Bluff YARDRAMP User manual

1

YARDRAMP®MODEL WITH CASTERS

Owner’s Manual

Page Contents

2 .........................................Instructions for Unloading Yard Ramps

3 .........................................Yard Ramp Leg Assembly

4–6 ......................................Yard Ramp Operating Instructions

6..........................................Yard Ramp Maintenance

7..........................................Warranty and Returned Goods Authorization

DO NOT SHIP YARD RAMP

ON ITS BOTTOM OR ON ITS TOP

SHIP AND RECEIVE UNIT

ONLY ON ITS SIDE

11-2012

2

INSTRUCTIONS FOR UNLOADING YARD RAMPS

FROM FLATBED TRAILERS

If an overhead crane of sufcient capacity is not available, use a forklift with a minimum capacity rating

of 8,000 pounds to unload catalog listed yard ramps. Customers who purchase custom size yard ramps

which exceed the catalog sizes in width, length or rated capacity should seek a recommendation from Bluff

Manufacturing for forklift capacity due to additional weight.

A nylon sling of at least 48" in length is recommended. The sling may be of the “2 eye” or “endless”

conguration. A minimum capacity rating of 10,000 pounds for the basket method of lifting is recommended.

To lower the yard ramp onto its belly:

1. Create a solid stack of cement blocks or pallets that can hold the weight of the yard ramp during

assembly. This stack needs to be at least 48” high for installing the legs, and be able to support up to

8,000# for standard yard ramps of up to 30,000# capacity and 84” wide.

2. Position the forklift on the underside of the yard ramp. Attach sling as described above.

3. Lift the yard ramp by the sling and lower the yard ramp until the edge of the lip (the end with the chains)

rests on the solid stack created in #1 above.

4. Continue lowering the ramp until the opposite end touches the ground.

5. Tilt the forks back fully and move slowly away from the yard ramp, lowering the forks at the same time.

Continue moving and lowering the forks until the ramp is resting on its belly, the front apron resting rmly

on the solid stack.

6. BEFORE ATTACHING LEGS, MAKE SURE THAT YOU ENGAGE A SECONDARY FAILSAFE

SYSTEM FOR SUPPORTING THE YARDRAMP WHILE YOU INSTALL THE LEGS. THIS CAN

CONSIST OF pallets or wood blocks that stack up to a minimum of 48”, OR A FORKLIFT OR

FORKLIFT WITH SLING THAT IS RATED FOR THE WEIGHT OF THE YARDRAMP.

Additional information on slings and hitches can be supplied by sling providers.

Continued on next page ...

