Blue Ribbon 311 User manual

Blue Ribbon Corporation

Installation Manual

Model 311

Hazardous Approved

Transmitter

Model BR311 Hazardous Approved Installation Manual

Table of Contents

1. IntroductIon . . . . . . . . . . . . . . . . . . . . 1

1.1. Product Description.............................1

1.2. Warning. ....................................1

1.3. Unpacking/Inspection. .........................1

1.4. Using This Manual. ............................1

2. InstallatIon . . . . . . . . . . . . . . . . . . . . . 2

2.1. Mounting/Process Connection. ...................2

2.2. Power Supply Connection. .......................2

2.3. Wiring/Grounding. ............................3

2.4. Environment. .................................4

3. operatIon/MaIntenance/HandlIng . . . . . . . . . 4

4. trouble sHootIng/return InforMatIon . . . . . . 4

4.1. No output. ...................................4

4.2. Erratic output or zero drift. ......................5

4.3. Slow Response. ...............................5

5. Warranty . . . . . . . . . . . . . . . . . . . . . . 6

6. appendIx a - approval Info . . . . . . . . . . . . . 7

6.1. Approval Documentation:. ......................7

1

Model BR311 Hazardous Approved Installation Manual

1. IntroductIon

1.1. Product Description

The Model 311 is an oil field service pressure transmitter with a ”NPT(F) pressure port fitting

(standard - optional ports available), 4-20 mA output and measures pressures up to 75,000

psi (5168 bar).

1.2. Warning

Pressurized vessels and associated equipment are potentially dangerous. The product de-

scribed in this guide should be operated only by personnel trained in the procedures that will

assure safety to themselves, to others, to the equipment, and to the product. Specific warnings

are noted as in specific installation/operation sections.

1.3. Unpacking/Inspection

The Model 311 was carefully tested, inspected and packed. Upon receipt of the shipment thor-

oughly inspect the transducer. If you see any visible signs of obvious shipping damage, notify

the freight company immediately.

1.4. Using This Manual

This manual is intended to help the end user install, maintain, and provide general service of

the Blue Ribbon Corp. Model 311 pressure transmitter. The user should have a general under-

standing of current loops and general instrument control. The Model 311 is a precision instrument

and should be given the same care as any other precision instrument during installation and

operation.

Return to Table of Contents

DISCLAIMER: No representations or warranties are made with respect to the contents of this Installation Guide. Blue Ribbon

Corporation reserves the right to revise this guide and to make changes periodically to the content thereof, without

obligation to notify any persons of such revisions.

2

Model BR311 Hazardous Approved Installation Manual

Return to Table of Contents

2. InstallatIon

2.1. Mounting/Process Connection

The standard Model 311 transducer is supplied with a ¼” NPT(F) pressure port. Installation

of the device shall be in accordance with industry standard pipe fitting requirements for this

size. Torque shall only be applied to the transducer during installation (or removal) from the

wrench flats provided on the pressure port. As a general rule of thumb, the device shall be

torqued “wrench-tight” to preclude leakage from the process connection. Contact Blue Ribbon

Corp. sales personnel for additional information if required, or for specific installation require-

ments for non-standard process connections.

Insure media is compatible with 15-5 SST (standard material, optional materials available,

check part number (Appendix A) to verify wetted material) to avoid premature corrosion of the

diaphragm. This can cause performance degradation and eventual sensor rupture/failure.

Properly tighten process connections before applying pressure to insure no leaks or mechani-

cal failure can occur.

Never insert sharp objects into diaphragm. This could cause permanent damage to the sensor

and/or mechanical failure/diaphragm rupture.

2.2. Power Supply Connection

For best operation, the pressure transmitter needs clean, regulated power with an output im-

pedanance less than 20 Ω. Minimum voltage is 10 volts with no resistive loading, to a maxi-

mum of 36 Vdc (Z, P + X Series) (28 Vdc for I, AI + GI Series units). As loads are added to the

current loop (galvanic barriers, current measuring devices resistors), the minimum excitation

voltage must increase in order to maintain proper operating voltage.

Exceeding maximum supply voltage can damage electronics and cause malfunction or failure,

and can cause an explosion with Intrinsically Safe units. Please refer to the attached IS con-

nection diagram (Appendix B), and applicable local codes, for proper electrical installation.

Always inspect/clean electrical connection and sealing surface prior to installation.

