Bluerock Tools PTK-300 Quick start guide

OPERATIONAL MANUAL

MODEL: PTK-300 PIPE THREADING KIT FOR PD-

300/PTM-300

by BLUEROCK ® Tools

Volume

1.0

MWS-

PTK-300 PIPE THREADING KIT

UNPACKING THE ITEM

Caution: This machine is packed together with items that may be sharp, oily and overly heavy objects. Remove the machine from

the packaging in a safe manner. Check to ensure all accessories are included with the item while unpacking. If any parts are found

to be missing, contact the retailer as soon as possible. Do not throw away the packaging until the item is out of the guarantee

period. Dispose of the packaging in an environmentally responsible manner. Recycle if possible. Keep all plastic bags away from

children due to risk of suffocation.

WEEE - Waste Electrical & Electronic Equipment. Note this machine should be disposed of as electrical & electronic

waste.

ãTHE NEWMAN TRADING COMPANY LLC DBA BLUEROCK® TOOLS 2021

1033 Andover Park East, Tukwila WA 98188 USA

Phone 206.604.8363 • Fax 425.572.5167

www.bluerocktools.com

PTK-300 PIPE THREADING KIT

Table of Contents

SAFETY' 1!

PRE-OPERATIONAL SAFETY CHECKS! 1!

OPERATIONAL SAFETY CHECKS! 1!

SPECIFICATIONS' 3!

INCLUDED'ACCESSORIES' 3!

ADDITIONAL'AVAILABLE'ACCESSORIES' 3!

ADDITIONAL ACCESSORIES FOR THIS MACHINE CAN BE FOUND IN BLUEROCK ® TOOLS ONLINE SHOP AT

WWW.BLUEROCKTOOLS.COM OR FROM YOUR LOCAL RETAILER.! 3!

OPERATIONS' 4!

MACHINE COMPONENTS! 4!

PURPOSE! 4!

MACHINE SET-UP (IF USING THE OPTIONAL PD-300 POWER DRIVE)! 4!

PREPERATION FOR THREADING WITH THE PTK-300! 5!

RUNNING THE OPTIONAL POWER DRIVE WITH PTK-300 PIPE THREADING KIT! 9!

TROUBLESHOOTING'11!

CORRECTION'11!

GENERAL'MAINTENANCE'12!

PARTS'LIST'13!

PTK-300 PIPE THREADING KIT

1

Safety

DO NOT USE THIS MACHINE UNLESS YOU HAVE READ THE OPERATING INSTRUCTIONS!

Safety glasses must be worn at all times in

work areas. Use a full face mask whenever

possible.

Long and loose hair must be

contained.

Appropriate footwear must be worn.

Close fitting/protective clothing

must be worn.

Read operational manual prior to use.

Hearing protection should be

worn when using this machine.

PRE-OPERATIONAL SAFETY CHECKS

Ø Examine the power cord and plug for damage.

Ø Examine the body of the machine and inspect for damage or defects.

Ø Examine the cutting dies and die head to insure they are operable.

Ø Ensure that the die head and dies are correctly attached to the machine.

Ø Make certain the on/off switch is in the off position before plugging into power to prevent unintentional starting.

OPERATIONAL SAFETY CHECKS

Ø ONLY to be operated by qualified personal who have read instructions.

o NOTE: Failure to read and follow instructions could result in electrical shock, fire, property damage and/or

serious injury!

Ø DO ensure all non-essential people are clear of the immediate work area.

Ø DO stay alert and use common since when using this tool.

Ø DO remove adjusting keys or wrenches prior to turning machine on.

Ø DO guard against electric shock by preventing body contact with grounded surfaces such as pipes, radiators, ranges,

refrigerators, etc.

Ø DO keep the working area clean and brightly illuminated for optimum operational safety.

Ø DO secure machine to bench or stand. Support long heavy pipe with pipe supports. This practice will prevent tipping.

Chapter

1

PTK-300 PIPE THREADING KIT

2

Ø DO operate machine from side with REV/OFF/FOR switch. This eliminates the need to reach over the machine.

Ø DO keep hands away from rotating pipe and fittings. Stop the machine before wiping pipe threads or screwing on

fittings. Allow the machine to come to a complete stop before touching the pipe or machine chucks. This practice will

prevent entanglement and serious injury.

Ø DO tighten the chuck handwheel and engage rear centering device on the pipe BEFORE turning on the machine. This

will prevents oscillation of the pipe.

Ø DO be mindful that power tools can expose an operator to vibrations transmitted through contact with the machine.

Prolonged exposure can lead to medical issues, which should be discussed with a medical professional.

Ø DO NOT wear gloves or loose clothing when operating machine. Keep sleeves and jackets buttoned. Do not reach

across the machine or pipe. Clothing can be caught by the pipe or machine resulting in entanglement and serious

injury.

