Bloomy Battery Simulator 1200 User manual

Battery Simulator 1200

Installation Manual

Bloomy Energy Systems

8700-00001 V1.1

2 Bloomy Energy Systems Battery Simulator 1200 Installation Manual

Copyright Bloomy Energy Systems 2013

Bloomy Energy Systems

257 Simarano Drive

Marlborough, MA 01752

508.281.8288

BES_info@bloomy.com

www.bloomyenergysystems.com

Bloomy Energy Systems provides energy storage test and data acquisition products that enable battery,

grid storage, and automotive companies to improve quality and reduce time to market.

FCC STATEMENT:

This equipment has been tested and found to comply with the limits for a Class A digital device, pursuant

to Part 15 of the FCC Rules. These limits are designed to provide reasonable protection against harmful

interference when the equipment is operated in a commercial environment. This equipment generates,

uses, and can radiate radio frequency energy and, if not installed and used in accordance with the

instruction manual, may cause harmful interference to radio communications. Operation of this equipment

in a residential area is likely to cause harmful interference in which case the user will be required to

correct the interference at his own expense.

NOTE:

Do not open the enclosure. This product contains no user-serviceable parts. Opening the enclosure will

void the warranty.

Battery Simulator 1200 Installation Manual Bloomy Energy Systems 3

Important Information

This symbol identifies messages in this document related to safety.

DANGER

DANGER indicates an imminently hazardous situation, which, if not avoided, will result in death or

serious injury.

Failure to follow the instructions given will result in death or serious injury.

WARNING

WARNING indicates a potentially hazardous situation, which, if not avoided, could result in death or

serious injury.

Failure to follow the instructions given can result in death or serious injury

CAUTION

CAUTION indicates a potentially hazardous situation, which, if not avoided, may result in minor or

moderate injury.

Failure to follow these instructions can result in personal injury.

NOTICE

NOTICE alerts you to practices unrelated to personal injury, such as those that can cause property

damage.

Failure to follow these instructions can result in property damage.

IMPORTANT

IMPORTANT indicates additional information about making effective use of this product.

Battery Simulator 1200 Installation Manual Bloomy Energy Systems 4

Table of Contents

1. Introducing the Battery Simulator 1200.............................................................................. 5

1.1 Features .............................................................................................................................................. 5

1.2 Application Example............................................................................................................................ 7

2. Installation............................................................................................................................ 8

2.1 Wiring Remote Sense ....................................................................................................................... 10

3. Specifications......................................................................................................................11

3.1 Cell Simulation .................................................................................................................................. 11

3.2 Auxiliary I/O Specifications................................................................................................................ 11

3.3 Physical Specifications...................................................................................................................... 12

4. Maintenance ........................................................................................................................13

4.1 Cleaning Instructions......................................................................................................................... 13

Battery Simulator 1200 Installation Manual Bloomy Energy Systems 5

1. Introducing the Battery Simulator 1200

The Battery Simulator 1200 provides a safe and efficient method for battery, grid storage, and automotive

companies to accurately simulate a broad range of battery pack and cell conditions. The Battery

Simulator 1200 provides 12 individually controlled simulated cells and several auxiliary analog and digital

I/O channels. Integrated computing allows the unit to be configured for custom battery profiles and

simulated events. Multiple units can be combined in series to simulate higher channel count battery

packs.