3

Model BR311 Hazardous Approved Installation Manual

Return to Table of Contents

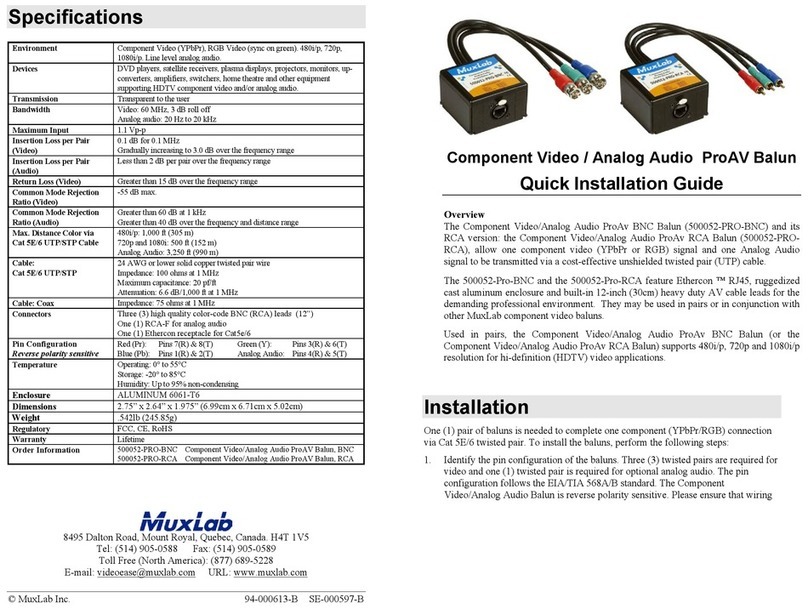

2.3. Wiring/Grounding

Wire per Fig. 1 connection diagrams for standard wiring or specific shunt option. Do not run

wires next to power lines, electrical systems, motors, generators, or any other equipment which

may generate a significant amount of electrical noise or magnetic fields.

POWER

SUPPLY

POWER

SUPPLY

POWER

SUPPLY

4-20m A

METER

4-20m A

METER

4-20m A

METER

CASE/GND

CASE/GND CASE/GND

SEE

NOTE 2

NO SHUNT

(STANDARD)

NON-POWERED SHUNT

(OPTION NC)

POWERED SHUNT

(OPTION NB)

SEE

NOTE 2

+EXC/SIG

- EXC/SIG

+EXC/SIG

- EXC/SIG

+EXC/SIG

- EXC/SIG

+SHUNT/CAL

-SHUNT/CAL

SHUNT/CAL

SHUNT/CAL

NOTE 1: QUALIFIED END-USER TO INSTALL GROUND WIRE PER CODE REQUIREMENTS.

NOTE 2: SHORT WIRES TOGETHER OR CLOSE SHUNT SWITCH (SUPPLIED BY END USER)

TO ACTIVATE SHUNT.

Fig. 1: Connection Diagrams (for IS units see Appendix B)

Install only after verifying both input power and line pressure are off and at zero.

Avoid contact with exposed leads or connector pins, high voltage may be present on leads

and can cause electrical shock.

Observe safe ESD handling precautions to avoid static damage to sensitive components.

4

Model BR311 Hazardous Approved Installation Manual

Return to Table of Contents

2.4. Environment

The typical operating temperature range for the electronics is from -40°F (-23°C) to 185°F

(85°C). The unit should be mounted as close to the process as possible with the ambient tem-

perature surrounding the electronics in the range as specified above.

Exceeding maximum temperature rating can cause electronics malfunction or failure, and is

an explosion risk with IS units.

Protect electrical connection from direct/continued exposure to fluids. Moisture ingress can

occur and cause eventual electrical failure.

3. operatIon/MaIntenance/HandlIng

The Model 311 is designed to give a 4-20 mA output directly proportional to pressure. Specif-

ic pressure range, input voltage requirements and electrical connections are marked on unit.

See Appendix A for all performance specifications. Standard electrical connection is a HEYCO

connector on the I.S. approved product +½” NPT M on Explosion Proof Series and pressure

port is ¼” NPT(F). Appropriate mating con nections are required for proper installation and

safety. Other port and electrical connections are available and noted as option code in part

number. See Appendix A for list of options.

Replace broken fasteners (available through the factory) as they may compromise the seal and

cause contamination and/or electronics failure.

Unit can be hot when removed from service. Wear protective gloves when handling unit in this

condition.

5

Model BR311 Hazardous Approved Installation Manual

4. trouble sHootIng/return InforMatIon

4.1. No output

Verify power supply voltage meets transmitter requirements

Check wiring connections

Verify pressure if being applied

Verify output load is not shorted

4.2. Erratic output or zero drift

Verify pressure applied is constant

Verify power supply remains within specifications

Inspect electrical connections for discontinuity or damage

Verify output with a multi-meter

Check insulation resistance between amplifier and transmitter case

4.3. Slow Response

Verify pressure port is not clogged

If the problem persists, please call the factory as indicated below for assistance

and have the following information ready:

Serial number

Model number

Loop setup – power supply, resistor, cable routing/length

What action caused devices to fail?

