Model 48VTR - Version 5.0 – January 2006

4

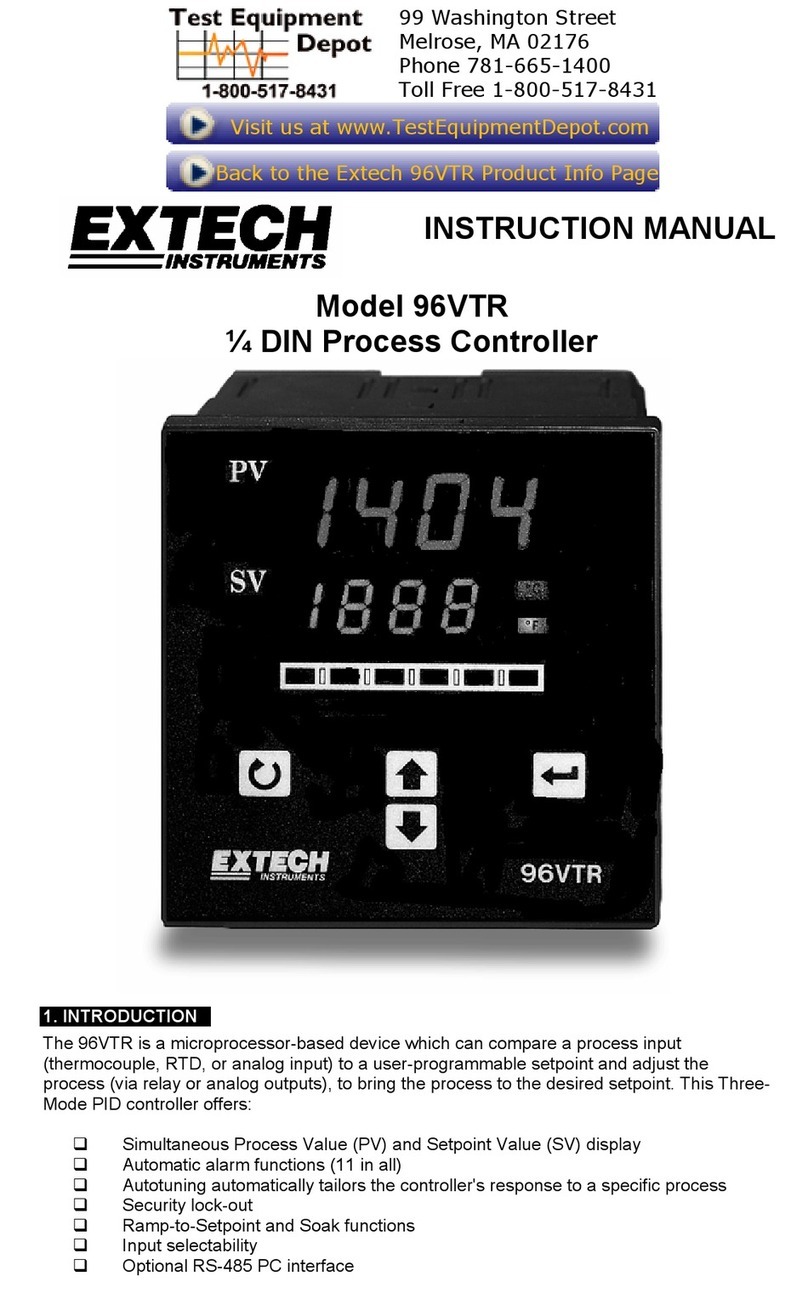

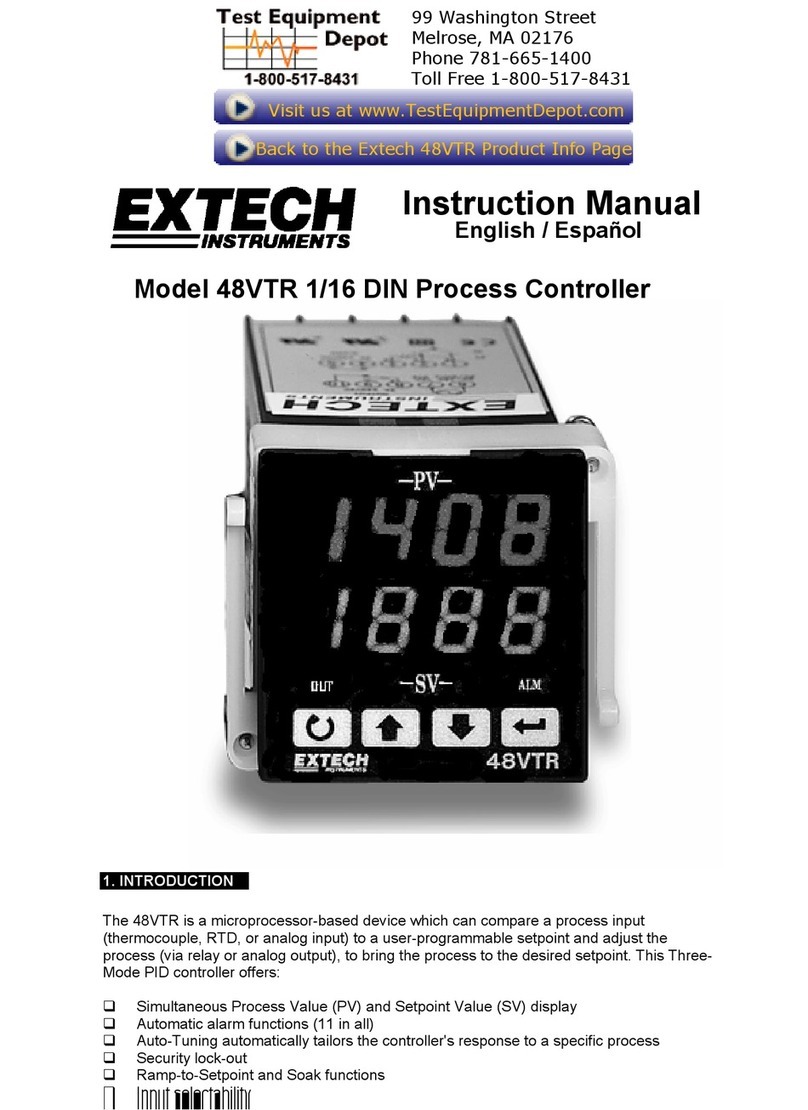

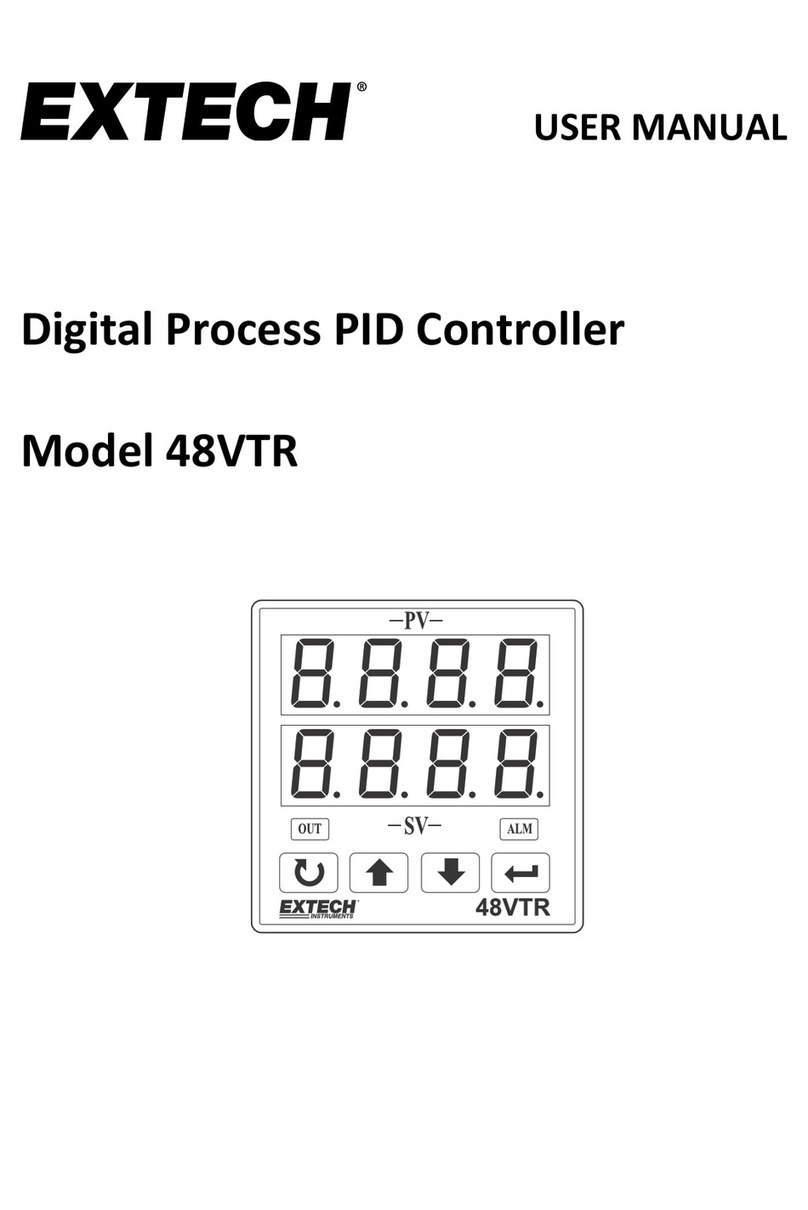

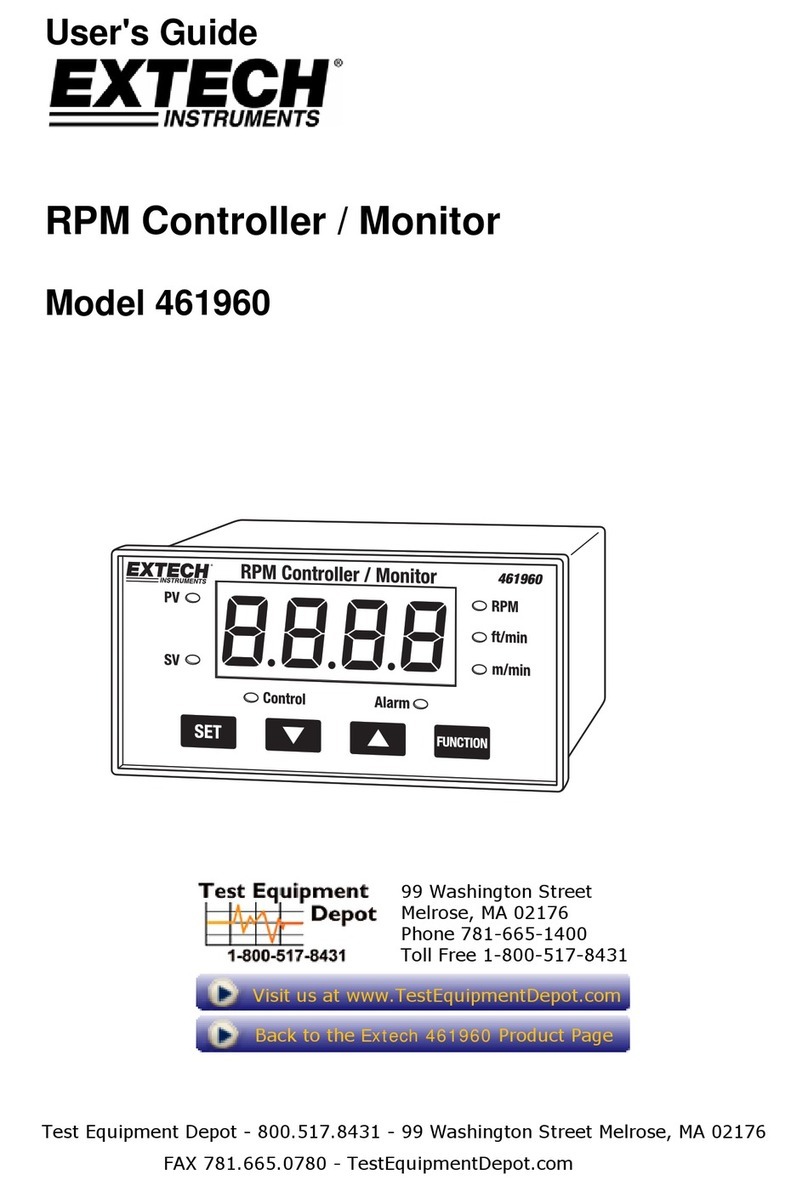

Controller Overview

Controller Wiring

The controller must be wired before use. The controller’s input, outputs, and AC power are

connected via its rear terminals. Refer to the Wiring Section for details.

Programming Menus

The controller has four (4) Programming Menu Levels. Each menu includes a series of

parameters that customize the controller to meet the user’s needs. The menu structure and

parameter descriptions are detailed in the Programming Menu Levels Section. Check the

factory default settings for each parameter and only change a setting if necessary.

Inputs

The controller accepts an input from a Thermocouple, RTD, or Analog signal. Wire the

