Reduces installation time signicantly • No hot-work precautions • Installation while at sea

• Quick installation (45 sec. per penetration) from

above requiring only a cordless drill driver

• No welding certificate or hot-work precautions

required

• Can be installed by one man alone

• Can be installed at a late stage of the building process

NO MORE WELDING!

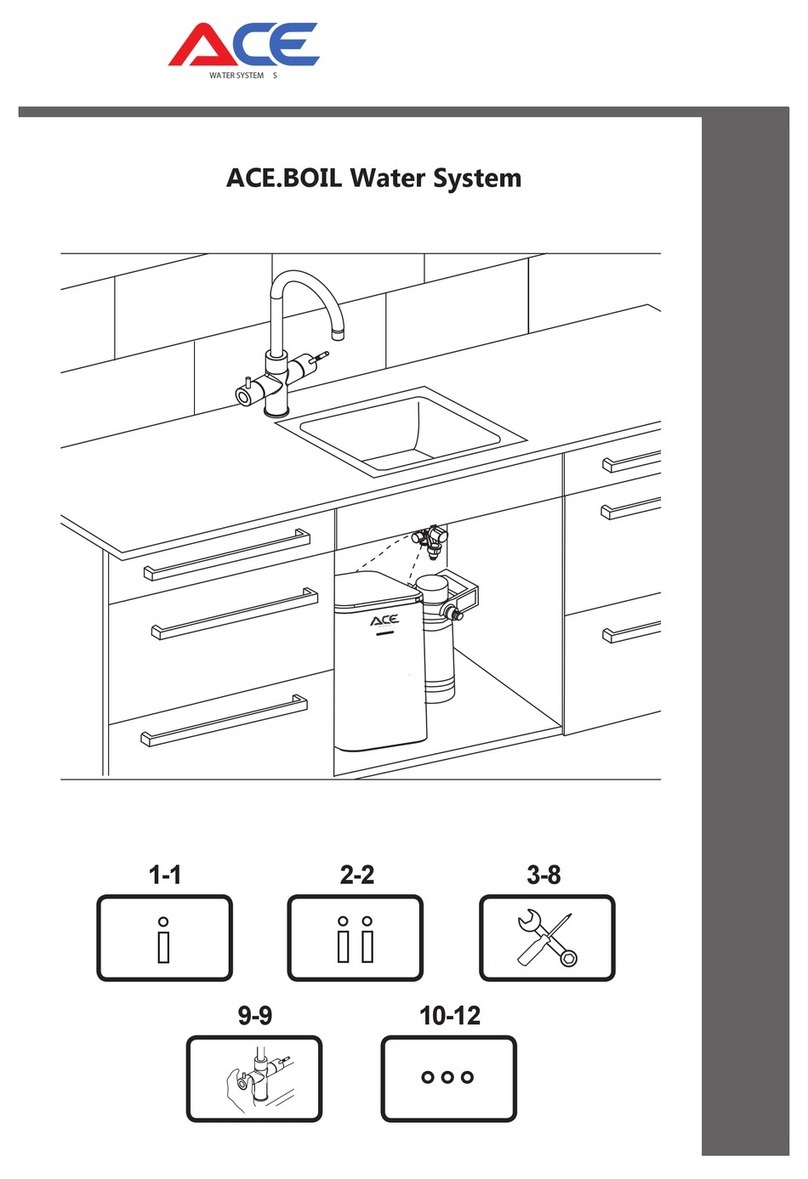

BLÜCHER has developed an entirely new solution for installing flanged drains

and penetrations in steel structures by means of a patent-applied screw-lock

system.

Installation of a penetration in just 45 seconds!

How it works

Drains and penetrations come with a special screw-lock system with sealing

ring for each fixing point and a sealing ring for the entire drain/penetration.

Installation can be carried out from above using an electric drill/screwdriver

and/or a torque wrench, tightening all fixings to 35 Nm.

Range

Flanged lower parts types 470 and 475

Flanged single-pipe penetration type 868, sizes 50, 75 and 110 mm

Flanged jointing unit with group penetration type 490.

Material

Stainless steel - AISI 316L

Testing

Vibration test: According to IACS E10: Rev. 5. Dec. 2005

Tightness test: According to DNV Guideline: STANDARDS FOR CERTIFI-

CATION No. 2.9 Type Approval Programme 8-471.19-1

Fire testing: According to FTP Code A.754(18) Fire resistance tests for “A”

class constructions, fire classes A0, A30, A60 - certificate MED-B-7599

Drains and penetrations with flange for installation without welding

• For repair/ret

• For decks 4,5 - 10 mm thickness

• Water- and gastight solution (up to 1 bar water or

0,1 bar gas)

• Fire-rated A0-A60 (bulkhead A0-A30)