose to the

PSU. Make sure the high-pressure hose doesn’t chafe around hard corners.

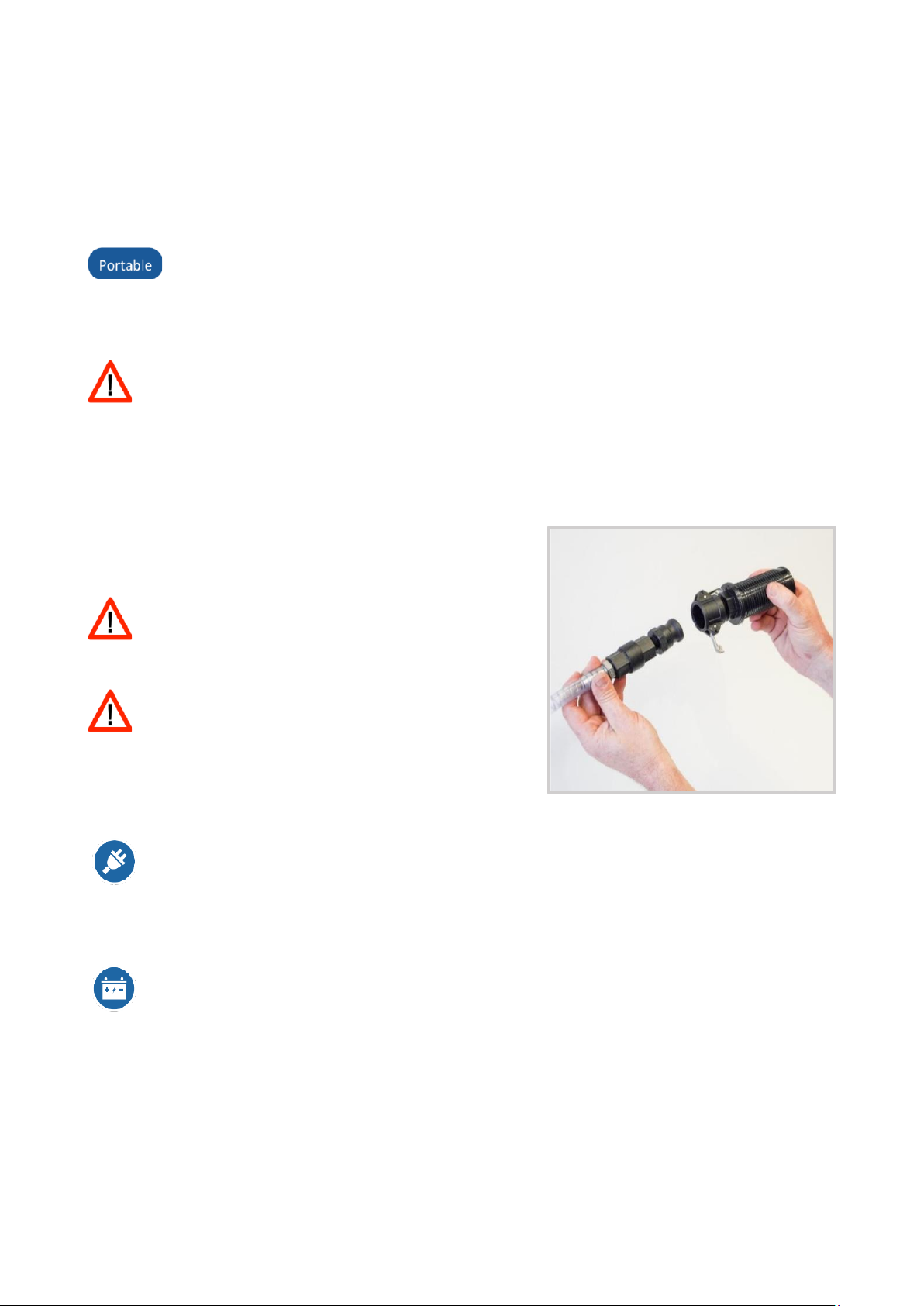

3. Remove the plastic spiral intake hose from the

PSU and remove the cap. Attach the strainer to

the end of the pickup hose.

Starting the unit with the cap in place will

damage the pumps.

4. Place the intake hose in the source water.

Make sure the intake hose is submerged and is

not on the sea floor or among seaweed, which

can cause blockage.

5. Direct the green brine hose overboard.

6. Direct the white product hose overboard. Do not put it into your water tank at this stage.

7. Ensuring the power switch is off, plug the power cord into an AC power source. If using a

generator, make sure it is rated to at least 2000 Watts peak, 1600 Watts continuous power.

If using a Honda portable generator, make sure the eco-throttle is off. Once the Rainman is

running, you can switch the eco-throttle back on. Make sure the voltage and frequency

match the unit (eg. 115VAC/60Hz or 230VAC/50Hz).

Ensuring the power switch/circuit breaker is in the off position, connect the unit to a 12VDC

power supply. During startup, the 12v PSU might draw up to 40A for a brief period and will

settle down to 28-32A in normal operation once the motor and crank case have reached

normal operating temperature. Therefore, it is important that the 12V supply can support

this current draw without a significant drop in voltage.

Cable runs should be kept to a minimum. If an extension cable is used, it must be of sufficient

gauge to minimise voltage drop. Several easy to use ‘voltage drop calculators’ are available

online.

8. Ensure the pressure valve in the RO unit is in an open position (fully anti-clockwise).