Page 2 Technical Manual Temperature-, Humidity-, Pressure-Controller TAR x260

Technical Data

Operating Voltage .............. see type overview

Power Consumption ........... approx. 3,5 VA

Output relays....................... 3x potential free

Relay rating ........................ 8A cos phi=1, 3A ind. / 250V AC

Operating Temp. ................ -10...+55°C / 14...131°F

Storage Temp..................... -30...+70°C / -22...158°F

Air humidity......................... max. 85% r.H., not condensing

Signal inputs ....................... 2x TF201(PTC) orTF501 (Pt1000),

1x 4...20 mA, 100 ohms shunt

Transmitter supply.............. appr. 12VDC unreg., max. 35 mA

Display ................................ LED, character height 13mm

19"-module : char. height 10mm

Resolution........................... 0,1 / °C, 0,2 / °F

Control-/Display range ....... -100...+300 (°C, bar, °F up to +572)

Data storage parameters ... typ. 10 years

Relay indicator.................... LED 2 mm, red

Digital Input (Optocpl.) ....... 230V, 3mA (1260: external switch)

Analogue output .................. 0-10 V DC, max. 3 mA

Resolution Analogue Outp. . 8 bit within the set limit values

Data interface ..................... RS-485 (

E-Link

)

Electrical connection .......... Screw terminals 2,5mm

19"-module : connector "F"

Housing, Protection

TAR 1260 ................ 77 x 35 mm, IP 54 from front

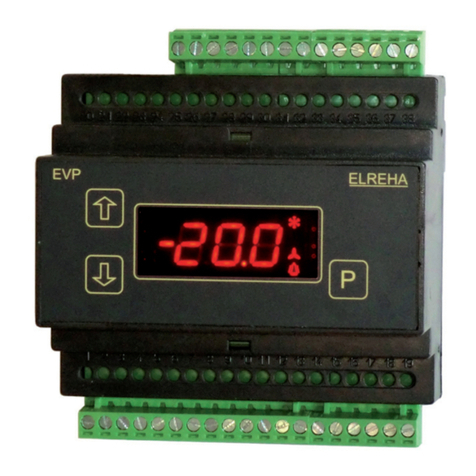

TAR (2)3260 ............ for 35mm DIN-rail, IP 30

TAR (2)5260 ............ 96 x 48 mm, IP 54 from front

TAR (2)19260 .......... 19"module, 8 TE

Further information you will find in the parameter listing

Type Overview

TAR 1260 ........... Panel mounting, 12-24V AC/DC

TAR 3260 ........... for 35mm DIN-rail, 230V~, 50-60 Hz

TAR 5260 ........... Panel mounting, 230V~, 50-60 Hz

TAR 19260 ......... 19"-Module, 8TE, 230V~, 50-60 Hz

TAR 23260 ......... for 35mm DIN-rail, 115V~, 60 Hz

TAR 25260 ......... Panel mounting, 115V~, 60 Hz

TAR 29260 ......... 19"-Module, 8TE, 115V~, 60 Hz

Accessories (please order separately)

- TemperaturesensorTF201(max.80°C)

or

PT1000(max.300°C)

- Two-wire pressure transmitter, Type DG... or similar with

4-20 mA signal output

- Humidity transmitter FF 2520 with 4...20mA output

- For type TAR 1260: Matching transformer, please contact us.

- For type TAR 19260: Subrack or Panel housing

Contents

page

Safety Instructions ..........................................................2

Operating / Operating Elements / Failure Displays..........3

Access protection..............................................................3

Parameter listing ...............................................................4-5

Functional Description

Value sources, Operating modes

Alarm, Switching modes, Digital Input, Analogue output

Networking.........................................................................9

Dimensions/ Wiring ...........................................................11

Run-Up Examples .............................................................15

Please read before Start-up

• Limit of Application: This product is not designed nor

manufactured for use in equipment or systems that are

intended to be used under such circumstances that may

affect human life.

Forapplicationsrequiringextremelyhighreliability,please

contact the manufacturer first

• Electrical installation and putting into service must be

done from authorized personnel.

• Please note the local safety instructions !

• Before installation: Check the limits of the controller and

yourapplication.Beforestartingupwerecommendyouto

readthefollowinginstructionsfor use, since onlybydoing

so you can avoid damage or malfunction and you will

benefit all the advantages offered by this product.

•During installation and wiring never work when the

electricity is not cut-off !

• If the units should be networked, never connect the

secondary coil of 12/24V transformers to PE !

• To control servo drives/actuators, a TAR 1260 must be

supplied by a separate transformer

• Mounting the controller close to power relays is

unfavourableincaseoftheelectro-magneticinterference.

• Before applying voltage to the controller:

Make sure that all wiring has been made in accordance

with the wiring diagram in this manual.

Check, if the supply voltage corresponds to the value

printed on the type label.

• Connect the ‘PE’ terminal carefully to ground because

otherwise the operation of the internal noise filter will be

disabled.

• Respect the environmental limits for temperature and

humidity. Outside these limits malfunctions may occur.

•Never operate unit without housing.

• Observe the maximum admitted current rate for the

relays (see technical data). Compare with the peak start-

up current of the controlled devices (valve, fan,

compressor, heater..)

• Sensor cables may be up to some hundred meters in

length. Use shielded sensor cable only. Don’t install them

in parallel with high-current cables to prevent inductive

interference. A cross section of min. 0,5mm² is sufficient.

• Shielding has to be connected to PE at the end near the

controller

• All used temperature sensors must be identical. Never

use PTC (TF 201) and PT1000 (TF 501) mixed. This will

not work.

• TF-type sensors are moisture-proof but they are not

designed for being immersed in water for a long period of

time(not pressure-proof).Insuch acase,always usedip-

fittings.

• Be care that the wiring of interface lines meets the

requirements

CONNECTION & SAFETY INFORMATIONS