Brano 15-00-CON-W User manual

translation of the original instructions for use (also applies to special designs)

BRANO a.s., 747 41 Hradec nad Moravicí

the Czech Republic

tel.: +420/ 553 632 303

http://www.brano-zz.cz; http://www.brano.eu;

OPERATION MANUAL

SECURITY PRINCIPLES, OPERATION AND MAINTENANCE

FOR

RACK JACK

Type

15-00

load capacity

2,5t

and

5t

Type

15-01

load capacity

10t

CONTAINER WALL-MOUNTED CONSTRUCTION – CON-W

CONTAINER DESIGN – CON

these versions are further available in variants:

DESIGN WITH RATCHET CRANK – RK

DESIGN WITH RATCHET HANDLE-LEVER – RKP

DESIGNED IN EXPLOSIVE ENVIRONMENTS – NEXP

Peruse the operation manual before using the jack. It comprehends substantial security

instructions and instructions for use, installation and maintenance of the product.

Ensure the Operation Manual is available for all responsible persons.

Keep for next usage!

Edition 4

th

JANUARY

2021

Registration number 1

-

55830

-

0

-

1

2

CONTENTS

1

DEFINITION ........................................................................................................................3

2

DEVICE

PURPOSE.............................................................................................................3

3

SECURITY

PRINCIPLES ....................................................................................................4

3.1 SECURITY PRINCIPLES OVERVIEW ............................................................. 4

3.2. SECURITY PRINCIPLES................................................................................. 4

3.2.1 Prior to use..................................................................................................... 4

3.2.2 When in use ................................................................................................... 4

3.2.3 Risk analysis .................................................................................................. 5

3.2.4 Maintenance .................................................................................................. 5

4

PACKING,

STORAGE

AND

HANDLING..............................................................................5

4.1 PACKING.......................................................................................................... 5

4.2 STORAGE ........................................................................................................ 5

4.3 HANDLING ....................................................................................................... 5

5

MAIN

SPECIFICATIONS .....................................................................................................6

5.1 MECHANICAL CLASSIFICATION .................................................................... 7

5.2. MATERIAL AND FINISH.................................................................................. 8

5.3 DATA ON THE PRODUCT ............................................................................... 8

6

JACK

INSTAL

L

A

TION............................................................................................................9

6.1 ANCHORAGE TO A STRUCTURE................................................................... 9

6.2 TEST PRIOR TO USE .................................................................................... 10

7

OPERATION

AND

MAINTENANCE...................................................................................10

7.1 JACK APPLICATION ...................................................................................... 10

7.2 SAFETY WORK ENVIRONMENT................................................................... 10

8

JACK

CHECK....................................................................................................................11

8.1 INSPECTION .................................................................................................. 11

8.1.1 Inspections types ......................................................................................... 11

8.1.2 Daily inspection............................................................................................ 11

8.1.3 Regular inspection ....................................................................................... 11

8.1.4 Jack occasionally used ................................................................................ 11

8.1.5 Report on inspection .................................................................................... 11

8.2 INSPECTION PROCEDURE .......................................................................... 12

9

TROUBLE-SHOOTING .....................................................................................................13

10

GREASING .....................................................................................................................13

10.1 GENERAL..................................................................................................... 13

10.2 JACK MECHANISM ...................................................................................... 13

11

MAINTENANCE ..............................................................................................................14

11.1 SECURITY PRINCIPLES.............................................................................. 14

11.2 REPLACEMENT OF BRAKE INSERTS AND BRAKE ADJUSTING............. 14

11.2.1 Brake disassembly (fig. 4).......................................................................... 14

11.2.2 Brake assembly and adjusting (figures 4 and 5) ........................................ 15

11.3 BEARINGS ................................................................................................... 15

11.4 GENERAL INSTRUCTIONS ......................................................................... 15

11.5 CHECK UP ................................................................................................... 15

11.6 REPAIR......................................................................................................... 15

11.7 TEST............................................................................................................. 15

12

PUTTING

OUT

OF

OPERATION

–

DISPOSAL................................................................15

13

RELATED

DOCUMENTATION........................................................................................16

14

FINAL

REQUIREMENTS

OF

THE

PRODUCER

TO

THE

CUSTOMER............................16

3

1 DEFINITION

! HAZARD

Hazard: it adverts to an imminent hazardous situation, which will inflict

death or serious injury, if the operation personnel do not avoid it.

! WARNING

Warning: it adverts to a possible hazardous situation, which could

inflict death or serious injury, if the operation personnel do not avoid it.

! NOTICE

Notice: it adverts to a possible hazardous situation, which could inflict

any minor or slight injury, if the operation personnel do not avoid it. The

notice can warn against hazardous practices as well.

Load capacity (Q): is the maximum permitted weight (working load limit) of a load, the

jack can be loaded by when handling it on conditions specified in this Operation Manual.

