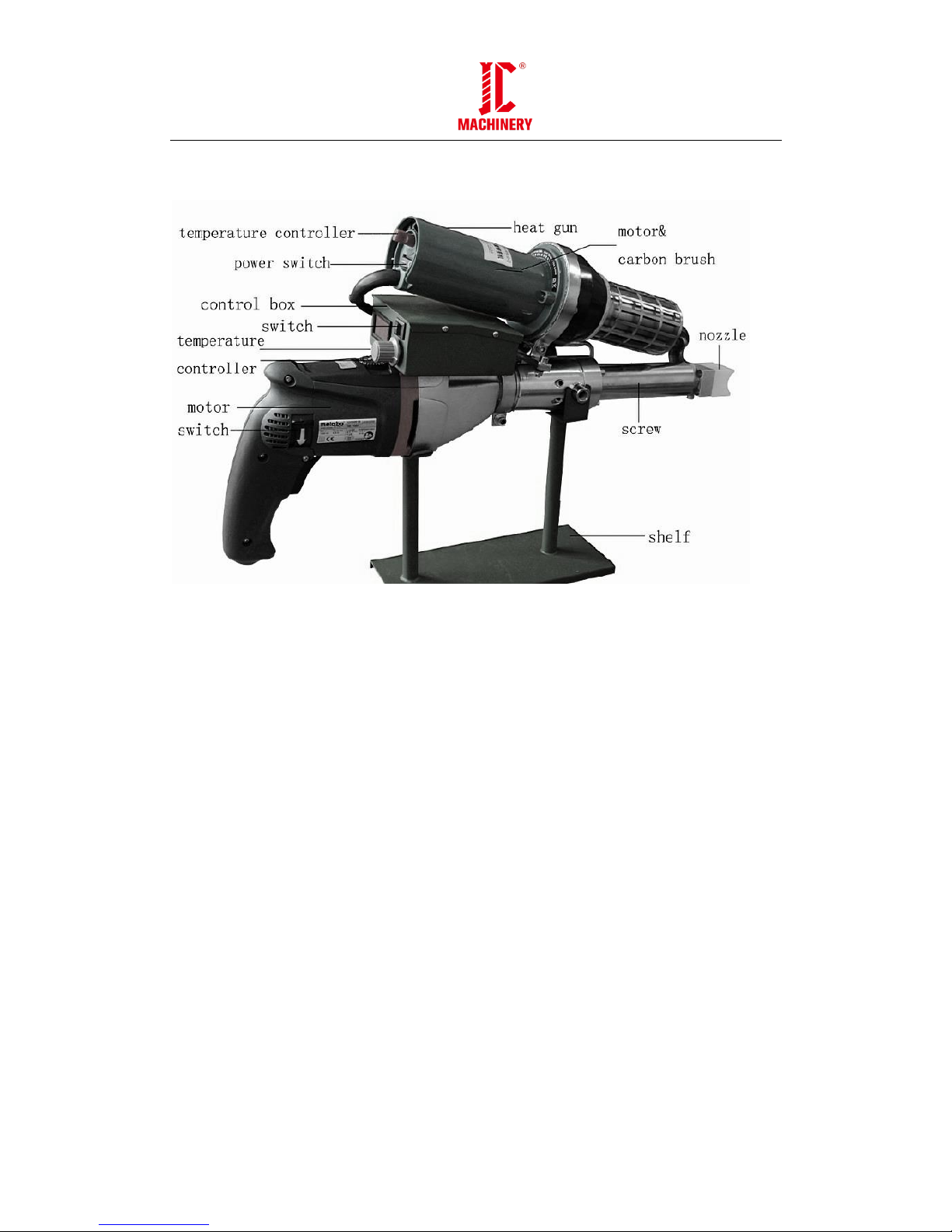

i. Product Overview

Extruding plastic gun is a new type of hot air welder which is imported foreign

advanced technology, well-developed. The major components (hot air gun and

drive motor) are made of imported brand-name accessories, stable performance,

long service life; They are two independent systems, one is for preheating raw

material, another is for welding rod extrusion. Reasonable structure, convenient

operation, continuous welding, high working efficiency, powerful extrusion, to

make the weld strength is greatly improved. It is the ideal product for a variety

of thermoplastic welding processing.

This product is with two major components, preheating raw material’s hot air

part and welding rod’s extrusion part. Hot air part with adjustable temperature

controller to heat automatically, and extrusion part with independent

thermostatic heating control system to send hot air independently, It is easy to

adjust extrusion speed and use screw extruding for powerful extrusion pressure.

Using power supply uniformly to weld plastic sheets, tube and other

thermoplastic products, especially for both ends of large diameter hollow wall

pipe, producing pipe and repairing pipe and so on.

Available welding materials: thermoplastic HDPE, PP, PVDF, especially PE .Do not

apply in a conductive plastic (PE-EL), or cause the machine to produce a

conductive short-circuit.

Replacement of the different welding nozzle, can be applied:

1) Plastic container’s welding, stitching, etc.;

2) The large diameter plastic pipe’s pipe welding, repairing, splicing, sealing, etc.;

3) The thicker plastic membranes, geomembrane splicing, patching and so on.