bluMartin freeAir100 Assembly instructions

Table of contents

Popular Water Filtration System manuals by other brands

Genebre

Genebre FT00 Series Assembling instructions

AREBOS

AREBOS AR-HE-SA/G/S Original user manual

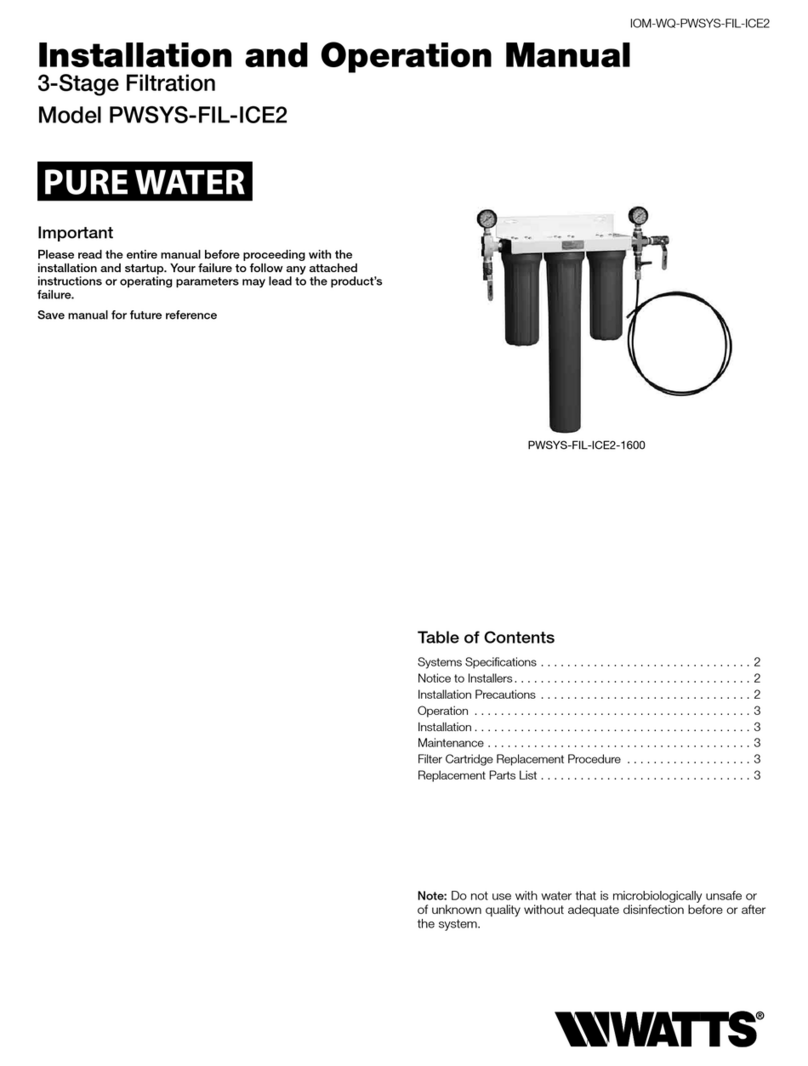

Watts

Watts Pure Water PWSYS-FIL-ICE2 Installation and operation manual

SunSun

SunSun CPF Series Operation manual

Campbell Hausfeld

Campbell Hausfeld MP513803 operating instructions

Steinbach

Steinbach Speedclean Comfort 50 ORIGINAL OWNER'S MANUAL

Anetsberger Brothers

Anetsberger Brothers GoldenFRY FFM-80 Specifications

Forbes

Forbes FLO user manual

Pentair

Pentair Autotrol 255 Logix 740-760 Installer manual

TCL

TCL Breeva A3 quick start guide

Bauer

Bauer FAN Separator Green Bedding Service manual

resideo

resideo Braukmann MiniPlus FF06 installation instructions

Crystal Quest

Crystal Quest CQE-SP-00809 Installation and operation guide

Pall

Pall UR629 Series Service instructions

Xtralis

Xtralis VESDA VSP-005 Cartridge Replacement Instructions

Hamilton Beach

Hamilton Beach AquaFusion 87325 Replacement

Hague Quality Water

Hague Quality Water WaterMax H6000 Owner's manual and installation guide

3M

3M 6001 User instructions