2 DEVICE PURPOSE

2.1 Rack jack type 15-00 with a load capacity of 2.5 t and 5 t, type 15-01 with a load

capacity of 10 t in the container design - CON, wall container - CON-W in any

combination of designs (-RK, -RKP) and in the design for environments with a risk of

explosion -NEXP (hereinafter referred to as the product, or NEXP = structurally identical

product, differing in the surface protection of selected parts, the material of the marking

label and documentation) is destined entirely for anchorage to structures for the purpose

of manual raising and lowering of movable parts of structures (e.g. covers or container

roofs, waste gates of water basins, screens of sewage disposal plant etc.). The weight

of a movable part of a structure when handling does not have to exceed specified

permitted load capacity of the jack.

2.2 The jack by its design meets requirements provided by Directive 2006/42/EC of the

European Parliament and of the Council as amended by the Czech technical regulation

– ministerial order No. 176/2008 of the Collection of Laws as amended as well as

requirements of the ČSN EN ISO 12100 and ČSN EN 1494+A1 harmonized technical

standards.

2.3 The product has been designed in compliance with the requirements stipulated by

Directive 2014/34/EU of the European Parliament and of the Council, as amended by

the Czech technical regulation – Government Directive No. 116/2016 Coll., as amended.

The product has been designed as IM2ExhIMb equipment pursuant to EN ISO

80079-36:2016 and EN ISO 80079-37:2016. It complies with the conditions stipulated

for use in mining environments classed as “hazardous atmospheric conditions 2”

pursuant to ČSN EN 1127-2.

2.4 The product has been designed in compliance with the requirements stipulated by

Directive 2014/34/EU of the European Parliament and of the Council, as amended by

the Czech technical regulation – Government Directive No. 116/2016 Coll., as amended.

The product has been designed as II2GExhIICT6Gb, II2DExhIIICT85°CDb

equipment pursuant to EN ISO 80079-36:2016 and EN ISO 80079-37:2016. It complies

with the conditions stipulated for use in environments classed as „zone 1 and zone 21“,

“zone 2 and zone 22“ pursuant to ČSN EN 1127-1.

Note: Articles 2.3 and 2.4 apply to NEXP product design.

4

3 SECURITY PRINCIPLES

3.1

SECURITY

PRINCIPLES

OVERVIEW

A hazard exists when handling movable parts of structures especially in the event that

the jack is not use in the right way or is badly maintained. Whereas as a result an

accident or severe injury could happen, it is necessary to observe the special security

measures when handling, assembling, maintaining and checking the jack.

! VAROVÁNÍ

ALWAYS ensure the raised part of the structure against drop (e.g. by brace rod), if

you intend to work under it.

NEVER jack up persons.

NEVER burden the jack more than is the load capacity indicated on the jack.

ALWAYS warn persons in surroundings before starting work.

ALWAYS read the operation manual and security instructions.

Bear in mind that the oper

ation staff is responsible for faultless technique of raising.

Hence verify all national directives, regulations and standards whether they contain

other information on safety work with your jack.

3.2.

SECURITY

PRINCIPLES

! WARNING

3.2.1 Prior to use

ALWAYS ensure the jack would be operated by physically fit, qualified and

instructed persons older than 18 years, familiarized with the operation

manual and trained in security of work and mode of operation.

ALWAYS check up the jack every day before starting work according to Section 8.2.

(1) „Daily inspection“.

NEVER use the defective or outworn jack.

NEVER use the jack without visible load capacity marking on the jack.

NEVER use the jack marked with the label „OUT OF OPERATION“.

ALWAYS consult the producer or his authorized representative any application of the

jack in nonstandard or extreme environment.

ALWAYS check that the product is grounded through the ground terminal when

working in an explosive atmosphere

ALWAYS wipe off any dust before handling the product in an explosive atmosphere

3.2.2 When in use

ALWAYS make sure the jack is properly mounted in equipment construction.

ALWAYS pay increased attention, if the jack is drawn up to maximum position.

ALWAYS work with the jack only with manpower.

ALWAYS we recommend with respect to actuating forces the jack operation is

ensured by two persons when handling parts of structures the weight of

which approximate to safe working load of the hoister.

5

NEVER use the separate jack (not mounted in the structure for which it is destined)

to handling free loads

NEVER allow the lifted part of the structure would give rise to impacts or vibrations.

NEVER leave the loaded jack without supervision or other securing of a raised part

of the structure.

3.2.3 Risk analysis

The possible risks analysis in light of design, operation and environment of the jack

appointment is presented in freestanding document „Risk analysis“. It is possible to

require the document in service centers.

3.2.4 Maintenance

ALWAYS make possible to competent persons to carry out the regular inspection of

the jack.

ALWAYS ensure slipping parts (except the brake) are sufficiently greased.

At maintenance only such interventions can be done that will be in accordance with

producer’s requirements stated in the chapter 11 and 14 of this OM.

IT IS NOT PERMITTED to carry out repairs and maintenance in other manner than

specified by the producer. It concerns namely the forbiddance of using of unoriginal

spare parts or carrying out changes on the product without the approval of the producer.

4 PACKING, STORAGE AND HANDLING

4.1

PACKING

4.1.1 Jacks are supplied in assembled state in bulk in transport cases.

4.1.2 The following accompanying documentation is a part of the delivery:

a) Operation Manual

b) EC Declaration of Conformity

c) Quality and Completeness Certificates and Guarantee Certificate.

c1) Guarantee period is stated in the Guarantee Certificate.

c2) The guarantee does not apply to defects caused by infringement of the

instructions stated in the Operation Manual and defects arisen by improper

using and unskilled action.

c3) The guarantee does not apply as well to changes on the product or using

of unoriginal spare parts without the approval of the producer.

c4) Reclaiming of product defects is carried out according to applicable

provisions of commercial code eventually as amended.

d) List of service centers.