1.1 Features

•Simulate 12 independent cells per unit

•Sink and source 5 VDC and 500 mA per channel

•1000 VDC channel-to-channel and channel-to-ground isolation

•Auxiliary analog and digital I/O

•Ethernet (LAN) and high-speed CAN control communications

•High speed CAN interface compliant with ISO 11898

•NI LabVIEW drivers

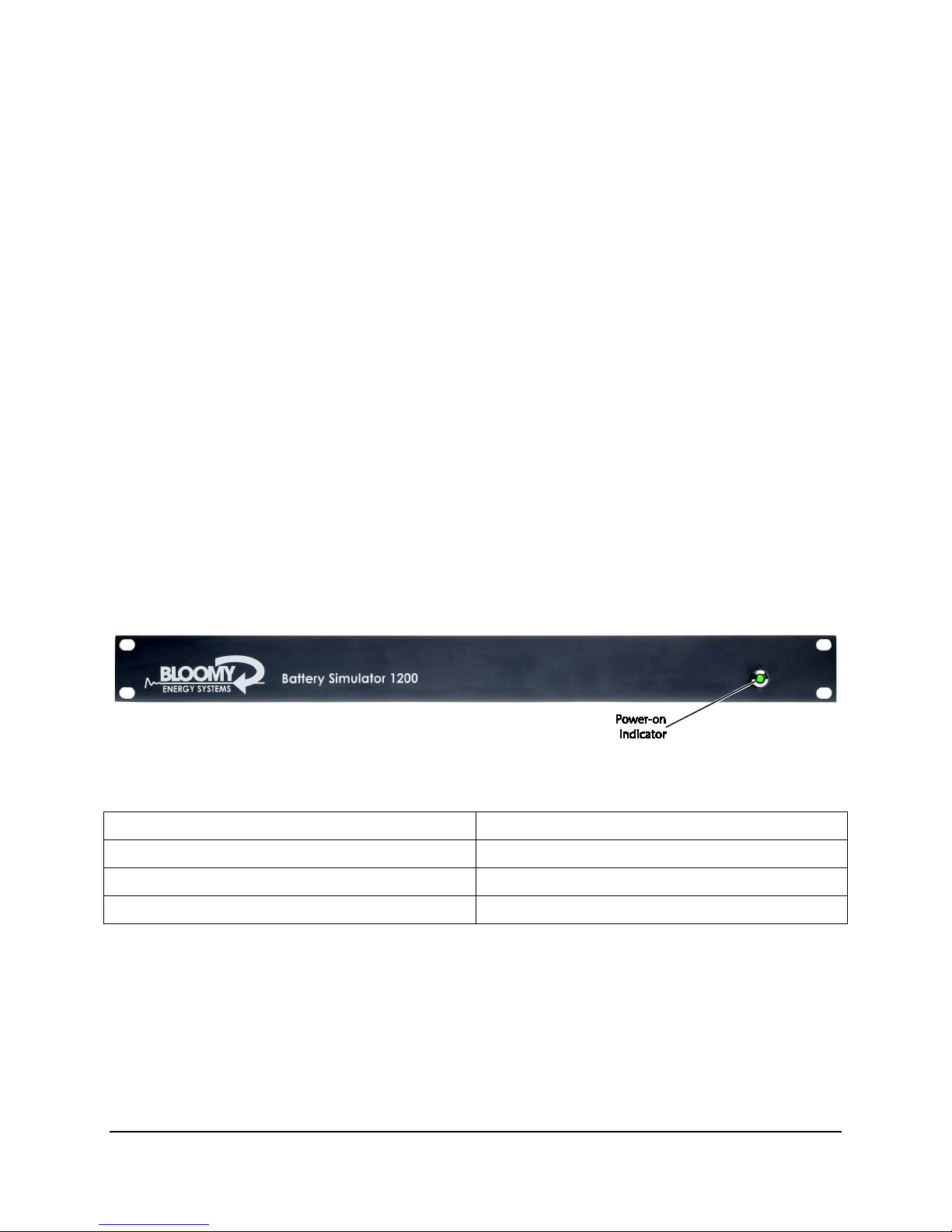

Figure 1: Front View of Battery Simulator 1200 solid running blinking = error state

Power indication:

Power-on Indicator LED Condition

Constant green Operating

Blinking green Error state

Off System off

1. Introducing the Battery Simulator 1200

6 Bloomy Energy Systems Battery Simulator 1200 Installation Manual

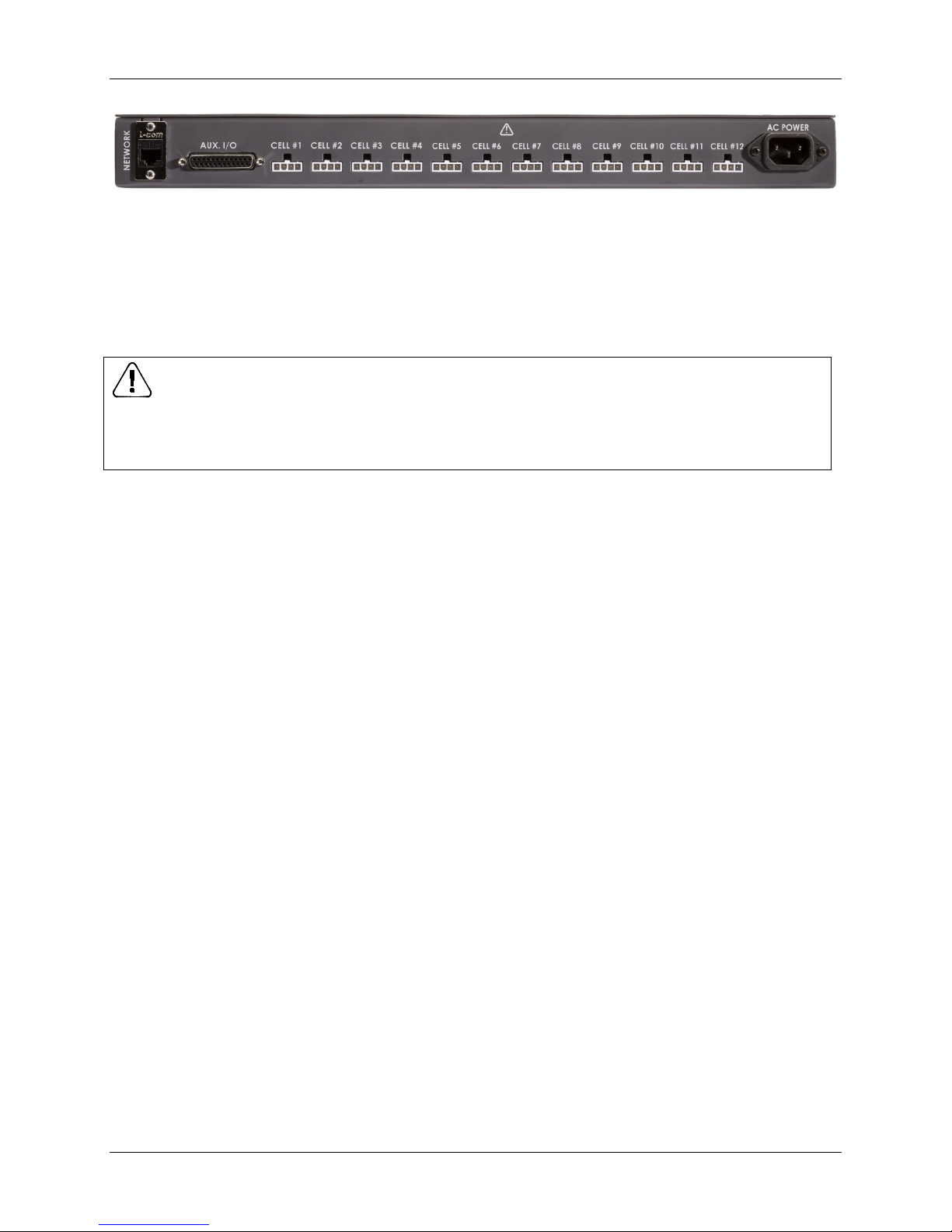

Figure 2: Rear View of Battery Simulator 1200

The outputs of the Battery Simulator 1200 may be connected in series to simulate a pack. This must be

done with extreme caution as hazardous voltages can be generated due to the additive nature of the cell

outputs. For example, 12 cells in series with each cell at 4 volts will generate 48V total.

WARNING

Hazardous voltages can result from connecting outputs in series. Use extreme caution when

connecting outputs in series.

Failure to follow the instructions given can result in death or serious injury

1. Introducing the Battery Simulator 1200

Battery Simulator 1200 Installation Manual Bloomy Energy Systems 7

1.2 Application Example

Highly isolated cells provide the flexibility to integrate the Battery Simulator 1200 into many custom

system architectures. In the example shown below, two units are stacked above a 680V external power

supply to provide an overall pack voltage of 800V.

Typical applications include

•Battery management system testing, verification, and validation

•Battery pack simulation, up to 200 cells

•Hardware-in-the-Loop (HIL) system integration

Battery Simulator 1200 Installation Manual Bloomy Energy Systems 8

2. Installation

To install your Battery Simulator 1200, follow the instructions below.

