Connection Diagram

[PSEL、ASEL]

For PSEL and ASEL controller, the same wiring is applied.

*1 When the PC is connected to the controller using the USB cable, it is required to attach

the dummy plug to the controller to short Safety Gate Signal for the PC application

software and teaching pendant.

Warning When the PC is connected to the controller using the USB cable, the emergency stop box can

not be connected. In the case of stop in an emergency, process it in the system.

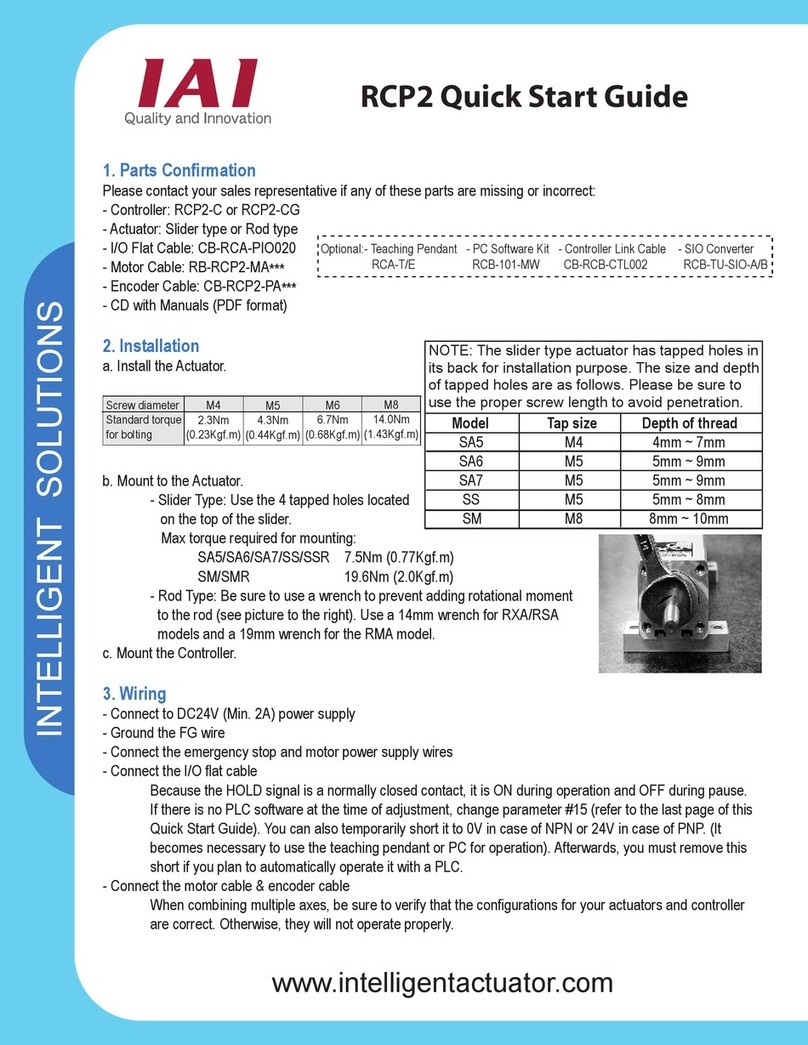

Wiring for the Power/Emergency Stop Circuit and Brake Forced Release Switch

[PSEL、ASEL] Shown is an example when two or more

controllers on the whole system

emergency stop circuit, are stopped in an

emergency.

*1 The connection of the teaching pendant is automatically recognized using the controller.

*2 For the CR contacts between EMG “+” and EMG “-”, use 24VDC, 0.5A/contact or more.

*3 When the safety category requirements include the motor driving source interception,

connect CR.

I/O Signals

Program Mode

Input

Pin

No.

Electric

wire

color

Port

No.

Function in Standard

Setting

(in Delivery)

Parameter

No. Parameter Name

Input

Function Set

Value (at the

delivery from

factory)

Input

Function

Set Value

*1

Function

1A BR-1 - I/O power connector + 24V - - - 0 Universal Input

1B RD-1 016 Program No. 1 Selection

(MSB)

251

Input Function Selection 016

9 1 Program Start (BCD) (ON Edge)

Signal

2A OR-1 017 Program No. 2 Selection

(The second bit)

252

Input Function Selection 017

10 2 Program Start (BIN) (ON Edge)

Signal

2B YW-1 018 Program No. 4 Selection

(The third bit)

253

Input Function Selection 018

11 3 Software Reset (Turning ON for

1 second)

3A GN-1 019 Program No. 8 Selection

(The fourth bit)

