Bluevua RO500X6 User manual

1-888-637-0009 (24/7 Customer Service)

https://www.facebook.com/Bluevua https://www.instagram.com/bluevua/

https://twitter.com/Bluevua

https://www.bluevua.com

BLUEVUA WEBSITE

1. Preparation

1.1 Precautions

1.2 Before Installation

1.3 Required Tools

1.4 Specifications

1.5 Product & Accessories List

1.6 Product Overview

2. Installation

2.1 Step 1: Install The Feed Water Tubing

2.2 Step 2: Install The Pure Water Tubing

2.3 Step 3: Install The Waste Water Tubing

2.4 Step 4: Install Water Leakage Protector

2.5 Step 5: Plug In The Power And Start Up System

Thank you for choosing Bluevua!

Every product sold allows us to bring more people to

a healthier lifestyle with clean water, and to a more

sustainable future with less plastic waste.

CONTENTS

2

1

2

2

3

4

6

7

9

10

10

11

12

12

13

13

14

16

3. OSD Function

3.1 Operating Display

6. Warranty

4. Maintenance

4.1 Filter Replacement Cycle

4.2 Filter Replacement Steps

4.3 Automatic Flushing

4.4 Tube Detachment

5. FAQ

Open the packaging and take out the entire machine, as well as all the accessories.

Confirm them in accordance with the list to ensure that nothing is missing or damaged

during the shipping. If there is any part broken or cracked, please stop the installation

and contact Bluevua Support Team instead. To ensure a smooth installation, please

watch the installation video from our website: www.bluevua.com

1

Note: The pure water rate is affected by water pressure and water temperature. The

feed water is measured under 0.2 MPa water pressure and 25ºC water temperature.

When water pressure and water temperature fluctuate, the water rate also fluctuates.

Note:

All contents in this chapter are related to safety, users must comply with it.

All contents in this chapter are only for the correct use of this product.

1.3 Required Tools

1.4 Specifications

1.2 Before Installation

Tel:1-888-637-0009 Mon-Fri 9:00 AM-5:00 PM CST

Email: [email protected]

PREPARATION PREPARATION

● Variable speed drill

● Drill bit: 1/4” (for the drainpipe),1/4” (for faucet hole)

● Adjustable wrench, pliers

● Screwdriver

● Utility knife or scissors

● Flashlight

● Towel

Pure Water Rate

Feed Water Requirement

Feed Water Temperature

Feed Water Pressure

Product Size (L*W*H)

Product Model RO500X6-Bluevua

L425*W150*H417mm

0.15~0.4 MPa

41~100ºF / 5~38ºC

Tap Water

1.3L Per Minute / 500 Gallon Per Day

Input 100~240V AC

Output 24V DC; 3.0A

Power Specifications

2

Prohibition

Avoid installing

under direct sunlight

and outdoor places

Do not expose to an

environment below

0 ºC

Do not store

near the machine

Warning

When the machine breaks down,

supply quickly

Keep out of reach of children

Please do not let children operate

the machine

1.1 Precautions

Attention

Do not disassemble the machine by

yourself as to prevent water leakage

and damage to the machine

Please make sure the temperature

of water source is 5-38 ºC

for more than 24 hours, please shut

power supply

In order to run the machine

smoothly, please use accessories

1.5 Product & Accessories List

PREPARATION PREPARATION

1.6 Product Overview

3 4

Water Leakage

Protector × 1

RO Faucet

× 1 Set

RO Feed Water Adapter

3/8”-1/2” × 1 Set

Adjustable Wrench

Drain Saddle 1/4”

× 1 Set

× 1

User Guide

× 1

White 3/8” PE

Tube × 60”

Tube × 60”

Power Adapter

× 1 Set

Tube × 60”

RO Water System With

PCP+RO500+CF Filters × 1

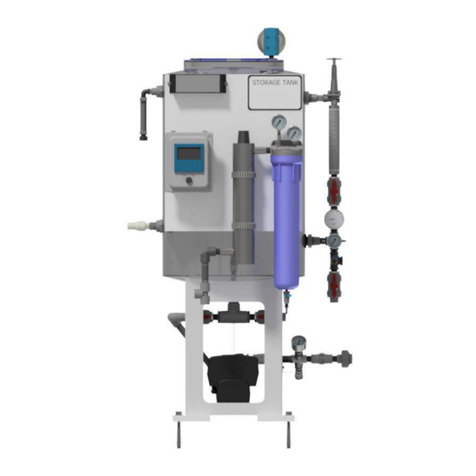

The accessories are installed and connected as shown in the following (Figure 2).