4.2

STORAGE

Store jacks in dry and clean stores void of chemical impacts and noxious fumes.

(1) Wipe away all dust, water and impurities from the jack.

(2) Grease the rack of the jack.

(3) Put the jack in a dry place.

(4) In next using follow instructions in the article 8.1.4 „Jack occasionally used“.

4.3

HANDLING

During transportation and handling, observe technical regulations and standards in force

for work with heavy loads.

6

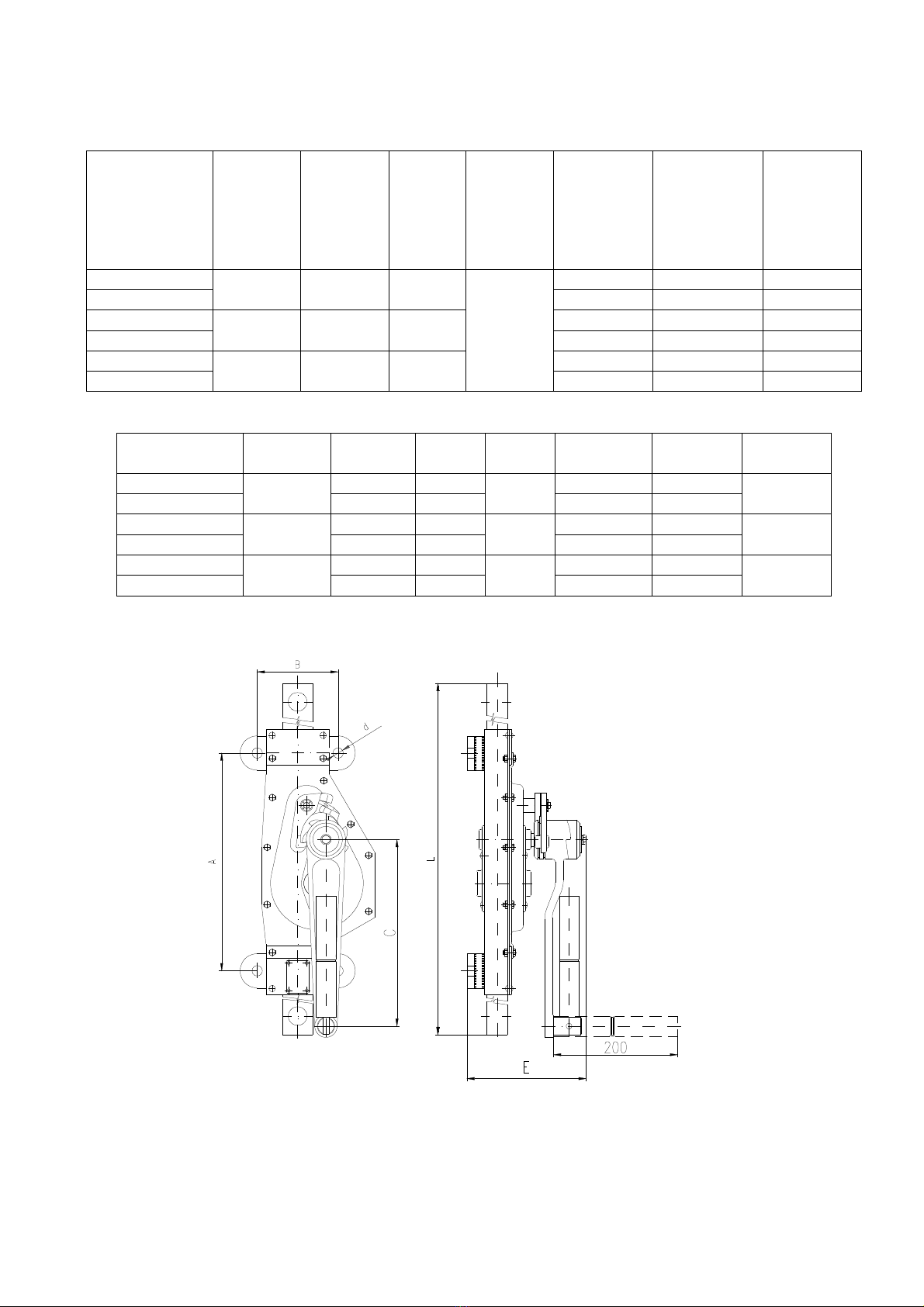

5 MAIN SPECIFICATIONS

Specifications

Type-design Load

capacity

(t)

Lift

(mm)

Actua-

ting

force

on

crank

(

N)

Range of

opera-

ting

tempera-

ture

Weight

rack

L = 660

(kg)

Weight

rack

L = 970

(kg)

Weight

rack

L = 1200

(kg)

