BlueRange BRBJ3T User manual

Model No’s:

BRBJ3T ~ 3 Tonne

BRBJ5T ~ 5 Tonne

BRBJ10T ~ 10 Tonne

IMPORTANT:

We reserve the right to update our product speci ication, data and parts with out notice, as part o

our continuous improvement policy.

We accept no liability or any incorrect use o this product.

Document BRBJ – Dated 1st May 2021 Rev 1.2

PROTECT THE ENVIRONMENT

When this product reaches the end o its use ul/working li e it should be

recycled in line with local policies and regulations. Take the product to you

recycling centre to be disposed o in an environmentally riendly manner.

IMPORTANT:

KEEP THESE INSTRUCTIONS SAFE FOR FUTURE REFERENCE.

READ INSTRUCTIONS CAREFULLY, FOLLOW THE SAFE WORKING PRACTICES

OUTLINED AND HEED THE WARNINGS. FAILURE TO DO SO MAY LEAD TO PERSONAL

INJURY OR DAMAGE THE PRODUCT.

HYDRAULIC

BOTTLE JACK

1 2

SAFETY

Before use ensure the Bottle Jack is in good working order and not damaged. If the Bottle Jack

is damaged remove from service immediately. Damaged parts should be repaired or replaced

before the unit is used again. This should be undertaken using genuine parts by a trained

technician.

●Ensure the load is within the lifting capacity of the jack.

●Ensure the jack is used on level ground, preferably concrete. void soft surfaces like

Tarmacadam as the jack may sink.

●Ensure all but essential personnel keep a safe distance while the jack is in use.

●Ensure the work area is well lit, clean and free from clutter.

●Ensure work area floor is sound and not slippery so a firm footing can be maintained.

●Ensure only competent personnel operate the hydraulic jack.

●Ensure the area is clear before lowering the load

●Ensure the lifting point is centred and stable on the jack saddle – to avoid loads slipping.

●If using the jack on a Vehicle:-

●Ensure the vehicle weight is within capacity and that the recommended lifting points

are used – see owner’s manual. Position the Jack to avoid operating it from under the

vehicle.

●Ensure jacking the vehicle will not result in a leakage of fuel or other dangerous fluids.

●Ensure wheel nuts are slightly loosened before jacking, and only lightly tightened

before lowering. Fully tighten the nuts to the specified torque when the car is on the

ground. This process avoids moving the vehicle while it is raised. Check wheel nut

torque again after a short journey.

●Ensure the hand brake is applied (in Park for utomatics), engine switched off and

chocks placed under the wheels.

●Ensure a minimum clearance of 0.5m between the vehicle and any other objects to

allow for raising and tilting during jacking.

●Ensure all occupants are out of the vehicle before lifting and never let anybody in the

vehicle while on the jack or axle stands.

●Ensure suitable axle stands, correctly positioned, are used to support the vehicle

before placing any part of your body under the vehicle.

DANGER – Changing the wheel at the roadside is hazardous. Take extra care -avoid

jacking on Tarmac, tra ic may cause the vehicle to rock, use hazard warning lights and

NEVER go under the vehicle. I in doubt seek pro essional help – especially with caravans

or trailers.

DANGER

Use the jack for lifting only – never to support the lifted load for other work tasks eg welding..

●DO NOT exceed the rated capacity Jack or exceed its maximum pump stroke.

●DO NOT allow untrained personnel to operate the Jack.

●DO NOT remove labels from the Jack – replace any damaged or unclear labels.

●DO NOT modify the Jack or use it for any purpose it was not intended for.

●DO NOT use when under the influence of drugs, alcohol or medication that may cause

drowsiness.

●DO NOT top the Jack up with Brake fluid. USE only the recommended hydraulic oil.

●DO NOT use the lever hoist if any chains are kinked or knotted.

BOTTLE JACK

IMPORTANT-CAUTION

Install, operate and maintain this equipment in accordance with these instructions. Failure to do so

may lead to personal injury, damage to the Jack and invalidation of the warranty.

Take immediate action to repair or replace damaged parts by contacting your supplier. Ensure that

all accessory lifting devices are suitably certified. If Jack is damaged, remove from service

immediately.

Read thoroughly the contents before use and keep this handbook for future use.

