Blue Giant BGL-22 User manual

OPERATOR’S MANUAL

BGL-22 WALKIE COUNTERBALANCED

STACKER

WARNING

Do not operate or service this product unless you have read and fully

understand the entire contents of this manual. Failure to do so may result in

property damage, bodily injury or death.

ISSUE DATE:MAY 5, 2020 REV.0 (PART # 038-926EO)

1

FOREWORD

As a lift truck operator, you are

responsible for a machine that is use-

ful, powerful, and can be hazardous if

not operated as described. Your

Blue Giant truck may weigh more than

some cars, depending on the

model. Observing and practicing

the safety warnings in this manual

cannot be overemphasized. Just

knowing the warnings, however, is

no substitute for common sense.

Using your common sense will, in

almost all cases, prevent accidents.

Think of the truck as your own. In

this way you will learn its

capabilities and limitations.

This manual is intended to remain

with the truck at all times as a handy

reference guide to operation. Detailed

maintenance procedures are found in

the parts and service manual for the

specific truck model, and are to be

performed only by a qualified techni-

cian. For further information on

obtaining a complete parts and ser-

vice manual, see page 21 of this man-

ual.

The operator who knows his truck will

learn to spot problems as they

develop. This is accomplished by per-

forming the Daily Checks and report-

ing any problems to the designated

authority.

TABLE OF CONTENTS

SAFETY SYMBOLS ..............................................................................................2

GENERAL DESCRIPTION ....................................................................................2

NAME PLATE AND WARNING DECAL................................................................2

LOAD CAPACITY ..................................................................................................4

BEFORE OPERATION ..........................................................................................5

Optional Features....................................................................................8

INSTRUMENTS AND CONTROLS .......................................................................7

Optional Features....................................................................................8

OPERATION ..........................................................................................................9

Forward and Reverse Travel and Speed Control..................................9

Steering ....................................................................................................9

Stopping.................................................................................................10

Parking ...................................................................................................10

Battery Charging ...................................................................................11

Load Handling .......................................................................................11

Moving a Disabled Truck ......................................................................11

NOTICE - OBTAINING A PARTS AND SERVICE MANUAL ..............................21

2

SAFETY SYMBOLS

WARNING and CAUTIONS are both signal words intended to alert the viewer to

the existence and relative degree of a hazard. They are both preceded by a safety

alert symbol consisting of an exclamation mark enclosed by a triangle.

A Warning indicates a hazard which could result in injury or death if proper pre-

cautions are not taken.

A Caution indicates a reminder of routine safety practices.

A prohibition slash (circle with diagonal slash through it) indicates a procedure or

action that should not be performed under any circumstances, as both personal

injury and/or damage to equipment will result.

GENERAL DESCRIPTION

Blue Giant Pallet trucks lift and

transport loads on rigid forks.

Control for steering, braking, forward

and reverse travel, horn, lift, lower and

speed control are all located on the

control handle.

Trucks in this series may vary in load

capacity, battery arrangement, and

instrumentation, depending on model

and options.