15-00-CON-W 2,5 345 - 850

380

-20

0

C

to

+50

0

C

12,8 15,2 17,0

15

-

00

-

CON

11,4

13,8

15,6

15-00-CON-W 5 360 – 850

550 22,1 25,6 28,5

15

-

00

-

CON

19,0

22,5

25,4

15

-

0

1

-

CON

-

W

10 345 – 825

540

35

40

45

15-01-CON 33 38 43

Dimensions

Type-design Load

capacity

A B C E d L

15-00-CON-W 2,5 320 80 250 180 13 660,

970, 1200

15

-

00

-

CON

-

-

150

-

15-00-CON-W 5 350 80 300 190 13 660,

970, 1200

15

-

00

-

CON

-

-

160

-

15

-

0

1

-

CON

-

W

10

490

80

300

22

5

13

660,

970, 1200

15-01-CON - - 195 -

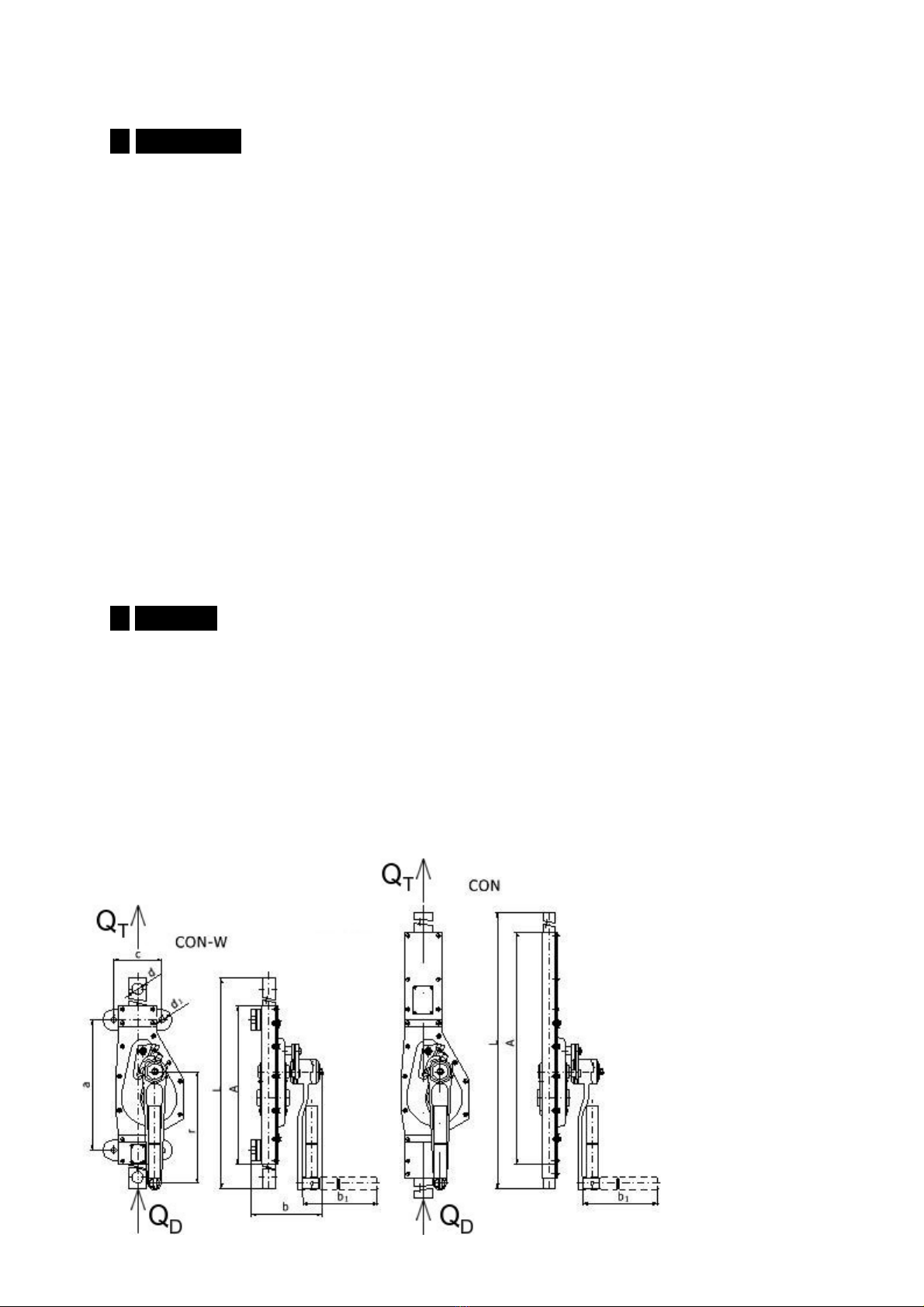

Fig.1 Product design – CON-W

7

Fig.2 Product design – CON

5.1

MECHANICAL

CLASSIFICATION

Safety and working life of the jack is guaranteed providing that it works in accordance

with specified classification.

The jack is designed for class 1Bm according to the FEM 9.511 regulation – see table

5.1. (it corresponds to mechanism classification M3 according to the ISO 4301/1).

Average daily operating time is specified in the load diagram.

