Blue Demon BLUEARC 200STI AC/DC User manual

1

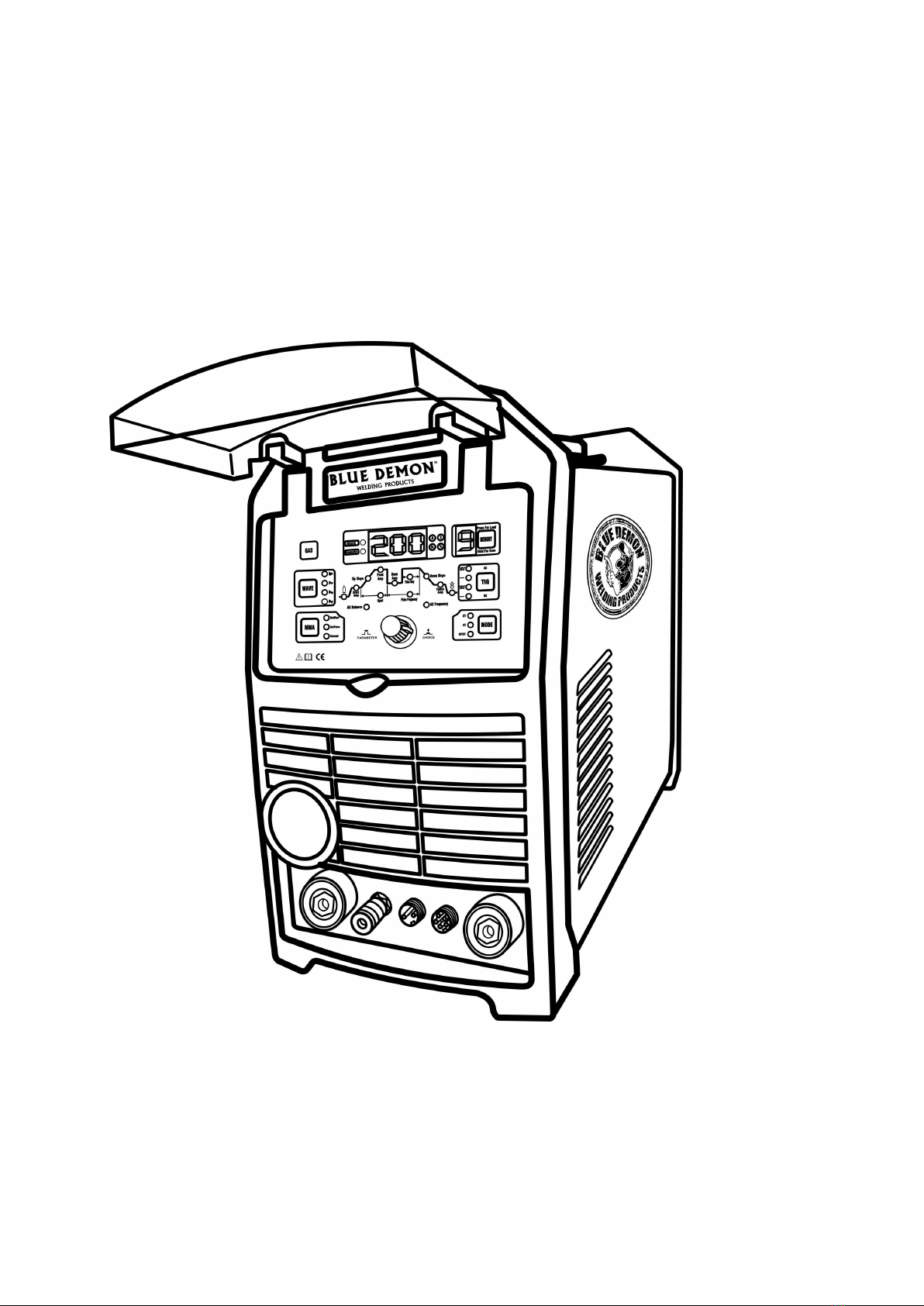

BLUEARC 200STI AC/DC

OWNERS MANUAL

(Plastic Panel)

MCU AC/DC PULSE TIG/MMA WELDING MACHINE

2

WARNING! Please read these instructions before installing and

commissioning the device.

1. GENERAL COMMENTS

Start-up and operation of the device can only be made after carefully reading this

Operator's Manual

Damage to the device due to improper handling will result in the loss of warranty

rights.

It is forbidden to modify devices and interfere in its construction.

ATTENTION

Welding may endanger the safety of the operator and other persons in the vicinity.

Therefore, special precautions should be taken during welding. Before welding, read

the occupational health and safety regulations in force at the workplace.

