7

Contents

Introduction ..................................................2

Features ...................................................2

Included accessories .......................................2

Safety information ............................................3

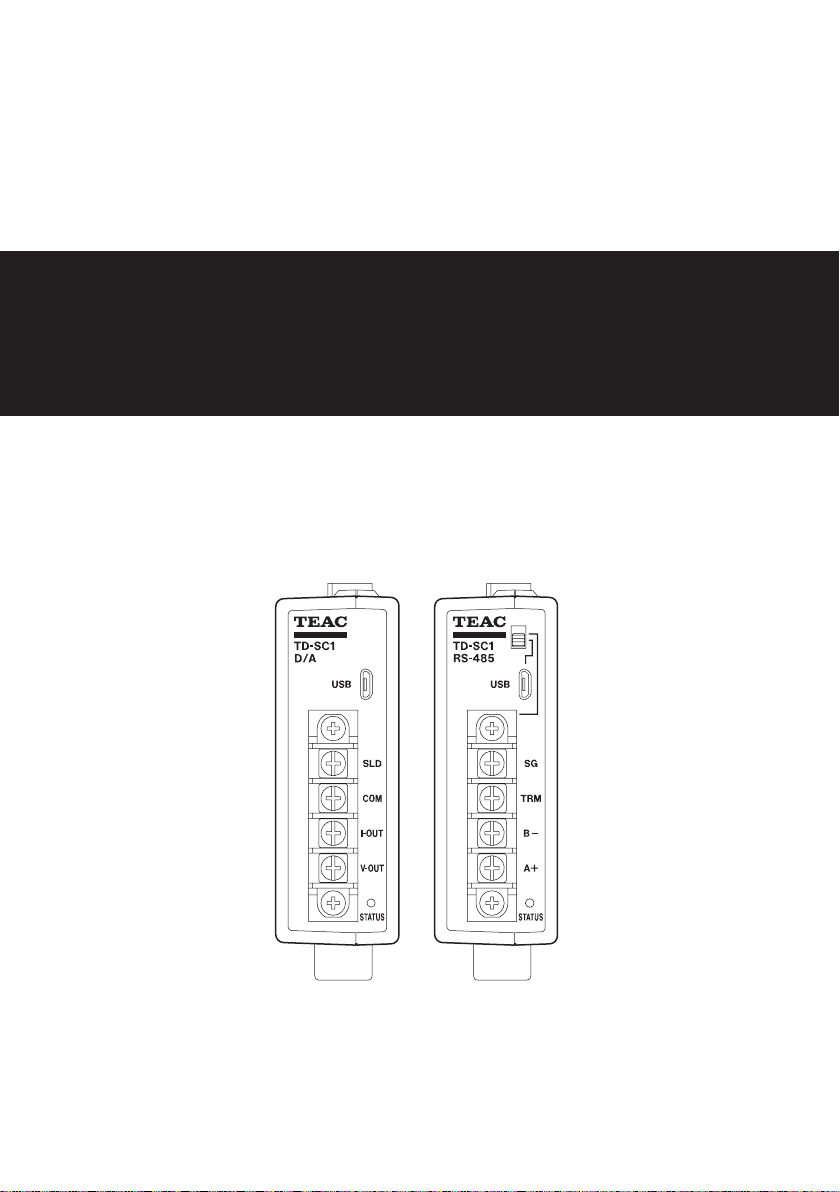

1. Names and functions of parts...............................9

1-1. Front...................................................9

1-2.Top .................................................. 10

1-3. Bottom .............................................. 10

2. Installation ............................................... 11

2-1. Attaching to a DIN rail................................ 11

2-2. Removing from a DIN rail............................. 11

3. Making connections ...................................... 12

3-1. Connecting to the input/output connector .......... 12

3-1-1. Input/output connector ........................ 12

3-2. Connecting a strain gauge transducer................ 12

3-2-1. About the remote sense function............... 12

3-2-2.Notes about bridge voltage (excitation voltage)...12

3-3. Control input and output terminals .................. 14

3-3-1. Control input terminals......................... 14

3-3-2. Connecting control input terminals............. 14

3-3-3. Comparison output terminals .................. 15

3-4. Connecting the DC power supply input terminals .... 15

4. Control app .............................................. 16

4-1. App availability ...................................... 16

5. USB ...................................................... 17

5-1. Connections ......................................... 17

5-1-1. USB port ....................................... 17

5-1-2.When using a TD-SC1 (485) ..................... 17

5-2. Commands .......................................... 17

6. RS-485.................................................... 18

6-1. RS-485 overview ..................................... 18

6-2. Connections ......................................... 18

6-2-1. RS-485 terminals ............................... 18

6-2-2. Inserting and removing RS-485 terminal bank .. 18

6-2-3. Connecting the RS-485 terminals ............... 18

6-2-4. Selecting RS-485 transmission .................. 18

6-3. RS-485 transmission settings ......................... 19

6-4.Transmission protocols (TD Format/TD Format (BCC)). 20

6-4-1. Commands..................................... 20

6-4-2. Responses...................................... 21

6-5.Transmission commands ............................. 22

6-5-1. Polling (0001)................................... 22

6-5-2. Status Polling (0002)............................ 23

6-5-3. Indicator Value Polling (0003) ................... 24

6-5-4.Setting value writing/execution command format ..24

6-5-5. Setting value loading command format ........ 25

6-5-6.TEDS command format......................... 25

6-5-7. Continuous transmission format................ 26

6-5-8. Real-time value/hold value format .............. 26

Status .......................................... 26

6-6. Commands .......................................... 27

6-6-1. Execution ...................................... 27

6-6-2. Polling ......................................... 27

6-6-3. Calibration ..................................... 27

6-6-4. Condition settings.............................. 28

6-6-5. Comparison settings ........................... 29

6-6-6. Hold function settings.......................... 30

6-6-7. System settings ................................ 30

6-6-8.TEDS ........................................... 32

7. D/A converter ............................................ 33

7-1. D/A output terminals ................................ 33

7-2. D/A Zero............................................. 33

7-3. D/A Full Scale ........................................ 34

7-4. D/A Output Mode ................................... 34

7-5. D/A Maximum Voltage ............................... 34

8. Calibration. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

8-1. Procedures shared by all calibration methods ........ 36

8-1-1. Locking and unlocking calibration values ....... 36

8-1-2. Remote Sense .................................. 36

8-2. Equivalent input calibration .......................... 37

8-2-1. Bridge Voltage.................................. 37

8-2-2. Decimal Point Position.......................... 37

8-2-3. Rated Output Value............................. 37

8-2-4. Rated Capacity Value ........................... 37

8-2-5. Zero Balancing ................................. 37

8-2-6. D/A Output Mode .............................. 38

8-2-7. D/A Maximum Voltage ......................... 38

8-2-8. Calibration Value Lock .......................... 38

8-3. Actual load calibration ............................... 38

8-3-1. Bridge Voltage.................................. 39

8-3-2. Decimal Point Position.......................... 39

8-3-3. Zero Balancing ................................. 39

8-3-4. Rated Capacity Value (load calibration).......... 39

8-3-5. D/A Output Mode .............................. 39

8-3-6. D/A Maximum Voltage ......................... 39

8-3-7. D/A Full Scale .................................. 39

8-3-8. Maximum Display Value ........................ 39

8-3-9. Calibration Value Lock .......................... 39