Ø DO NOT use this machine if the foot switch is broken or missing. Foot switch is a safety device to prevent serious

injury.

Ø DO NOT make adjustments to machine while the machine is running.

Ø DO NOT cut or saw work-pieces by hand while the machine is running

Ø DO NOT use dull cutting dies as the machine is more likely to bind and the user lose control. This can also overload

the motor.

Ø DO NOT use excessively long pieces of pipe in the machine. Keep the machine balanced and stable at all times.

Ø DO NOT leave the machine running when not in use.

Ø DO NOT hold the work piece by hand or using body. Always mechanically clamp or secure work piece.

Ø DO NOT allow liquids or dust to enter the machine’s ventilation system.

Ø DO NOT operate machine outside of machine specifications.

Ø DO NOT touch moving parts while the machine is running as death or dismemberment could occur.

Ø DO NOT remove machine’s panels while machine is connected to a power source. Only to be removed for service by

qualified personal and put back on the machine after service is complete.

Ø DO NOT allow children or untrained personal to operate machine.

Ø DO NOT use this machine in the rain or a wet environment. If using outdoors, make sure the machine is dry.

Ø DO NOT operate in the presence of explosive materials as power tools create sparks which may ignite dust or fumes.

Ø DO NOT use on a pipe that may contain a live electrical wire/circuit.

Ø DO NOT use this machine if the ON/OFF switches are broken.

Ø DO NOT use this machine to make or break fittings. This practice is not an intended use of the machine and can

result in serious injury.

Ø DO NOT operate the machine with covers removed. Exposure to moving parts may result in entanglement and

serious injury.

Ø DO NOT operate this machine on the same work surface where welding is being performed. This could result in

severe damage to the machine or personal injury to the user.

Ø DO NOT operate this machine on a lower voltage as this could limit the motor life and work efficiency.

o NOTE: Use of long small gauge power extension cords can result in decreased voltage. As local voltages

can vary, it may be a good idea to test the voltage at the end of the extension cord to ensure proper voltage

requirements are met. You might also consult an electrician to make sure the length of cord matches up

with the proper wire gauge for this size motor. Make sure to use outdoor cords when operating outdoors.

Use a GFCI circuit if using in wet locations.

PTK-300 PIPE THREADING KIT

3

Specifications

MECHANICAL DATA

Pipe Capacity

½” to 2” Diameter NPT

811A Die Head Size

½”-3/4” One Set 14 Threads/Per Inch

1”-2” One Set 11 Threads/Per Inch

Rockwell Hardness HRC58-62

(Interchangeable with Ridgid® 811A/815A Die Head)

Die Size

HSS NPT (Interchangeable with Ridgid® 811A/815A Dies)

SHIPPING DATA

Shipping Weight

53lbs

Shipping Carton

560mm x 350mm x 300mm

Included Accessories

DESCRIPTION

QTY

Instruction Manual

1

BLUEROCK PTK-300 Pipe

Threading Kit

1

811A Die Head

1

Set of 4: ½”-3/4” Dies

1

Set of 4: 1”-2” Dies

1

Pipe Reamer

1

Pipe Cutter

1

Carriage

1

Additional Available Accessories

Additional accessories for this machine can be found in BLUEROCK ® Tools online shop at

www.bluerocktools.com or from your local retailer.

RIDGID® Marks are trademarks of RIDGID, Inc. and are used for product identification purposes only.

Chapter

2

PTK-300 PIPE THREADING KIT

4

Operations

Note

THOROUGHLY READ THROUGH THE ENTIRE MANUAL BEFORE OPERATING THIS MACHINE!

MACHINE COMPONENTS

Ø The main components of the BLUEROCK PTK-300 Pipe Threading Kit Assembly is the 811A die head, pipe

cutting assembly, and pipe reamer assembly and assembly carriage.

o These components must be not be removed except by a qualified technician. Power must be

disconnected prior to any service.

PURPOSE

Ø The BLUEROCK PTK-300 Pipe Threading Kit Assembly (die head, pipe cutting assembly, and pipe reamer

assembly) is designed to fit on a power drive unit. It will fit on either a BLUEROCK ® PD-300 Power Drive

or a Ridgid ® type 300 power drive.

o The BLUEROCK PD-300 (base power drive unit) is an electric motor-driven machine which

centers and chucks pipe, conduit and rod (bolt stock) and rotates it while threading, cutting and

reaming operations are performed. Forward (clockwise) or Reverse (counterclockwise) rotation

can be selected with the FOR/OFF/REV switch and a foot switch provides ON/OFF control of the

motor.