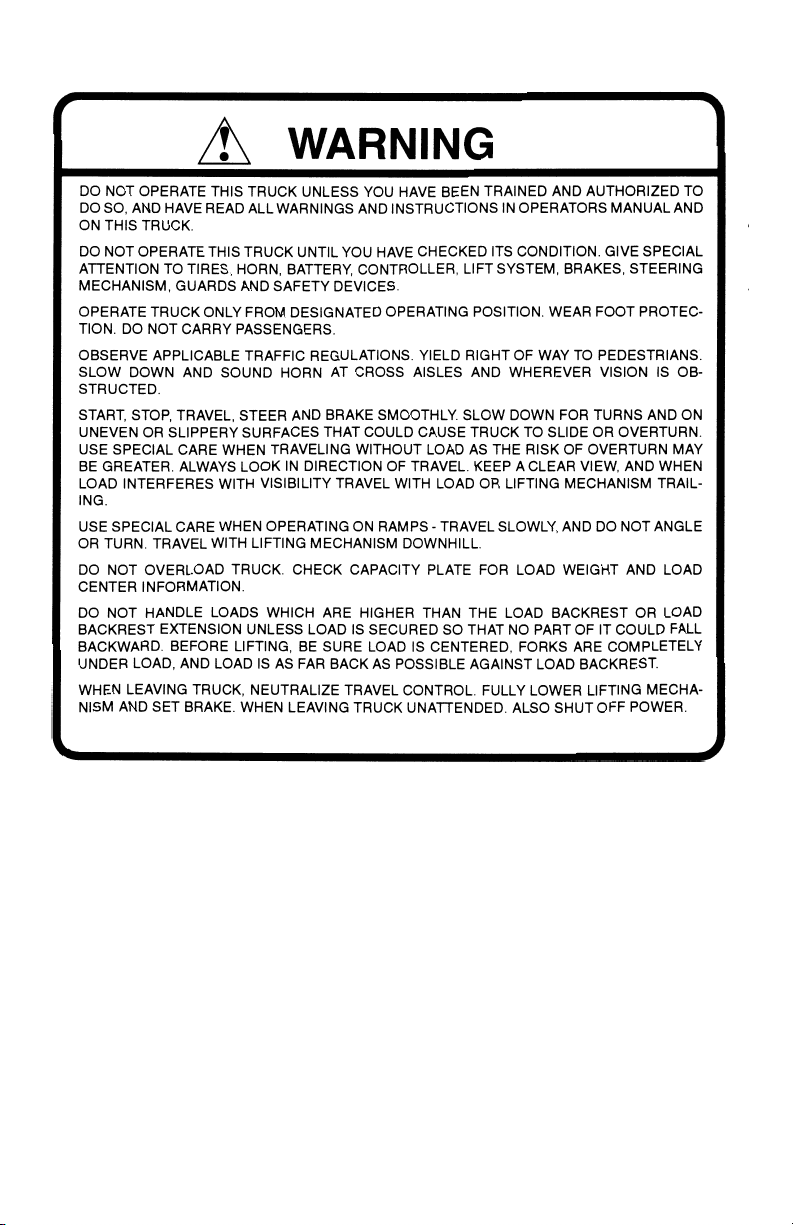

NAME PLATE AND WARNING DECAL

Name plate and warning decal loca-

tions may vary between models, but

they are always near the steering arm

within sight of the operator.

If the name plate or warning deal are

lost or damaged they should be

replaced immediately. Have your

supervisor or the designated authority

contact Blue Giant Authorized Dealer

for replacement.

The name plate shows the model

number; serial number; truck type;

battery type, voltage and minimum

weight. It also contains information on

the load capacity and load center. The

warning decal contains warnings

which also appear, with illustrations, in

the Operating Precautions section of

this manual.