During electric welding with MMA and TIG methods, there are the following hazards:

• ELECTRIC SHOCK

• NEGATIVE EFFECT OF ARC LIGHT ON EYES AND SKIN

• POISON AND GAS DAMAGE

• BURNS

• NOISE

Prevention of electric shock:

connect the device to a technically efficient electrical installation with proper

protection

assemble current wires with the device switched off,

do not use handles and power cables with damaged insulation,

in conditions of particular danger of electric shock (work in environments with

high humidity and closed tanks) work with a helper supporting the work of the

welder and watching over safety, use clothing and gloves with good insulating

properties

if you notice any irregularities, you should ask competent people to remove

them,

It is forbidden to operate the device with covers removed.

Prevention of the negative impact of the electric arc on the eyes and human

skin:

• Wear protective clothing (gloves, apron, leather shoes),

• Use shields or protective shields with a properly selected filter,

3

• Use protective covers made of non-combustible materials and properly choose

the color of the walls that absorb harmful radiation.

Prevention of poisoning by vapors and gases emitted during welding from

electrode lagging and metal evaporation:

use ventilation devices at work stations

blow with fresh air when working in a confined space

Prevention of burns:

Use appropriate protective clothing and footwear to protect against burns from

arc radiation and spatter

Avoid soiling the clothes with lubricants and oils that may lead to ignition of the

clothing.

Prevention of negative impact of noise:

Use earplugs or other noise protection measures,

Warn of the dangers of nearby people.

Before starting the device:

Check the condition of electrical and mechanical connections. It is forbidden to

use handles and power cables with damaged insulation. Improper insulation

of holders and power cords may result in electric shock,

Ensure proper working conditions, ensure the right temperature, humidity and

ventilation in the workplace. Outside of enclosed spaces, protect against

atmospheric precipitation,

Persons operating the welder should:

have the power to weld electric electrodes with coated electrodes and the TIG

method,

know and follow the health and safety regulations applicable when carrying out

welding work,

use appropriate, specialist protective equipment: gloves, apron, rubber boots,

shield or welding helmet with a properly selected filter,

be familiar with the contents of these operating instructions and operate the

welder for its intended purpose

Any repairs to the device may only be made after disconnecting the plug from the mains

socket. When the device is connected to the power it is not allowed to touch any elements

constituting the welding current circuit with bare hands or through damp clothing. It is

forbidden to remove the external covers when the device is connected to the power.

Maintenance and repair work may only be carried out by authorized persons subject to the

safety and operating conditions applicable to electrical equipment.

4

2. GENERAL DESCRIPTION

The welding machine is used for manual welding by direct current and alternating

structural steels with coated electrodes (MMA method), as well as quality steels and

non-ferrous metals in the inert gas shield (TIG method). In the design and

construction of the device the latest developments in the field of PWM technology

(pulse width modulation) and IGBT modules (bipolar transistors with an insulated

gate) were used, thanks to which the welder is characterized by small size and low

weight.

The ARC FORCE function is available during MMA welding. During TIG welding it is

possible to regulate the rise and fall of current, pre-outflow and gas outflow as well as

pulse and AC current parameters. The device has a memory of 10 sets of parameter

settings for the TIG HF and MMA methods.