254

Input Function Selection 019

12 4 Servo ON signal (ON Edge)

3B BL-1 020 Program No. 10 Selection

(The fifth bit)

255

Input Function Selection 020

13 5

Automatic Start Program Start-up

Signal

(ON Edge)

4A PL-1 021 Program No. 20 Selection

(The sixth bit)

256

Input Function Selection 021

14 6 All servo-axes soft interlock

(OFF level)

4B GY-1 022

Program No. 40 Selection

(LSB

•

The seventh bit)

257

Input Function Selection 022

15 7 Operation Pause Cancellation

(ON Edge)

5A WT-1 023 Software Reset 258

Input Function Selection 023

3 8 Pause Signal (OFF level)

5B BK-1 000 Program Start 30

Input Function Selection 000

1 9 Program No. appointment

(MSB)

6A BR-2 001 Universal Input 31

Input Function Selection 001

0 10 Program No. appointment

(The second bit)

6B RD-2 002 Universal Input 32

Input Function Selection 002

0 11 Program No. appointment

(The third bit)

7A OR-2 003 Universal Input 33

Input Function Selection 003

0 12 Program No. appointment

(The fourth bit)

7B YW-2 004 Universal Input 34

Input Function Selection 004

0 13 Program No. appointment

(The fifth bit)

8A GN-2 005 Universal Input 35

Input Function Selection 005

0 14 Program No. appointment

(The sixth bit)

8B BL-2 006 Universal Input 36

Input Function Selection 006

0 15 Program No. appointment

(LSB

•

The seventh bit)

9A PL-2 007 Universal Input 37

Input Function Selection 007

0 16 Error Reset (ON edge)

9B GY-2 008 Universal Input 38

Input Function Selection 008

0 17 Driving Power Interruption

Cancellation Input (ON Edge)

10A WT-2 009 Universal Input 39

Input Function Selection 009

0 18 Homing Command Signal for All

Effective Axes (ON Edge)

10B BK-2 010 Universal Input 40

Input Function Selection 010

0 19 All Increment Effective Axes

Homing(ON Edge)

11A BR-3 011 Universal Input 41

Input Function Selection 011

0 20

PC and Teaching Pendant

Servo-Motor Movement Command

Receipt Permission Input

11B RD-3 012 Universal Input 42

Input Function Selection 012

0 21 Remote Mode Control Input

12A OR-3 013 Universal Input 43

Input Function Selection 013

0 22 First Axis Brake Forced Release

Input

12B YW-3 014 Universal Input 44

Input Function Selection 014

0 23 Second Axis Brake Forced

Release Input

13A GN-3 015 Universal Input 45

Input Function Selection 015

0

*1 When the input function set values (0 to 23) are set in the I/O parameters 30 to 45 (input function selection 000 to

015) and I/O parameters 251 to 258 (input function selection 016 to 023), the set functions are allocated.

Program Mode

Output

Pin

No.

Electric

wire

color

Port

No.

Function in Standard

Setting

(in Delivery)

Parameter

No. Parameter Name

Output

Function Set

Value (at the

delivery from

factory)

Output

Function

Set Value

*1

Function

13B BL-3 300 Alarm Output 46

Output Function Selection

300 2 0 Universal Input

14A PL-3 301 READY Output 47

Output Function Selection

301 7 1 Error Output at the Operation

Cancellation Level or more(ON)

14B GY-3 302 Universal Output 48

Output Function Selection

302 0 2 Error Output at the Operation

Cancellation Level or more(OFF)

15A WT-3 303 Universal Output 49

Output Function Selection

303 0 3 Error Output at the Operation

Cancellation Level or more+

Emergency-stop Output (ON)

15B BK-3 304 Universal Output 50

Output Function Selection

304 0 4 Error Output at the Operation

Cancellation Level or more+

Emergency-stop Output (OFF)

16A BR-4 305 Universal Output 51

Output Function Selection

305 0 5 READY Output (PIO Trigger

Program Operation Available)

16B RD-4 306 Universal Output 52

Output Function Selection

306 0 6 READY Output (PIO Trigger

Program Operation Available)

and without occurrence of any

error at the operation

cancellation level or more

17A OR-4 307 Universal Output

53

Output Function Selection

307 0 7 READY Output (PIO Trigger

Program Operation Available)

and READY Output (PIO Trigger

Program Operation Available,

and without occurrence of any

error at the cold start level or

more or more level or more

17B YW-4 N I/O power connector 0V - - - 8 Emergency-stop Output(ON)

9

Emergency-stop Output (OFF)

10

AUTO Mode Output

11

Output during the Automatic

Operation

12

Output at the time of “All

Effective Axes Homing (=0)”

13

Output when all the effective

axes homing is completed

14

Output when all the effective axes

home preset coordinates are set

15

System Memory Battery (Option)

Voltage Drop

Warning Output

16

Voltage Drop Warning Output for

the Battery (Option) for

maintaining the Absolute Data

17

Driving Source Interception

(SDN) Notification Output

24

Output during the first axis servo ON

25

Output during the second axis

servo ON

*1 When the output function set values (0 to 17, 24, 25) are set in the I/O parameters 46 to 53 (output function

selection 300 to 307), the set functions are allocated.