MACHINE SET-UP (IF USING THE OPTIONAL PD-300 POWER DRIVE)

Ø The PD-300 Power Drive machine is designed to mount securely to the H-300 Tri-Stand.

o CAUTION: This machine should be picked up and moved with at least 2 people

o DO NOT allow the cord or plug to drag along the floor when transporting.

Ø Make certain the set-up work area is dry.

Ø Use barriers to keep non-essential personal away from rotating pipe.

Ø Place machine away from passageways and make certain the operator is able to see all parts of the work-

piece.

Ø DO NOT set-up or modify the machine in a manner that is not intended.

Ø If using pipe extending more than 1 meter from the rear output of the machine chuck, make certain to use a

pipe support. Add multiple supports if necessary, to ensure machine stability.

Chapter

3

PTK-300 PIPE THREADING KIT

5

PREPERATION FOR THREADING WITH THE PTK-300

Ø CAUTION: Before making any adjustments, ensure the main machine switch is in the “off” position.

Ø Installing pipe in power drive

o Chuck operations

§ Check to insure the cutter, reamer and die head is swung to the rear of the carriage.

§ Mark the pipe at the desired length if it is being cut to length

§ Rotate the forward and rear chucks clockwise to open them up and make room for the

pipe.

§ Insert the pipe into the Power Drive so that the end to be worked or the cutting mark is

located about 12 inches to the front of the speed chuck jaws.

§ Insert workpieces less than 2 feet long form the front of the machine. Insert longer pipes

through either end so that the longer section extends out beyond the rear of the Power

Drive.

• CAUTION: Use pipe supports when necessary to prevent machine tipping.

§ To close the chuck around a piece of pipe, turn the chuck handwheel in the counter-

clockwise direction.

• Check the pipe is perfectly centered in the chuck and attempt to spin the

handwheel tight again.

o If the pipe is not centered, reverse the operation until the pipe is

loose and re-center the pipe.

• Secure the pipe by using repeated and forceful counterclockwise spins of the

speed chuck handwheel at the front of the Power Drive. This action

“hammers” the jaws tightly around the pipe.

o NOTE: This prevents movement of the pipe that can result in poor

thread quality.

• CAUTION: Keep hands and fingers away from the chuck jaws when the

machine is plugged into a power source. Closing chuck jaws can cause

serious damage to bodily parts.

Ø Removing pipe from the optional power drive

o Flip directional switch to “off” position.

o Use repeated and forceful clockwise spins of the speed chuck handwheel at the front of the

Power Drive to release the workpiece from the speed chuck jaws.

o If necessary, loosen the rear centering device using a clockwise rotation of the handwheel at the

rear of the Power Drive.

o Slide the workpiece out of the Power Drive, keeping a firm grip on the workpiece as it clears the

Power Drive. To avoid injury from falling parts or equipment tip-overs when handling long

workpieces, make sure that the end farthest from the Power Drive is supported prior to removal.

o Clean up any spills or splatter on the ground surrounding the Power Drive.

Ø Pipe cutter operations

o Check to insure the reamer and die head are in the UP position.

o Securely clamp the pipe into the chuck as described in the above section.

PTK-300 PIPE THREADING KIT

6

o Move pipe cutter down onto pipe and move carriage with carriage lever to line up cutter wheel

with mark on pipe.

o Set the pipe-cutting wheel at the point where the pipe will be cut.

o Open the cutting knife rack so that the rollers are straddling the pipe (see figure below).

o Switch the main on/off switch to the “FOR” (Forward) position. Depress and hold down the foot

switch with the left foot.

o Grasp the pipe cutter’s feed handle with both hands.

o Slowly cut into the pipe by feeding the cutting wheel into the pipe by rotating the handle

clockwise while the pipe is rotating (see figure below).

• DO NOT force the cut, as it will distort the pipe and cause damage to the pipe

cutting assembly.

§ CAUTION: Once the pipe piece is cut, the steel remnant will fall.

o Release the foot switch and remove your foot from the housing.

o Swing pipe cutter back to the UP position.

o

Ø Pipe reamer operations

o Move reamer arm down into reaming position.

o Check the directional switch to insure it is in the FOR (Forward) position. Depress and hold the

foot switch down with the left foot.

o While the pipe is still secured in the chuck, position the center of the reamer tip to be placed

inside the spinning pipe with the right hand (see figure below).

o Gently apply pressure to the outside reamer assembly taking extreme caution with metal

fragments and the spinning pipe.

o Continue until pipe is reamed.

o Retract reamer bar and return reamer to the UP position.

o Release foot switch and remove your foot from the housing.