For a more efficient installation, please check and be familiar with the corresponding

location (Figure 1), and remember to press the unlocking ring (Figure 12) to remove

the trumpet-shaped cap from the port before the installation.

Figure 1

Front View Back View

Water Leakage

Protector Port

Pure Water Port

Waste Water Port

Power Port

Feed Water Port

Touch Panel Display

Side Cover

6. Connect the white 3/8” PE tube to the feed water port on the machine (Figure 4).

Pure Water Port to RO Faucet

INSTALLATION

LEGEND

RO Feed Water Adapter to Feed Water Port

Waste Water Port to Drain Pipe

Water Leakage Protector to Water Leakage Protector Port

Power Outlet to Power Port

5 6

PREPARATION

UP

A B

D

C

F E

H

J

G

I

Cold Water

Supply Valve

Hot Water

Supply Valve

Feed Water Tubing

White PE Tube

Waste Water Tubing

Pure Water

Tubing

Kitchen

Faucet

RO

Faucet

Figure 2

JI to

HG to

FE to

DC to

A Bto

2.1 Step 1: Install The Feed Water Tubing

1. Close the cold water supply valve. Turn on the kitchen faucet to release the water

pressure. Please make sure the kitchen faucet has remained open without any water

coming out, then proceed to the next step.

2. Unscrew the cold water pipe from the cold water supply valve.

3. Insert the white 3/8” PE tube into the side with pull buckle on the RO feed water

adapter. Please make sure the tube is fully inserted and locked.

4. Screw the cold water pipe onto the RO feed water adapter with the original washer

in between. Then tighten the pipe firmly with an adjustable wrench.

5. Screw your RO feed water adapter onto the cold water supply valve with washer in

between. Then tighten the adapter firmly with an adjustable wrench.

Step 1:

Step 2:

Step 3:

Step 4:

Step 5:

3. Insert the white 3/8” PE tube to the adapter

2. Unscrew from the cold water supply valve

4.

Screw onto the adapter with washer between

1. Close the cold water supply valve.

5.

Screw onto the adapter with washer between

Water Supply

Valve

Original Washer

RO Feed Water Adapter

White 3/8” PE Tube

1/2” Cold Water Pipe

Washer

Note 1: DO NOT turn on the cold water supply valve and the RO feed water adapter

before starting up the system.

Note: If there is no existing hole available on the countertop, please refer to the

following procedures to drill a hole. When drilling the hole, please remember to wear

safety goggles to protect your eyes.

7. Connect the cut blue 1/4” PE tube to the pure water port on the machine (Figure 5).

5. Push the blue 1/4” PE tube into the other end of the Quick-Connect Fitting.

6. Measure the needed length of blue 1/4” PE tube to reach the machine. Then use the

utility knife or scissors to cut the tube.

1. Place upper-cap and mounting-washer on the faucet rod.

1. Choose matching drill bits for the

material of the counter: use diamond

core for granite, and use a carbide drill

bit for stainless steel. Avoiding using a

hammer drill on natural stone, glass or

ceramic.

2. Stick the bottom of the faucet rod on

the sink or countertop. Start drilling at

the lowest speed, and hold the drill

straight with firm pressure to prevent the

bit from slipping.

3. Drill a suitable hole according to the

size (1⅜") of the faucet rod.

4. Once the drill bit breaks through the

surface, slightly swirl the drill to apply

pressure in a circle evenly.

2. Insert the RO faucet into the hole on the countertop. If there is no existing hole,

please refer to the later Note.

