Blueview ANS2-10 User manual

ANS2-10

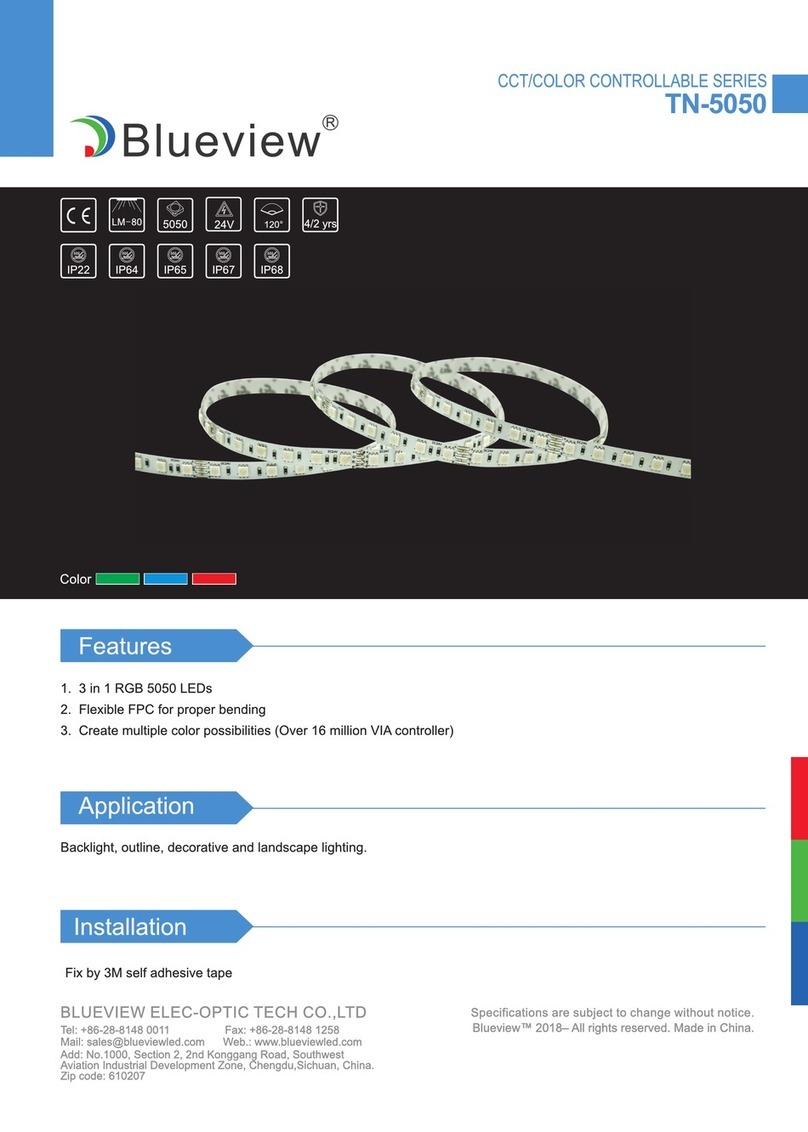

LED SILICONE NEON FLEX

Other Parameters

Model No.

Model No. LED Quantity

(pcs)

Series

Connection

(m)

Mini Cuttable

Length

(m)

Max Run

(m)

Color Temperature

Wavelength

(K/nm)

Luminous

Flux[Typical]

(lm/m)

Efcacy

(lm/m)

Voltage

(V)

ANS2-10

ANS2-10 120 50 50 0.0625

4119K

588.8nm

523.4nm

463.9nm

617.2nm

132

132

132

132

132

≥80

/

/

/

/

33 8.8

8.8

8.8

8.8

8.8

34.1

220

220

220

220

220

37.7

7.53

17.6

290.4

300.0

331.7

66.3

155.2

Beam Angle Ra Power

(W/m)

-25~+60℃-25~+70℃

Working

Temperature

Storage

Temperature

NOTE:

Test environment temperature : 25±2°C.

The above data is typical values. The actual data of each single product may differ from the typical values. The

data is subject to change without notice.

Different color temperature will make luminous ux different.