PTK-300 PIPE THREADING KIT

7

o

Ø Pipe threading operations

o Check to insure the cutter and reamer are to the rear of the carriage

o Ensure pipe is securely fastened in the chuck.

o Always install the correct dies for the die assembly.

o Set die head to proper size.

o Lower die head into threading position.

o Rotate throwout lever to the CLOSED position. Push throwout lever down until the release trigger

cocks.

o Apply Thread Cutting Oil to end of the pipe.

§ NOTE: Apply plenty of thread cutting oil to the dies during threading. Cutting oil is a

necessary part of pipe threading. T

o Assume the correct operating posture.

o Check directional switch to insure it is in the FOR (Forward) position. Depress and hold the foot

switch down with the left foot.

o CAUTION: To avoid serious injury from rotating parts, allow adequate clearance between your

hand and rotating parts when oiling.

o Feed the diehead into contact with the pipe.

§ Apply pressure to the diehead assembly arm until the dies are engaged and start

threading.

§ When thread is completed, raise throwout lever to open position, retracting dies. When

die head trigger contacts end of pipe, throwout lever automatically opens.

§ Release foot switch and remove your foot from the housing.

§ Turn the main on/off switch to the “off” position.

§ Manually push the spanner forward on top of the diehead assembly to release the dies

from the threads.

§ Move carriage lever away from pipe end and return die head to the UP position.

§ Check the thread for length and depth.

PTK-300 PIPE THREADING KIT

8

§ Loosen the chuck handwheels clockwise and remove the pipe from the rear of the

machine. Be careful not to damage the threads.

§

§

Ø Installing Dies in the Diehead (for 811A Diehead that comes with the PTK-300 Pipe Threading Kit)

o CAUTION: Ensure the machine is unplugged.

o Remove the diehead assembly from the sledge.

o Lay die head on bench with numbers face up

o Flip throwout lever to OPEN position (see figure below)

o Loosen clamp lever approximately three turns.

o Lift tongue of clamp lever washer up and out of slot under size bar. Slide throwout lever all the

way to end of slot in the OVER direction indicated on size bar (in direction of CHANGE DIES

arrow on rear of cam plate).

o Remove dies from die head.

o Select the dies that are the correct size for the pipe diameter you are cutting.

o Insert the dies (numbered 1, 2, 3, 4) into the corresponding diehead slots (also numbered 1, 2, 3,

4). See Figure below.

PTK-300 PIPE THREADING KIT

9

o Slide throwout lever back so that tongue of clamp lever washer will drop in slot under size bar.

o Adust die head size bar until the index line on lock screw or link is aligned with proper size mark

on size bar. For bolt threads, align index line with BOLT line on size bar.

o Tighten clamp lever.

o If oversize or undersize threads are required, set the index line in direction of OVER or UNDER

size mark on size bar.

o Place the diehead assembly back in the sledge.

o

o

RUNNING THE OPTIONAL POWER DRIVE WITH PTK-300 Pipe Threading Kit

Ø Do all pre-operational and operational safety checks from Chapter 1.

Ø Consider your security and stability as well as the orientation of the machine in the work area.

o Consider the work surface material, condition, strength, density and rigidity. These factors

directly affect the tools operation and user safety.

Ø Ensure the machine handles are free of grease or oil.

Ø Select appropriate die head and die depth for the specific pipe you are threading.

o Inspect the dies to ensure they are sharp and in the correct position.

PTK-300 PIPE THREADING KIT

10

§ Improperly installed or dull cutting dies can cause binding or poor quality threads.

o To prevent tipping, long lengths of pipe should be supported by a pipe stand.

Ø Plug the machine into power source.

Ø Place pipe in the chuck and secure, evenly tightening the chuck handwheel (see section above for

specifics about using the chuck).

Ø Ensure the machine main power and footswitch are operating correctly.

o Turn the main machine switch to the “on/FOR” position.

o Depress the on/off foot pedal to check the rotation and engagement of the chuck.

o Disengage the foot pedal to ensure the “off” function is working properly.

§ NOTE: Be sure to position the foot pedal in an accessible place.

§ CAUTION: Always allow the pipe to completely stop turning before touching the chuck

handwheel, pipe, die assembly, pipe cutting assembly or pipe reamer assembly.

§ CAUTION: Ensure the main on/off switch is “off” before making adjustments any

adjustments.

Ø Cut the pipe end to ensure a clean edge (see figure above for specifics using the pipe cutter)

Ø Use the pipe reamer to clean the inside edge (see figure above for specifics using the pipe reamer).

Ø Engage the cutting dies with the clean rotating pipe end (see above section for specifics on engaging

cutting dies).

o Apply plenty of thread cutting oil to the dies during threading. This will reduce the and on the

motor and extend the life of motor components and dies.

PTK-300 PIPE THREADING KIT

11

Troubleshooting

Note

SERVICING SHOULD ONLY BE DONE BY A QUALIFIED TECHNICIAN.