1. Mount the Battery Simulator 1200 in a 19-in. rack. It uses 1U of space. The cooling air flows from

left to right when viewed from the front of the unit. You can mount additional units above and

below; no space is required between units.

2. Make wiring connections as needed (see Table 1: Connections for Cells 1 –12 and Table 2: Aux

I/O Connections). See also Figure 3: Wiring Remote Sense

3. Connect the AC power cord to the back panel of the unit and to a properly grounded power

receptacle controlled by an input power disconnect device near the equipment and within easy

reach of the operator.

CAUTION

DO NOT open the equipment enclosure. This product contains no user-serviceable components.

Failure to follow these instructions can result in personal injury.

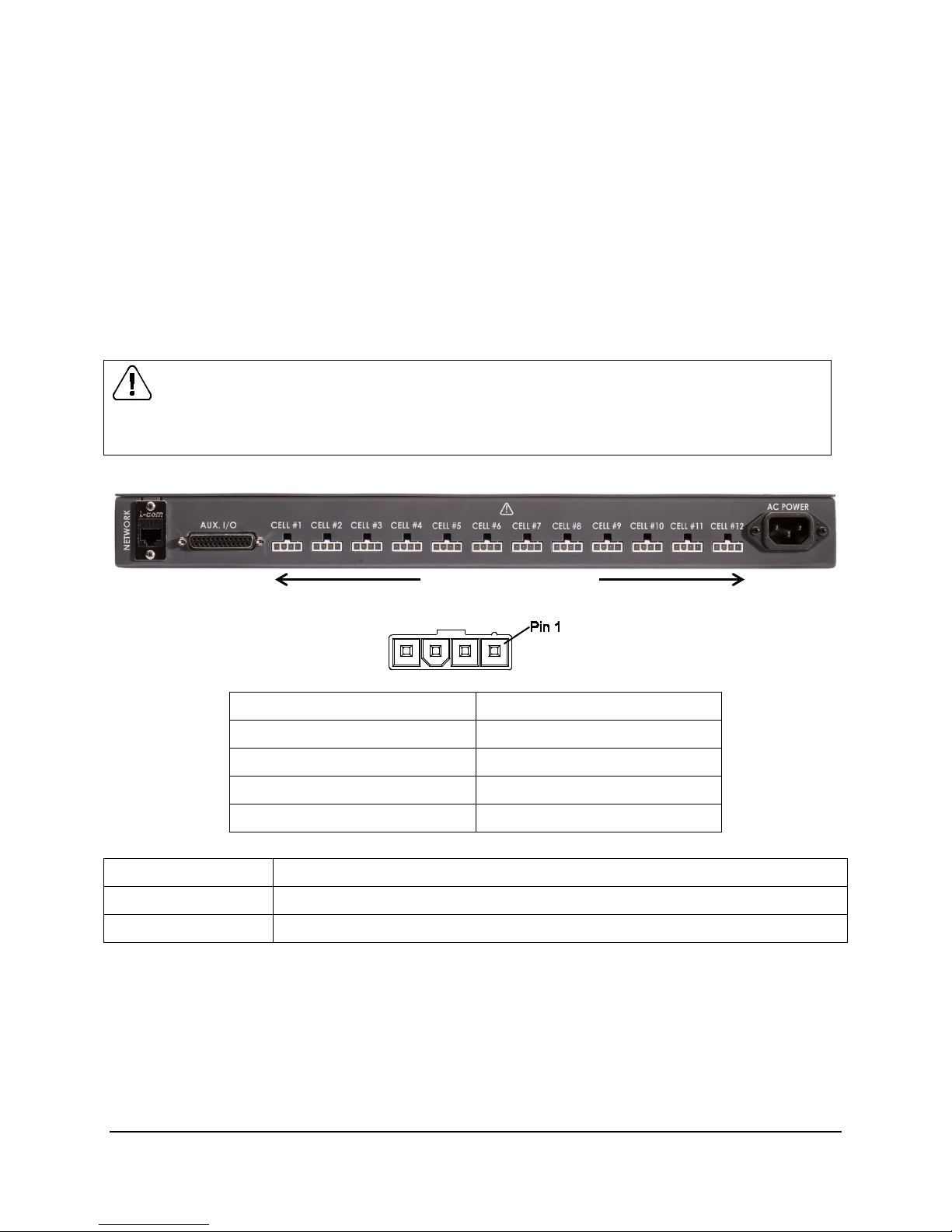

Ethernet Auxiliary I/O Cell Connections (1 – 12) AC Power

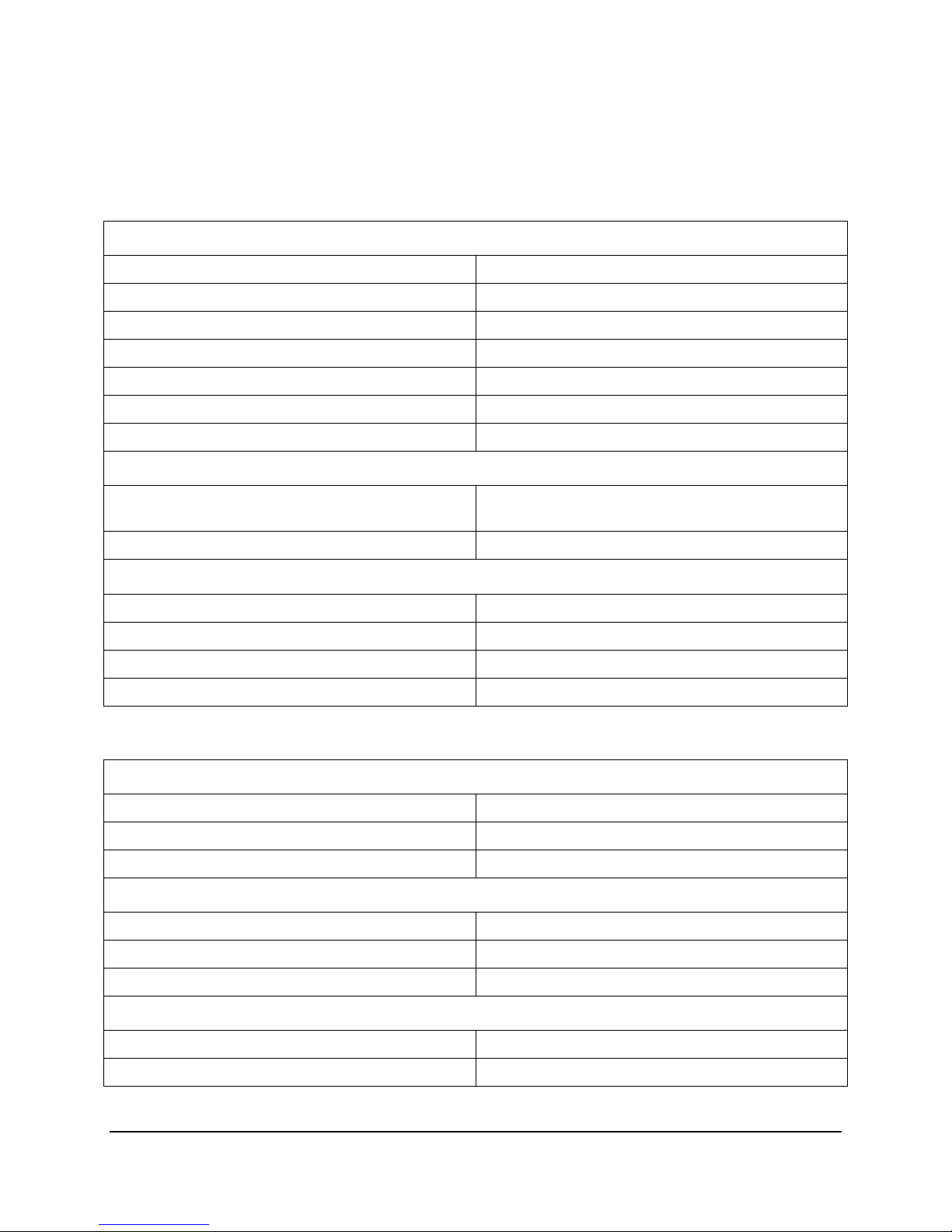

Table 1: Connections for Cells 1 –12

Pin number Signal

Pin 1 Sense+

Pin 2 Vout+

Pin 3 Vout–

Pin 4 Sense–

Cell Connection Function

Vout +/– Cell simulator output capable of both sourcing and sinking current

Sense +/– Remote sensing of the Vout +/–signals

NOTE: When connected, the system compensates for voltage drop when current flows through the Vout

+/– cables. The Battery Simulator 1200 contains resistors that connect Vout +/– to Sense +/– to allow

proper sensing at the output connector if the Sense lines are not connected. The system is designed to

compensate for up to 200 mV of total round-trip cable loss.