3

Name Plate and Warning Decal Locations - Typical

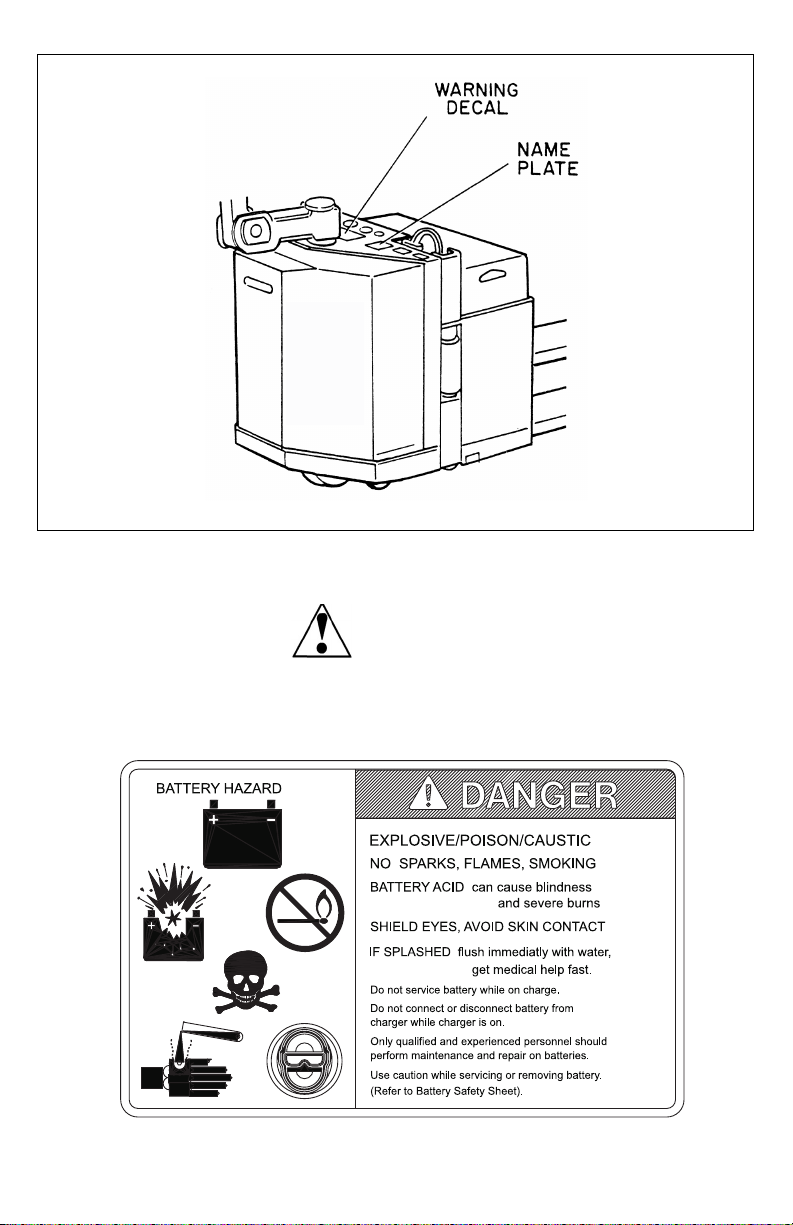

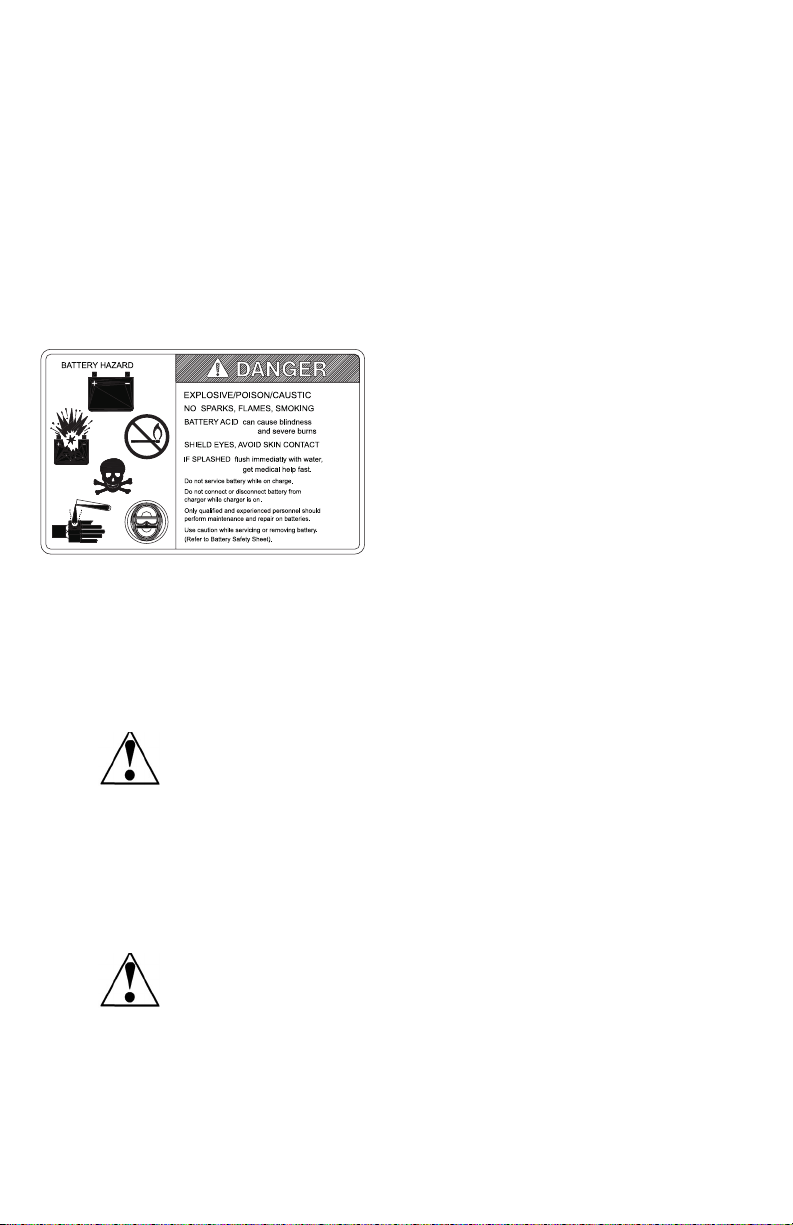

This truck is equipped with a battery. Read and heed the warning decal located

near the battery. An example is shown here:

WARNING:

R4906

4

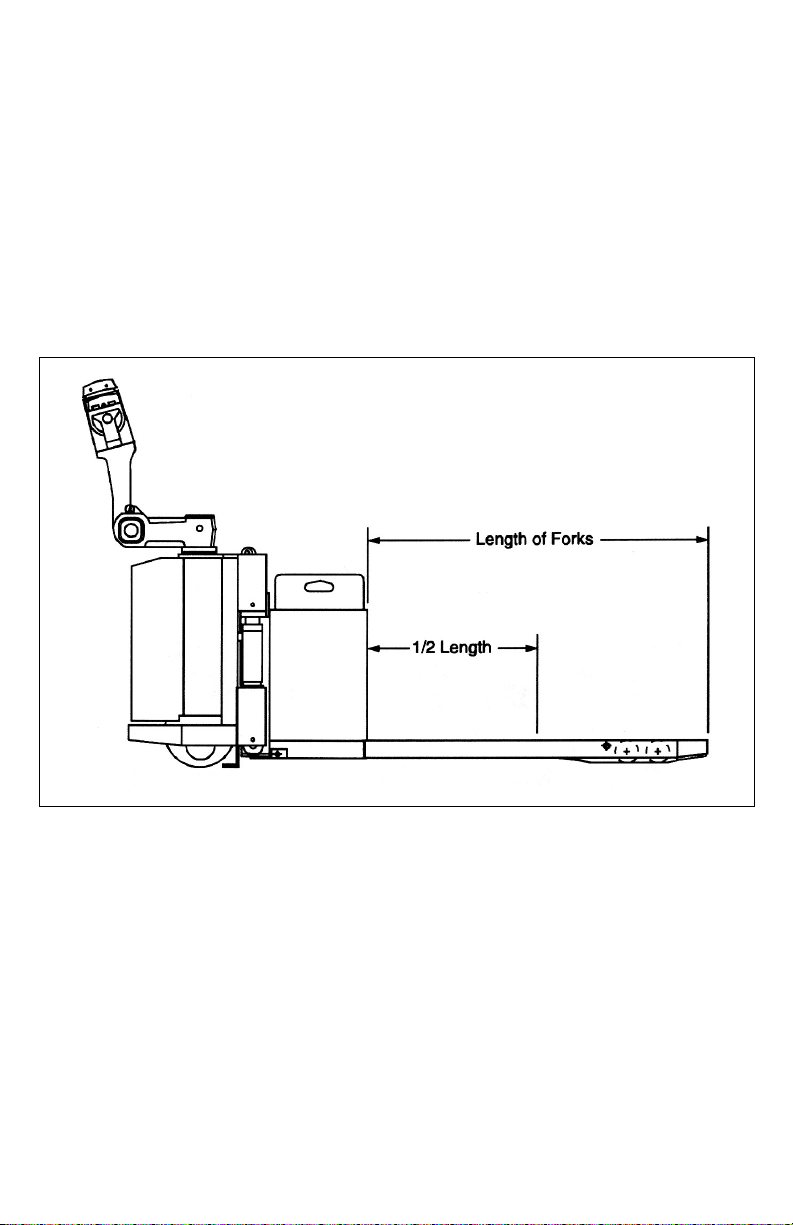

LOAD CAPACITY

Do not overload truck. Check capacity

plate for load weight and load center

information.

The load capacity depends on the

load center. The load maximum

capacity listed on the capacity plate

assumes a uniform load whose center

is at 1/2 the length of the fork and cen-

tered between the forks. The maxi-

mum load capacity is reduced when

the load center exceeds 1/2 the length

of the forks or is not centered between

the forks. The fork length and wheel-

base must be adequate for the skid or

bin to be handled.

Note that a truck undergoing speed

changes is less stable than a standing

truck. If you are not sure that the truck

can lift a certain load, consult your

supervisor or the designated authority.

Load Center

R5060

5

BEFORE OPERATION

The table on page 6 covers important

inspection points on trucks which

should be checked prior to operation.

Depending on use, some trucks may

require additional checks.

The illustration below shows a sample

format for a Operator Checklist, which

can be modified as necessary to fit

your operation.

Periodic maintenance of this

truck by a QUALIFIED TECH-

NICIAN is required.

A QUALIFIED SERVICE

TECHNICIAN should check the

truck monthly for proper lubrica-

tion, proper fluid levels, brake

maintenance, motor mainte-

nance and other areas speci-

fied in the parts and service

manual maintenance section.