DON’T FORGET TO UNPLUG POWER TO UNIT PRIOR TO SERVICE!

PROBLEM

CAUSE

CORRECTION

Motor does not

start (IF USING

OPTIONAL PD-

300)

Threading machine unplugged

Plug into power source

Fuse blown

Replace the fuse

Capacitor blown

Replace capacitor

Bad on/off switch

Replace Switch

The cutting knife

will not cut

Cutting blade is dull

Replace blade

Lead screw on cutting blade assembly is

damaged

Replace assembly

Too much force being applied

Cut slower

Motor sounds

Overloaded (IF

USING

OPTIONAL PD-

300)

Overload because of dull dies

Replace dies

Bad quality or insufficient thread cutting oil

Use thread cutting oil in adequate quantity

Sparks coming

from motor (IF

USING

OPTIONAL PD-

300)

Bad contact between brushes and brush

holder

Tighten the screws, make sure brush is pressed

firmly onto armature

Brushes do not touch armature properly

Replace worn brushes

Sharp edge on brush

Break edge with sand paper

Die head does

not start

threading

Dull or broken dies

Replace dies

Improperly set dies

Reset dies

Damaged

Thread

Dull dies

Replace dies

Dies not assembled in correct sequence

Put dies in correct sequence

Low quality pipe

Make sure only pipe of good quality is used

Bad quality or insufficient thread cutting oil

Use only thread cutting oil in adequate quantity

Chuck jaws are not tightening enough

Inspect chuck jaws

Pipe turns while

threading

3-jaw chuck not tight

Tighten handwheel chuck

3-jaw chuck teeth dirty

Clean with wire brush

3 jaw chuck teeth damaged or dull

Replace 3-jaw chuck

Chapter

4

PTK-300 PIPE THREADING KIT

12

General Maintenance

Note

SERVICING SHOULD ONLY BE DONE BY A QUALIFIED TECHNICIAN.

DON’T FORGET TO UNPLUG POWER TO UNIT PRIOR TO SERVICE!

Ø Inspect electrical cords and electrical connections if using optional PD-300 power drive.

Ø Keep machine clean and free of debris.

Ø Check for misalignment, binding and breakage of all moving parts. If damaged, repair tool before use.

Ø Check the cutting blade on the pipe cutting assembly.

Ø Clean dies and inspect for chips. Also check the sharpness on the dies. If they are dull or broken, replace ALL dies

with identical set.

Ø Clean chuck teeth with wire brush if using optional PD-300 power drive. Check the attrition of the claw points on the

3-jaw chuck. If the points are worn, replace with identical piece.

Ø Proper lubrication is essential to trouble-free operation and long life of the optional PD-300 Power Drive. Grease

main shaft bearings every 2 to 6 months depending upon amount of Power Drive use. Grease fittings are provided

on side base, one at each end of shaft. Use a good grade of cup grease.

Ø After each use coat all working surfaces with corrosion resistant oil.

Ø Check brushes for wear and replace if worn if using optional PD-300 power drive.

Chapter

5

PTK-300 PIPE THREADING KIT

13

Parts List

PTK-300 811A Diehead (425/811A - 37400)

S/N

new Ref. No.

Ridgid Ref.

Description

1

50103153

32205

Screw UNC1/4-20x5/8

2

40303028

97020

Retaining Ring

3

40901028

46520

Throw-Out Lever

4

40401013

39860

Lock Screw

5

41802013

39950

Link

Chapter

6

PTK-300 PIPE THREADING KIT

14

6

41001008

26957

Lever Washer

7

40901027

39970

Clamp Lever

8

30108019

59832

Post Component

9

40303027

40922

Head w/post

40957

10

40303026

43360

Cam Plate

PTK-300 Pipe Reamer (524 - 37500)

S/N

new Ref. No.

Ridgid Ref.

Description

1

40402007

47155

Pin (2)

2

41701007

43790

Reamer Bar

3

50702003

44700

Latch Spring 1x6.5x3012.5

4

41001009

46665

Reamer Latch

5

42001016

47065

Hinge Pin

6

41801009

46585

Reamer Knob

PTK-300 PIPE THREADING KIT

15

7

50103154

46515

Screw UNC1/4-20x3/4

8

40304017

43230

Reamer Arm

9

40602006

36277

Cone

10701004

42365

Reamer complete

PTK-300 Pipe Cutter (624 - 37600)

S/N

new Ref. No.

Ridgid Ref.

Description

1

30104004

43625

Handle Component

2

41801010

Support Pillar

3

40304019

43595

Cutter Frame

4

42001017

45505

Support Arm

PTK-300 PIPE THREADING KIT

16

5

40402009

45520

Pin

6

40402008

45435

Retaining Pin

7

40601003

33105

Cutting Wheel H.D.