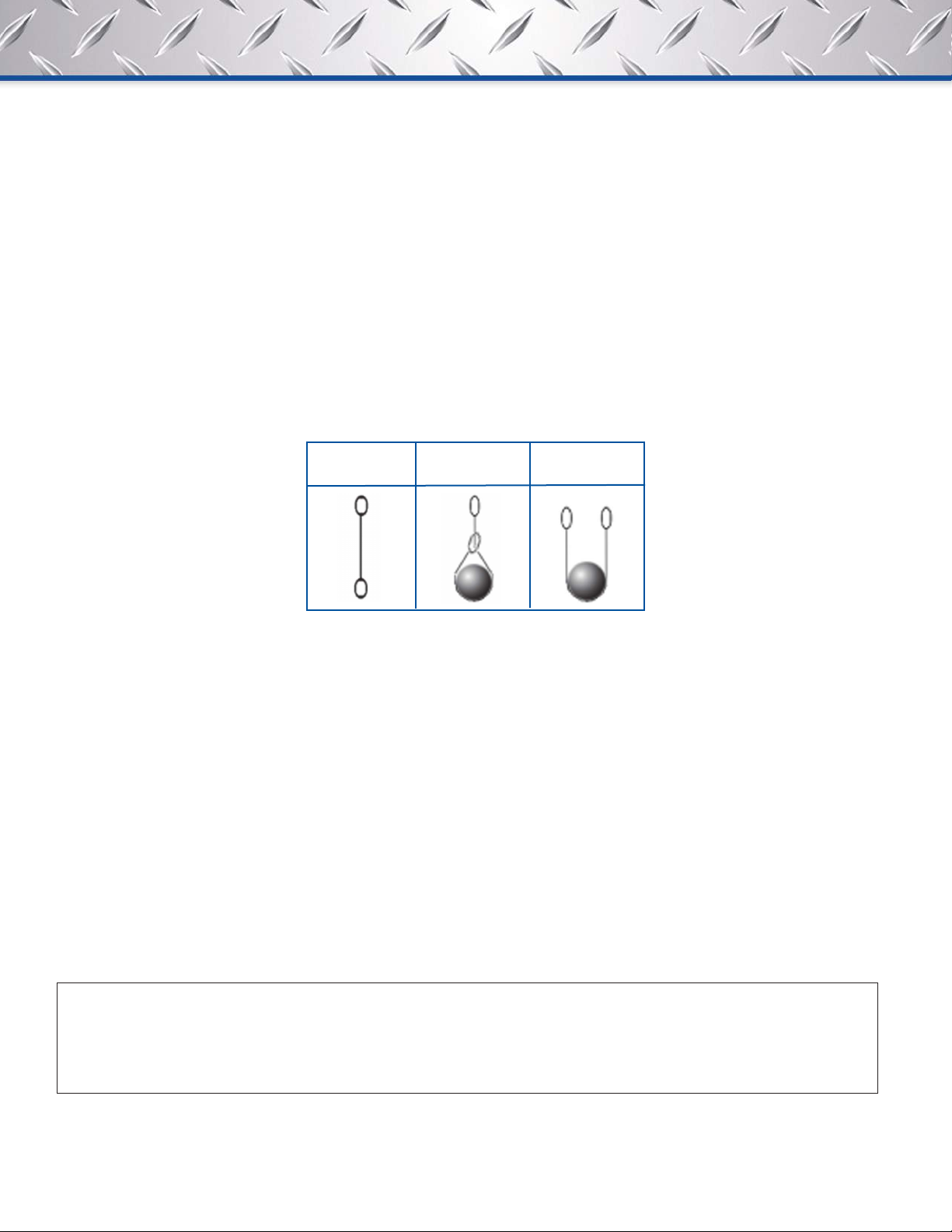

Vertical

Hitch

Choker

Hitch

Basket

Hitch

3

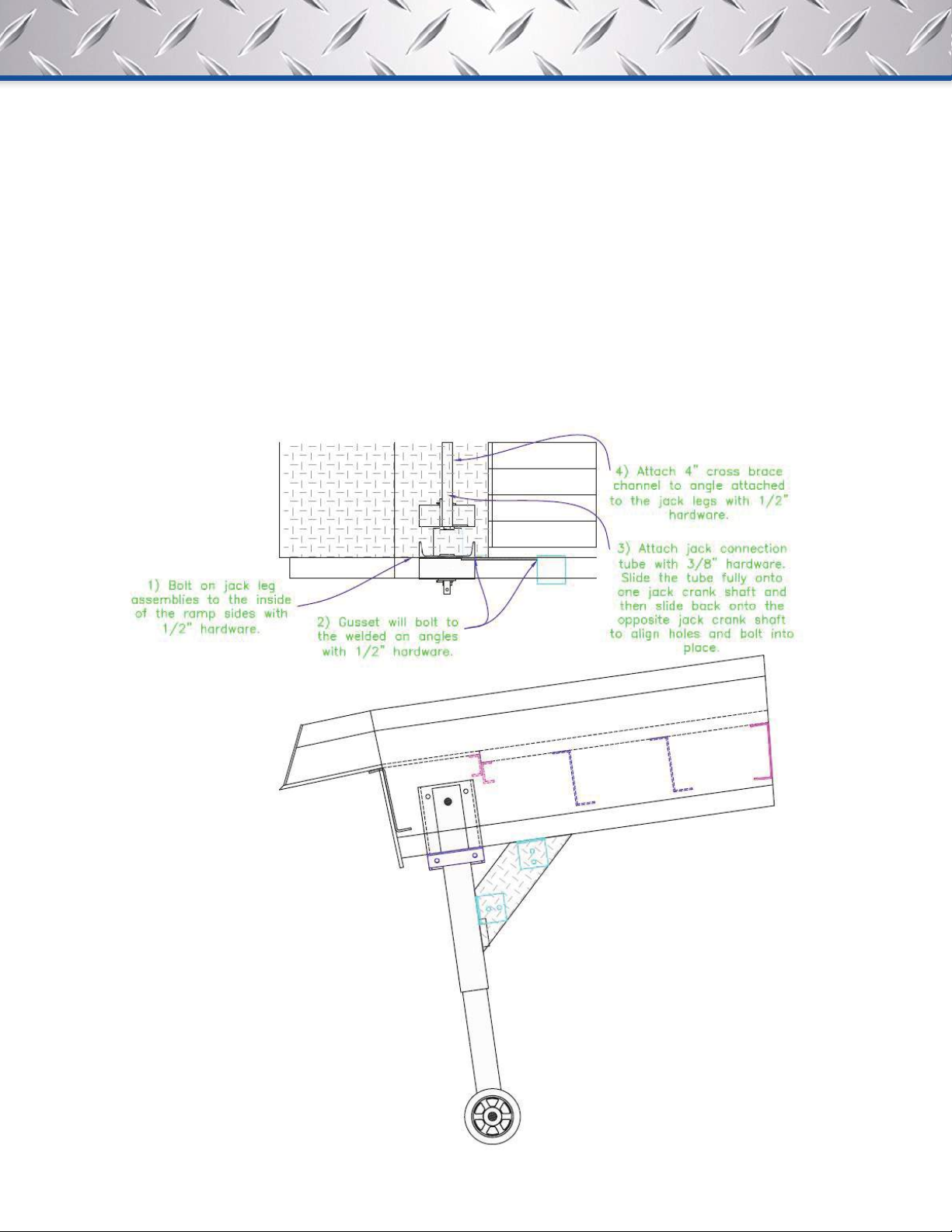

YARD RAMP LEG ASSEMBLY

You should receive the yard ramp with the legs and hardware on a separate pallet.

1. Bolt on jack leg assemblies to the inside of the ramp sides with ½” x 1 ½ hex bolt and hex nut.

2. Gusset will bolt to the welded on angles with ½” x 1 ½” hex bolt and hex nut.

3. Attach jack connection tube with 3/8” x 2” hex bolt and hex nut. Slide the tube fully onto one jack crank

shaft and then slide back onto the opposite jack crank shaft to align holes and bolt into place.

4. Attach 4” cross brace channel to angle attached to the jack legs with ½” x 1 ½” hex bolt and hex nut.

4

YARD RAMP OPERATING INSTRUCTIONS

Balance

Wheels are located at the opposite end as the ramp clamp hole for ease of operation and to make the yard

ramp trail properly when being towed. The balance will shift as the yard ramp is elevated.

Towing

The towing speed will be governed by prevailing conditions, but should not be such as to cause severe

jostling. Towing speeds should not exceed 4 mph. The ramp clamp is intended for short towing distances and

precise positioning of yard ramp units. Over-the-road towing is limited by governing state and federal laws, but

we do not recommend it.

ALWAYS TOW YARD RAMP WITH THE LEGS ALL THE WAY UP AND THE YARD RAMP IN ITS

LOWEST POSITION

NEVER USE RAMP WITH LEGS EXTENDED. RAMP SHOULD ALWAYS SIT FIRMLY ON FRONT &

REAR APRONS DURING USE.