If the truck is found to be unsafe

and in need of repair, or con-

tributes to an unsafe condition,

report it immediately to the des-

ignated authority. Do not oper-

ate it until it has been restored

to a safe operating condition.

Do not make any unauthorized

repairs or adjustments. All ser-

vice must be performed by a

qualified maintenance techni-

cian.

Sample of Operator Check List

WARNING:

WARNING:

WARNING:

R6235

6

Operator Checks

ITEM PROCEDURE

Transmission and hydraulic

systems

Check for signs of fluid leakage.

Forks Check for cracks and damage.

Guards and load backrest Check that safety guards are properly secured

and not damaged.

Safety signs Check that warning labels, nameplate, etc.,

are in good condition and legible.

Horn Check that horn sounds when operated.

Steering Check for binding or looseness in steering

arm when steering.

Travel controls Check that speed controls on control handle

operate in all speed ranges in forward and

reverse and that belly button switch functions.

Wheels Check drive wheel for cracks or damage.

Move truck to check load wheels for freedom

of rotation.

Hydraulic controls Check operation of lift and lower, and tilt to

their maximum positions.

Brakes Check that brakes actuate when steering arm

is raised to upright position, and when lowered

to horizontal position.

Deadman/Parking brake Check that steering arm raises to upright posi-

tion when released and brake applies.

Battery disconnect Check that battery can be disconnected and

reconnected. Check for connector damage.

High speed limit switch Allow for enough space to operate truck in

high speed. Disengage third speed using the

high speed cut-out switch, then test drive truck

to check if high speed is cut out.

7

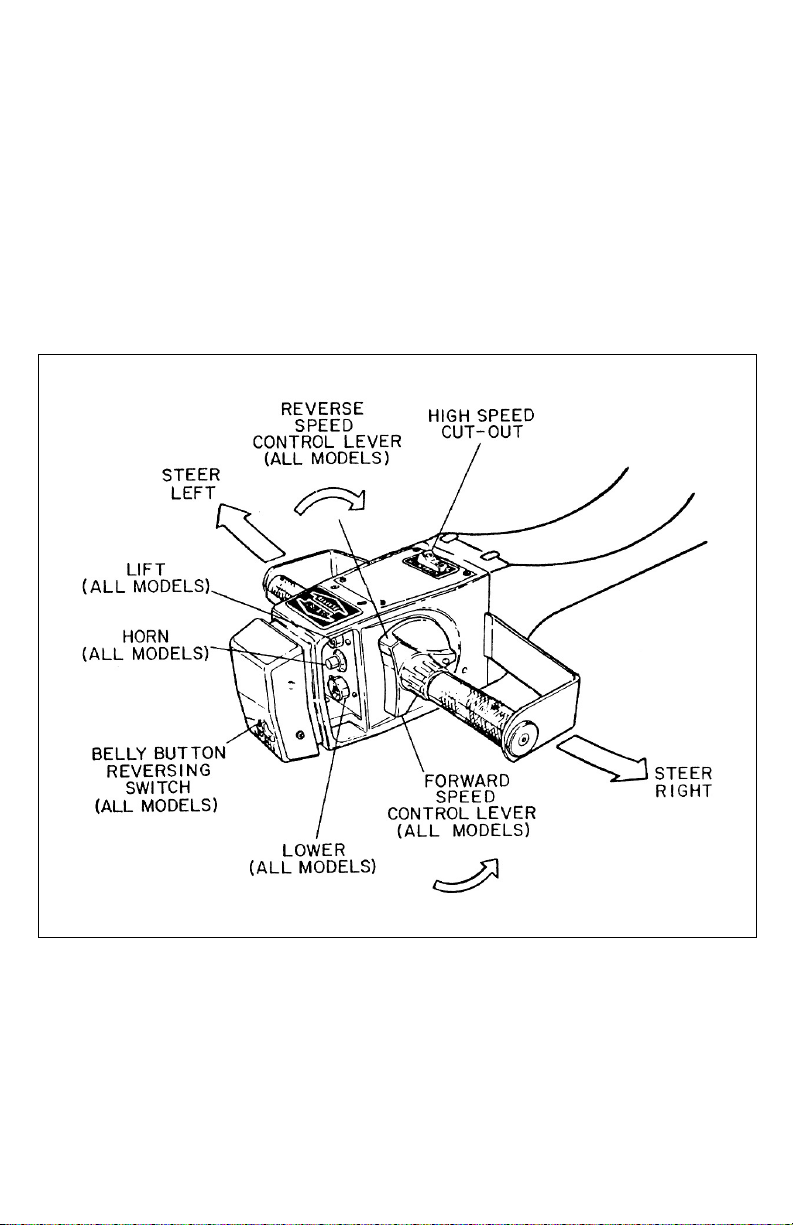

INSTRUMENTS AND CONTROLS

The steering arm and control handle

provide controls for steering, forward

and reverse speed control, braking,

raising and lowering the forks, and

horn. Control handles on some mod-

els have the high speed cut-out

switch. Control handles on all models

have a “belly-button” reversing switch

which reverses the direction of the

truck upon contact with the operator.