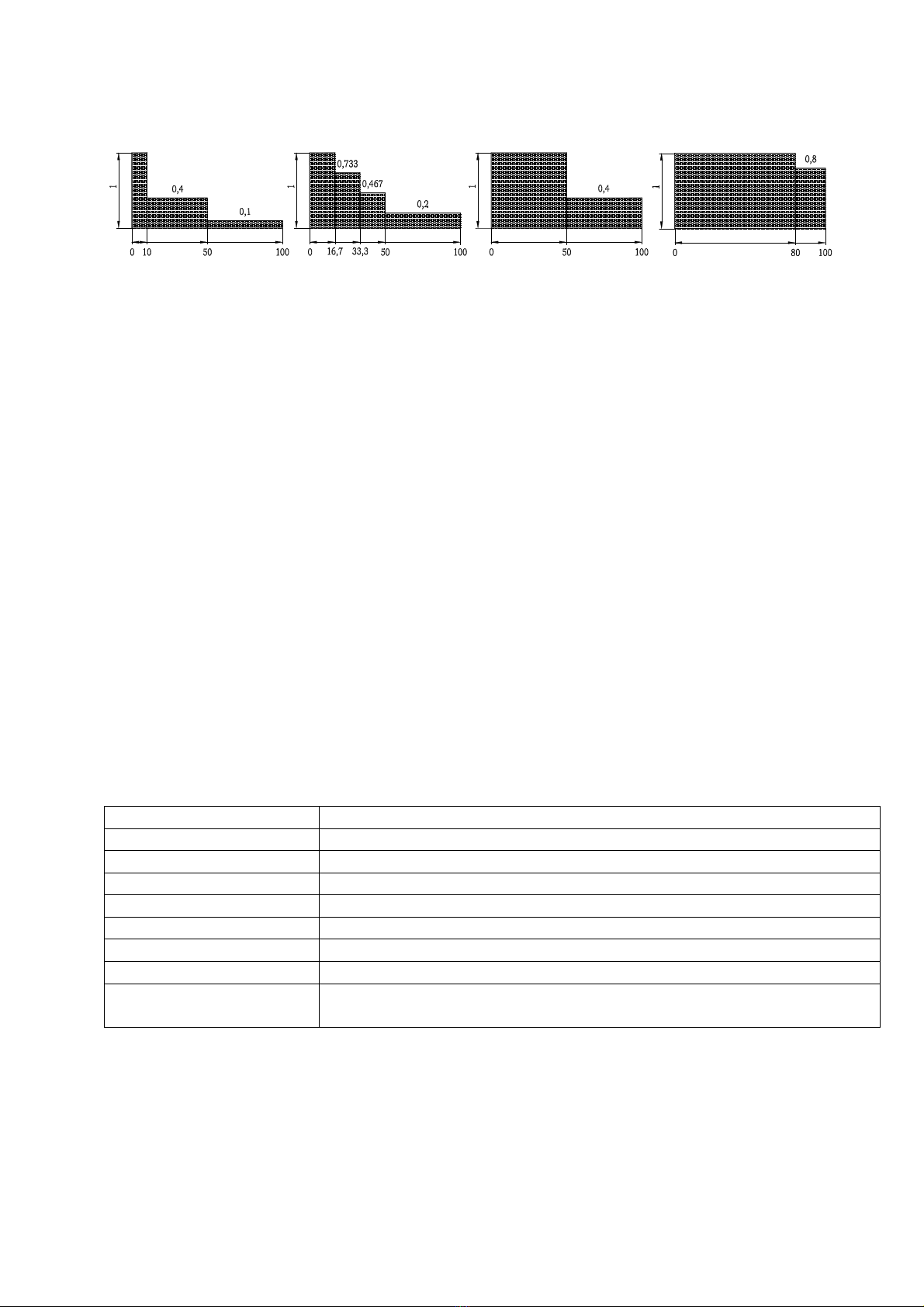

Tab. 5.1 MECHANICAL CLASSIFICATION

Load diagram

(load distribution) Definition Load coefficient Average daily

operating time

(h)

1

(light)

Jacks usually being subject to

the low load and only in

special cases to the

maximum load.

k ≤0,50 1 - 2

2

(mean)

Jacks usually being subject to

the low load, but quite often

to the maximum load.

0,50 < k ≤0,63 0,5 - 1

3

(heavy)

Jacks usually being subject to

the mean load, but frequently

to the maximum load.

0,63 < k ≤0,80 0,25 – 0,5

4

(very heavy)

Jacks usually being subject to

the maximum load or load

approximating to the

maximum.

0,80 < k ≤1,00 0,12 – 0,25

8

Load diagram Load diagram Load diagram Load diagram

1 2 3 4

Percentage of operating time

5.2.

MATERIAL

AND

FINISH

5.2.1 All parts of the jack are manufactured from steel and cast iron.

5.2.2. Materials inclinable to creation of an incendiary spark in terms of the annex

No. 2 article 1.3.1 to the ministerial order No. 116/2016 of the Coll. of Laws and

the ČSN EN 1127-2 article 6.4.4 ČSN EN 1127-1 article 6.4.4 and EN ISO 80079-

36 article 6.4.2.1 harmonized technical standards are not used.