2. Installation

Battery Simulator 1200 Installation Manual Bloomy Energy Systems 9

Table 2: Aux I/O Connections

Analog I/O Connection Description

Analog Inputs 1 – 8 Single-ended inputs

Capable of measuring 0 to 5 VDC

Analog Output 1 – 2 Can be configured to output voltages of 0 to 5 VDC

CAN+, CAN– Controller area network connections

Digital I/O 1-8 3.3V digital I/Os that can be configured as inputs or outputs capable of

sourcing and sinking up to 3 mA

GND Ground

Pin Number Connection

Pin 1 Analog In #1

Pin 2 Analog In #3

Pin 3 Analog In #5

Pin 4 Analog In #7

Pin 5 GND

Pin 6 Analog Out #1

Pin 7 GND

Pin 8 Digital I/O #2

Pin 9 Digital I/O #4

Pin 10 Digital I/O #6

Pin 11 Digital I/O #8

Pin 12 GND

Pin 13 CAN+

Pin Number Connection

Pin 14 Analog In #2

Pin 15 Analog In #4

Pin 16 Analog In #6

Pin 17 Analog In #8

Pin 18 GND

Pin 19 Analog Out #2

Pin 20 Digital I/O #1

Pin 21 Digital I/O #3

Pin 22 Digital I/O #5

Pin 23 Digital I/O #7

Pin 24 GND

Pin 25 CAN–

IMPORTANT

•Battery Simulator 1200 does not contain a CAN bus termination resistor.

•If needed, add CAN bus termination between the CAN signals at the AUX I/O connector.

•Provide a dedicated CAN network for your Battery Simulator 1200s to avoid addressing conflicts.