ALWAYS USE THE YARD RAMP WITH THE WHEELS RAISED OFF THE GROUND.

Raising and Lowering the Yard Ramp

To lower or raise the wheels, insert the handle into the crank shaft at the head of the leg, and push until gear is

engaged. Turn lever to raise or lower the wheels. The ramp can be adjusted from either side.

Positioning

To position the yard ramp, ALWAYS MOVE THE YARD RAMP TO THE TRUCK. DO NOT MOVE THE TRUCK

UNDER THE YARD RAMP.

Position the yard ramp so that the front lip is over the surface on which it is to rest with the stop plates resting

against the end of trailer or face of dock.

DO NOT BACK TRUCKS UP TO AND UNDER LIP OF YARD RAMP.

Always move the yard ramp to the truck.

Continued on next page ...

Ramp Clamp

5

5. By gently moving the forklift in the ramp clamp, position the yard ramp close to the dock, trailer or railcar.

6. Raise the lip of the yard ramp with the hand crank so that it clears the surface of to the dock, trailer, or

portable dock. Yard ramps are recommended for use with railcars only if it can be placed properly on the

oor of the railcar and secured with the chains provided.

7. Roll the yard ramp toward the surface that it will be used to bridge. Make sure that the lip of the yard

ramp is all the way over the surface. If a trailer or rail car is end loaded, at least 6” of the lip must rest on

the bed. As soon as the end load has been taken off, the yard ramp should be repositioned so that all 16”

of lip are supporting the yard ramp.

Continued on next page ...