Detailed operating instructions are in

the Operation section of this manual.

A battery disconnect is mounted near

the steering arm. Pulling the discon-

nect removes all power from truck cir-

cuits in the event of an emergency.

Control Handle

R4070

8

Walkie/Rider Pallet Trucks have a

grab handle which also contains lift,

lower and horn controls.

Optional Features

The optional battery capacity indica-

tor, hour meter and keyswitch mount

on the panel near the control handle.

The battery capacity indicator moni-

tors the battery discharge rate to indi-

cate the remaining battery capacity.

The hour meter records the accumu-

lated hours that electrical energy is

being drawn from the battery to run

the pump and drive motors. The key-

switch provides added security to the

truck, preventing unauthorized per-

sonnel from operating the machine.

Grab Handle

R4907

9

OPERATION

Forward and Reverse Travel and

Speed Control

Control Handle

All directional and speed controls are

located on the control handle.

Forward and reverse are controlled by

rotating the speed control lever as

shown. The lever is spring loaded to

return to neutral when released. Fur-

ther rotation in either direction will

progress the truck from slow to maxi-

mum travel speed.

To change directions or to stop the

truck, rotate the speed control lever in

the opposite direction. The truck will

come to a stop and then, unless the

controls are returned to the center

neutral position, accelerate in the

opposite direction.

Steering

Moving the control handle (which con-

nects to the steering arm) right or left

will turn the truck right or left. When

maneuvering around corners, make

square turns and be sure there is

adequate clearance.

