Document# P36687 Rev. I

© Copyright

BAND-IT-IDEX, Inc. 2013

All rights reserved

www.BAND-IT-IDEX.com

BAND-IT-IDEX, Inc.

A Unit of IDEX Corporation

4799 Dahlia Street Denver,

CO 80216-3070 USA

P: 1-800-525-0758 F: 1-800-624-3925 8

Junior Clamp

Application Tool

4. Setting Pull-up Pressure: Pull the identified regulator knob and turn clockwise to reach

pull-up pressure. Approach pressure setting from below by increasing pressure. Many

factors should be considered when choosing the correct operating setting for the tool.

The fitting design as well as the type, thickness and durometer of the hose material must

be considered when setting the correct pressures for your assembly.

5. Holding Pressure reflects a lower pressure designed to allow the hose assembly to be

rolled up in preparation for setting the lock with the shearing or cutting action on the clamp

tail. A setting too low will cause difficulty in shearing the clamp tail and leaving an

excessive burr on the buckle at the point of lock. A setting too high may cause the clamp

tail to free of the band gripper, cause the lock to slip back under the buckle or cause

a sudden jolt to the S75099 tool.

6. Setting Holding Pressure: Cycle the tool, holding the foot pedal in the toe forward position.

The tool will reach pull-up tension and kick down to a holding pressure. Read the gauge

and repeat the cycle turning the holding regulator clockwise to raise pressure or counter

clockwise to lower pressure. Allow the tool to settle after each cycle before reading the

value on the gauge.

7. Check pressure setting by cycling tool until hold pressure gauge stops.

8. Reset tool by depressing heel end of foot pedal. Remove foot.

9. Repeat steps 2, 4, 6, and 7. At pressure kick down, verify all settings and adjust if

necessary. Lock settings in place.