1

2

3

Installation

Optical & Electrical Parameters

By clips

ANS2-10

LED SILICONE NEON FLEX

Length vs. power vs. voltage drop

Working Length

(m)

1 0.044 220 217.3 217.3 0

0

0.2

0.6

0.7

1.7

2.5

3.7

4.8

5.7

6.1

217.1

216.9

216.5

216.1

215.1

214.3

213.1

212.0

211.3

210.7

217.1

217.1

217.1

216.8

216.8

216.8

216.8

216.8

216.8

216.8

9.68 -

-

-

-

-

-

-

-

-

-

-

49.28

98.18

147.18

196.24

245.08

294.14

343.2

391.6

440

484

220

220

220

220

220

220

220

220

220

220

0.224

0.446

0.669

0.892

1.114

1.337

1.56

1.78

2.0

2.0

5

10

15

20

25

30

35

40

45

50

Rated Current

(A)

Rated Voltage

(AC V)

Rated Power

(W)

Power Supply

Method(DC V)

Voltage at the

beginning(DC V)

oltage at the

end (DC V)

Voltage Drop

(DC V)

Prole Drawing

Unit:mm

Please ask the sales for detail drawing.

NOTE:

ANS2-10

LED SILICONE NEON FLEX

AVERAGE BEAM ANGLE(50%):115.7° C0/180,117.6°

C90/270,113.8°

Unit:cd

Luminous Intensity Distribution Diagram

ANS2-10

LED SILICONE NEON FLEX

Average Illumination

The test sample is 1m with color temperature of 4119K. Please

ask the sales for data of other color temperature or colors.

Note:

Luminous Flux output:208.9ml

1cm 280402,981720 lx 3.01cm

6.02cm

9.02cm

12.03cm

15.04cm

18.05cm

21.06cm

24.07cm

27.07cm

30.08cm

70701,245430 lx

31156,109080 lx

17525,61358lx

11216,39269 lx

7789,27270 lx

5722,20035 lx

4381,15339 lx

3462,12120 lx

2804,9817 lx

Height Eavg,Emax Beam Angle:115.18° Diameter

2cm

3cm

4cm

5cm

6cm

7cm

8cm

9cm

10cm

ANS2-10

LED SILICONE NEON FLEX

End exit (FREE)

Quantity(50m):3pcs

3.5cm Aluminum track

(Optional)

Quantity(50m):100pcs

Silicone glue (Optional)

Quantity(50m):1pcs

End cap (FREE)

Quantity(50m):3pcs

Screw (FREE)

Quantity(50m):100pcs

Plastic clip (FREE)

Quantity(50m):100pcs

Grip Plate (Optional)

Quantity(50m):100pcs

Accessories

Packaging

Roll the product on the

reel and tie it with PE lm

Put the reel and

accessory bag together

into carton box

Accessories

bag

Label the reel

Seal and label the box

Match each reel with

accessory bag

Use packing belt to pack.

Add edge protectors if

necessary.

1

4

2

5

3

6

Model No.

ANS2-10 50000*15*10 375*375*200 1 6.50(1±10%) 9.50(1±10%)

Product Size(mm) Carton Size(mm) Total Quantity Net Weight(kg) Gross Weight(kg)

Packaging information

The above quantity and weight are only for the illustrated packaging method. There will be differences

in the quantity and weight with other packaging methods.

Note:

ANS2-10

LED SILICONE NEON FLEX

Installation

1.Tools

2.Accessories

Cutter Electric batch Brush

End exit (FREE)

Quantity(50m):3pcs

3.5cm Aluminum track

(Optional)

Quantity(50m):100pcs

Silicone glue (Optional)

Quantity(50m):1pcs

End cap (FREE)

Quantity(50m):3pcs

Screw (FREE)

Quantity(50m):100pcs

Plastic clip (FREE)

Quantity(50m):100pcs

Grip Plate (Optional)

Quantity(50m):100pcs

Accessories can be provided according to customer's requirements

Note:

ANS2-10

LED SILICONE NEON FLEX

3.Installation steps

4.Installation by clip

Installation of the end cap

Installation of end exit

Solder the wire to the PCB board

First put some glue inside of the plug,

then push into the tape light

Screw the clip into the installation

position

Then slowly press the tape light into the

clip

The tape light is atly and rmly stuck in

the clip

Wipe off the excess glue and wait for the

glue to solidify.

