Blue-White industries F-300 User manual

Other Blue-White industries Measuring Instrument manuals

Blue-White industries

Blue-White industries F-410 User manual

Blue-White industries

Blue-White industries Sonic-Pro S6A Series User manual

Blue-White industries

Blue-White industries Sonic-Pro S6A Series User manual

Blue-White industries

Blue-White industries F-2000 User manual

Blue-White industries

Blue-White industries F-452 Series User manual

Blue-White industries

Blue-White industries F451 Series User manual

Blue-White industries

Blue-White industries F-1000 User manual

Blue-White industries

Blue-White industries F-400 User manual

Blue-White industries

Blue-White industries F-451 User manual

Blue-White industries

Blue-White industries F-1000 User manual

Popular Measuring Instrument manuals by other brands

Electronics International Inc

Electronics International Inc UBG-16 operating instructions

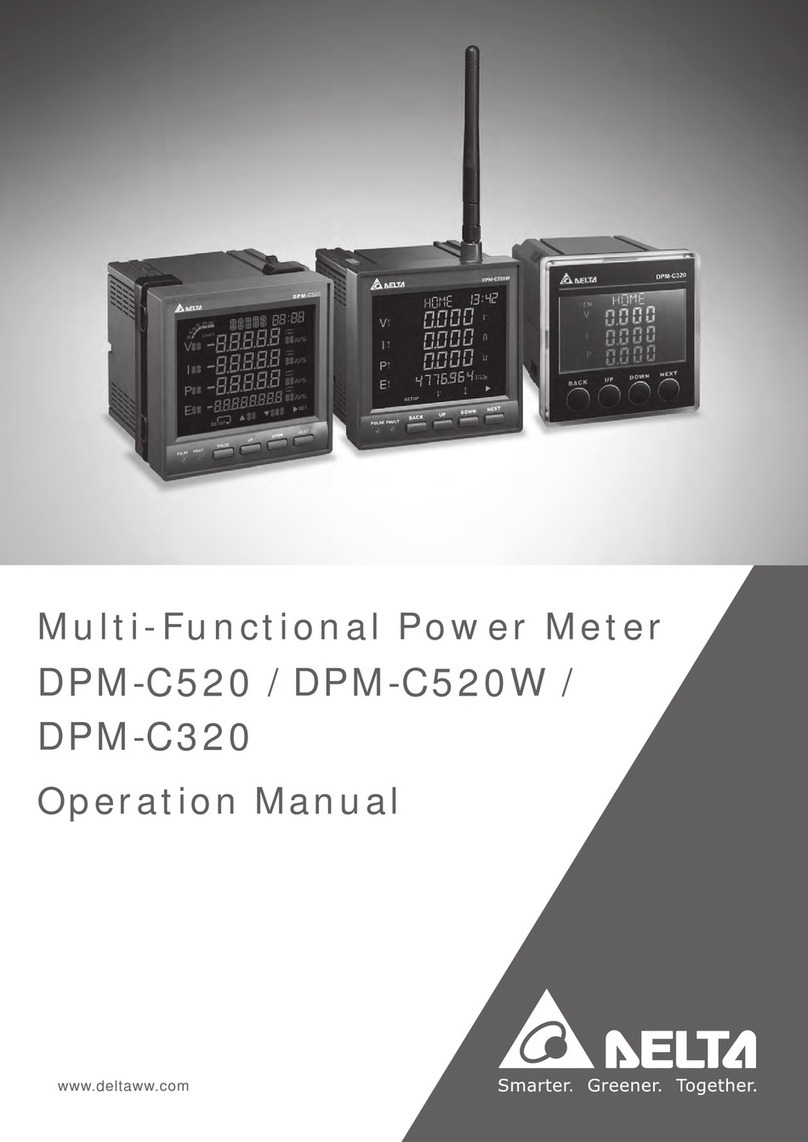

Delta

Delta DPM-C320 Operation manual

Unit

Unit UT255A operating manual

In-situ

In-situ Aqua Troll 400 quick start guide

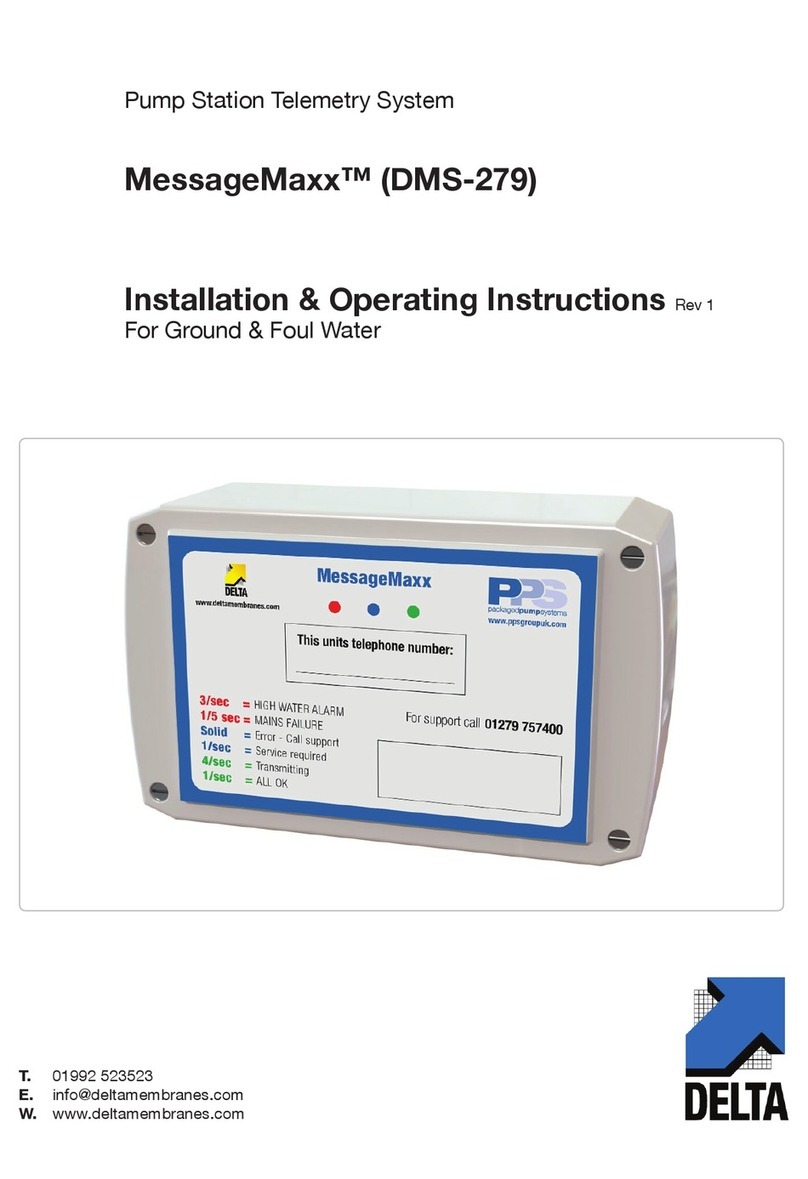

Delta

Delta MessageMaxx DMS-279 Installation & operating instructions

adpower

adpower Wattman HPM-100A manual