Setting Controls

and Tool

Operation

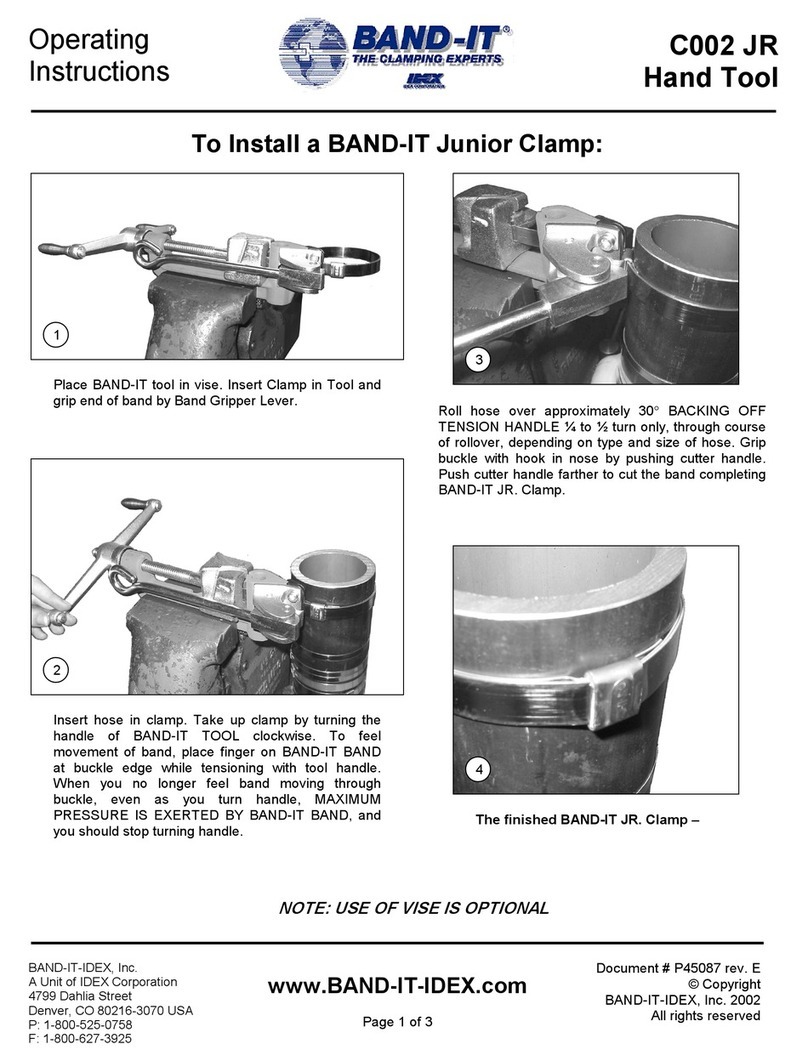

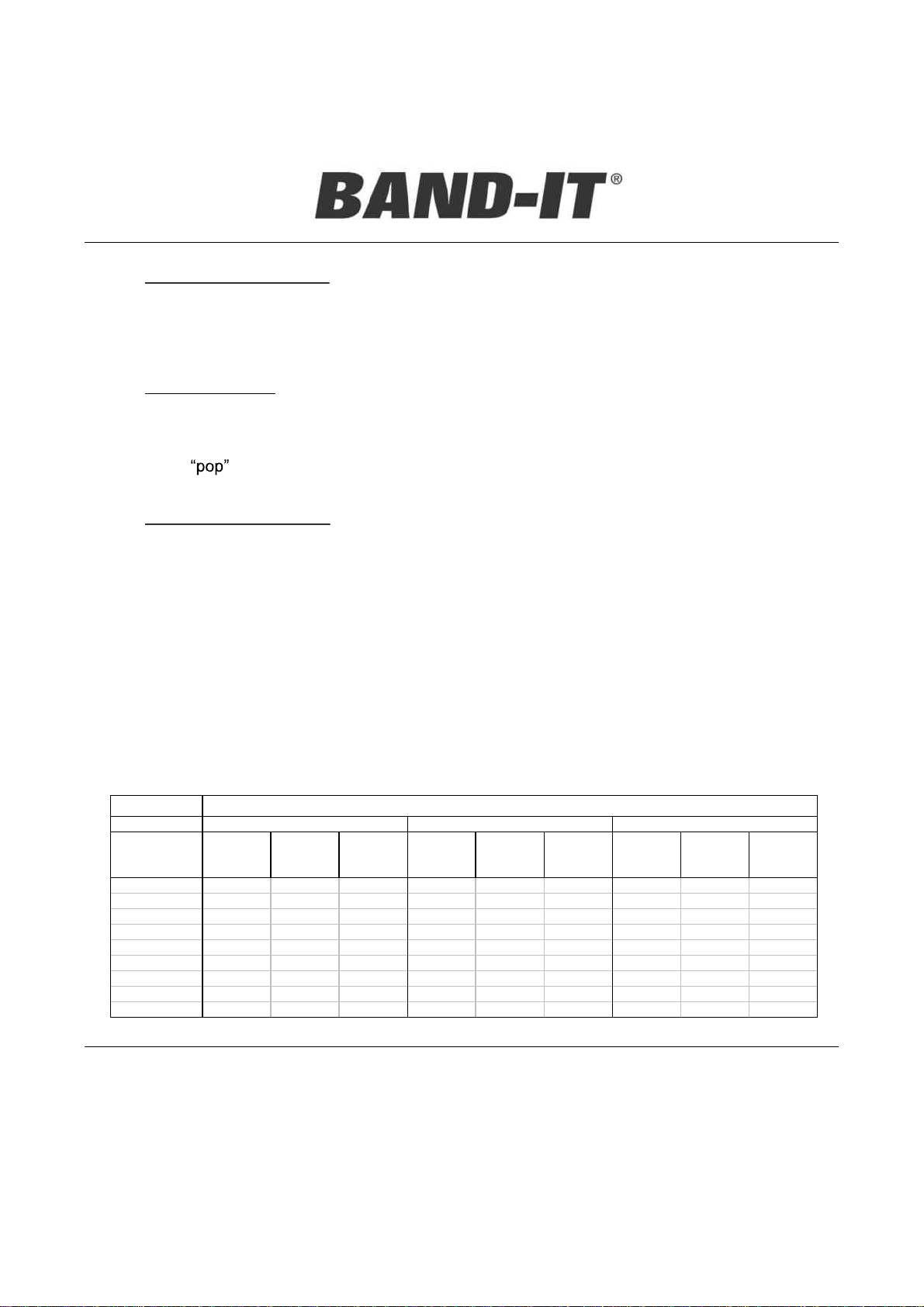

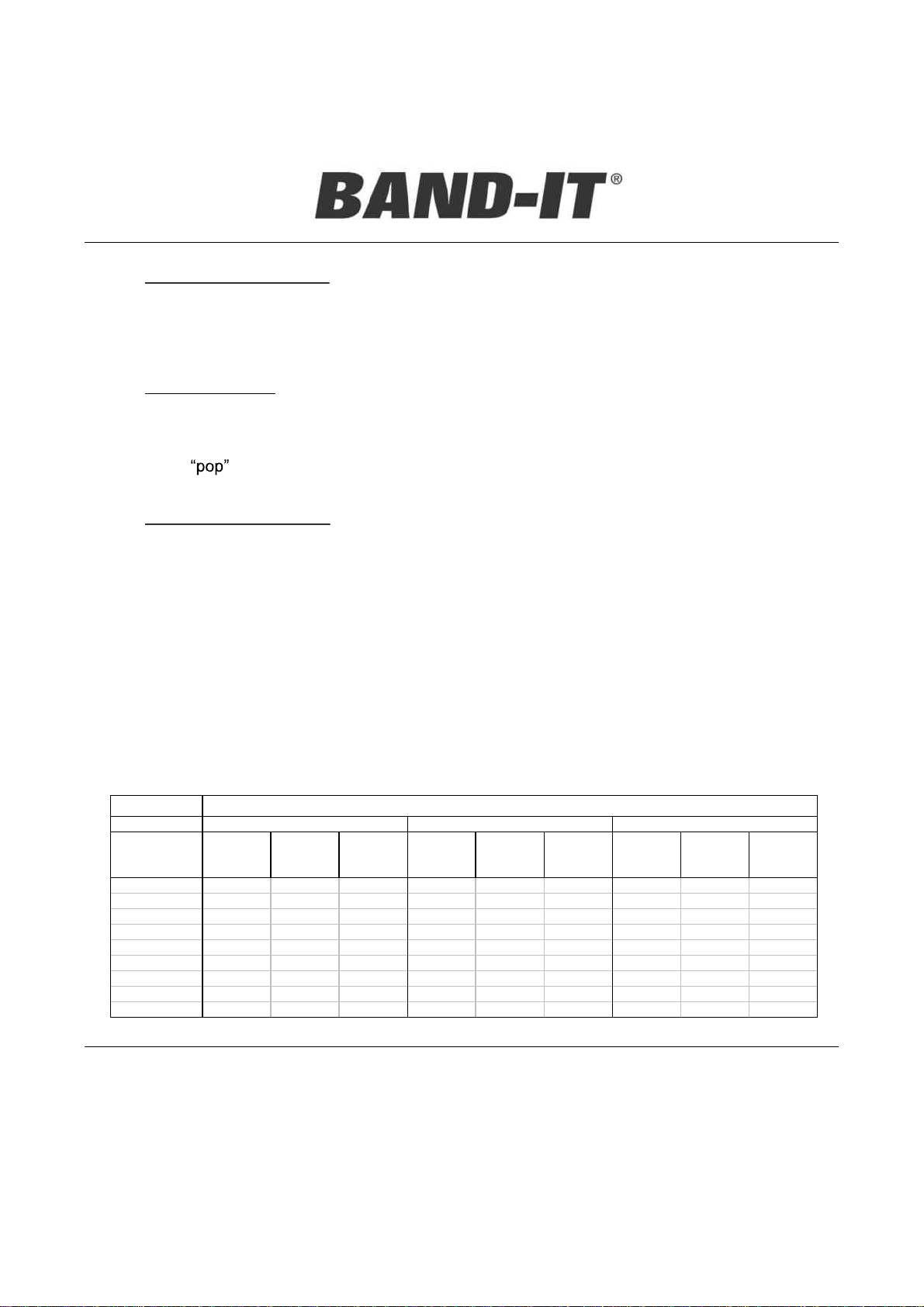

Clamp Width

Inch

Pull Up

Pressure

(PSI)

Holding

Pressure

(PSI)

Speed

Control

Setting

Pull Up

Pressure

(PSI)

Holding

Pressure

(PSI)

Speed

Control

Setting

Pull Up

Pressure

(PSI)

Holding

Pressure

(PSI)

Speed

Control

Setting

1/4" (6.4mm) 15 4 Blue 15 4 Blue NA NA NA

3/8" (7.5mm) 25 5 White 20 5 White 25 6 Blue

1/2" (12.7mm) 40 6 White 35 6 White 40 7 White

5/8" (15.9mm) 50 7 Red 40 7 Red 50 8 White

3/4" (19.1mm) 60 8 Red 50 8 Red 60 9 Red

Galvanized Carbon Steel316 Stainless Steel201 Stainless Steel

Guide for Operating Pressures for the S75099 Air tool

Rule: Allow air to completely exhaust between each stage of the tools cycle. Failure

to let air completely exhaust may result in clamps not pulling up tight.