First put waterproof glue inside of the end

exit, then push into the tape light

Wipe off the excess glue and wait for the

glue to solidify

1

1

1 2 3

2

2

3

When soldering, pay attention to the positive and negative poles of wire and PCB

board; positive to positive and negative to negative

1.

Each connection point must use 10g silicone glue, and treat waterproof and

insulation well;

2.

Screw should perpendicular to installation surface and be fastened, as shown in

the right.

3.

Note:

ANS2-10

LED SILICONE NEON FLEX

5.Attentions

Do not do live-line working for high voltage product.

1.

Follow the instructions of wiring diagram (first connect the load and then the

power supply) to avoid short circuit.

2.

Make sure the correct connection of positive and negative poles between led

module and power supply. Otherwise, the light will not be on.

3.

Make sure the power cord rmly screwed into the terminal as it can not be pulled

out by hands.

4.

The terminal should have insulation, waterproof and anti-corrosive treatment.5.

Cuttable mark Neat and smooth cut Slide a spindle into the

roll and then place the roll

with spindle on top of the

box provided.

Gently unroll the xture

without excessive force.

Do not repeatedly

bending This will damage

the circuit

Do not wring Do not bend 90° No embossing operation

No cutting distort No embossing

operation

Do not twist

Warning

Cutting marks are on the PCB and can be observed outside.

1.

The above diagram only shows the correct or wrong way of operation, only as the

reference.

2.

Note:

ANS2-10

LED SILICONE NEON FLEX

Common Faults and Troubleshoot

Quick Guide Warning

Problems

All LEDs can

not light on.

LEDs can not

light on partly.

Brightness of

LED

is inconsistent

tor insufcient.

LED icker.

Automatic power protection

from the open or short

circuit in output of the power

supply. Fix the short circuit problem.

Correctly connection

Check the power supply

system to x it.

Replace with more powerful

power

Make sure led module working

voltage within ±5% of standard

voltage, or keep balance by

circuit power consumption.

Repair should be operated by a qualied technician, if the external circuit or main line of this product is damaged.

The parameters given in this manual are typical values and for reference only.

All illustrations and drawings in this manual are for reference.

This product is subject to change without notice.

LED lighting products belongs to electronic products, please do recycling treatment according to the relevant WEEE directives.

Reduce the quantities of LED

modules in series connection

to meet requirement.

Fix the short circuit problem.

Wrong connection of power

supply.

Some switching mode power

supplies are not powered.

Power supply line error.

Mistaken wire connection of

some of products

Power overloaded.

Connection point fault. Remove bad connection point.

Replace a new power supply.

Please follow the instructions

Power supply circuit

excessive consumption.

Excessive quantities in series

connection of LED modules.

Switching power supply

failure.

Wrong Installation or use of

products

Reasons

No electric supply.

Solutions Do not disassemble or retrot the light. Do not touch the surface of the

light with a sharp object.

Do not do live-line working during installation,especially for high voltage

product.

Do not use any organic chemical solvents.

Use neutral glass adhesive to x this product and it needs to be dried 4

hours in the open environment after operation.

Treat the ends and the circuit connection points that are not connected

to the main line with insulation,waterproof, and anti-corrosion in the

installation.

Use 18AWG (0.75mm2 or thicker core wire to avoid adverse

consequences caused by overheating, if the power cable need to

lengthen.

Make sure the input voltage meets the requirements and lines are

connected correctly before lighting on.This product is as backlight of

signage, and do not use as general lighting.Series connection within the

max run.

The length of the power cable between the power supply and the led

strip should not exceed 2 meters.Otherwise, large circuit loss will lead

to inconsistent brightness

Installation, maintenance and repair should be operated by a qualied

technician.

Statements and Recycling

Statements:

Recycling:

Table of contents

Other Blueview Light Fixture manuals