Blue Ribbon BB4000 User manual

Blue Ribbon Corporation

Instruction Manual

Model BB4000

Station Controller

Blue Ribbon Corp

2770 Long Road

Grand Island, NY 14072

Ph: 716-773-9300

email: [email protected]

Website: www.blueribboncorp.com

DISCLAIMER: No representations or warranties are made with respect to the contents of this Instruction Manual. Blue Ribbon Corp

reserves the right to revise this manual and to make changes periodically to the content thereof, without obligation

to notify any persons of such revisions.

Model 311 Hazardous Approved Installation Manual

Table of Contents

1. IntroductIon . . . . . . . . . . . . . . . . . . . . 1

1.1. Applications. .................................1

1.2. Standard Features. ............................1

1.3. Optional Features..............................1

1.4. Specications. ................................1

1.5. Ordering Information...........................2

2. operator Interface functIons . . . . . . . . . . . 3

2.1. How to View a Setup Parameter Value. ............3

2.2. How to Change a Setup Parameter Value. ..........3

2.3. How to Simulate Levels..........................4

2.4. How to Enter the Security Code. ..................4

3. Menu - systeM setup . . . . . . . . . . . . . . . . 5

4. Menu - data dIsplay. . . . . . . . . . . . . . . . 10

5. puMp call sequence - setup paraMeters . . . . . 12

5.1. Number of Pumps Present - Parameter P.13. .......12

5.2. Number of Pumps Allowed to Run at the Same Time - Parameter P.14.

12

5.3. Number of Pumps Allowed to Run On Generator - Parameter P.15. 12

5.4. Alternator Sequence Mode - Parameter P.16. .......13

6. puMp call sequence - setup paraMeters . . . . . 13

6.1. Pump Stop Mode - Parameter P.17................13

Model 311 Hazardous Approved Installation Manual

6.2. Automatic Alternation - Parameter P.18............14

6.3. Forced Lead Pump Position - Parameter P.39.. . . . . . . 14

6.4. Time Based Alternation - Parameter 5.1. ..........14

7. alternatIon sequence Mode . . . . . . . . . . . 15

7.1. Standard Alternation Parameter P.16-1. .........15

7.2. Pump 1 Always Lead...........................15

7.3. Pump 1 Always Lead...........................16

7.4. Split Alternation Parameter P.16 = 4. ...........16

7.5. Fixed Alternation Parameter P.16 = 5. ...........17

7.6. Stepped On/Off Sequence. .....................17

8. dIscrete Input functIons . . . . . . . . . . . . . 18

8.1. Pump 1 (2, 3, 4) Disable - Functions 1-4. ..........18

8.2. Level Freeze - Function 5. ......................18

8.3. External Alternation - Function 6. ................18

8.4. On Generator - Function 7. .....................19

8.5. All Pump Disable - Function 8. ..................19

8.6. Sequence Input 1 (2, 3, 4) - Functions 9 - 12........19

8.7. Call Pump 1 (2, 3, 4) Last - Functions. .............19

8.8. Low Level Alarm - Function 17. ..................19

8.9. High Level Alarm - Function 18. .................20

8.10. Telemetry E - D - Functions 19 - 30.. . . . . . . . . . . . . . 20

8.11. Normal Pump Operation Disable - Function 31......20

8.12. Float Backup - Lower Level - Function 32. .........20

8.13. Float Backup - Off Level - Function 33. ...........21

8.14. Float Backup - 1st On Level - Function 34. ........21

8.15. Float Backup - 2nd On Level - Function 35. .......21

8.16. Float Backup - 3rd On Level - Function 36.........21

Model 311 Hazardous Approved Installation Manual

8.17. Float Backup - 4th On Level - Function 37. ........21

8.18. Float Backup - High Level - Function 38. .........22

8.19. Start Flush Cycle - Function 39. .................22

9. systeM status . . . . . . . . . . . . . . . . . . . 22

9.1. High Level Alarm. ............................22

9.2. Low Level Alarm. .............................23

9.3. Power Indication..............................23

9.4. Fault Indication...............................23

9.5. Fault Code - Parameter FLC. ....................23

9.6. Last Fault Code - Parameter LFC. ................24

9.7. Fault Code Table. .............................25

10. analog level Input (4-20 Ma Input)- calIbratIon procedure

27

10.1. Level Input Zero - Parameter P.25. ...............27

10.2. Level Input Span - Parameter P.24..............27

10.3. Level Display Span VS. Transducer Calibration. ..28

11. varIable frequency drIve speed control optIon setup

29

11.1. VFD Speed Control - Setup Parameters. ...........29

12. flush cycle . . . . . . . . . . . . . . . . . . . 30

12.1. Flush Cycle Steps:. ............................30

12.2. Automatically Starting Flush Cycle:. ..............30

12.3. Manually Starting / Stopping Flush Cycle:. .........31

12.4. Flush Cycle - Setup Parameters. .................31

Model 311 Hazardous Approved Installation Manual

13. flow calculator . . . . . . . . . . . . . . . . . 32

13.1. Latest Inow Rate - The Most Recently Determined Flow Rate into the Lift Station.32

13.2. Average Daily Inow Total - The Flow Totals from the Last 7 days Averaged Together.

32

13.3. Pump Outow Rate - The Most Recently Determined Outflow Rate of Each Pump.

32

13.4. Flow Calculator - Setup Parameters. ..............33

13.5. Flow Calculator - Surface Area Calculation. ........34

13.6. Flow Calculator - Display Parameters. ............34

14. coMMunIcatIon wIth ascada systeM . . . . . 35

14.1. MODBUS Functions Supported. ..................35

14.2. Setup for Connection to a SCADA System. ..........35

15. rs232 serIal port . . . . . . . . . . . . . . . . 36

16. ethernet port - optIon . . . . . . . . . . . . . 37

16.1. Features. ...................................37

16.2. Setup of Ethernet Port..........................37