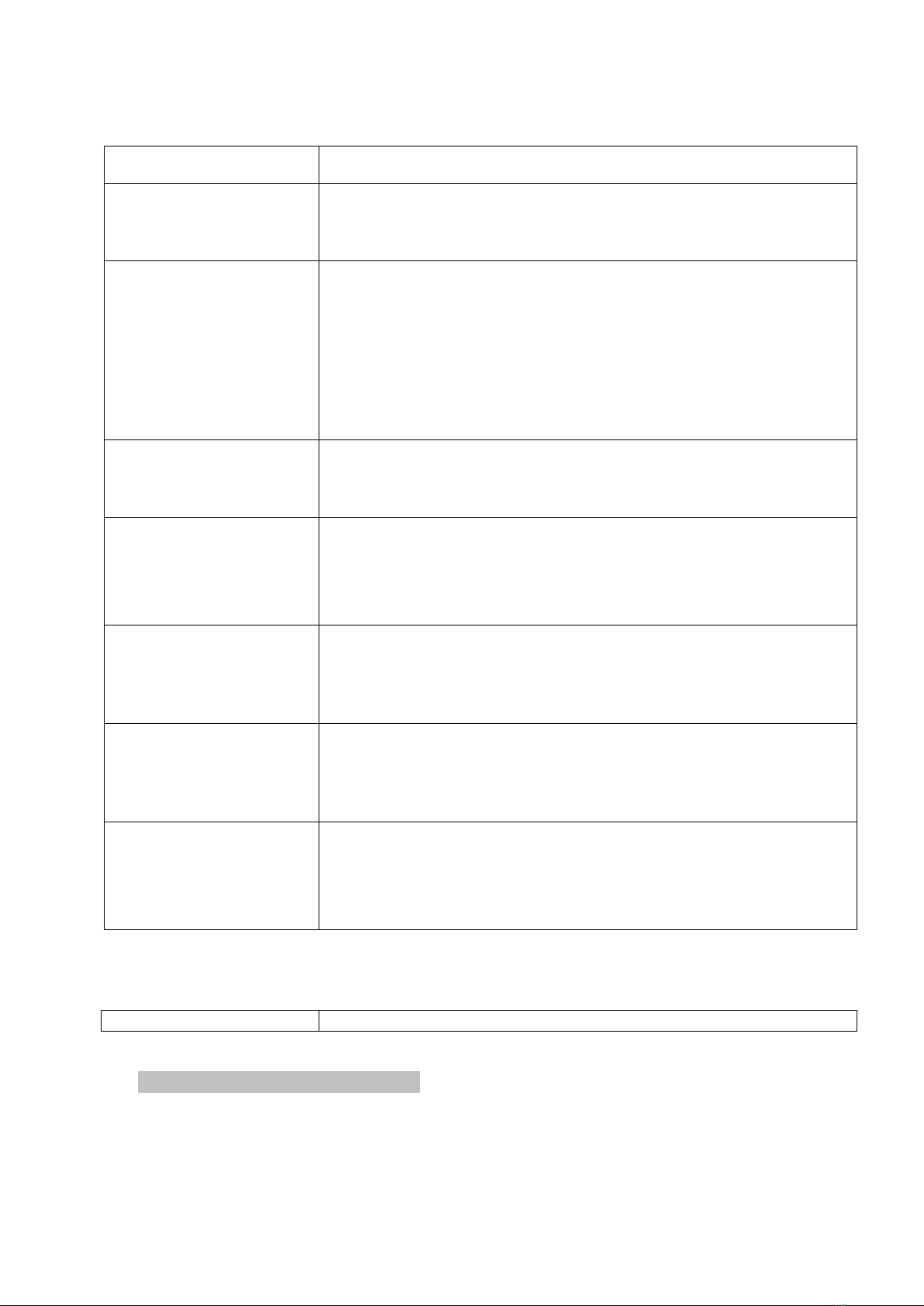

3. TECHNICAL PARAMETERS

3.1Machine

Model

BLUEARC 200STI AC/DC

Power supply voltage

AC 230V ±10% 50Hz/60Hz

AC 110V ±10% 50Hz/60Hz

Max. Power consumption

MMA: 5,7 KVA, TIG: 4,1 KVA

MMA: 4,0 KVA, TIG: 3,1 KVA

Welding current / work cycle

MMA: 180 A / 60%

TIG: 200 A / 60%

MMA: 120 A / 60%

TIG: 140 A / 60%

No-load voltage

67 V

67 V

Power consumption

MMA: 24,0 A, TIG 19,0 A

MMA: 50,0 A, TIG 37,0 A

Weight

17 kg

Dimension

510 x 210 x 380 mm

Protection Class

IP23

3.2 Parameters adjustment ranges

Model

BLUEARC 200STI AC/DC

Power supply voltage

AC 230V ±10% 50Hz/60Hz

AC 110V ±10% 50Hz/60Hz

Arc Force

0 – 100 A

0 – 100 A

Pre gas flow time

0,1 – 15 s

0,1 – 15 s

Post gas flow time

0,1 – 15 s

0,1 – 15 s

Up slope time

0 – 15 s

0 – 15 s

Down slope time

0 – 15 s

0 – 15 s

Start current

5 – 200 A

5 – 140 A

Current

MMA: 20-180 A TIG:5-200 A

MMA: 20-120 A TIG:5-140 A

Base Current

5 – 200 A

5 – 140 A

Stop current

5 – 200 A

5 – 140 A

Pulse frequency

0,5 - 999 Hz

0,5 - 999 Hz

Pulse Duty

10 – 90 %

10 – 90 %

AC Frequency

1 – 250 Hz

1 – 250 Hz

AC Balance width

15 – 50 %

15 – 50 %

Spot time

0,1 – 15 s

0,1 – 15 s

5

Level of security

IP determines to what extent the device is resistant to solid and water contamination.

IP23 means that the device is designed to work indoors and is not suitable for use in

the rain.

(Plastic Panel)

4. CONSTRUCTION AND OPERATION

The basis for the construction of the welding power conversion system are electronic

circuits made in IGBT technology that enable operation in the frequency range above

50kHz. The principle of operation consists in straightening the single-phase voltage

of the power supply network to DC voltage, converting the obtained direct voltage

into a high-frequency rectangular waveform, transforming the voltage into the range

required by the welding process and re-straightening the received voltage to DC

voltage.

The welder is equipped with a power supply compensation circuit, which allows them

to be operated at voltage fluctuations in the supply network up to 10%.

6

5. PREPARATION OF THE DEVICE FOR WORK

If the device is stored or transported in low temperatures, the device should be

brought to the right temperature before starting work !!!