OPERATION

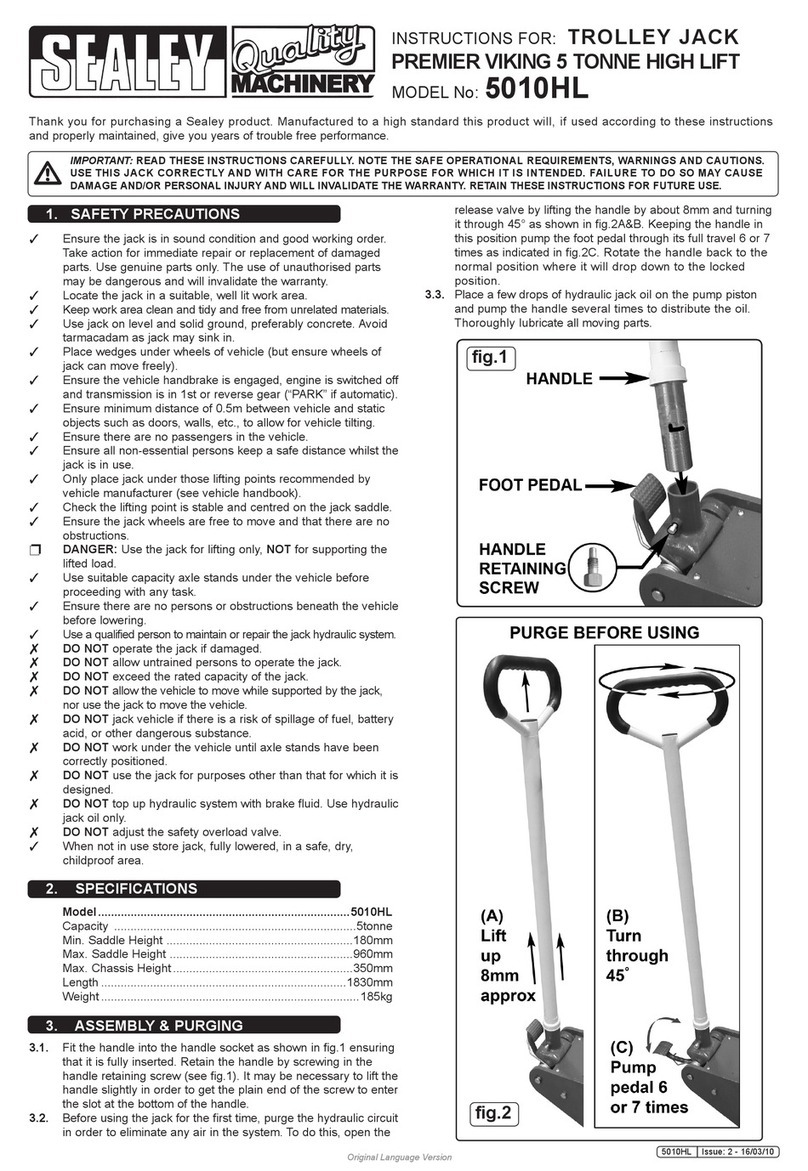

The Bole Jack may have accumulated air during transit, to ensure this is eliminated by purging

the system as follows. Open the release valve ( ) and pump the system several "mes. Close the

release valve ( ) .

●LIFTIN

1. Before operating estimate the weight of the load. Do not operate the jack

above its rated load.

2. Identify the centre of gravity of your load and place the jack on hard

ground. suitable solid pad may be used under the jack to avoid it sinking

or leaning in softer surfaces.

3. Before operating the jack, insert the notched end of the handle into

the release valve (1).Turn the operating handle clock wise until the release

valve is closed. Do not over tighten the valve.

4. Insert operating handle into the socket slowly pump until the saddle

touches the load. Ensure it seats properly with the load, then slowly

continue pumping until the load is at the required height. The ram will stop

rising when the maximum height is reached – do not try to over extend the

jack.

BOTTLE JACK

3 4

BOTTLE JACK

1. Release valve lever

2. Base

3. 0-Ring

4. Hydraulic cylinder

5. Ram

6. Hydraulic oil

7. 0il-tight tank

8. Extension screw

9. Top cap

10. Pump plunger

11. Pump Body

12. 0-Ring

SCHEMATIC DIA RAM

OPERATION

●LOWERIN

1. Lower the Jack by turning the release valve (1) slowly anti-clockwise with

the notched end of the handle. Do not release the valve too much as this

could result in an uncontrolled descent of the load.

2. To stop the descent at any time close the release valve with an clockwise

turn.

BOTTLE JACK

MAINTENANCE & STORA E

●LOWERIN

1. Lower the Jack by turning the release valve (1) slowly anti-clockwise with

the notched end of the handle. Do not release the valve too much as this

could result in an uncontrolled descent of the load.

2. To stop the descent at any time close the release valve with an clockwise

turn.

●STORA E

Before storing the Jack clean and lubricate all moving parts with a acid

free oil. The Jack should be stored in a clean dry area.

When storing the jack the ram should be in its lowest position to minimise

corrosion and the handle removed and stored safely.

●MAINTENANCE

IMPORTANT only fully qualified personnel should attempt any maintenance.

DO NOT use the Jack if it is believed to have been subject to abnormal loads

or shock. Inspect the unit and take appropriate remedial action.

Before each use visually check the Jack for abnormal wear, cracks, corrosion

or other signs of wear or damage.

t ambient temperatures (-3C – 45C) use machine oil (GB 443-84) N15 at

temperatures 15C to 13C use synthetic spindle oil (GB44164)

Ensure sufficient oil is in the Jack to enable it to reach its full lift.

●

Dual Document

EC DECLARATION

OF CONFORMITY

UKCA DECLARATION

OF CONFORMITY

Designation: Hydraulic Bottle Jack 3 Tonne, 5 Tonne, 10 Tonne.

Model No: BRBJ3T / BRBJ5T / BRBJ10T

Complies wit t e following directives:

Machinery Directive 2006/42/EC

The con ormity assessment procedure ollowed was in accordance with EN ISO

1494:2000+A1:2009

Manufacturing Date/serial number :

Please re er to product data label or Batch number

Technical ile holder : Bluerange

Authorised signatory

Dated: 11/05/2021

Signature:

Name: Mr Malcolm Lewis

Position: Brand Manager

Company:

Bluerange 76 Regent Road Bootle Merseyside L20 1BL

9 10

Malcolm Lewis

BOTTLE JACK

BOTTLE JACK

This manual suits for next models

2

Popular Jack manuals by other brands

Sunex Tools

Sunex Tools NSJ0101 quick start guide

Evercraft

Evercraft 776-1006 manual

Faller

Faller 120277 manual

Norco

Norco 71550 Setup, Operation, Maintenance Instructions

Rieco-Titan Products

Rieco-Titan Products OSI-433N installation manual

Cattini Oleopneumatica

Cattini Oleopneumatica YAK 2120X Operating and maintenance manual