17. scada regIsters . . . . . . . . . . . . . . . . 38

18. scada features . . . . . . . . . . . . . . . . . 42

18.1. Level. 42

18.2. Discrete Inputs. ..............................42

18.3. Auxiliary Analog Input Data.....................43

18.4. Pump On / Off and Alarm Levels. ................43

18.5. Disabling Pump Operation......................43

18.6. Forcing a Pump On. ...........................43

18.7. Setting Speed of Pumps Forced On. ..............44

Model 311 Hazardous Approved Installation Manual

18.8. Forcing Pump Alternation.......................44

18.9. Forcing Lead Pump Position. ....................44

18.10. Remote Control of Relays.................44

18.11. Flush Cycle. ...........................45

18.12. Flow Calculator Data. ...................45

18.13. High Level Telemetry. ...................45

18.14. Low Level Telemetry.....................45

18.15. Fault Codes. ..........................46

18.16. Pump Speed Reference. .................46

18.17. Elapsed Time Meters. ...................46

19. scada trouble shootIng . . . . . . . . . . . 46

19.1. Communication Activity Indicator. ................46

19.2. Address of Last Slave Polled by Master. ...........47

19.3. Record of Last Modbus Message. ................47

19.4. Communication Fault Codes. ....................47

20. connectIon dIagraM. . . . . . . . . . . . . . . 48

20.1. Standard Features. ...........................48

20.2. Connection Diagram - Optional Analog I/O. .......49

20.3. Connection Diagram - Lead Pump Selector Switch. ..50

20.4. Connection Diagram - Analog Level Input . ........51

20.5. Connection Diagram - Level Probe. ..............52

20.6. Level Probe - Placement and Setup. ..............53

20.7. Control Schematic Example. ....................54

20.8. Float Backup Example - Pump Down. .............55

20.9. Operator Interface. ...........................57

20.10. Enclosure Mechanical Layout. ............58

20.11. Panel Cutout. .........................59

21. warranty. . . . . . . . . . . . . . . . . . . . . 60

1

Model BB4000 Controller Instruction Manual

1. IntroductIon

1.1. Applications

Simplex, Duplex, Triplex, or Quadraplex

Liquid Level Control

Pump Down (Empty a Tank) or Pump Up (Fill

a Tank)

Fixed or Variable Speed Control

Where Connection to a SCADA System is

Required

1.2. Standard Features

All Setup Parameters Values may be viewed or

changed from the front of the unit.

Level Input Source - Menu Selectable:

–Analog Level Input [4-20mA from

Pressure Transducer]

–Level Probe [Conductance Probe with

10 Electrodes]

Regulated +20Vdc power for Analog Level

Input

RS-232 Serial Port with Modbus RTU Protocol

High and Low Level Alarm Relays and Alarm

Indication

Adjustable lag Pump(s) Delay

Alternation Schemes - Menu Selectable:

–Standard Alternation

–Pump 1 Always Lead - Stays On with

other Pumps

–Pump 1 Always Lead - Turns Off with

other Pumps On

–Split Alternation - Pumps 1&2, and

Pumps 3&4

–Fixed Sequence - Pump 1 Always Lead

–Stepped On/Off - Only One Pump

Runs at a Time

Alternator Logic Skips Disabled Pumps

First On - First Off or First On - Last Off

Alternation

Level Simulation (Automatically ends after 1

minute)

Security Code Protected Parameter Setup

18 Discrete Inputs programmable for the

following functions:

–Pump disable with HOA in OFF, or

pump fault

–External Lead Pump Selector Switch

–All pump disable - for connection to

Phase Monitor

Return to Table of Contents

–Limit number of pumps called while on

emergency power

–Alternation by External Time Clock

–Freeze wet well level during a bubbler

tube purge

–Call pump last

–Float switch backup

–Low Level Pump Cutoff

–Start Flush Cycle

–A variety of SCADA functions

Status of Discrete Inputs may be viewed from

front of Controller

Backup Control, and High & Low Alarms using

a Level Probe

Output Relays may be programmed for control

through SCADA

Automatic Flush Cycle to reduce sludge build up

Flow Calculator that provides the following Flow

Data:

–Latest Inflow Rate

–Average Daily Inflow Total (Average of Last

7 Days)

–Pump Outflow Rate (Latest for Each Pump)

1.3. Optional Features

Up to four Isolated 4-20mA Analog Outputs

that may be used for VFD speed control or for

sending out a copy of the Level Input

Up to four Isolated 4-20mA Auxiliary Analog

Inputs that may be used to collect analog data

for SCADA

4-20mA Analog Level Input may be ordered as

an Isolated Input

Ethernet Port with the following Protocols:

Modbus TCP or Modbus RTU

1.4. Specications

Input Power: 120 VAC ±10%, 13 VA max

External Dimensions: 6.9”x 8.5”x 4.9”

Agency Approvals: UL 508, CAN/CSA

Ambient Operating Temperature:

Without Analog Outputs:

-20 °C to +65 °C (-4 °F to +149 °F)

With Analog Outputs:

-20 °C to +50 °C (-4 °F to +122 °F)

Level Display: 3 Digit, 7 Segment LED

2

Model BB4000 Controller Instruction Manual

Return to Table of Contents

Level Display Range: 0-999 feet

(Decimal Point Position is Selectable)

Indicators: LED

Color: White with Blue Lettering

Relays: 6A @ 250VAC

Analog Level Input: 4-20mA, 250Ω Load, Transient Protected

Level Probe Inputs: ±8V, 60Hz Square Wave ±0.8mA max, Transient Protected

Discrete Inputs: 24Vdc, Transient Protected

Power for Discrete Inputs: Unregulated +24Vdc, Transient Protected

Power for Analog Level Input: Regulated +20Vdc ±1V, Transient Protected

Analog Outputs: Isolated 4-20mA Maximum Load Resistance: 600Ω

Auxiliary Analog Inputs: Isolated 4-20mA, 250Ω Load, Transient Protected

1.5. Ordering Information

Part Number: BB4000 - X X X X

Number of Optional

Analog Outputs:

0 = Zero Analog Outputs

1 = One Analog Output

2 = Two Analog Outputs

3 = Three Analog Outputs

4 = Four Analog Outputs

Number of Optional

Auxiliary Analog Inputs:

0 = Zero Auxiliary Analog Inputs

1 = One Auxiliary Analog Input

2 = Two Auxiliary Analog Inputs

3 = Three Auxiliary Analog Inputs

4 = Four Auxiliary Analog Inputs

Blank = RS232 Port

E = RS232 Port & Ethernet Port

Blank = Non-Isolated Analog Level Input

S = Isolated Analog Level Input

3

Model BB4000 Controller Instruction Manual

Return to Table of Contents

2. operator Interface functIons

2.1. How to View a Setup Parameter Value

1. Press push-button PB-M until the Menu Scroll Mode indicator comes on.

2. Press push-button PB-D and PB-U as needed to arrive at the desired Parameter view.

3. Parameters Shown on Front of Controller:

The value of the Parameter is displayed

whenever the indicator next to the Para-

meter label is on.

Parameters in the System Setup Sub-Menu:

The value of the Parameter in the System Setup Sub-Menu may be

viewed by using the push-button PB-M to toggle from the Parameter

number (P. 13, for example) to the Parameter value.

2.2. How to Change a Setup Parameter Value

1. Press push-button PB-M until the Menu Scroll mode indicator comes on.

2. Press push-button PB-D and PB-U as needed to arrive at the Parameter you wish to

change.

3. Parameters Shown on Front of Controller:

Press Push-button PB-M until the Value change indicator comes on.

4

Model BB4000 Controller Instruction Manual

Return to Table of Contents

Parameters in the System Setup Sub-Menu:

Press push-button PB-M until the Value Change indicator comes

on. The current value of the Parameter will then be displayed.

4. Press and hold for 4 seconds, either push-button PB-D or PB-U, to change the Para-

meter to the desired new value. (If the Parameter values will not change, they may be

locked. See directions below to un-lock Parameters.)

5. Press push-button PB-M or PB-L to exit the Value Change mode.

2.3. How to Simulate Levels

1. Press push-button PB-S.

Note: The Simulation starts from the actual level displayed prior to entering the

Level Simulation mode.

2. Press push-button PB-D or PB-U as needed to change the simulated level.

3. To end the level simulation press push-button PB-L.

Note: If you do not exit the Level Simulation mode, normal operation will resume

automatically 60 seconds after the last time the PB-U, PB-D, or PB-S push-buttons

were pressed.

2.4. How to Enter the Security Code

1. Press the push-button PB-M until the Menu Scroll mode indicator comes on.

2. Press push-button PB-U until the display reads SEC.

3. Press push-button PB-M to change to the Value Change mode.

4. Press and hold for 4 seconds, either push-button PB-D or PB-U, to change the value

displayed to that of the correct security code.

5

Model BB4000 Controller Instruction Manual

3. Menu - systeM setup

Return to Table of Contents

Parameter Default

Value

Current

Value Setting DefinitionS

- 2.0 ft Low LevelAlarm SCADARegister 40021 Range: 0.1 - 99.9 ft

Note: To DisableAlarm, see Parameter P.50.

- 3.0 ft 1st Pump Off Level SCADARegister 40013 Range: 0.2 - 99.9 ft

- 6.0 ft 1st Pump On Level SCADARegister 40012 Range: 0.2 - 99.9 ft

- 4.0 ft 2nd Pump Off Level SCADARegister 40015 Range: 0.2 - 99.9 ft

- 7.0 ft 2nd Pump On Level SCADARegister 40014 Range: 0.2 - 99.9 ft

- 4.5 ft 3rd Pump Off Level SCADARegister 40017 Range: 0.2 - 99.9 ft

- 8.0 ft 3rd Pump On Level SCADARegister 40016 Range: 0.2 - 99.9 ft

- 5.0 ft 4th Pump Off Level SCADARegister 40019 Range: 0.2 - 99.9 ft

- 9.0 ft 4th Pump On Level SCADARegister 40018 Range: 0.2 - 99.9 ft

- 10.0 ft High LevelAlarm SCADARegister 40020 Range: 0.5 - 99.9 ft

- 5 sec. Lag Pump(s) Delay Range: 1 - 100 seconds

SEC 0Security Code - Enter Your Security Code Here toAllow Parameters to be

Changed. Change to other Number to Re-lockAll Parameters.

Note: The Security Code may be Customized using Parameter P.26. See Page 6.

P.13 4Number of Pumps Present See Page 12.

1 = 1 Pump 2 = 2 Pumps 3 = 3 Pumps 4 = 4 Pumps

P.14 4Number of PumpsAllowed to Run at the Same Time See Page 12.

1 = 1 Pump 2 = 2 Pumps 3 = 3 Pumps 4 = 4 Pumps

P.15 4Number of PumpsAllowed to Run On Generator See Page 12.

1 = 1 Pump 2 = 2 Pumps 3 = 3 Pumps 4 = 4 Pumps

Note: Must Connect Transfer Switch Contacts to Discrete Input Programmed for Function 7.

P. 16 1

Alternator Sequence Mode

1 = StandardAlternation See Page 15.

2 = Pump 1Always Lead - Stays On With Other Pumps See Page 15.

3 = Pump 1Always Lead -Turns Off With Other Pumps See Page 16.

4 = SplitAlternation - Pumps 1&2, and Pumps 3&4 See Page 16.

5 = Fixed Sequence - Pump 1Always Lead See Page 17.

6 = Stepped On/Off - Only One Pump Runs at a Time See Page 17.

P.17 2Pump Stop Mode See Page 13.

1 = First On Last Off 2 = First On First Off

P.18 1AutomaticAlternation See Page 14.

1 = Enabled 2 = Disabled

P.19 1Pump Up or Down Mode

1 = Pump Down - Empty a Tank 2 = Pump Up - Fill a Tank

Note: When Parameter P.19 is Changed, New Default Level Parameter Values will be Loaded.