3. Under the sink, place the bottom-cap and the nut on the faucet rod. Tighten them up

until the faucet stands firmly on the counter.

4. Place the Quick-Connect Fitting to the bottom of faucet rod. Pull it few times to make

sure it is connected firmly.

INSTALLATIONINSTALLATION

Figure 3

7 8

2.2 Step 2: Install The Pure Water Tubing

Mounting Washer

Upper-Cap

Bottom-Cap

Nut

Blue 1/4” PE tube

Quick-Connect

Fitting

Counter

Screw On

Screw On

3/8”

Converter White 3/8” PE tube

Note 2: For 4 and 5, If the cold water pipe is 3/8” instead of 1/2’’, please use the

attached 3/8” converter (Figure 3).

Figure 4

Figure 5

Feed Water

Port

Blue

1/4” PE tube

Pure Water Port

1. Plug the water leakage protector into the water leakage protector port on the

machine (Figure 8).

1. Plug the power adapter into the power outlet, then connect the DC cable to the

power port on the machine (Figure 9).

2. The machine will automatically start flushing for 45 seconds. Turn on the RO faucet.

Let the faucet runs for 30 minutes to flush out the protective liquid in the RO filter. Pay

close attention to each joint of the system during the flushing process. Make sure all

tubing is installed correctly and there is no leakage at any joint, fitting, valve, or PE tube

connection. Be aware that a slow water flow is normal when the RO faucet is turned

on, and the water is NOT drinkable during the flushing process.

2. Tear off the double-sided tape on the water leakage protector; then stick the water

leakage protector near the machine.