5.2.3. Materials with dangerous effects of static electricity within the meaning of the ČSN

EN 1127-2 article 6.4.7, ČSN EN 1127-1 article 6.4.7, EN ISO 80079-36 article

6.7 and ČSN ČSN CLC/TR 60079-32-1 are not used in the chain block.

5.2.4 The jack does not exceed the noise values specified in the Annex No.1 article

1.7.4.2 letter u of the ministerial order No. 176/2008 of the Collection of Law (EP

and RE directive No. 2006/42/EC).

Note: Articles 5.2.2 and 5.2.3 3 apply to NEXP product design.

5.3

DATA

ON

THE

PRODUCT

Each product is equipped with the label with specified data as follows:

Standard finish:

NEXP produc

t de

sign

:

Mark of the producer

Mark of the producer

Address of the producer

Address of the producer

Product type

Product type

Load capacity

Load capacity

Serial number

Serial number

Production year

Production year

CE marking

CE marking

Protection type symbol (IM2ExhIMb for group I, II2GExhIICT6Gb

and

II2

D

Ex

h

I

II

C

T

85

°C

D

b

for group II)

9

6 JACK INSTALLATION

! WARNING

ALWAYS before installation check up thoroughly whether the jack is not damaged.

NEWER the weight of the jacked up structure or resulting pushing (pulling) force on

the rack bar have to exceed the safe working load of the jack.

The NEXP product must be installed in such a way as to prevent creeping charges.

Charging mechanisms stronger than manual friction must be avoided at the installation site

.

A NEXP product when used in a mine or other environment where the product could

collide with falling, flying… objects (rock, stones…) must be protected to minimize the

likelihood of a collision (sufficiently dimensioned cover, …).

6.1

ANCHORAGE

TO

A

STRUCTURE

6.1.1 Product design – CON-W:

Two grips on the coating with holes for screws M12 (2,5t load capacity) or M16

(5t ,10t load capacity) and holes at the ridge bar ends with ∅25 mm (2,5t load

capacity) or ∅30 mm (5t,10t load capacity) serve for mounting to a structure.

6.1.2 Product design – CON:

The manufacturer of the equipment, in which the jack will be used, specifies the

assembly method for the structure. The jack anchorage to the equipment as a

rule represents an intervention to the jack design (e.g. welding very grip,

mounting of other parts on the jack).

! NOTICE

Any guarantee does not apply to the jack modified according to Article 6.1.2,

unless the modification type is negotiated and approved by the manufacturer.

ALWAYS we recommend consulting a technical department of the jack manufacturer

the type of intended modification.

6.1.3 Installation of jack with respect to rack load.

When installing the – CON and – CON-W rack jacks it is essential to assure that

the load on the jack is in the right direction. The pressure (tension) load on the

rack must always act in the direction from the handle hub to the catches (see

diagram), and never the other way round.

Q

T

– tensile load

Q

D

– pressure load

10

6.1.4 Documentation:

Method of the container jack anchorage and eventual jack modifications are

necessary to be documented by drawing documentation and stress analysis.

The equipment manufacturer has to elaborate the operation manual to the

equipment, in which the jack is used.

! WARNING

The jack anchorage to a structure must be solved so that the ridge bar is not

stressed by bend. Loading only by simple pulling or pushing forces is permitted.

Maximum force on the jack must not exceed maximum load capacity of the jack.

6.2 TEST PRIOR TO USE

! NOTICE

(1) At first go over again the previous Articles of this Operation Manual and make sure

that all steps were well done and all parts are safely mounted.

(2) Inspect visually the jack and anchoring in the structure whether they are without any

defect.

(3) Test the function of the jack by crank motion.

(4) Jack up and consequently lower the movable part of the structure. At the same time

verify whether the jack holds the load without slipping when lowering and stopping.

7 OPERATION AND MAINTENANCE

7.1 JACK APPLICATION

7.1.1 The jack is a single purpose device destined entirely for anchorage to structures

with the purpose of manual jacking up and lowering of movable parts of structures.

It can be used not only in current environment, but also in environments with

explosion risk in the event that there is the symbol of the protection type marked

on the label – see articles 2.3, 2.4 and 5.3 of this OM.

7.1.2 The jack is operated by a crank. Jacking up and lowering of a structure can be

interrupted in any lift height. A lowering brake and pawls system with forced mesh

in the crank ensure position stability.

7.1.3 By reason that the work with heavy loads can constitute unexpected hazard it is

necessary to follow all „Security principles“ according to Chapter 3 of this OM.

7.2 SAFETY WORK ENVIRONMENT

! WARNING

(1) The operating personnel must be demonstrably acquainted with this Operation

Manual; they must adhere to valid security and hygienic regulations and must be

qualified for operation of this equipment.

(2) When working with the jack the operation staff must be equipped with gloves and

appropriate footwear.

(3) When operating by more persons always one worker must be determined who is

trained in safety at work and is responsible for jack handling.

(4) Before starting the work, the operation staff must check up whether all work area is

safety and whether there is a possibility of eventual escape from the environment of

jeopardy.

(5) With a product load capacity of 2,5t and 5t, the cover with the product casing is not

sufficiently dimensioned in terms of "breakthrough", therefore any cover that could

cause a collision with gears must be repaired or replaced. If the product collides with

a falling, flying (object (rock slide…) that could sufficiently damage the covers, work

must be stopped immediately and the product inspected.