P.20 - P.23. - VFD Speed Control Setup See Page 29.

All Level Settings Have the Decimal Point Artificially Inserted Based on Parameter P.36.

6

Model BB4000 Controller Instruction Manual

Return to Table of Contents

Parameter Default

Value

Current

Value Setting DefinitionS

P.24 11.5 ft

Level Input Calibration - Span Range: 0.9 - 99.9 ft See Page 27.

Notes:

1. 20 mAis Typically Applied to theAnalog Input while Setting the Span.

2. Parameter P.24 Shows the Wet Well Level, while allowing the Up & Down

Push-buttons to Change the Internal Number used to Calculate the Displayed Level.

3. When Controller is set to Operate using a Level Probe, Parameter P.24 shows “77.7”.

P.25 0.0 ft

Level Input Calibration - Zero See Page 27.

Notes:

1. 40 mAis Typically Applied to theAnalog Input while Setting the Zero.

2. Parameter P.25 Shows the Wet Well Level, while allowing the Up & Down

Push-buttons to Change the Internal Number used to Zero the Displayed Level.

3. When Controller is set to Operate using a Level Probe, Parameter P.25 shows “77.7”.

P.26 0

Security Code Setup Parameter - Establishes What Value Will beAccepted as

the Security Code at Parameter SEC. Range: 0 - 255

Note:

1. To Change Parameter P.26, the Current Security Code Must First be Entered into SEC.

2. When You Change Parameter P.26 and Exit the Value Change Mode Parameter, P.26 Will

No Longer be Viewable, Until You Enter the New Security Code into Parameter SEC.

3. If You Forget Your Security Code, Consult the Factory for the Master Security Code.

P.28 1 SlaveAddress See Page 35.

P.29 - P.32 - RS232 Serial Port Setup See Page 36.

P.33 1 RegisterAccess Mode See Page 35.

P.35 1 sec. Stop Pump Delay Range: 1 - 100 seconds

Note: This is the Time Period that the Wet Well Level Must RemainAt or Below (At orAbove for

Pump UP P.19=2) the Respective OFF Level Setting in order to Turn Off a Pump.

P.36 1 Display Decimal Point Position 0 = No Decimal Point 1 - XX.X 2 = X.XX

P.37 1 min. Pump Re-enable Delay after Float Backup Low Level (High Level)

Notes: Range: 1 - 255 minutes

1. Pump Down (Parameter P.19 = 1) - Delay Starts when the Low Level Float Input Opens.

2. Pump Up (Parameter P.19 = 2) - Delay Starts when the High Level Float Input Opens.

P.38 1 min. Delay Canceling Remote Control Commands

Notes: Range: 0 - 254 minutes

1. Delay Starts when Serial Communication is Lost.

2. To Allow all Remote Commands to Remain in Effect (Until Power Loss) Set P.38 = 255.

P.39 0Forced Lead Pump Position SCADARegister 40022 See Page 14.

0 = NormalAlternation 1 (2, 3, 4) = Pump 1 (2, 3, 4) as Lead

P.40 - P.43 - Flush Cycle Setup See Page 31.

P.44 - P.47 - Flow Calculator Setup See Pages 33 - 34.

P.49 240 Analog Level Input - Signal Conditioning Control Range: 1 - 254

10 = Very Slow 100 = Slow 240 = Normal 250 = Fast

P.50 1Low LevelAlarm Mode 0 = Disabled 1 = Enabled

Note: Setting “0” Disables Low LevelAlarms from theAnalog Level Input or Level Probe Inputs.

P.51 0Time BasedAlternation Range: 1 - 255 1/6 hour See Page 14.

0 = Disabled 1 = 1/6 hour 6 = 1 hour 48 = 8 hours 144 = 24 hours

P.52 0 Pump 1 (2, 3, 4) Disable - Discrete Input Mode 0 = Normal 1 = Logic Inverted

FLC -Fault Code SCADARegister 40047 See Fault CodeTable on Pages 25-26.

Note: ThisAutomatically Returns to Zero when the Fault Clears (Except for Faults 20-29).

All Level Settings Have the Decimal Point Artificially Inserted Based on Parameter P.36.

Menu - SySteM Setup

7

Model BB4000 Controller Instruction Manual

Return to Table of Contents

Parameter Default

Value

Current

Value Setting DefinitionS

LFC -Last Fault Code SCADARegister 40048 See Fault Code Table on Pages 25-26.

Note: This is a Copy of the Last Non-Zero Fault Code that was shown on Parameter FLC.

oPr - Operating Program Revision Number - Controller SCADARegister 40063

EPr - Operating Program Revision Number - Ethernet Board

All Level Settings Have the Decimal Point Artificially Inserted Based on Parameter P.36.

Menu - SySteM Setup

F.01 1Discrete Input 1

Function Function of Input: Connect To:

F.02 2Discrete Input 2

Function 0 = No Function

1 = Pump 1 Disable . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . HOAand Fault Logic

2 = Pump 2 Disable . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . HOAand Fault Logic

3 = Pump 3 Disable . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . HOAand Fault Logic

4 = Pump 4 Disable . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . HOAand Fault Logic

5 = Level Freeze . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Bubbler Tube Purge Logic

6 = ExternalAlternation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .External Time Clock

7 = On Generator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Automatic Transfer Switch

8 =All Pump Disable . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Phase Monitor

9 = Sequence Input 1 . . . . . . . . . . . . . . . . . . . . . . . . . .Lead Select Switch - 1 as Lead

10 = Sequence Input 2 . . . . . . . . . . . . . . . . . . . . . . . . .Lead Select Switch - 2 as Lead

11 = Sequence Input 3 . . . . . . . . . . . . . . . . . . . . . . . . .Lead Select Switch - 3 as Lead

12 = Sequence Input 4 . . . . . . . . . . . . . . . . . . . . . . . . .Lead Select Switch - 4 as Lead

