Model 408 NO Calibration Source Manual Rev. D-3

vii

SAFETY INFORMATION

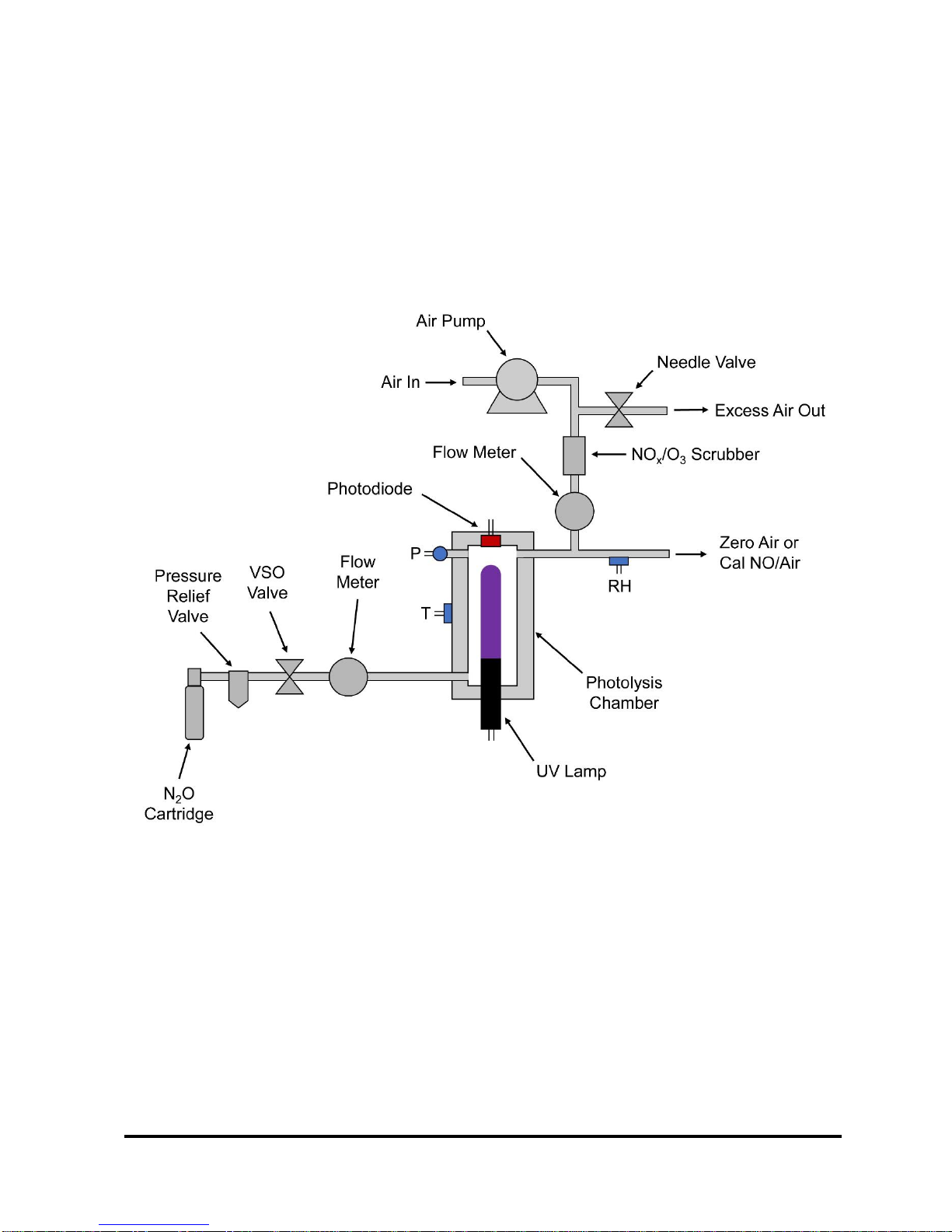

WARNING: This device produces toxic gas. The toxic gas produced is nitric oxide

(NO) dilute in air. The purpose of the Nitric Oxide Calibration Source is to produce

known concentrations of NO/Air in the range 20-1000 parts per billion by volume

(ppb). Nitric oxide is a toxic gas and should be handled with caution. The same kind

of care should be taken in handling the output of the Nitric Oxide Calibration Source

as for NO dispensed from a compressed gas cylinder. Under normal operating

conditions, the instrument will produce nitric oxide in air at concentrations up to ~2

parts per million by volume (ppm); however, an instrument failure could result in small

volumes of air containing NO at higher concentrations. The NIOSH exposure limit for

nitric oxide is 25 ppm (8-hour time-weighted average).

The output of the NO Calibration Source also contains approximately 3% nitrous oxide

(N2O). The nitrous oxide is supplied by a cartridge containing liquid N2O having a

vapor pressure inside the cartridge of 58.5 bar at 20°C. These cartridges are the

same or similar to ones sold as a consumer product for producing whipped cream.

Nitrous oxide or “laughing gas” is also used as a general anesthetic at concentrations

up to 50% and is thus well tolerated by humans. There are no known toxicological

effects of N2O other than asphyxiation at extremely highly concentrations due to

exclusion of oxygen. N2O is not itself combustible, but it strongly supports combustion

of organic materials and reducing agents. Contact with liquid N2O can cause frost bite

due to cooling as the liquid rapidly evaporates.

N2O Cartridge and Regulator Warnings:

•Do not exceed the minimum or maximum temperature listed on the N2O

cartridges.

•Store N2O cartridges out of the reach of children.

•Do not use N2O cartridges for any purposes not described in this manual.

•Never use excessive force to remove or install N2O cartridges. Contact 2B

Tech if you are having trouble installing or removing cartridges.

•Whenever there is a pressurized N2O cartridge in the regulator assembly, keep

the instrument level and do not invert the N2O cartridge.

•Do not make any modifications or repairs to the pressure regulator assembly

yourself.

•Never use the pressure regulator assembly if dropped or damaged (e.g.,

cracked or dented). If the pressure regulator is dropped or damaged, it should

be returned to 2B Tech for a safety inspection.

The Material Safety Data Sheet (MSDS) for N2O may be found here:

https://www.airgas.com/msds/001042.pdf

The MSDS for NO may be found here:

https://www.airgas.com/msds/001039.pdf

USE ONLY SUPPLIED AC/DC ADAPTER