R4070

10

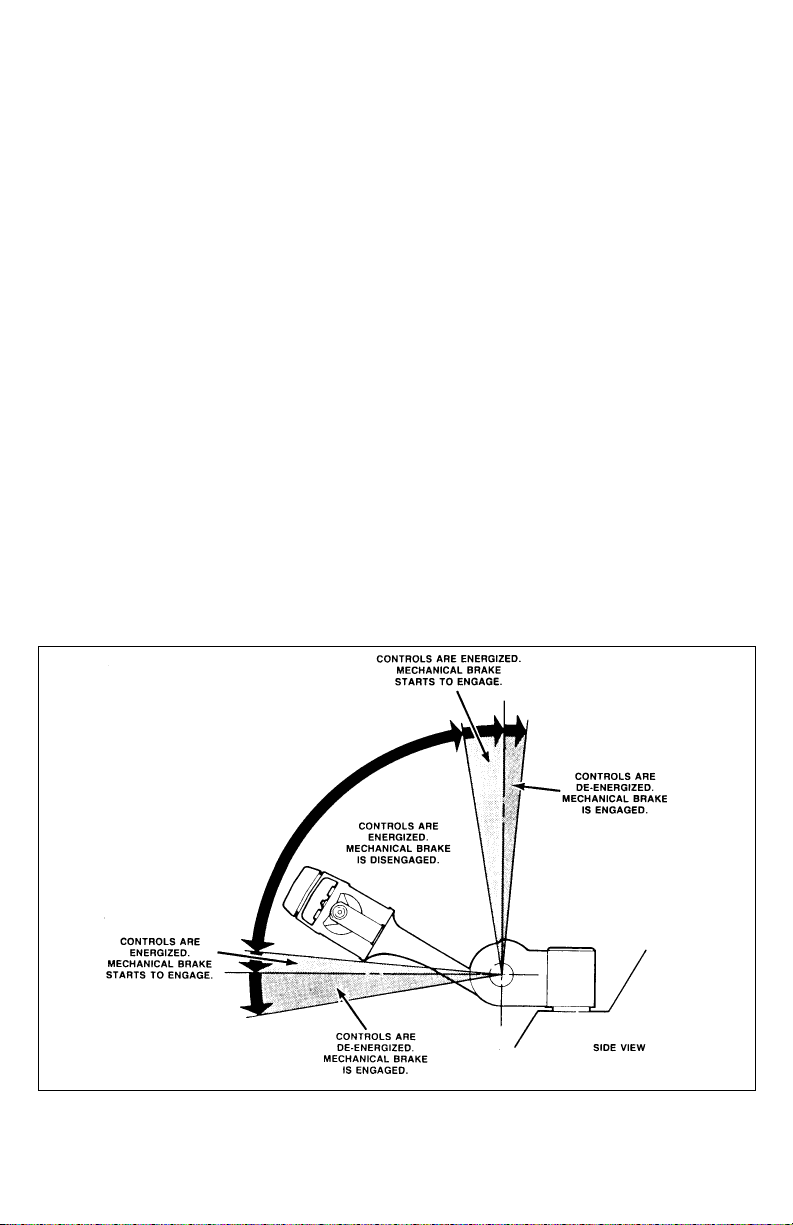

Stopping

Stop the truck as gradually as possi-

ble. Unnecessary rapid stopping could

be hazardous. Load could become

unstable.

There are four possible ways to stop

the truck:

1. Plugging: This electrical braking

function consists of rotating the

speed control lever in the oppo-

site direction of travel and then

releasing it when the truck stops.

Plugging is a convenient way to

stop the truck during normal

operation. If the control is not

released, the truck will accelerate

in the opposite direction.

2. Steering arm in horizontal

position: Lowering the steering

arm to the horizontal position

applies brake pad pressure to the

brake disc. Lowering the steering

arm below the horizontal position

increases the braking force and

de-energizes the controls.

3. Steering arm in vertical posi-

tion: Raising the steering arm to

near vertical position applies

brake pad pressure to the brake

disc. Further vertical positioning

increases the braking force and

de-energizes the controls. This

position services as a parking

brake. As a safety precaution, the

steering arm is spring loaded to

return to the vertical position in

the event the driver releases the

control handle during operation.

This is known as deadman brak-

ing.

Parking

When parking the truck, do not

obstruct traffic lanes or aisles.

1. Park the truck in its designated

parking area.

Steering Arm Braking Positions

R3629

11

2. Raise the steering arm until verti-

cal to apply the parking brake.

3. Fully lower forks.

4. Turn keyswitch (if so equipped) to

off position. Remove key for

added security.

5. Pull out battery disconnect.

Battery Charging

Refer to DOC 245 for battery safety

and maintenance.

NOTE: Battery charging instructions

are contained in the service

manual.

Load Handling

Handle only loads arranged for

stability and always use cau-

tion. Raise and lower the load

smoothly to prevent the load

from falling.

Always be sure the load and

load center are within the

capacity of the truck. If in doubt

check the nameplate.

1. Approach the load slowly.

2. Move the truck slowly into posi-

tion so that the forks are centered

about the load.

3. Make sure the load is against the

backrest and then raise the forks

until the pallet clears the rack.

4. Lead the truck by the control han-

dle with the load trailing except

when in confined areas. Ramps

should be traveled with operator

uphill of truck when empty, or

operator downhill of truck with

load on forks.

5. Always look in the direction of

travel. Move slowly and check

clearances when approaching

obstructions.

6. Do not make sudden starts and

stops. Operate truck smoothly

and gradually.

7. Travel slowly and squarely

around corners. Remember that

the trailing load wheels do not fol-

low the turn path of the drive

wheel. Instead they tend to cut

the corner.

8. Line up the truck with the unload-

ing area.

9. Stop the truck and check the load

alignment with surrounding

objects.

10. Be careful not to damage or

move adjacent loads and objects.

11. Lower the forks until the load is

resting on its own.

12. Move the truck back until the

forks are clear of the pallet.

Moving a Disabled Truck

Do not attempt to move a disabled

truck; notify your supervisor or proper

authority.

WARNING:

WARNING:

12

The following operating instructions appear on the truck warning decal, which is

located near the steering arm.

R4071

Do not operate this truck unless you have

been trained and authorized to do so,

and have read and understand all warn-

ings and instructions contained in this

operator’s manual and on this truck.

R4072

Do not operate this truck until

you have checked its condition.

Give special attention to tires,

horn, battery, controller, lift sys-

tems, brakes, steering mecha-

nism, guards and safety

devices. If you have any ques-

tions, notify your supervisor or

proper authority.