13 = Call Pump 1 Last . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Logic Contact

14 = Call Pump 2 Last . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Logic Contact

15 = Call Pump 3 Last . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Logic Contact

16 = Call Pump 4 Last . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Logic Contact

17 = Low LevelAlarm . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Low Level Float Switch

18 = High LevelAlarm . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . High Level Float Switch

19 = Telemetry E . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Telemetry Contact

20 = Telemetry F . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Telemetry Contact

21 = Telemetry G . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Telemetry Contact

22 = Telemetry H . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Telemetry Contact

23 = Telemetry J . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Telemetry Contact

24 = Telemetry K . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Telemetry Contact

25 = Telemetry L. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Telemetry Contact

26 = Telemetry M . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Telemetry Contact

27 = TelemetryA . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Telemetry Contact

28 = Telemetry B . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Telemetry Contact

29 = Telemetry C . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Telemetry Contact

30 = Telemetry D . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Telemetry Contact

31 = Normal Pump Operation Disable . . . . . . . . . . . . . . . . . . . . . . . . . . .Fault Contact

32 = Float Backup - Low Level . . . . . . . . . . . . . . . . . . . . . . . . .Low Level Float Switch

33 = Float Backup - Off Level . . . . . . . . . . . . . . . . . . . . . . . . . . .Off Level Float Switch

34 = Float Backup - 1st On Level . . . . . . . . . . . . . . . . . . . . .1st On Level Float Switch

35 = Float Backup - 2nd On Level . . . . . . . . . . . . . . . . . . . .2nd On Level Float Switch

36 = Float Backup - 3rd On Level . . . . . . . . . . . . . . . . . . . . 3rd On Level Float Switch

37 = Float Backup - 4th On Level . . . . . . . . . . . . . . . . . . . . .4th On Level Float Switch

38 = Float Backup - High Level . . . . . . . . . . . . . . . . . . . . . . . . High Level Float Switch

39 = Start Flush Cycle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .External Time Clock

Notes:

1. Function of Discrete Inputs may be set to “0” when Input is used only to

collect data for SCADAand no other Function is desired.

2. All Discrete Inputs may be read from SCADARegisters 40035 - 40037,

regardless of the Function assigned to the Input

3. See Pages 18-22 for description of each of the above Functions.

4. Pump 1 (2,3,4) Disable logic may be inverted. See Parameter P.52.

F.03 3Discrete Input 3

Function

F.04 4Discrete Input 4

Function

F.05 5Discrete Input 5

Function

F.06 6Discrete Input 6

Function

F.07 7Discrete Input 7

Function

F.08 8Discrete Input 8

Function

F.09 9Discrete Input 9

Function

F.10 10 Discrete Input 10

Function

F.11 11 Discrete Input11

Function

F.12 12 Discrete Input 12

Function

F.13 13 Discrete Input 13

Function

F.14 14 Discrete Input 14

Function

F.15 15 Discrete Input 15

Function

F.16 16 Discrete Input 16

Function

F.17 17 Discrete Input 17

Function

F.18 18 Discrete Input 18

Function

8

Model BB4000 Controller Instruction Manual

Return to Table of Contents

All Level Settings Have the Decimal Point Artificially Inserted Based on Parameter P.36.

Menu - SySteM Setup

Parameter Default

Value

Current

Value Setting DefinitionS

F.19 1

Level Input Source

1 =Analog Level Input (4-20 mA) on J21

2 = Level Probe Input on J25

3 = Level Probe Input on J25 (Flashes Level Probe Electrode No. of Level Settings.)

4 = Remote Level Input (Follows the Level written to SCADARegister 40025.)

Note: Level Probe not suitable for applications measuring Storm Water or Well Water.

F.20 12 in. Level Probe Electrode Spacing Range: 3 - 24 Inches

F.21 0.0 ft Level Offset Range: 0.0 - 5.0 ft

Note: This adds to the Level from theAnalog Level Input or Level Probe Input.

F.22 100 Level Probe Sensitivity Range: 90 - 210

100 - Typical Sewage 150 = Light Sewage

Check value of Parameter L.10 with Electrode 10 covered, add 40 to it, and enter value for F.22.

Note: Level Probe not suitable for applications measuring Storm Water or Well Water.

F.23 1 Analog Output 1 Function 1 = Pump 1 Speed (Active When Pump 1 is Called)

2 - Pump 2 Speed (Active When Pump 2 is Called)

3 - Pump 3 Speed (Active When Pump 3 is Called)

4 - Pump 4 Speed (Active When Pump 4 is Called)

5 - Speed Reference any Pump (AlwaysActive)

6 = Copy of Wet Well Level

F.24 2 Analog Output 2 Function

F.25 3 Analog Output 3 Function

F.26 4 Analog Output 4 Function

F.31 1HI Relay Output Function

0 = Disabled 1 = High LevelAlarm 2 = Remote Control (SCADACoil 25)

Note: High Level indicator on front of unit will operate regardless of setting.

F.32 1LO Relay Output Function

0 = Disabled 1 = Low LevelAlarm 2 = Remote Control (SCADACoil 26)

Note: Low Level indicator on front of unit will operate regardless of setting.

F.33 1P1 Relay Output Function

0 = Disabled 1 = Pump 1 Call 2 = Remote Control (SCADACoil 27)

Note: When set on “0” or “2” Pump 1 will be skipped over in allAlternation Sequence Modes.

F.34 1P2 Relay Output Function

0 = Disabled 1 = Pump 2 Call 2 = Remote Control (SCADACoil 28)

Note: When set on “0” or “2” Pump 2 will be skipped over in allAlternation Sequence Modes.

F.35 1P3 Relay Output Function

0 = Disabled 1 = Pump 3 Call 2 = Remote Control (SCADACoil 29)

Note: When set on “0” or “2” Pump 3 will be skipped over in allAlternation Sequence Modes.