Contact: [email protected]

716-773-9300

Repairs should only be done by Blue Ribbon Corporation. Repairs done by customer will void

any warranties and may cause permanent damage to unit. Repairs done by customer on In-

trinsically Safe units will void the approvals and are a potential explosion hazard.

Returned products that have been exposed to hazardous substances must be cleaned prior to

return and must include the Material Safety Data Sheet for all substances.

Return to Table of Contents

6

Model BR311 Hazardous Approved Installation Manual

5. Warranty

Blue Ribbon Corporation warrants its products to the original customer/purchaser against

defects in material and workman ship for a period of one (1) year from the date of delivery

by Blue Ribbon Corp., as shown in its shipping documents, subject to the following terms and

conditions:

Without charge Blue Ribbon Corp. will repair or replace products found to be defective in ma-

terials or workmanship within the warranty period provided that:

1. The product has not been subjected to abuse, neglect, accident, incorrect wiring

(not provided by Blue Ribbon Corp.), improper installation or servicing, or use in

violation of instructions furnished by Blue Ribbon Corp.

2. As to any prior defect in materials or workmanship covered by this warranty, the

product has not been repaired or altered by anyone except Blue Ribbon Corp. or its

authorized service agencies.

3. The serial number has not been removed, defaced or otherwise changed.

4. Examination discloses, in the judgement of Blue Ribbon Corp., a defect in materials

or workmanship which developed under normal installation, use and service; and

5. Blue Ribbon Corp. is notified in advance of, and approves, the return by issuing a

Return Material Authorization Number; and the products are returned to Blue Rib-

bon Corp. transportation prepaid. Products returned without an RMA number will

not be accepted and be returned to sender at sender’s expense.

THIS WARRANTY IS THE ONLY WARRANTY AND IS IN LIEU OF ANY OTHER WARRANTY EXPRESSED

OR IMPLIED, INCLUDING ANY WARRANTY OR MERCHANTABILITY OR FITNESS. NO REPRESEN-

TATIVE OR PERSONS ARE AUTHORIZED TO GIVE ANY OTHER WARRANTY OR TO ASSUME FOR

BLUE RIBBON CORP. ANY OTHER LIABILITY IN CONNECTION WITH THE SALE OF ITS PRODUCTS.

BLUE RIBBON CORP. DOES NOT ASSUME THE COSTS OF REMOVAL AND/OR INSTALLATION OF

THE PRODUCT OR ANY OTHER WORKMANSHIP, OR WILL BLUE RIBBON CORP. BE LIABLE FOR ANY

CONSEQUENTIAL DAMAGES RESULTING FROM THE USE OR INSALLATION OF ITS PRODUCT.

For a copy of our repair policy, visit our website at www. BlueRibbonCorp.com

or call our repair department at 716-773-9300.

WECO® is a Federally Registered Trademark with FMC Technologies.

Copyright© 2005 GP:50

All rights reserved. This specification must not be reproduced in any form without written per-

mission of the copyright owner.

Return to Table of Contents

7

Model BR311 Hazardous Approved Installation Manual

6. appendIx a - approval Info

6.1. Approval Documentation

packages to be shipped with units, per option code

AI - ATEX Intrinsic Safety

o A8EG-10AIA.CC-ATEX C of C

o 8C1-55.01-2-ATEX/IEC Connection Diagram, Model 311

o A8EG-10AIA.DC - CE: ATEX Declaration of Conformity

o A8EG-10AIE.DC - CE: EMC Declaration of Conformity

o A8EG-10AIP.DC - CE: PED Declaration of Conformity

EC - CE Compliance (EMC and PED)

o A8EG-10AIE.DC – CE: EMC Declaration of Conformity

o A8EG-10AIP.DC – CE: PED Declaration of Conformity

I - FM/CSA Intrinsic Safety

o A8EG-10IC.CC – CSA C of C

o A8EG-10IF.CC – FM C of C

o 8C1-56.01-2 – FM/CSA Connection Diagram, Model 311

Return to Table of Contents

Model BR311 Hazardous Approved Installation Manual

Blue Ribbon Corporation

2770 Long Road

Grand Island, NY 14072

U.S.A.

Tel: 716.773.9300

Toll Free: 877-774-4751

Fax: 716. 773.5019

email: [email protected]

Visit our website www.blueribboncorp.com

Return to Table of Contents

Table of contents

Other Blue Ribbon Transmitter manuals