13

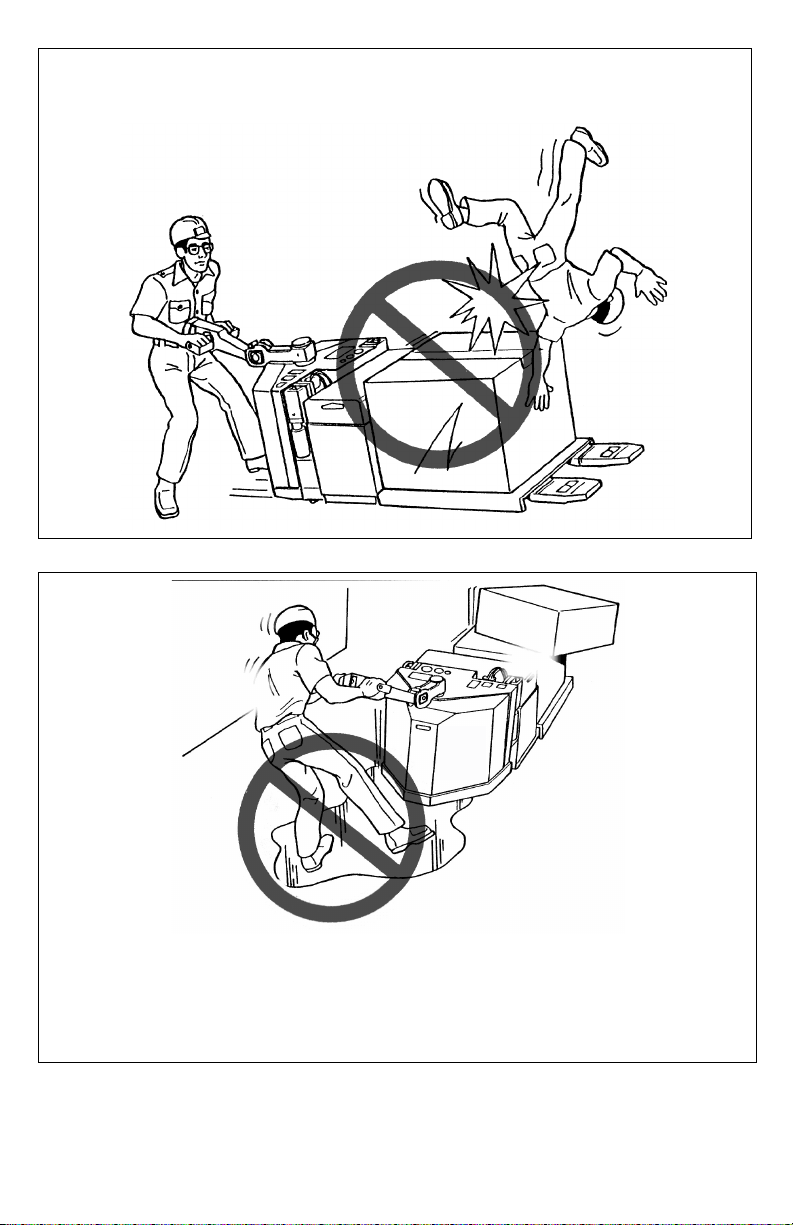

R4073

Walkie Pallet Trucks: Operate

truck only from walking position.

R4905

Walkie/Rider Pallet Trucks:

Keep feet within limits of truck.

14

R4074

Wear foot protection and

keep feet clear of truck.

R4075

Do not carry passengers.

15

R4076

Observe applicable traffic regulations. Yield right-of-way to pedestrians.

Slow down and sound horn at cross aisles and wherever vision is

obstructed.

R4077

Start, stop, travel, steer and brake smoothly. Slow down for turns and on

uneven or slippery surfaces that could cause truck to slide or overturn. Use

special care when traveling without load as the risk of overturn may be

greater.

16

R4078

Always look in direction of travel. Keep a

clear view, and when load interferes with

visibility, travel with load or lifting mecha-

nism trailing (except when climbing

ramps.

R4079

Use special care when operating on ramps; travel slowly, and do not angle

or turn. Travel unloaded with lifting mechanism downhill, and travel loaded

with load uphill.

17

R4081

Do not handle loads which are higher

than load backrest or load backrest

extension unless load is secured so that

no part of it could fall backward.

R4082

Before lifting, be sure load is centered,

forks are completely under load, and

load is as far back as possible against

load backrest.

18

R4904

Keep hands out of lifting mechanism.

R4083

When leaving truck neutralize travel con-

trol. Fully lower lifting mechanism and

set brake. When leaving truck unat-

tended also shut off power.

Other manuals for BGL-22

1

Table of contents

Other Blue Giant Forklift manuals