11

8 JACK CHECK

8.1

INSPECTION

8.1.1 Inspections types

(1) Introductory inspection: it precedes first use. The responsible competent person

must check up all new or repaired jacks to ensure the qualified fulfilment of

requirements of this OM.

(2) The jack inspections carried out regularly are generally divided to two groups

according to inspections intervals. Intervals depend on the state of critical parts of

the jack and rate of wear, damage or malfunction. Two main groups are here

marked as daily and regular ones. The appropriate intervals are defined as follows:

(a) Daily inspection: visual inspection carried out by the operation staff determined by

the user that is made at the beginning of each use.

(b) Regular inspection: visual inspection carried out by the competent person

determined by the user.

Current operation – once a year,

1) Heavy operation – every six month,

2) Special or occasional operation – according to recommendations of the competent

person at first use and according to the order of qualified employees (maintenance

workers).

8.1.2 Daily inspection

Check up at parts recommended in Section 8.2(1) „Daily inspection“, whether the jacks

are not damaged nor have no defect. Carry out this inspection also during operation in

the interval between regular inspections. Qualified employees will determine whether

any defect or damage can constitute a hazard and whether the detailed inspection is

necessary.

8.1.3 Regular inspection

Carry out overall inspections of the jack in the form of recommended regular

inspections. The recommended regular inspection stated in Section 8.2(2) must be

performed under the supervision of competent persons who will determine, whether the

jack is necessary to be taken to parts. These inspections comprise also requirements of

the daily inspection.

8.1.4 Jack occasionally used

(1) Submit the jack not being in operation for a period of one month or longer but less

than a year to inspection complying with requirements in Section 8.1.2 before follow-

up putting it into operation.

(2) Submit he jack not being in operation for a period of one year to inspection

complying with requirements in Section 8.1.3 before follow-up putting it into

operation.

8.1.5 Report on inspection

Keep the record of performed tests, repairs, inspections and maintenances of jacks

every time. Carry out dating reports on inspections in intervals specified in Section 8.1.1

(2) (b) and keep them in the place specified by the user.

The person responsible for safety and determined by the user must be advised of

defects detected by the inspection or recorded during the operation.

12

8.2 INSPECTION PROCEDURE

(1) Daily inspection (carried out by operating staff or competent person)

Part Inspection method

Limi

t / criterion for

putting-out of

o

peration

Remedy

1. Jack function Visually,

aurally

The jack goes

hardly, stammers,

emits noise etc.

To clean up and

grease the jack. If

the defect will not

be removed, get the

jack repaired.

2. Pawls function Visual inspection

when jacking up

Pawls do not snap

behind dents of the

ratchet.

To clean up,

grease, eventually

change the spring.

3. Fixative parts

Visual inspection of

all screws, nuts,

rivets etc.

Faulty or missing

parts;

Released parts

Replace by new

ones;

To retighten

released parts

(2) Regular inspection (carried out by competent person)

Part

Inspection

method

Limit / criterion for

putting-out of

operation

Remedy

1. Fixative parts

Visual inspection

of all screws, nuts,

rivets etc.

Faulty or missing

parts;

Released parts

Replace by new

ones;

To retighten

released parts

2. All parts Visual inspection Outworn or

damaged parts;

Fouled and

ungreased parts

Replace by new

ones;

To take to parts,

clean up, grease

and again assemble

3. Label – marking of

load capacity on the

jack

Visual inspection Load capacity is not

readable

To repair or replace

by new one

4. Brake Jack up and lower

the part of the

equipment

When interrupting

jacking up the brake

must hold firmly the

load in each

position during

raising and lowering

If it will not be so,

ask for repair and

adjusting of the

brake

13

9 TROUBLE-SHOOTING

Situation Cause of trouble Remedy

1. Jack does not hold firmly

the load.

Brake slipping. Brake adjusting or repair

according to Chapter

„Maintenance“.

2. Jack jacks up heavily or

does not raise the load.

(1) Jack is overloaded.

(2) Damaged geared

transmission.

(1) Remove the cause-

sticking, seizing of

equipment mechanism

(2) Repair of the jack

3. Jack emits the special

noise.

Insufficiently greased

geared transmission.

Carry out the lubrication of

the geared transmissions

by grease.

4. Characteristic sound is

not heard when snapping

the pawls to dents of

ratchet.

Malfunction of pawls.

Rust, impurities, broken

spring.

Clean up, replace the

spring.

10 GREASING

10.1

GENERAL

Before application of the grease remove old grease, clean up components with grease

solvent and apply new grease. Use grease specified by the producer.

Lifters of load capacity 2,5, 5 a 10t are equipped with a lubrication plug on the cover of

the gear transfer. We recommend regular lubrication of the gear mechanism at least

once every 6 months.

Use grease: Universal lithium plastic lubricant, water resistant, usable in a minimum

range of working temperatures from -20°C to +50°C. For example A2, LV2EP.

! WARNING

All lubricants (grease, oil) used in the NEXP version must have an ignition temperature

higher than 135°C. E.g. LV2EP, ….