input as shown in the Mounting and Wiring Section. The measurement (PV for Process

Variable) is displayed on the controller’s top LED readout in red.

Setpoint Value (SV)

The Setpoint Value (SV) is the target value. For example, in an oven application the

desired oven temperature is the SV. This SV is changed using the front panel up/down

arrow keys. The SV is shown on the controller’s lower LED display digits in green.

Control Output

The control output is wired to an external control device such as a heater, valve, or switch.

See the Mounting and Wiring Section for details. The controller automatically controls an

external device to bring the Process Variable (PV) in line with the Setpoint Variable (SV).

Available outputs are Relay, DC trigger, and Analog Output.

Tuning

The controller must be tuned for every new application. Run the Automatic Tune function

after the controller is wired and ready to go. The Auto Tune function matches the response

of the controller to the characteristics and dynamics of the process it is controlling. Refer to

the Auto Tuning Section for details on automatic tuning. Although auto tuning will be

sufficient in most cases, there may be times when manual adjustments are required.

Qualified personnel can Manually Tune the controller using the PID parameters in the 2nd

Menu Level. Note that improper tuning can cause sever process disturbances. Always use

Auto Tuning when possible.

Alarm Output

The controller has one alarm output relay that can be used to switch on a light, sound a

buzzer, shut down a heater, etc. at a programmed alarm setpoint. A list of alarm functions

can be found in Appendix A. Use the ‘A1Fu’ parameter in the third programming level to

set the desired alarm type. Use the ‘A1SP’ parameter in the 1st Menu Level to set the

alarm setpoint.

Alarm Timers

The Alarm relay can be used as an EVENT or a SOAK timer. An Event Timer switches the

Alarm relay ON or OFF based on certain process condition. The SOAK timer allows the

controller to hold a desired Setpoint (SV) for a programmed period of time before switching

off. Refer to Appendix ‘A’ and the Soak/Event Timer Sections for details.

System Reset

To revert all of the parameters to their original factory default settings, press and hold the

UP and DOWN arrow keys simultaneously while turning the controller ON. Release the

keys after the self-test (when the display shows ‘8888’).

Locking Out the Controller

To lock out the controller, in order to avoid setpoint and program tampering, refer to the

‘REMO’ and ‘PARAMETER LOCK’ (PL) parameters in the 3rd Programming Level.