5.1MMA Method

The ends of the welding cables should be connected to the sockets (1) and (5)

on the front panel, so that the polarity of the electrode is on the electrode holder.

The polarity of the welding cable connection depends on the type of electrode

used and is given on the electrode packaging. The ground cable clamp must be

securely attached to the welded material. Connect the device's plug to a 110V or

230V 50Hz/60Hz mains socket.

5.2Tig Method

The tig torch should be connected to the negative polarity socket (1), carefully screw the

control plug of the holder to the socket (3) and the gas connection to the quick connector

socket (2). The gas pipe from the reducer should be led and attached to the gas

connector (9) located on the back of the housing. Connect the positive pole of the source

(5) to the material to be welded with a wire with a earth clamp. Connect the device's plug

to a 110V or 230V 50Hz/60Hz mains socket.

7

6. DESCRIPTION OF OPERATION

Front and rear panel

(1) Tig torch handle control socket (2) gas connector

(3) Negative polarization socket (4) remote socket (5) positive polarization socket

(6) switch on/off (7) ground terminal (8) supply power wire (9) spigot shield gas

6.1 CONTROL PANEL

B A I H G F

C D E

8

A –Gas check button

The button is used to check if the Gas is having or not. Press the button, Gas will output; release the

button Gas will close.

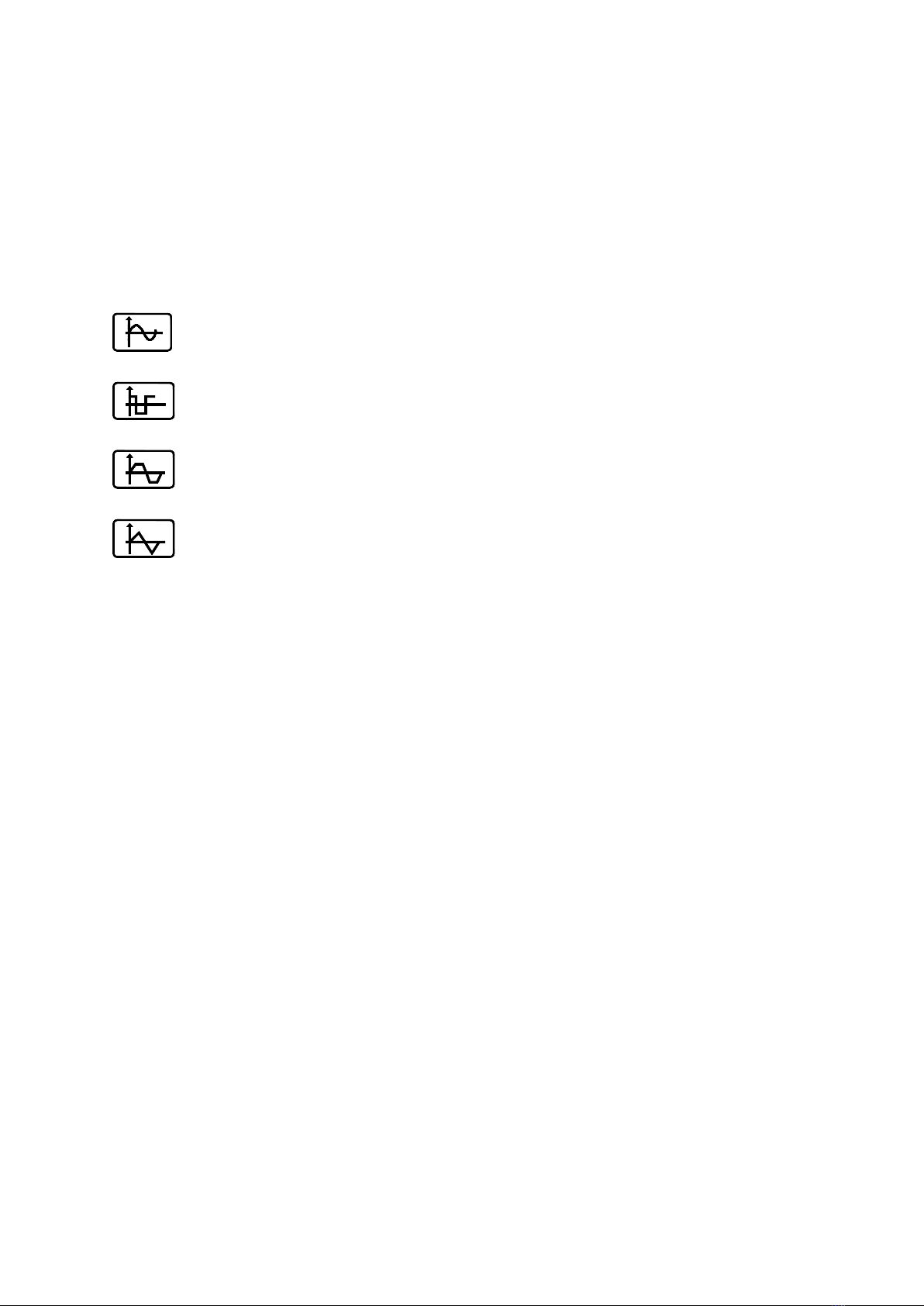

B – AC Wave Selection (Note: This action is working for TIG AC working mode only.)