The mixed allocation of output function set values 1, 2, 3 and 4 is not available.

The mixed allocation of output function set value 5, 6 and 7 is not available.

Positioner Mode Function description for I/O Signals

Input

Parameter No.25

Signal Abbreviation Signal Name Function Description 123416

PC1 to PC13

PC1 to PC11

Command Position

No. Signal

Input of the position number to m ove (binary input) { { {

Item Change Mode

PC1 to PC16

Position/Item No.

Signal

Input of the No. of item to be moved and position No. (Binary Input) {

DC-S-C1

Interchangeable Mode

PC1 to PC1000

Command Position

No. Signal

Input of the position number to move (BCD input)

(PC1 to 8 : Units Digit, PC10 to 80 : Tens Digit, PC100 to 800 : Hundreds Digit,

PC1000 : Thousands Digit)

{

RES Reset Signal An alarm will be reset when this signal is turned ON. Also, when it is turned ON in the

pause mode (*STP is turned OFF), the remaining movement amount can be cancelled. { { { {

CSTR PTP Strobing Signal

(Start Signal)

The actuator will start to move to the position set by the command position number. { { {

Double Axis

Independent Mode

CSTR1, CSTR2

PTP Strobing Signal

(Start Signal)

The actuator will start to move to the position set by the command position number.

•CSTR1 : First Axis

•CSTR2 : Second Axis

{

HOME

Home Return Signal

The controller will perform home return operation when this signal is turned ON. { {

Double Axis

Independent Mode

HOME1, HOME2

Home Return Signal

The controller will perform home return operation when this signal is turned ON.

•HOME1 : First Axis

•HOME2 : Second Axis

{

SON Servo ON signal The servo remains ON while this signal is ON, or OFF while this signal is OFF. { { {

Double Axis

Independent Mode

SON1, SON2

Servo ON signal The servo remains ON while this signal is ON, or OFF while this signal is OFF.

•SON1 : First Axis

•SON2 : Second Axis

{

PUSH Pressing Signal When the command position No. signal and start signal are input in the Signal ON

mode, the pressing operation is performed. { {

*ST P Pause Sig nal When this signal turns OFF while the actuator is moving, the actuator will decelerate to stop.

The remaining movement is retained and will resume when the signal is turned ON again. { { {

Double Axis

Independent Mode

*STP1, *STP2

Pause Sign al When this signal turns OFF while the actuator is moving, the actuator will decelerate to stop.

The remaining movement is retained and will resume when the signal is turned ON again.

•*STP1 : First Axis •*STP2 : Second Axis

{

DC-S-C1

Interchangeable Mode

STP

Pause Sign al When this signal turns ON while the actuator is moving, the actuator will decelerate to stop. The

remaining movement is retained and will resume when the signal is turned OFF again. {

*CANC Cancel Signal When this signal turns OFF while the actuator is moving, the actuator will decelerate to

stop. During the stop condition, the remaining movement amount is cancelled, so even

when this signal is turned ON, the movement is not restarted.

{ {

Double Axis

Independent Mode

*CANC1, *CANC2

Cancel Signal When this signal turns OFF while the actuator is moving, the actuator will decelerate to

stop. During the stop condition, the remaining movement amount is cancelled, so even

when this signal is turned ON, the movement is not restarted.

•*CANC1 : First Axis •*CANC2 : Second Axis

{

LINE Interpolation Signal When the double axis unit is used and this signal is turned ON, the two axes perform the

linear interpolation operation { { {

DC-S-C1

I

nterchangeable Mode

CPRES

CPU Reset Signal When this signal is turned ON the controller is re-started up.

{

Teaching Mode

JOG1 +, JOG1 -

JOG2 +, JOG2 -

Jog Signal When the MODE signal is turned ON and the mode is set to Teaching Mode, using the ON

edge detection of this signal, the jog operation is performed in plus or minus direction. When

the OFF edge is detected during the jog operation, it is decelerated and stopped.