10.2

JACK

MECHANISM

Lubricate products with a load capacity of 2,5t, 5t and 10t with a lubrication press via a

lubrication plug on the cover.

Grease all slipping or moveable surfaces on the crank of the jack.

! NOTICE

Imperfect maintenance and insufficient greasing can cause serious accidents.

ALWAYS grease it more often in corrosive environment (salt water, oceanic climate,

acids etc.) than in ordinary circumstances.

14

11 MAINTENANCE

11.1 SECURITY PRINCIPLES

! WARNING

Only qualified persons (service organizations), trained in safety and maintenance

of the jacks, can carry out maintenance and professional inspections.

ALWAYS use entirely components supplied by the producer.

It is not permitted to carry out repairs and maintenance in other way than

specified by the producer. It means namely the forbiddance of using

unoriginal spare parts or carrying out changes on the product without an

approval of the producer.

ALWAYS test jack function after carrying out the maintenance.

ALWAYS mark disabled or repaired jack with appropriate inscription (i.e. „OUT OF

OPERATION“).

NEVER carry out maintenance if there is a load on the jack.

NEVER work with the jack that is under repair!

ALWAYS when repairing the paint, it is necessary to observe the total thickness of the

paint layer maximum 0,2 mm (original + new paint, or after cleaning the

surface new paint, applies to NEXP product design).

11.2

REPLACEMENT

OF

BRAKE

INSERTS

AND

BRAKE

ADJUSTING

11.2.1 Brake disassembly (fig. 4)

Demount the crank from the jack. Unbolt safety screws (6) and consequently the nut (5).

Take out the spring (4) and crank arm (7). Take out from the hub (1) the ratchet (3) with

brake insert (2A), take off the brake insert (2B), and replace both brake inserts (2A)

(2B).

Fig. 4 Fig. 5

7

6

5

4

2A

3

2B

1

4 to 6 m m

15

11.2.2 Brake assembly and adjusting (figures 4 and 5)

Proceed in the opposite way when assembling. Slip over the hub (1) the friction insert

(2B); ratchet (3) and second friction insert (2A). Set it in the crank arm (7), slide on the

spring (4) and screw on the nut (5). Tighten the nut so that the clearance in the dent is

from 4 to 6 mm (see fig. 5) and screw down the screws (6).

11.3 BEARINGS

Cast iron plain bearings are used in the product. The theoretical service life of bearings

is several times higher than the theoretical service life of the product. Therefore, they do

not need any special maintenance except for cleaning and lubrication during the regular

inspection interval, see 8.1. In the event that the bearing is damaged during

disassembly, assembly or due to dirt (sand, rock, dust ...) entering the working space of

the bearing, the bearing must be replaced immediately.

11.4 GENERAL INSTRUCTIONS

Following instructions give general important information on disassembly, check up,

repair and assembly. If the jack was dismounted from any reason act upon the

instructions as follows.

1. Perform maintenance in clean environment.

2. NEVER disassemble the jack more than it is necessary to carrying out the needful

repair.

3. NEVER use excessive power when dismantling parts.

4. NEVER use heat (fire) as the mean when dismantling parts, if the parts are destined

for next use.

5. Keep the workplace clean and without foreign materials that could get into bearings

and other movable parts.

6. If you squeeze the part in vice, use always the appropriate pads for protection of

parts surfaces.

11.5 CHECK UP

Check up, whether all disassembled parts are suitable for next use.

1. Check up, whether no parts are worn out and have no chutes or fissures.

2. Check up, whether threaded parts have no damaged thread.

11.6 REPAIR

Outworn or damaged parts must be replaced.

Remove little burrs and scratches or other minor surface defects and flatten out with fine

grinder or abrasive cloth.

11.7 TEST

The load test must be performed at all repaired jacks by qualified person with the load

exceeding the load capacity by 10% for verification of function and brake of the jack.

12 PUTTING OUT OF OPERATION – DISPOSAL

The jack do not contain any noxious agents, its parts are from steel and cast iron. Hand

over the jack after putting it out of operation to the firm dealing with disposal of waste

metal.

16

13 RELATED DOCUMENTATION

EC declaration of conformity

The Operation Manual was elaborated in accordance with following technical regulations,

technical standards and national regulations:

•Ministerial order No.176/2008 of the Collection of Law as amended (EP and Council

directive 2006/42/EC)

•Ministerial order

No.116/2016 of the Collection of Law as amended (EP and Council

directive 2014/34/EU

)

•ČSN EN ISO 12100

•ČSN EN 1494+A1

•ČSN EN 1127 - 2

•ČSN EN 1127 - 1

•ČSN EN ISO 80079-36

•ČSN EN ISO 80079-37

•Regulation of CBM (Czech Bureau of Mine) No.22/89 of the Collection of Law

•ČSN CLC/TR 60079-32-1

.

14 FINAL REQUIREMENTS OF THE PRODUCER TO THE

CUSTOMER

Any changes of the product, eventually usage of unoriginal spare parts can be

realized only based on the approval of the producer.

When not observing this condition the producer does not guarantee safety of his

product. In this case, any producer’s guarantees do not apply to the product.

This manual suits for next models

3

Table of contents

Other Brano Jack manuals