40601008

44185

Cutting Wheel Std.

8

50705005

Cutter Shaft Ring Φ1.4x9

9

42001018

34780

Wheel pin

10

40403029

34305

Roll (2)

11

50705006

Ring Φ1.4x10 (2)

12

42001019

34310

Roll pin (2)

13

40304018

33400

Roll Housing Assembly

10801003

42370

Cutter complete

PTK-300 Carriage (10401006 - 227 - 37800

)

PTK-300 PIPE THREADING KIT

17

S/N

new Ref. No.

RIDGID Ref.

Description

1

41502021

44525

Spring ring (2)

2

41502020

44720

Snap Ring (2)

3

41502022

4

50103174

46050

Screw UNF1/4-28x1/4 (2)

5

30108016

44725

Ring Assembly (2)

6

41703009

44425

Support bar(2)

7

30109026

Carriage Assembly (7+21)

8

40401014

46220

Thumb Screw

9

41502019

Collar

10

40401015

46210

Shoulder bolt

11

30108017

46215

Collar Assembly (2)

12

50402004

46810

Detent assembly

13

50702005

14

50103187

15

40401016

46205

Eye Blot assembly

16

41902001

46235

Hand Grip

30104006

42385

Lever Assembly

17

30104005

43400

Lever arm

18

50102032

Nut UNC5/16-18

19

50702006

Adjusting Compression Spring 2x14x16x45

20

50103169

Adjusting Screw UNC5/16-18x18

21

30108018

45515

Stop bolt assembly

Table of contents

Other Bluerock Tools Tools manuals

Popular Tools manuals by other brands

parktool

parktool DT-3 instructions

FLORABEST

FLORABEST 280270 instructions

FLORABEST

FLORABEST FSG 85 D1 Translation of the original instructions

PROPOINT

PROPOINT Pistol-Grip Grease Gun instructions

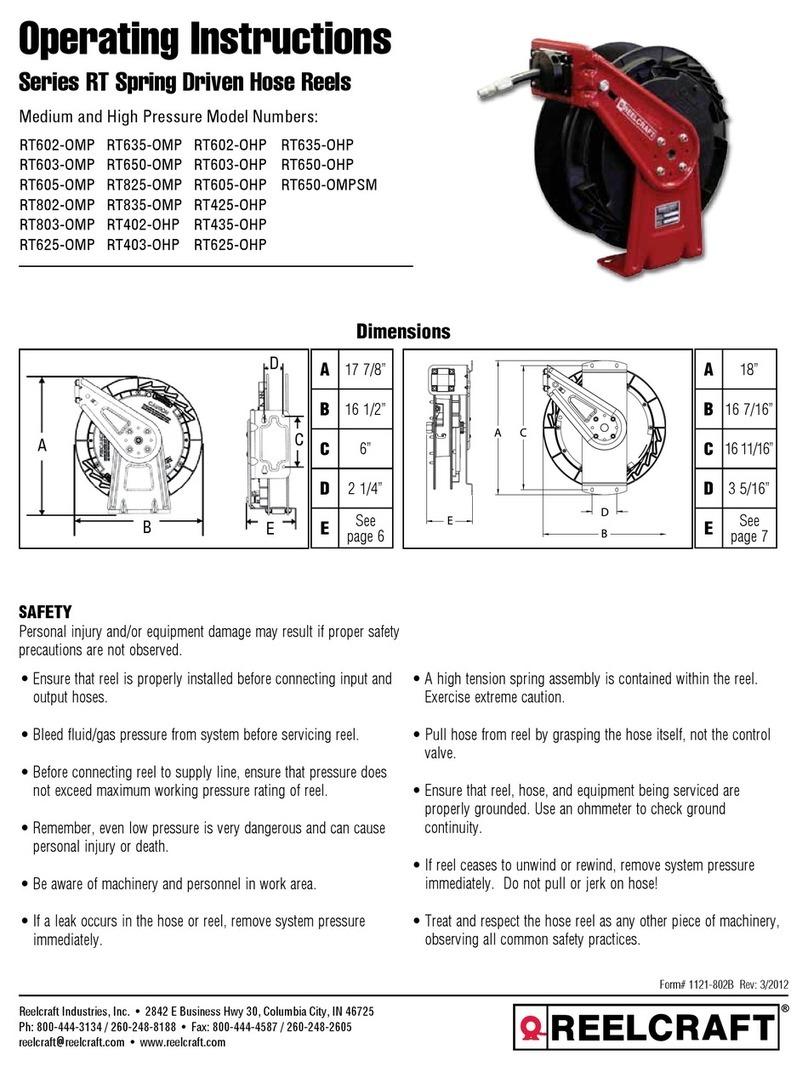

Reelcraft Industries, Inc.

