Table of contents

1

General............................................................................................................. 1-1

1.1 Purpose.............................................................................................................. 1-1

1.2 Product specifications......................................................................................... 1-1

1.2.1

Manufacturing address .......................................................................................... 1-1

1.2.2

Labelling................................................................................................................. 1-1

1.2.3

Declaration of conformity ....................................................................................... 1-2

1.2.4

Specifications for enquiries and order ................................................................... 1-3

1.2.5

Formalities of the operating manual ...................................................................... 1-3

1.2.6

Maximum load specifications................................................................................. 1-4

1.2.7

Connections ........................................................................................................... 1-4

1.2.8

Energy consumption .............................................................................................. 1-4

1.2.9

Intended usage ...................................................................................................... 1-4

1.2.10

Technical data sheet.............................................................................................. 1-5

2

Safety notes..................................................................................................... 2-1

2.1 Working in a safety-oriented manner ..................................................................2-1

2.2 Organisational measures.................................................................................... 2-2

2.2.1

User obligations ..................................................................................................... 2-2

2.2.2

Operator obligations............................................................................................... 2-2

2.2.3

Qualification of persons and activities carried out ................................................. 2-3

2.3 Product safety .................................................................................................... 2-4

2.3.1

Safe operation of the attachment........................................................................... 2-4

2.3.2

Safety and protective equipment ........................................................................... 2-4

2.3.3

Structural changes ................................................................................................. 2-4

2.3.4

Spare and wearing parts and auxiliary materials................................................... 2-4

2.3.5

Warranty and liability.............................................................................................. 2-5

2.4 Basic safety notes .............................................................................................. 2-5

2.4.1

General safety and accident prevention information ............................................. 2-5

2.4.2

Hydraulic system.................................................................................................... 2-7

2.4.3

Attachment............................................................................................................. 2-8

2.4.4

Cleaning, servicing and maintenance.................................................................... 2-9

2.5 Action-related safety notes and important information ...................................... 2-10

2.5.1

Action-related safety notes .................................................................................. 2-10

2.6 Warnings and instructions ................................................................................ 2-11

2.6.1

Warning notes...................................................................................................... 2-11

3

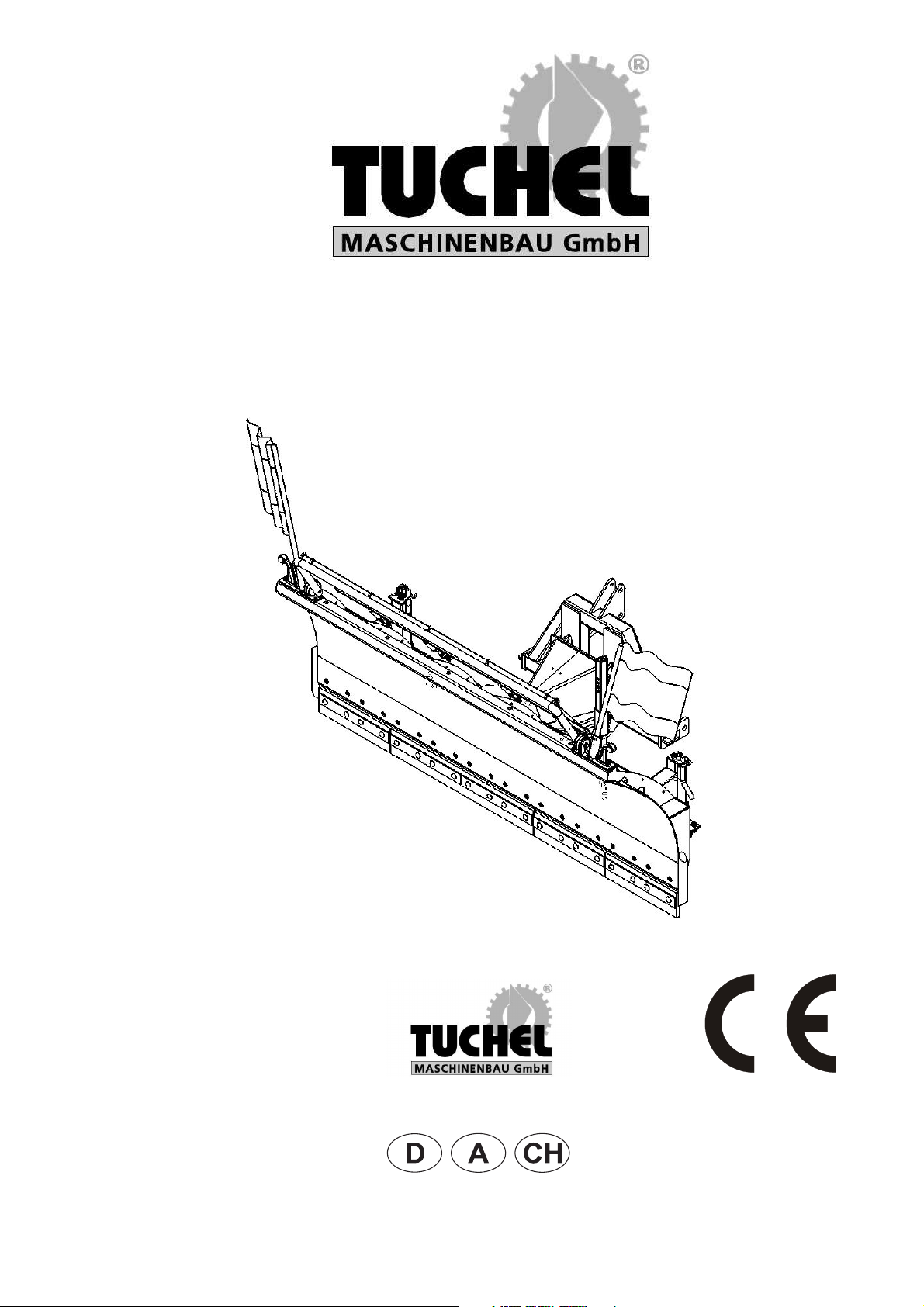

Product description ........................................................................................ 3-1

3.1 Overview – components ..................................................................................... 3-1

3.1.1

Description of the product and accessories........................................................... 3-2

3.2 Attachment parts ................................................................................................ 3-3

3.2.1

Spring segments .................................................................................................... 3-3

3.2.2

Castor wheels ........................................................................................................ 3-3

3.2.3

Angling system....................................................................................................... 3-4

3.2.4

Snow guide ............................................................................................................ 3-4

3.2.5

StVZO kit................................................................................................................ 3-4