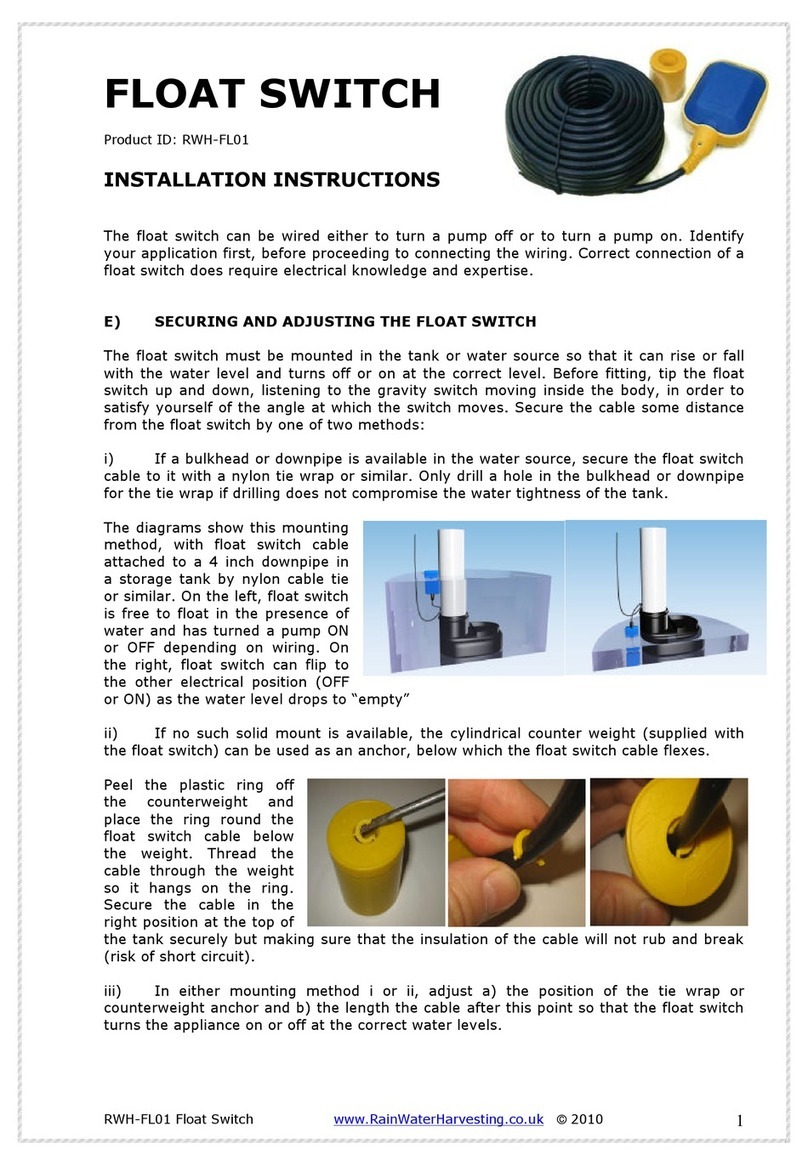

1. Choose a preferred location on the drainpipe to install the drain saddle. We highly

suggest to install the drain saddle on the vertical-directed drainpipe.

2. Drill a 1/4” hole on the side of the drainpipe. Be careful not to penetrate the other

side of the drainpipe.

3. Place the front plate on the end of the remaining black 1/4” PE tube, and insert the

tube into the drilled hole for about 1” deep (Figure 6).

4. Place the back plate on the other side of the drainpipe to combine to the front plate.

Use the adjustable wrench to tighten the plates with screws and nuts evenly.

Note: If the leakage protector is correctly installed, no further settings are needed.

When a leak occurs, the leakage protector will sound and pause the system. Please

contact Bluevua Support Team for technical support. If the leakage protection is

triggered by humidity or water from outside, please clean the water on and in the

leakage protector. After cleaning, press the RESET button to start again.

5. Connect the black 1/4” PE tube to the waste water port on the machine (Figure 7).

9 10

INSTALLATIONINSTALLATION

2.3 Step 3: Install The Waste Water Tubing

Figure 6

1”

Figure 9

Drainpipe

Black

1/4” PE Tube

Front Plate

Back Plate

2.4 Step 4: Install The Water Leakage Protector

2.5 Step 5: Plug In The Power and Start Up System

Figure 8

Figure 7

Power Port

DC Cable

Water Leakage

Protector

Leakage

Protector Port

Black

1/4” PE tube

Waste Water Port

3. Lift up the filter and twist in clockwise direction, then

pull out the expired filter (Figure 10).

Note:

1. Actual lifetime of the filters varies from different regions, water quality, season and

usage. Please replace the filters according to the reminder from the filter lifetime

indicator.

2. If the filters expire, please purchase and replace the filters as soon as possible.

Otherwise, the filtration efficiency will be greatly reduced and affect performance.

Power-On

Indicator Operating Status Display

When power is on, the buzzer

plays power-on sound, all button

lights and digital function menus

are on. The system will do

self-check. If there is no alarm,

the system will switch to

auto-flushing mode after 3

seconds.

Turn on the RO faucet, the

machine automatically starts

water production. Turn off the RO

water faucet, the machine stops

producing water.

When one or more filters expire,

the alarm buzzer rings rapidly as

a routine filter replacement

reminder. The alarm repeats on

every attempt of pure

water-making. After 360 hours

(15 days) of alarm, the system

will turn off inlet solenoid valve

and booster pump. The indicators

must be reset to restart the

lifetime reminder after the filter

replacement.

After replacing the filter(s),

long-press the Select indicator

for 3 seconds to enter filter

selecting mode, then press the

indicator to switch between

different filters. For a selected

filter, long press the Reset

indicator for 5 seconds to

complete the reset process.

The indicator flashes

during water-making

process, and turns off

when the process is

done.

The indicator of the

PCP/RO/CF filter is

always on. It lights up

when it is in the state

of auto-flushing and

pure water-making.

The indicators remain

white under normal

status. When the filter

expires, the indicator

flashes red until the

replacement and reset

process are

completed.

The indicators remain

on at all time, and

remain off during

standby mode.

11 12

OSD FUNCTION MAINTENANCE

3.1 Operating Display 4.1 Filter Replacement Cycle

4.2 Filter Replacement Steps

Reverse Osmosis Membrane Filter

Polypropylene Activated Carbon Filter

RO

Carbon FilterCF

PCP 12 Months

12 Months

24 Months

1. Turn off the power and water supply.

2. Find the edge of the side cover and then remove

the cover.