F.36 1P4 Relay Output Function

0 = Disabled 1 = Pump 4 Call 2 = Remote Control (SCADACoil 30)

Note: When set on “0” or “2” Pump 4 will be skipped over in allAlternation Sequence Modes.

E.01 - E.62 - Ethernet Port Setup See Page 37.

9

Model BB4000 Controller Instruction Manual

Return to Table of Contents

Menu - SySteM Setup

Parameter Default

Value

Current

Value Setting DefinitionS

Level Probe Backup Functions 0 = Function Not Used

1 = Electrode Input 1 on Connector J25-1

2 = Electrode Input 2 on Connector J25-2

3 = Electrode Input 3 on Connector J25-3

4 = Electrode Input 4 on Connector J25-4

5 = Electrode Input 5 on Connector J25-5

6 = Electrode Input 6 on Connector J25-6

7 = Electrode Input 7 on Connector J25-7

8 = Electrode Input 8 on Connector J25-8

9 = Electrode Input 9 on Connector J25-9

10 = Electrode Input 10 on Connector J25-10

b.01 0Low LevelAlarm

b.02 0 Pump Control - Off Level

b.03 0 Pump Control - 1ST On Level

b.04 0 Pump Control - 2ND On Level

b.05 0 Pump Control - 3RD On Level

b.06 0 Pump Control - 4TH On Level

b.07 0High LevelAlarm

Notes For Level Probe Backup Functions: For status of Level Probe inputs see Coils 583 - 592 in SCADARegister 40037.

1. When the controller is set up to follow a 10 Electrode Conductance Level Probe as the primary level input source (Parameter F-19 = 2

or 3), the backup functions described here are not needed and will not operate.

2. If a Function is not desired (such as Pump Control - 4TH On Level), set the respective parameter equal to zero.

3. An effective Backup Pump Control would involve having a 3 point Level Probe placed high in the wet well. The Level Probe would

be connected to Connector J25 terminals 1, 2, and 3. The Off Level should be made to operate from the bottom Electrode by setting

Parameter b.02 = 3. The 1STOn Level should be set to operate from Electrode 2 by setting Parameter b.03 = 2. The 2ND On Level

should be set to operate from Electrode 1 by setting Parameter b.04 = 1. If additional pumps are present, set the 3RD On and 4TH On

Levels to operate from Electrode 1 by setting Parameter b.05 = 1, and b.06 = 1.

4. If a Backup High LevelAlarm is desired, set Parameter b.07 to the number of the Electrode Input to which the High Level Probe is

connected. This feature is for alarm and telemetry only and will not function as a redundant pump call. See SCADAnotes page 42.

5. If a Backup Low LevelAlarm is desired, set Parameter b.01 to the number of the Electrode Input to which the Low Level Probe is

connected. This feature is for alarm and telemetry only and will not function as a redundant pump off. See SCADAnotes page 45.

6. Whenever the Backup Pump Control is active, the Fault indicator will be on and a fault code of 30 will be present in Parameter FLC,

and set Coil 15 in SCADARegister 40001.

10

Model BB4000 Controller Instruction Manual

Return to Table of Contents

4. Menu - data dIsplay

Parameter Data DeSCriPtion

L.01 Electrode 1 Status Value Level Probe Electrode Status Values

Normal Range when Un-Covered: 240 - 255

Normal Range when Covered by Typical Sewage: 55 - 70

Notes:

1. The Controller compares each of the Electrode Status Values with what is set on Para-

meter F.22. When the value drops below the setting on Parameter F.22, the Controller

logic considers the Electrode to be covered by liquid.

2. Parameters L.01 - L.10 are also used to diagnose Out of Sequence Faults (Fault Codes

21 - 29).

3. For the status of the Level Probe inputs see Coils 583 - 592 in SCADARegister 40037.

L.02 Electrode 2 Status Value

L.03 Electrode 3 Status Value

L.04 Electrode 4 Status Value

L.05 Electrode 5 Status Value

L.06 Electrode 6 Status Value

L.07 Electrode 7 Status Value

L.08 Electrode 8 Status Value

L.09 Electrode 9 Status Value

L.10 Electrode 10 Status Value

L.11

Level Probe Test Signal Status Normal Range: 230 -254

Note: This is a Measure of the ±8v, 60 Hz Square Wave Sent Out to Each Electrode to read the level. If the value is below 210, a

malfunction has occurred in the circuit that provides the Square Wave used to read the level. In this case, the wet well level display

will show zero, the Fault indicator will be turned on, and Fault Code 20 will be generated.

FLH Flow Calculator - Latest Inow Rate

See pages 32 - 35. FLH, FLL Gallons Per Minute

SCADARegister 40080

FLL

FdH Flow Calculator - Average Daily Inow Total

See pages 32 - 35. FdH, FdL Units set by Parameter P.45.

SCADARegister 40081

FdL

F1H Flow Calculator - Pump 1 Outow Rate

See pages 32 - 35. F1H, F1L Gallons Per Minute

SCADARegister 40082

F1L

F2H Flow Calculator - Pump 2 Outow Rate

See pages 32 - 35. F2H, F2L Gallons Per Minute

SCADARegister 40083

F2L

F3H Flow Calculator - Pump 3 Outow Rate

See pages 32 - 35. F3H, F3L Gallons Per Minute

SCADARegister 40084

F3L

F4H Flow Calculator - Pump 4 Outow Rate

See pages 32 - 35. F4H, F4L Gallons Per Minute

SCADARegister 40085

F4L

11

Model BB4000 Controller Instruction Manual

Menu - Data DiSplay

Parameter Data DeSCriPtion

n.01 Discrete Input 1 Status

Discrete Input Status

0 = Input Open

1 = Input Closed

Notes:

1. Discrete Input Status is used when troubleshooting the wiring and logic connected

to the Discrete inputs.