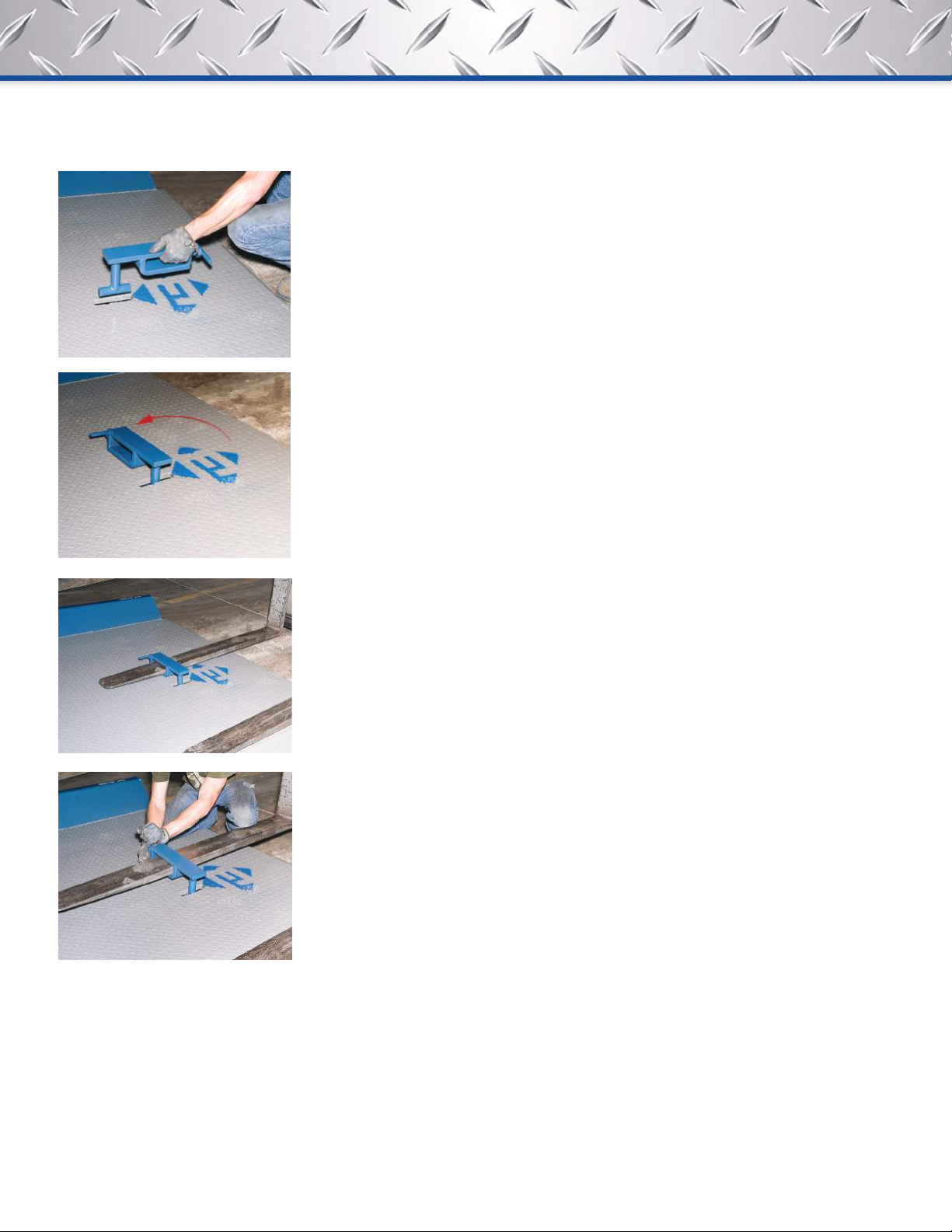

1. With the wheels raised (and the yard ramp

in its lowest position), grasp the Bluff Ramp

Clamp and insert “T” into slot as indicated.

2. Rotate in position as shown. Loosen the Ramp

Clamp screw enough to allow ample room to

insert fork.

3. Drive fork lift forward slowly to insert fork into Ramp

Clamp. Once in position, raise forks enough to

allow tightening of Ramp Clamp screw

4. Bluff Yard Ramp can now be positioned with

fork lift.

6

8. Using the hand crank, lower the yard ramp until the lip of the yard ramp is fully engaged on the trailer.

Continue raising the wheels until a minimum of 2” inches are clear between the ground and the caster.

This insures that as you load or unload the vehicle, the yard ramp will never rest on the wheels.