•JOG1 +, JOG1 - : First Axis •JOG2 +, JOG2 - : First Axis

{

Teaching Mode

IC001

IC01

IC05

IC1

Inching (Manual

Axis Operation)

Distance Signal

When the MODE signal is turned on and the mode is set to Teaching Mode, specifying

the inching (manual axis operation) distance and entering the jog signal (JOG1+,

JOG1-, JOG2+ or JOG2-), performs the inching (manual axis) operation.

•IC001 : Set the Inching (manual axis operation) Distance to “0.01mm”.

•IC01 : Set the Inching (manual axis operation) Distance to “0.1mm”.

•IC05 : Set the Inching (manual axis operation) Distance to “0.5mm”.

•IC1 : Set the Inching (manual axis operation) Distance to “1mm”.

When two or more inching (manual axis operation) distances (IC001 to IC1) are set, the

inching (manual axis operation) is performed for the total distance.

{

Teaching Mode

CSTR/PWRT

PTP Strobing Signal

(Start Signal)/

Current

Position Write Signal

When the MODE signal is turned OFF and the mode is set to Normal Positioning Mode,

it is used as the start signal.

When the MODE signal is turned ON and the mode is set to Teaching Mode, it is used

as the current position write signal. Specifying the write position and turning ON this

signal for 20msec or more, writes the current position onto the specified position.

{

Teaching Mode

MODE

Teaching Mode

Specifying Signal

When the MODE signal is turned OFF, the mode is set to Normal Positioning Mode.

When the MODE signal is turned OFF, the mode is changed to Teaching Mode.

(When the SERVO is turned ON and jog signal is turned ON, turning ON the MODE

signal starts up the actuator. Be careful.

{

Output

Parameter No.25

Signal Abbreviation Signal Name Function Description 123416

*ALM Controller Alarm

Status Signal

When the controller is turned ON normally, it is turned ON and when the controller is in alarm

mode, it is turned OFF. When the controller is recovered from alarm mode, it is turned ON again.

{ { { {

DC-S-C1

Interchange-

able Mode

ALM

Controller Alarm

Status Signal

When the controller is turned OFF normally, it is turned ON and when the controller is in alarm

mode, it is turned ON. When the controller is recovered from alarm mode, it is turned OFF again.

{

RDY Ready Signal

When the controller initialization is completed normally and the control is enabled, it is turned ON.

{ { { { {

PEND Positioning

Completion Signal

This signal is turned ON when the positioning is completed (the actuator reaches within the positioning range).

When the start signal is turned ON and the movement command is issued, this signal is turned OFF. Then, after the

movement, the start signal is turned OFF and the actuator reaches within the positioning width, this signal is turned

ON. Until the start signal is turned ON, even when the actuator is out of the positioning width, this signal is not turned

ON.

When the start signal continues to be turned ON, even when the actuator reaches within the positioning width, this

signal is not turned ON.

{ { {

Double Axis

Independent Mode

PEND1

PEND2

Positioning

Completion Signal

This signal is turned ON when the positioning is completed (the actuator reaches within the

positioning range).

When the start signal is turned ON and the movement command is issued, this signal is

turned OFF. Then, after the movement, the start signal is turned OFF and the actuator

reaches within the positioning width, this signal is turned ON. Until the start signal is turned

ON, even when the actuator is out of the positioning width, this signal is not turned ON.

When the start signal continues to be turned ON, even when the actuator reaches within the

positioning width, this signal is not turned ON.

•PEND1 : First Axis •PEND2 : Second Axis

{

HEND Homing

Completion Signal

When the power is input, it is in the OFF mode. This signal will turn ON when home

return has been completed. It is turned ON when the homing command is issued. { { {

Double Axis

Independent Mode

HEND1, HEND2

Homing

Completion Signal

When the power is input, it is in the OFF mode. This signal will turn ON when home

return has been completed. It is turned ON when the homing command is issued.

•HEND1 : First Axis •HEND2 : Second Axis

{

SVON

Servo ON Status Signal

This signal will remain ON while the servo is ON. { { {

Double Axis

Independent Mode

SVON1, SVON2

Servo ON Status Signal

This signal will remain ON while the servo is ON.

•SVON1 : First Axis •SVON2 : Second Axis {

PSED Pressing

Completion Signal

In the pressing operation, when the operation is completed, this is turned ON. When the swing error does

not occur (when the pressing operation is completed), the turning-off condition is continued.

{ {

SSER*1 System Battery

Error Signal

When the system memory battery (option) voltage drops, it is turned ON. { { { {

ABER*1

Battery for the Absolut