6. Restart the system. Turn on the RO faucet to flush

out the protective liquid in the filters. Do not drink until

the 30 minutes of flushing process is completed.

4. Insert new filter into the filter base: PCP→RO→CF

from left to right. Turn the filter in counter-clockwise

direction to twist in the filter until the triangle icon on

the top of the filter aligns with the triangle icon on the

filter base (Figure 11).

5. Long press the Select indicator for 3 seconds to

enter filter selecting mode, then press the indicator to

switch between different filters. For a selected filter,

long press the Reset indicator for 5 seconds to

complete the reset process.

FLUSH

SELECT

RESET

PCP

RO

CF

WORK

FLUSH

WORK

PCP

RO

CF

SELECT

RESET

Figure 10

Figure 11

Figure 10

13 14

FAQMAINTENANCE

The system automatically enters flushing mode under the circumstances below:

1. For The First Time Using

When the power is on, the system will automatically switch to auto-flushing mode and

start back-flushing for 18 seconds.

2. For Accumulative Working Time Over 24 Hours

To maintain and extend the lifetime of the filters, the system will do auto back-flushing

for 18 seconds when it accumulatively works up to 24 hours.

3. For No Usage Over 48 Hours

To secure fresh and healthy drinking water, the system will do auto back-flushing for 18

seconds if there is no pure water-making for more than 48 hours.

4. For Restored Power

When the power is restored from an outage, the system will be forced to have auto

back-flushing for 18 seconds.

4.3 Automatic Flushing

To detach the PE tube from the machine, use the adjustable wrench to press the circle

unlocking ring of the quick-connect fitting then pull out the tube.

4.4 Tube Detachment

Excessive bending of water tube: Check and straighten out the tube.

Q Why there is no water dispensing from the RO faucet or the water

output becomes weaker?

A1

RO feed water adapter is being turned off: Check and make sure the

RO feed water adapter switch is being turned on.

Water outage occurred: Check if there are any water outage in the

area. If yes, please wait for the local water supply to be fixed.

A2

A3

Filters clogged: Check filters to see if they are properly inserted. Make

sure all the filters are replaced and have not expired yet.

A4

Feed water pressure lower than rated value: Check and make sure

the tubing is properly connected and no leakage on the pipe(s).

A5

Temperature of feed water is low: Check and make sure the system

runs at water temperature between 41-100°F.

A6

Q Why the system does not function?

Power failure: Check if there is power outage. Check if the power

adapter is properly connected to the machine and power outlet. Or

simply disconnect the system and try another power outlet.

A2

Power-saving mode: Reset the power or touch the button several

times quickly to leave the mode.

A1

Power adapter failure: Replace the power adapter. If you are unsure

about the model of adapter, please contact our Customer Service for

further assistance

A3

Leakage alarm activated: The system automatically shuts down when

the leakage protector detects a leak. Check and make sure all tube

joints and filters are tightened, and check if the protector is accidently

triggered by moisture/liquid near the machine. Either way, unplug the

water leakage protector and clean up the water. After cleaning, press

the RESET button to start again.

A4

Figure 12

Actual lifetime and condition of a filter may vary due to different quality

of water supply or different water usage. Poor water quality and high

operating frequency might lead to the shorter lifetime.

Filter protective liquid remained: The brand new filter is covered with

protective liquid that needs to be washed off. Turn on the RO faucet

for 30 minutes to flush out the liquid after replacing filters.

The machine has remained unused for a long period: Restart the

machine and turn on the RO faucet to run for 10 minutes. If the smell

remains, please replace the filters.

15 16

Q Why the pure water looks dirty?

Activated carbon particles: It is normal that the pure water turns black

with activated carbon particles in the new CTO filter. Do not drink until

the 30 minutes of flushing process is completed.

A

WARRANTYFAQ

Q Why the pure water smells abnormal?

A2Expired filters remain unchanged for a long period: Replace the filters

A3

A1

Q Why the filters are clogged shortly after filter replacement?

A

Q Why the machine makes loud noise during operation?