2. Installation

10 Bloomy Energy Systems Battery Simulator 1200 Installation Manual

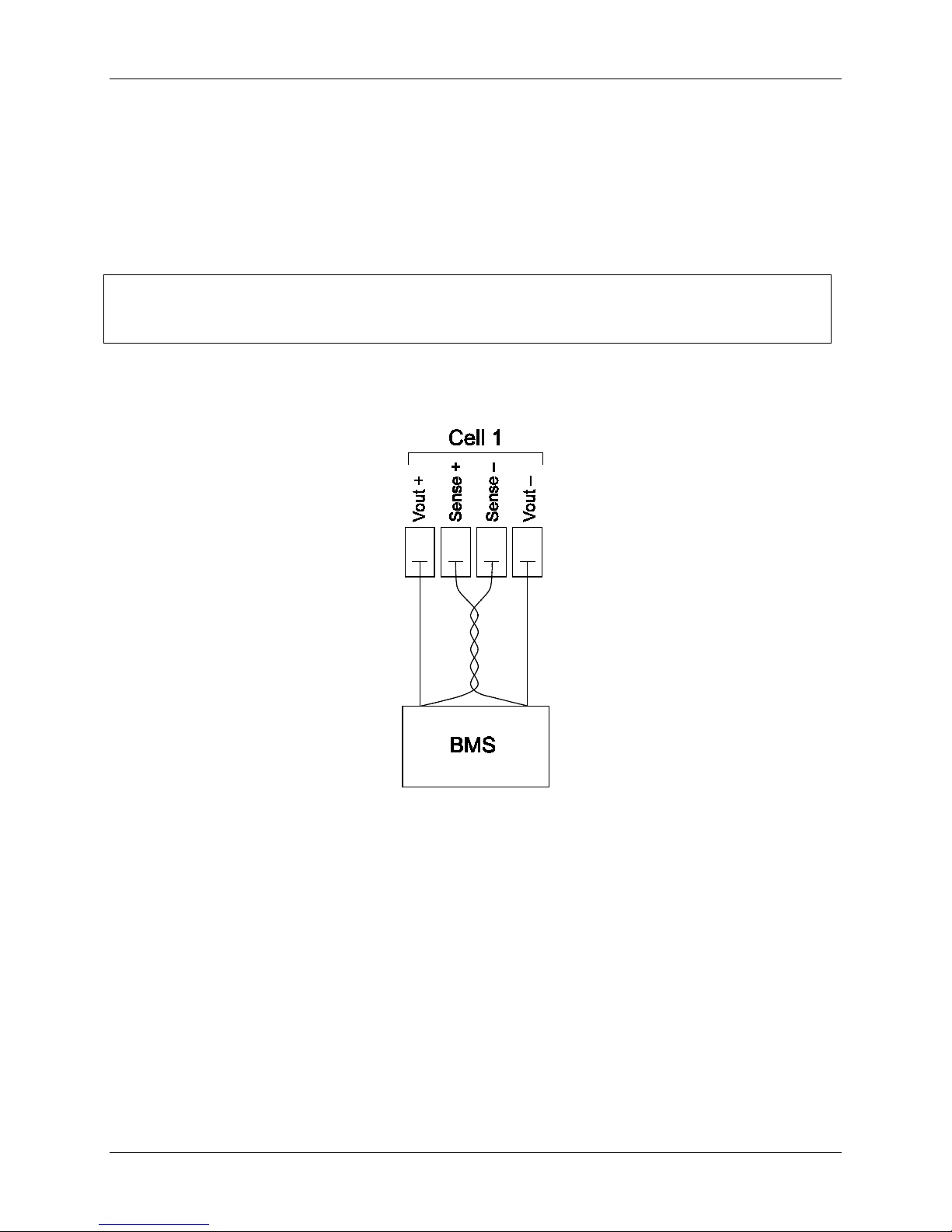

2.1 Wiring Remote Sense

Use remote sensing to regulate the output voltage at the device under test. This feature lets you

compensate for the voltage drop in the leads between the Battery Simulator 1200 and the device under

test.

To set up the remote sensing mode, refer to Figure 3: Wiring Remote Sense and follow these steps:

1. Connect a pair of sense leads from Sense + and Sense – to the device under test.

IMPORTANT

For system stability, use jacketed twisted-pair cables between the remote sense terminals of the unit

and the load.

2. Connect a pair of drive leads from drive Vout + and drive Vout – to the device under test.

Figure 3: Wiring Remote Sense

Battery Simulator 1200 Installation Manual Bloomy Energy Systems 11

3. Specifications

Note: All specifications subject to change.

3.1 Cell Simulation

Sink and Source

Number of Channels 12

Voltage Range 0.0 to 5.0 V

Voltage Resolution 0.1 mV

Voltage Accuracy ±3 mV

Current Range ± 500.0 mA; output derates linearly under 2 V

Current Resolution 0.1 mA

Isolation 1000 VDC CH-TO-CH, CH-TO-GND

Control

Communication LAN (Ethernet)

CAN (optional)

Drivers NI LabVIEW™

Readback

Voltage Resolution .1 mV

Voltage Accuracy ±3 mV

Current Resolution .1 mA

Current Accuracy ±4 mA

3.2 Auxiliary I/O Specifications

Analog Input

Number of Channels 8 (single -ended)

Resolution .1 mV

Max Voltage 5.0 V

Analog Output

Number of Channels 2

Resolution .1 mV

Max Voltage 5.0 V

Digital I/O

Channels 8 (bidirectional)

Logic Level 3.3 V

3. Specifications

12 Bloomy Energy Systems Battery Simulator 1200 Installation Manual

3.3 Physical Specifications

Dimensions 19” W x 1.75” H x 15” D (1U)

(482.6 mm W x 44.5 mm H x 381.0mm D)

Weight 7.5 lb (3.4 kg)

Operating Temperature 0 to 35° C

Input Power Single phase, 100 - 240 VAC/3A, 50/60 Hz

Altitude 9842 ft (3000 m), maximum

Pollution Degree PDX1

Battery Simulator 1200 Installation Manual Bloomy Energy Systems 13

4. Maintenance

4.1 Cleaning Instructions

To clean your Battery Simulator 1200, follow these steps:

1. Power down the unit.

2. Clean with a damp cloth.

Battery Simulator 1200 Installation Manual Bloomy Energy Systems 14

Table of contents