- sine wave, typical wave

- rectangular wave – the most popular wave

- trapezoidal wave – soft arc

- triangular wave - used for thin materials

C – MMA mode Selection

The button is used to select the MMA welding parameters, Arc Force, Hot Start and welding Current.

D – Control knob

The adjustment knob is used to change the welding parameters.

Short push of the knob causes a transition between the set parameters. The currently adjustable

parameter is marked by ignition of the corresponding diode, and the current parameter value appears

on the parameter display (I). Turning the knob to the left decreases and turning to the right increases

the value of the parameter. Pressing the knob again will save the parameter value and move to the

next parameter.

E – Work selection button (2T/4T/SPOT)

(Note: 2T/ 4T/SPOT action is working for TIG working mode only.)

In the two-stroke mode, pressing the switch in the grip handle will activate the ionizer and ignite the

arc. Welding is carried out with the switch pressed. Releasing the switch will end welding. In the four-

stroke mode, pressing the switch in the grip handle will activate the ionizer and ignite the arc, then

release the switch and conduct the welding with the released switch. Pressing the switch again will

end welding.

In the SPOT mode, the welding time is limited by the settled time, and the other is same as in the two-

stroke mode.

9

F – TIG mode Selection

The button is used to select the TIG welding work mode, AC with pulse and AC without pulse, DC

with pulse and DC without pulse.

G – Settings memory

The device has the memory of the last setting, i.e. after it has been turned off and on again, the last

set parameters are restored. The user can save a total of 20 settings. 10 for each TIG and MMA

method. To recall a previously saved set of settings, press the button (G) until the appropriate set

number appears on the memory display (H).

To memorize the current settings, press and hold the button (G) for 2 seconds, the number on the

display (H) will be pulsing. Turning the knob (D) change set number. If you push again during

10s to save actually adjusted setting. If you not push (G) button again, you back to main menu.

If the device is switched off, when a set of parameters is loaded in the memory, after switching on

again, the last used set will be automatically loaded and its number will appear on the display. If no

parameter set is loaded in the memory and the device is switched off, after re-enabling, the last used

parameters will be restored and a dash will appear on the display (H).

H – Display of the parameter set memory

The display shows the number of the parameter set that has been loaded or where the current set will

be saved.

I – Welding parameters display

The display shows the parameters during their setting and during welding. The lighting of the

corresponding LED on the side of the display indicates the parameter unit.

Overheating protection - the power source is equipped with a thermal, automatic overload

switch. When the temperature of the welding machine is too high, the protection will disconnect the

welding current, the Alarm LED will light and the error code "E00" will appear on the display. After the

temperature has dropped, the breaker will be automatically reset.

A LED indicating that the device is in remote control mode. The LED will light up

automatically after connecting the remote-control plug to the socket.

6.2. PARAMETER SETTING

6.2.1 MMA method

In the MMA method, it is possible to adjust the welding current, the Hot Start, and the ARC FORCE

function. While adjusting the welding current, the diode lights up, and the Hot Start and ARC FORCE

function can be adjusted after the diode is lit.

HOT START & ARC FORCE - allows you to adjust the dynamics of the welding arc. The shortening of

the arc length is accompanied by an increase in the welding current, which results in stabilization of

the arc. Decreasing the value gives a soft curve and a smaller depth of penetration, while increasing

the value causes deeper penetration and the possibility of short arc welding. When the large value of

10

the ARC FORCE function is set, you can weld while maintaining an arc with a minimum length and

high melting rate of the electrode. The adjustment range: 0 ~ 100A

6.2.2 TIG method

Select welding TIG using the welding mode selection button (F). Select current (DC) or alternating

current (AC), enables or disables the pulse. Press the (B) button to select the waveform.

Set the welding parameters:

PRE-FLOW ( )- time from pressing the button in the grip handle and opening the gas valve

until the arc is ignited. Usually should be more than 0,5s.

Adjustment range: 0,1 ~ 15s

START CURRENT (Start Amp) - the current appearing in the circuit after pressing the button in the

grip handle. The higher the initial current, the easier it is to ignite the arc.

Adjustment range: 5 ~ Max Current

TIME OF CURRENT INCREASE (Up Slope) - welding current rise time from the initial current to the

set welding current value.

Adjustment range: 0 ~ 15s

WELDING CURRENT (Peak Amp) – main welding current

Adjustment range: 5 ~ Max Current

TIME OF SPOT WELDING (SPOT) – spot welding time

Adjustment range: 0,1 ~ 15s

PULSE WIDTH (pulse duty) - duration of the impulse, allows you to adjust the depth of the penetration.