9. Attach the safety chains found on the front of the yard ramp to the vehicle being loaded/unloaded to

assure that the yard ramp will not pull away. If the yard ramp is end loaded and there is only a minimum of

the lip on the surface of the vehicle, be sure to use the chains to secure the ramp initially, and then when

more of the lip can be placed on the vehicle, re-tighten the securing chains.

10. Reverse steps 1 to 9 to disengage ramp.

REMEMBER: THE WHEELS ARE NOT DESIGNED TO CARRY ANY LOAD.

Securing

For safety, always secure the yard ramp in place utilizing the two safety chains located on the front of the

yard ramp. Chains should be looped around a sturdy part of the trailer, platform, or dock on which the yard

ramp is resting, using the grab hooks to complete the loop. The chains should be as tight and as horizontal as

possible, but allow for change in vehicle height caused by shifting loads.

Using

Vehicles traversing the yard ramp should always maintain a slow, steady speed, preferably in low gear. They

should not stop or change gears while on the yard ramp, as this may cause excessive wear and damage to the

vehicle tires.

Forklift trucks should ascend and descend with their forks tilted back and raised enough to avoid contact with

the yard ramp deck.

Storage

When nished using yard ramp:

1. Release the safety chains and place them securely on deck of yard ramp.

2. Crank legs to lift up the ramp.

3. Roll yard ramp away from platform, dock, or vehicle. Trucks may be driven away from the

yard ramp but not before steps 1 and 2 above have been performed.

4. Lower yard ramp to stored position.

YARD RAMP MAINTENANCE

Lubrication

The legs and casters have grease pins that should be greased every 6 months. Lubricate wheel hubs with

waterproof automotive grease by using standard "zert" grease gun.

Structure

Welded yard ramp structure should be inspected at least annually (or more often, according to usage) for

evidence of damage, including but not limited to cracks/failures in materials or welds.

Steel work should be repainted as required.

Continued on next page ...

7

BLUFF WARRANTY

Bluff Manufacturing warrants their products to be free from defects in material and workmanship for a period of

one year from shipping date to original purchaser. Yard ramp pumps and EOD hydraulic power units are war-

rantied for 90 days from shipping date to original purchaser. Warranty eligibility requires all products are used

and serviced in accordance with the company’s recommendations, product selection guides, product manuals

and installation instructions.

Bluff Manufacturing’s obligation under this warranty shall be limited to the repair, by Bluff Manufacturing or a

Bluff Manufacturing authorized technician, or exchange of any part or parts which may prove defective un-

der normal service within the time limitations set forth above, and which our examination shall disclose to our

satisfaction to be defective. Bluff Manufacturing requires the purchaser to send date stamped photographs for

initial review of warranty claim products.

This limited warranty does not cover any defects, malfunction or failure caused by or resulting from improper

or unauthorized service, maintenance, installation, repair or use not in conformance or accordance with Bluff

Manufacturing’s recommendations, product selection guides, product manuals or installation instructions and

the intended use and capacities or specications or from abuse, neglect, accident, weather related issues

or any other cause beyond the control of Bluff Manufacturing This limited warranty is made only to the origi-

nal purchaser, which shall be deemed to mean that person or organization to which the product is originally

shipped or installed.

Bluff Manufacturing does not approve nor authorize any other person or entity to obligate Bluff Manufacturing

to any other liability not described herein concerning the sale of its products.

Bluff Manufacturing shall not be liable for any incidental or consequential damages. And liability hereunder is

expressly limited to repair or replacement of any part or parts which may prove defective within the time pre-

scribed hereon.

This warranty is expressly in lieu of all other warranties, expressed or implied, including the warranties of mer-

chantability and tness for a particular purpose and all other obligations or liabilities on our part.

BLUFF RETURNED GOODS AUTHORIZATION (RGA)

Before returning any merchandise for any reason whatsoever, it is necessary to contact Bluff Manufacturing for

approval. All requests must be submitted with a date stamped photograph of item to be returned. If approval is

given, an RGA number will be given by Bluff Manufacturing. This RGA number must appear on all documents

involving the returned goods.

Freight charges on all RGA’s must be PREPAID on returns but not warranties.

RGA numbers will not be issued after ninety (90) days from date of shipment, except for warranty items, by

Bluff Manufacturing or its designated representative.

A restocking charge of 25% will be made on all merchandise except as allowed under warranty claims.

Returns will not be allowed on any custom, special or worksheet required items and products in non-resalable

condition.

Table of contents

Other Bluff Industrial Equipment manuals