The vibration generated by the pump: Move the machine away from

the side wall. Do not place the machine against the side wall or on the

uneven ground.

A1

Unstable feed water pressure: Check and confirm the water pressure

is between 21.7-58 PSI / 0.15-0.4 MPa.

A2

Abnormal power voltage: Contact our support team for assistance.

Do not attempt to repair as there may be electrical leakage.

A3

Scan me to register for

1 YEAR WARRANTY

Please scan the QR code above or visit website https://www.bluevua.com/warranty

for 1 year manufacturer warranty registration. Please also feel free to reach out to us if

you have any questions or concerns about your RO drinking water system. Your health

is our priority! We sincerely hope our product will bring health to you and your family!

Other manuals for RO500X6

1

Table of contents

Other Bluevua Water System manuals

Popular Water System manuals by other brands

MARLO

MARLO NXT2 Series Installation, operation and maintenance manual

gledhill

gledhill PulsaCoil 145 Design, installation & servicing instructions

Pfister

Pfister Marielle 34 Series instructions

Everpure

Everpure Twin Series Head EV9272-24 Specification sheet

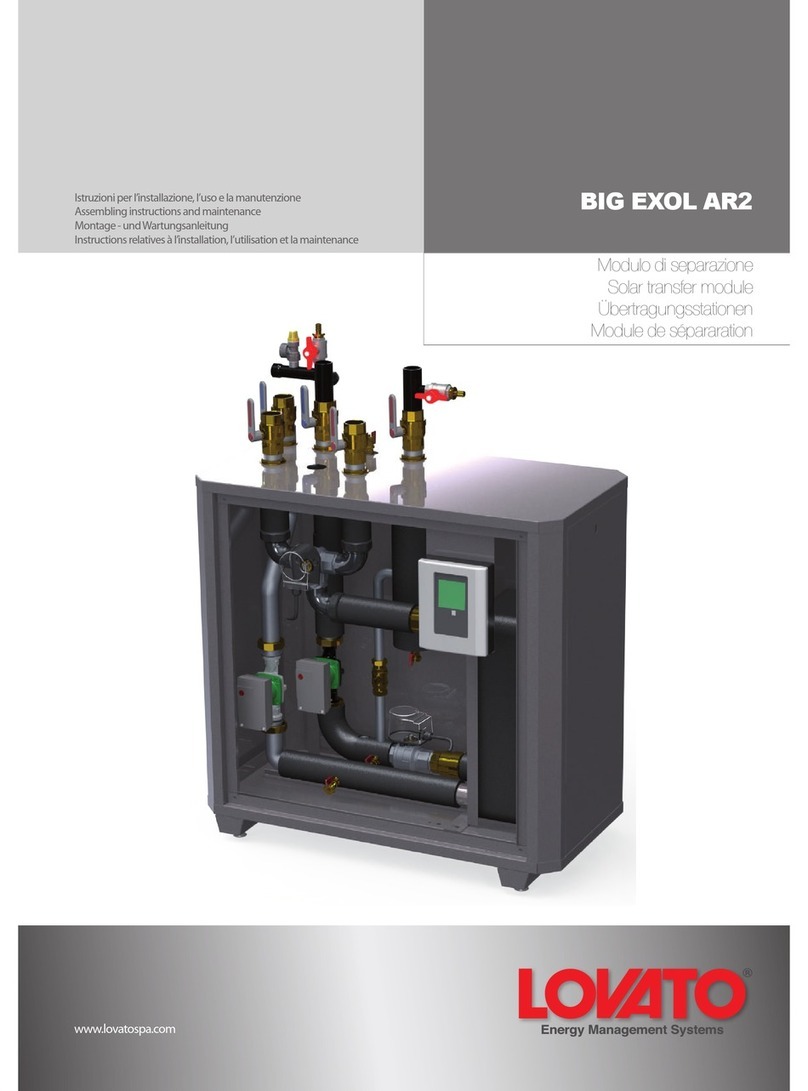

Lovato

Lovato BIG EXOL AR2 Assembling instructions and maintenance

Vetus

Vetus HYDRF12 Operation manual and installation instructions