The increase in width increases the depth of penetration, the reduction reduces the amount of heat

entering the material, reducing the risk of burning thinner sheets or smaller elements

Adjustment range: 10 ~ 90%

PULSE FREQUENCY - the frequency with which the value of the current pulse between the welding

current and the base current changes.

Adjustment range: 0,5 ~ 999Hz / suggest at 200Hz

BASE CURRENT (Base Amp) -the current responsible for maintaining the welding process, the lower

value of the current pulse. It makes it easier to control the amount of heat entering the material.

The base current adjustment is only possible during pulse welding

Adjustment range: 5 ~ Max Current

AC FREQUENCY -the function is useful when welding aluminum. The higher the frequency,

the better the weld quality and the better the arc focus

11

Adjustment range: 1 ~ 250 Hz/ suggest at 60Hz

AC BALANCE - The ratio of the duration of the positive to negative phase. The reduction of the

balance results in the introduction of more heat into the material, resulting in a narrower weld and

deeper penetration, and at the same time reduces the heat load of the tungsten electrode. Increasing

the balance results in the introduction of less heat into the material, resulting in better cleaning, a

broad joint and a shallower penetration, however, it significantly weighs the tungsten electrode.

Adjustment range: 15 ~ 50% / suggest 28%

TIME OF CURRENT DESCENT – (Down Slope) - time of transition current from main (current) to final

(I stop)

Adjustment range: 0 ~ 15s

FINAL CURRENT (Finish Amp) - current to fill the crater

Adjustment range: 5 ~ Max Current

POST GAS ( ) - time from quenching the arc to closing the gas valve to cover the solidifying weld

pool from the air and to cool the tungsten electrode. Too short time of outflow may result in oxidation

of the weld,

Adjustment range: 0,1 ~ 15s

7. WELDING

Welding with a coated electrode (MMA)

-Select the MMA method using the welding method selection button. In this mode it is possible to

adjust the welding current and adjust the ARC FORCE function. Adjusting the welding current is

possible directly after switching on the power supply. Turning the control knob will change the welding

current.

- Arc initiation when welding a coated electrode involves touching the electrode to the welded material,

short rubbing and detachment. In the case of arc initiation with electrodes, which after coating forms a

non-conductive slag, it is necessary to pre-clean the tip of the electrode by repeated impact against a

hard surface until metallic contact with the welded material.

Welding in shielded gas (TIG method) - The device is equipped with an ionizer that allows

contactless arc ignition. To ignite the arc in 2T mode, the electrode should be brought closer to the

welded material for a distance of 2 millimeters and press the button in the torch holder to activate the

ionizer. After correct arc initiation, carry out the welding with the button pressed. Releasing the button

on the handle causes the start of the current dropping phase and the end of the welding process. In

order to ignite the arc in 4T mode, the electrode should be brought closer to the material to a distance

of 2 millimeters and press the button on the torch handle to activate the ionizer. After correct arc

ignition, the button can be released and the welding can be carried out with the button released. To

stop welding, press and release the button on the handle again.

Welding in shielded gas (TIG LIFT) - To start the arc in the two-stroke mode, press the button in the

grip handle to activate the gas flow. touch the welding material with the electrode, shortly rub and tear

off. After correct arc initiation, carry out the welding with the button pressed. Releasing the button on

the handle causes the start of the current dropping phase and the end of the welding process.

To start the arc in the four-stroke mode, press the button in the grip handle to activate the gas flow.

touch the welding material with the electrode, shortly rub and tear off. After correct arc ignition, the

12

button can be released and the welding can be carried out with the button released. To stop welding,

press and release the button on the handle again.

Welding in 2T mode - TIG

0:Press and hold the handle button. The outflow of protective gas begins;

0~t1:Pre flow

t1~t2 : Arc ignition, welding current increases from the minimum value to the set welding current

value. If the pulsator is on, the current is modulated.

t2~t3:During welding, the handle button should remain pressed;

Note: If the pulsator is on, the welding current flashes, if the pulsator is turned off, the welding

current has a constant value.

t3:Release the torch button, the welding current begins to drop. If the pulsator is on, the falling

current is modulated;

t3~t4:Welding current falls to the minimum value, the arc is extinguished;

t4~t5:Post gas

t5:The solenoid valve closes the gas flow, completing welding.

Welding in 4T mode - TIG

0: Press and hold the handle button. The outflow of protective gas begins;

0~t1:pre flow

13

t1:Ignition of the arc, the starting current is set;

t2:Release the handle button, the current begins to rise to the set welding current value. If the

pulsator is on, the current is modulated

t2~t3: up slope

t3~t4:welding process

t4:Press the handle button. The welding current begins to drop to the value of the crater

current

t4~t5: down slope

t5~t6:end current

t6:Release the handle button. The arc is extinguished, shielding gas flows out;

t7:The solenoid valve closes the gas flow, completing welding.