2. Discrete Input Status data may be read by SCADAat Registers 40035 - 40037.

See Page 29.

n.02 Discrete Input 2 Status

n.03 Discrete Input 3 Status

n.04 Discrete Input 4 Status

n.05 Discrete Input 5 Status

n.06 Discrete Input 6 Status

n.07 Discrete Input 7 Status

n.08 Discrete Input 8 Status

n.09 Discrete Input 9 Status

n.10 Discrete Input 10 Status

n. 11 Discrete Input 11 Status

n. 12 Discrete Input 12 Status

n. 13 Discrete Input 13 Status

n. 14 Discrete Input 14 Status

n. 15 Discrete Input 15 Status

n. 16 Discrete Input 16 Status

n. 17 Discrete Input 17 Status

n. 18 Discrete Input 18 Status

n.19 AuxiliaryAnalog Input 1 Status Auxiliary Analog Input Status Range: 0-255

Where: 0 = 0.0 mA 51 = 4.0 mA 255 = 20 mA

Note: Auxiliary Analog Input data may be read by SCADA in either an

8-Bit or 10-Bit format. See Page 30.

n.20 AuxiliaryAnalog Input 2 Status

n.21 AuxiliaryAnalog Input 3 Status

n.22 AuxiliaryAnalog Input 4 Status

d.01 Voltage of +5 Volt Power Supply SCADARegister 40049 Normal Range: 8.5V - 11.3V

Note: Voltage is measured ahead of Voltage Regulator.

d.02 Voltage of +24 Volt Power Supply SCADARegister 40050 Normal Range: 21.1V - 25.5V

d.03 Pump 1 VFD Speed Reference (Percent of Full Speed, 0 - 100%) SCADARegister 40038

d.04 Pump 2 VFD Speed Reference (Percent of Full Speed, 0 - 100%) SCADARegister 40039

d.05 Pump 3 VFD Speed Reference (Percent of Full Speed, 0 - 100%) SCADARegister 40040

d.06 Pump 4 VFD Speed Reference (Percent of Full Speed, 0 - 100%) SCADARegister 40041

d.07 Serial CommunicationActivity Indicator See Page 46.

d.08 Serial Communication - Shows theAddress of the Last Slave Polled by the Master See Page 47.

d.09 Serial Communication - Shows the Last Modbus Function Code Received See Page 47.

d.10 - d.86 Serial Communication - Shows the Entire Rest of the Modbus Message Received

Return to Table of Contents

12

Model BB4000 Controller Instruction Manual

5. puMp call sequence - setup paraMeters

The following is a description of each of the Setup Parameters used to establish the Pump Call

Sequence:

Note: Discrete inputs programmed with Functions 1-4, 6-7, 9-12, and 13-16 are also available

to establish or modify the Pump Call Sequence. See the description of these Discrete Input Func-

tions on pages 14-16.

5.1. Number of Pumps Present - Parameter P.13

This Parameter establishes how many pumps are available at the Lift Station to perform level

control.

Simplex (1 pump) Duplex (2 pumps) Triplex (3 pumps) Quadraplex (4 pumps)

Parameter Default

Value Setting DefinitionS

P.13 4Number of Pumps Present

1 = 1 Pump 2 = 2 Pumps 3 = 3 Pumps 4 = 4 Pumps

5.2. Number of Pumps Allowed to Run at the Same Time - Parameter P.14

In cases where there is an inadequately sized discharge pipe, or inadequate electrical power,

running all available pumps at the same time may be a problem. This Parameter is used to set

an upper limit on the number of pumps called to run at the same time. If there is no need for

this feature P.14 may be left on its default value of 4.

Parameter Default

Value Setting DefinitionS

P.14 4Number of Pumps Allowed to Run at the Same Time

1 = 1 Pump 2 = 2 Pumps 3 = 3 Pumps 4 = 4 Pumps

5.3. Number of Pumps Allowed to Run On Generator - Parameter P.15

In cases where the Emergency Generator is not sized large enough to run all the available

pumps, this Parameter is used to set an upper limit on the number of pumps called to run

on the Generator. There must be a contact from the Transfer Switch connected to one of the

Controller’s Discrete Inputs and it must be programmed for Function 7. If there is no need for

this feature, Parameter P.15 may be left on its default value of 4.

Return to Table of Contents

Parameter Default

Value Setting DefinitionS

P.15 4Number of Pumps Allowed to Run On Generator

1 = 1 Pump 2 = 2 Pumps 3 = 3 Pumps 4 = 4 Pumps

13

Model BB4000 Controller Instruction Manual

5.4. Alternator Sequence Mode - Parameter P.16

This Parameter is provided to allow the Controller to accommodate a variety of special

sequence requirements.

Return to Table of Contents

Parameter Default

Value Setting DefinitionS

P.16 1

Alternator Sequence Mode

1 = Standard Alternation See Page 15.

2 = Pump 1 Always Lead - Stays On With Other Pumps See Page 15.

3 = Pump 1 Always Lead - Turns Off With Other Pumps See Page 16.

4 = Split Alternation - Pumps 1&2, and Pumps 3&4 See Page 16.

5 = Fixed Sequence Pump - 1 Always Lead See Page 17.

6 = Stepped On/Off - Only One Pump Runs at a Time See Page 17.

6. puMp call sequence - setup paraMeters

6.1. Pump Stop Mode - Parameter P.17

This Parameter establishes which pump is the next one to be stopped, when there are two or

more pumps on.

The Controller has a corresponding “Pump Off Level” setting for each of the “Pump On Level”

settings. For the “Pump Stop Mode” feature to operate, the “Pump Off Level” settings must be

set on different levels. If all the “Pump Off Level” settings are set on the same level it does not

matter what Parameter P.17 is set on.

First On Last Off - In this mode, as the level reaches one of the “Pump Off Level” settings, the

pump that was most recently turned on is turned off, leaving the one that was called to run first

still running.

First on First Off - In this mode, as the level reaches one of the “Pump Off Level” settings, the

pump that was most recently turned on is left on and the pump that has been on the longest is

turned off. This results in a longer cool down period for each pump between starts. This mode

works the best in stations where one pump is required to run for a long period of time, with an

occasional need for an additional pump.