Reelcraft Industries, Inc. RT635-OMP operating instructions

woodmizer

woodmizer BMT150 Safety, Operation, Parts & Maintenance Manual

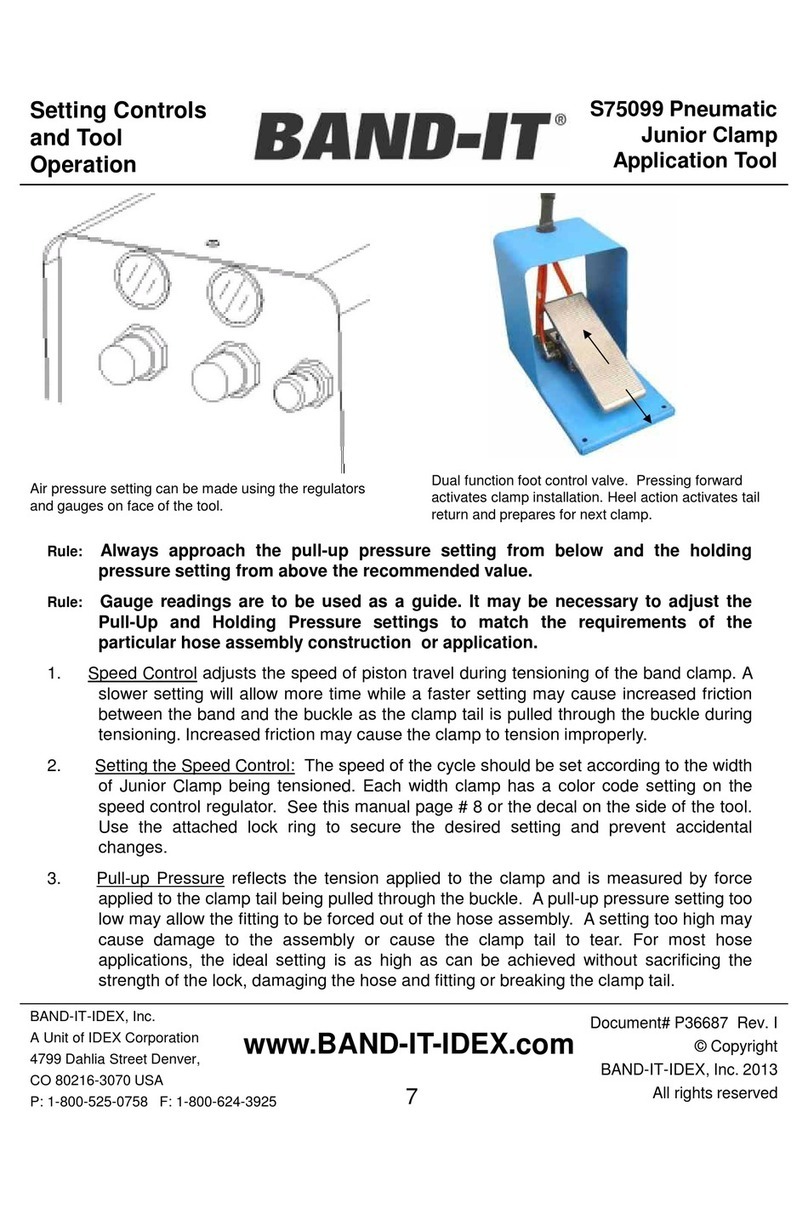

Band-it

Band-it S75099 quick start guide

Centech

Centech 40963 Set up and operating instructions