Welding in SPOT mode - TIG

0:Press and hold the handle button. The outflow of protective gas begins;

0~t1:Pre flow

t1~t2 : Arc ignition, welding current increases from the minimum value to the set welding current

value,and the spot welding starts now. If the pulsator is on, the current is modulated.

t2~t3:During welding, the handle button should remain pressed;

Note: If the pulsator is on, the welding current flashes, if the pulsator is turned off, the welding

current has a constant value.

t3:It is time to finish spot welding , the welding current begins to drop. If the pulsator is on, the

falling current is modulated;

t3~t4:Welding current falls to the minimum value, the arc is extinguished;

t4~t5:Post gas

t5:The solenoid valve closes the gas flow, release the button, completing welding.

8. PROBLEM AND SOLUTION

In case of malfunction of the device, before sending the welder to the service, check the list of basic

failures and try to remove them yourself. Any repairs to the device may only be made after

disconnecting the plug from the mains socket.

14

SYMPTOMS

FIND SOLUTION

The control panel does not

light up, the fan does not

work, no output voltage

1. Make sure that the switch is in the ON position

2. Check the protection and voltage in the network

3. Remove the housing and check the connection of all electrical plugs

inside the device

The control panel is on, the

fan is not working, no output

voltage.

1. Check whether the device has been connected to a higher voltage

network. If so, connect to the 230V grid and turn it on again

2. The power supply voltage is unstable and causes the overvoltage

protection to be activated. Switch the device off for 2-3 minutes and switch it

on again

3. The short-term switching on and off of the switch has triggered the

overvoltage protection. Switch the device off for 2-3 minutes and switch it on

again

4. There was another damage requiring repair by an authorized service

center

The control panel is on, the

fan is running, problems with

arc ignition

Check the TIG torch, replace the consumables if they are worn

The control panel is on, the

fan is running, problems with

arc ignition

1. Check the terminals and the correct electrical conductivity of the electrode

and ground wires

2. Check the connection of the TIG torch to the device, make sure that the

pins in the socket are not broken or jammed.

3. Unscrew the handle of the TIG torch and check that the switch in the

holder is working

The control panel is on, the

fan is working, the O.C diode

is on. "E00" message on the

display

The device has been overheated. Wait a few minutes. After the diode goes

out, continue welding.

Unsatisfactory weld quality

during MMA welding, the

electrode is bonded to the

material being welded

1. Check the polarity of the welding cable connections

2. Check that the electrode is not wet. Replace the electrode.

3. The welder is powered from a generator set or a long extension with too

small a cable cross section. Connect the device directly to the mains

Unsatisfactory weld quality

for TIG welding

1. Replace consumable parts. Change the tungsten electrode or gas cylinder

with higher quality materials

2. Check that shielding gas flows with the appropriate intensity

3. Check the gas supply hose, improve the hose and couplings connection

and the condition of quick couplers

4. Check reducer.

List of error codes:

E00

Overheating of the device or incorrect welding current parameters

9. OPERATING INSTRUCTIONS

Operation of the device should take place in an atmosphere free from corrosive ingredients and high

levels of dust. Do not place the device in dusty places, near grinders, etc. Dust and contamination with

metal filings of control boards, wires and connections inside the device can lead to an electrical short

circuit and consequent damage to the welder.

15

Avoid operation in environments with high humidity, in particular in situations of dew on metal

elements.

In the case of dew on metal elements, for example, after entering a cool device into a warm room, wait

until the dew disappears. It is recommended that when the machine is used outdoors, it should be

placed under the roof in order to protect it from adverse weather conditions.

10. MAINTENANCE INSTRUCTIONS

As part of everyday service, keep the welder clean, check the condition of external connections and

the condition of wires and electric cables.

Replace consumable parts regularly.

Periodically clean the device inside by blowing with compressed air to remove dust and metallic filings

from the control plates as well as wires and electrical connections.

At least once every six months a general review and condition of electrical connections should be

made, in particular:

- protection against electric shock

- insulation condition

- security system status

- correct operation of the cooling system

11.STORAGE AND TRANSPORT INSTRUCTIONS

The device should be stored at -10 ° C to + 40 ° C and relative humidity up to 80% free from corrosive

fumes and dust. The transport of packaged devices should take place in covered transport means.

During transport, the packed device should be secured against shifting and ensure their proper

position.