Parameter Default

Value Setting DefinitionS

P.17 2 Pump Stop Mode 1 = First On Last Off 2 = First On First Off

14

Model BB4000 Controller Instruction Manual

6.2. Automatic Alternation - Parameter P.18

This Parameter is provided so that normal automatic alternation may be disabled (turned off).

Typically, normal alternation is disabled only in applications that have an external Time Clock

used to alternated the pumps. (The Time Clock would be connected to a Discrete Input pro-

grammed for “External Alternation”, Function 6.)

Return to Table of Contents

Parameter Default

Value Setting DefinitionS

P.18 1 Automatic Alternation 1 = Enabled 2 = Disabled

6.3. Forced Lead Pump Position - Parameter P.39

This Parameter is provided so that a fixed sequence may be established with the selected pump

always as lead. For example setting Parameter P.39 on 1 will cause a fixed pump call sequence

of 1-2-3-4. Parameter P.39 may also be changed by writing a 0,1,2,3 or 4 to SCADA Register

40022.

Parameter Default

Value Setting DefinitionS

P.39 0Forced Lead Pump Position SCADA Register 40022

0 = Normal Alternation 1(2,3,4) = Pump (1(2,3,4) as Lead

6.4. Time Based Alternation - Parameter 5.1

This feature may be used to ensure that alternation periodically occurs even in applications that

tend to run one pump for a long period of time. The internal Time Clock starts and runs when-

ever at least one pump is called to run. When it times out, it forces the alternation of the pumps

and then resets the Time clock. The Time Clock is also reset each time a Normal Alternation

Occurs.

Parameter Default

Value Setting DefinitionS

P.51 0Time Based Alternation Time Clock Range: 1 - 255 1/6 hour

0 = Disabled 1 = 1/6 hour 6 = 1 hour 48 = 8 hours 144 = 24 hours

Table of contents

Other Blue Ribbon Controllers manuals

Popular Controllers manuals by other brands

MSA

MSA SMC Sentry-IT NEMA Retrofit Kit operating manual

Phasetronics

Phasetronics EP1-xx10 Series Operation and service manual

Honeywell

Honeywell 5 Nm Series Product data

White Rodgers

White Rodgers 50A55 troubleshooting guide

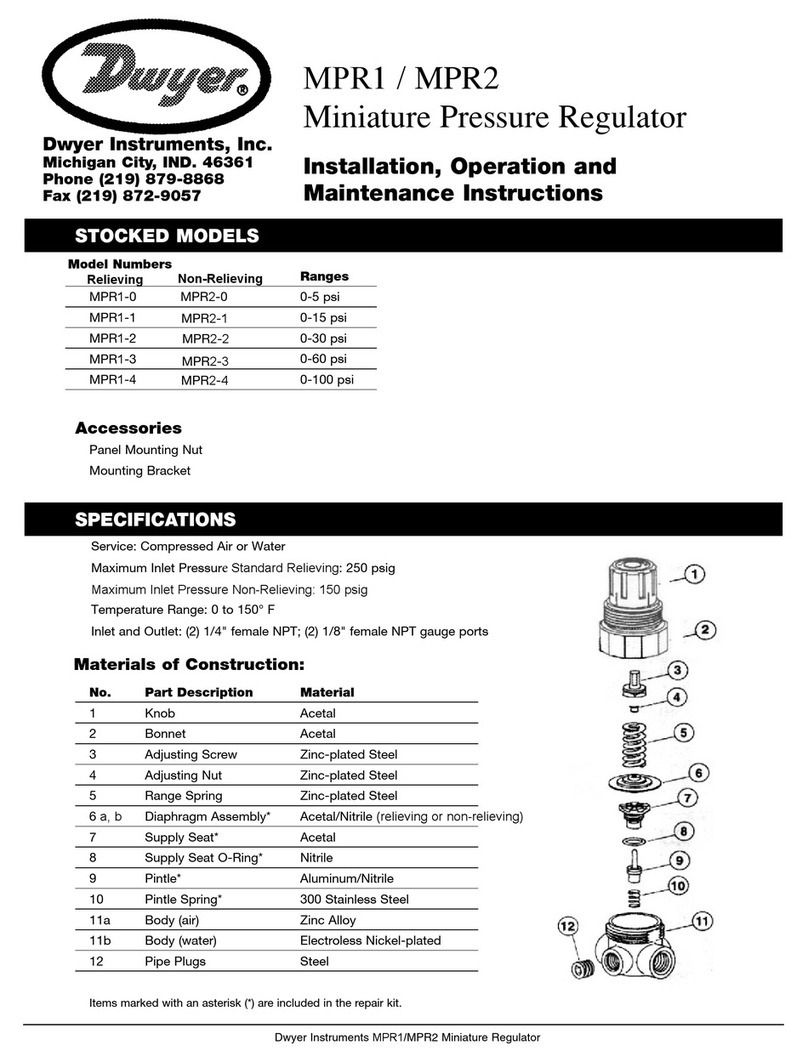

Dwyer Instruments

Dwyer Instruments MPR1 Installation, operation and maintenance instructions

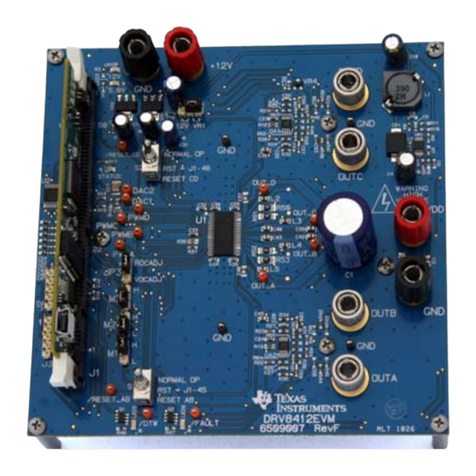

Texas Instruments

Texas Instruments C2000 Piccolo LaunchPad quick start guide