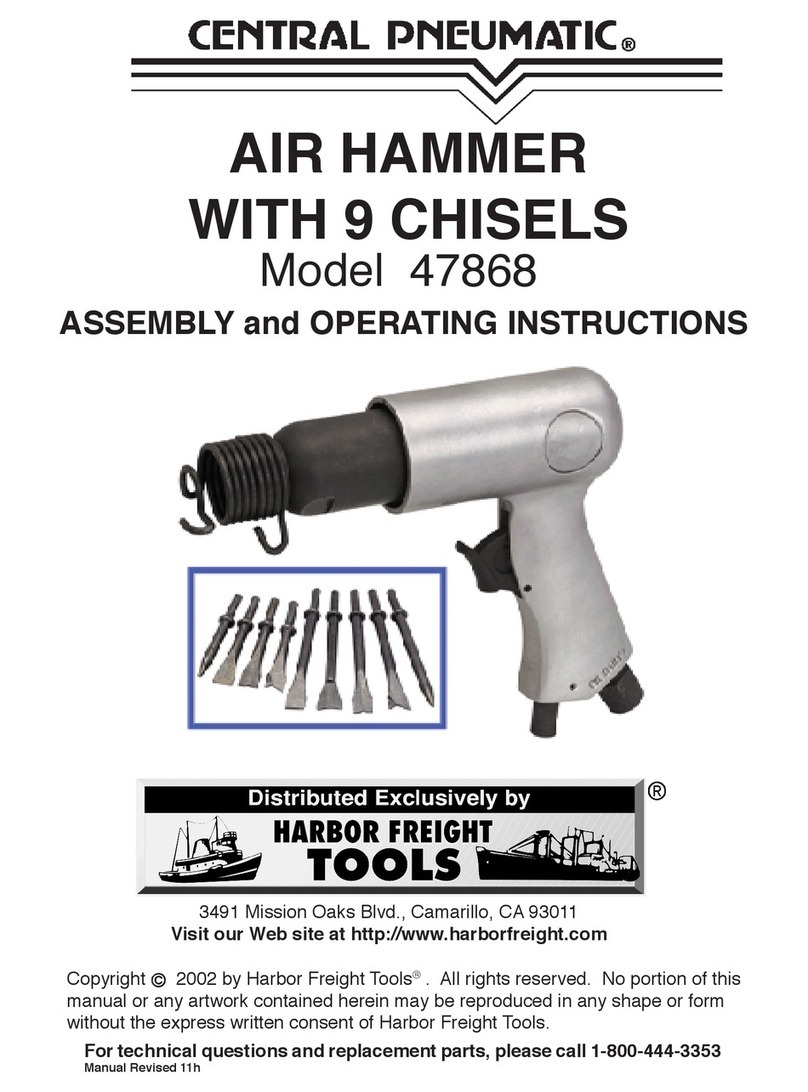

Central Pneumatic

Central Pneumatic 47868 Assembly and operating instructions

Power Fist

Power Fist 8549024 owner's manual

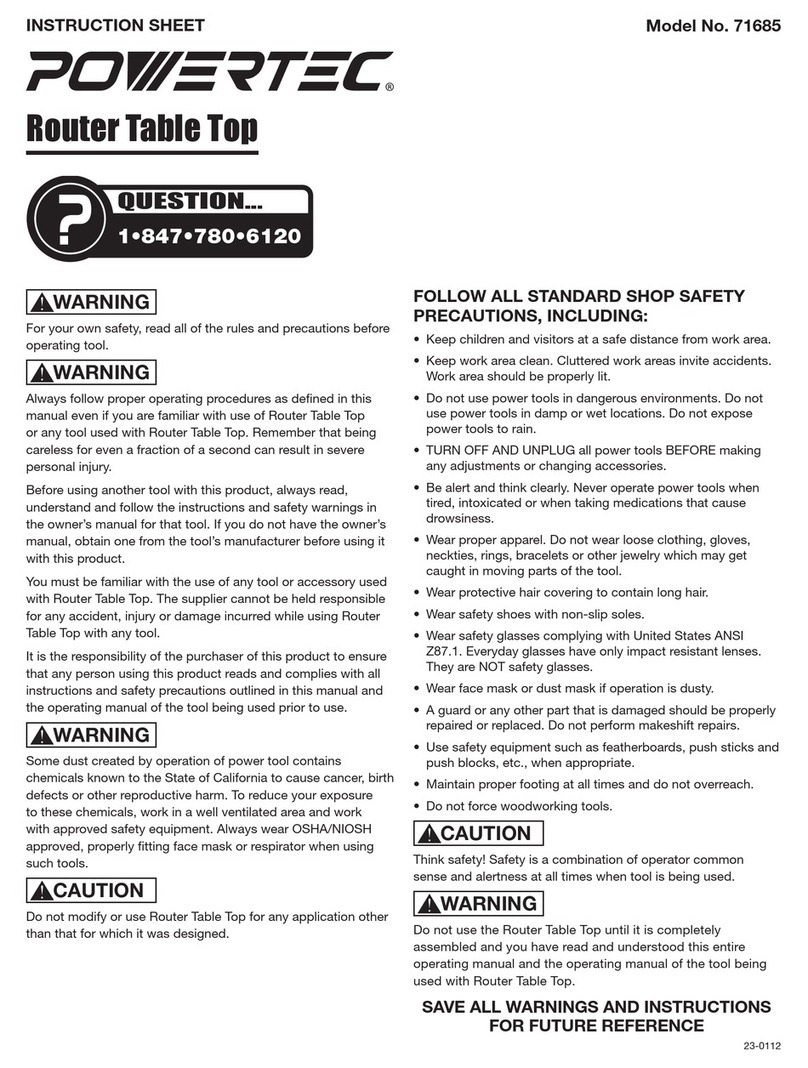

Power Tec

Power Tec 71685 instruction sheet

Power Fist

Power Fist Air Line Delivery Kit manual