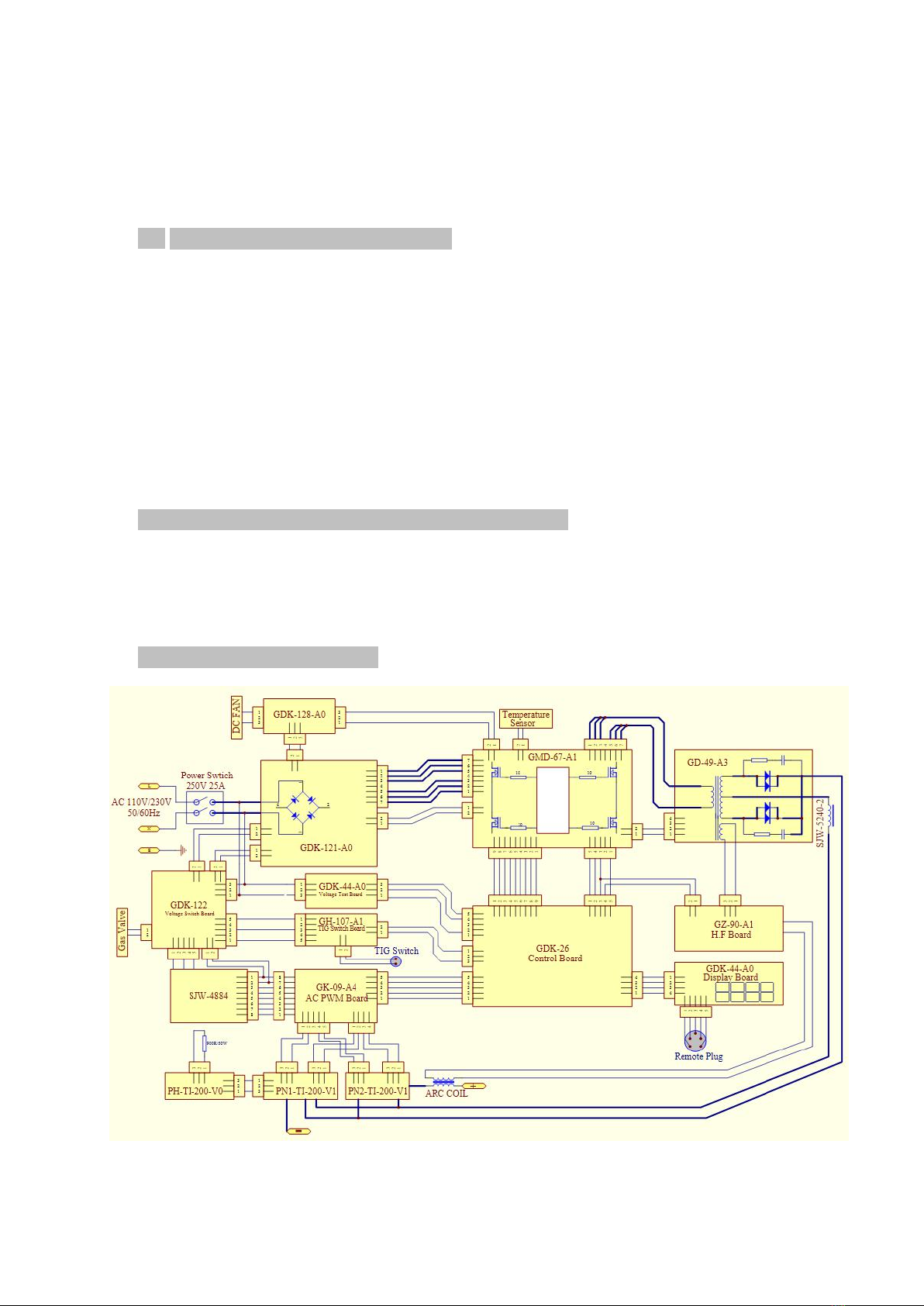

12.ELECTICAL DIAGRAM

16

IGBT Equipment Warranty

Welding Material Sales

Effective Jan 1, 2019

Limited Warranty

This warranty applies to the original purchaser and is subject to the terms and conditions

listed below.

This Limited Warranty is for new equipment sold after the above date, providing coverage for

defects in material and workmanship at the time it is shipped from the factory.

Limited to the warranty periods listed below, Welding Material Sales will repair or replace the

item under warranty that fails due to defects in material and workmanship. Welding Material

Sales, Inc. must be notified within 30 days of the failure, so as to provide instructions on how

to proceed with the repair of your welder and warranty claim processing. Warranty period

begins at the time the welder is purchased from an authorized Welding Material Sales, Inc.

distributor and/or retailer. Proof of purchase will be required for Welding Material Sales to

proceed with any and all warranty claims, no exceptions.

Warranty Periods

Limited Warranty is divided into two categories: No warranty and 1 year.

No Warranty

Normal wear items including but not limited to MIG gun parts (contact tips, nozzle, adapter,

liner), TIG torch parts (collet, cup, back cap, torch body) drive roll, contactor, and electrode

holder are not covered under warranty.

1 Year

Solenoid valve, PC board, controls, gas valve, drive motor, and drive system. Parts and labor

performed by authorized repair center with original equipment repair parts. Call 888-905-

6737 for a repair center near you.

Table of contents

Other Blue Demon Welding System manuals