1DESCRIPTION OF THE HARDNESS TESTER

1.1Purpose of the Hardness Tester

The hardness tester is designed to perform on-the-spot measurement of structural carbon steels in Brinell (HB),

Rockwell (HRC) and Vickers (HV) (main) hardness scales by means of dynamic (contact impedance) method.

The hardness tester is designed to perform (referential) hardness check of structural carbon steels in Rockwell (HRA),

Rockwell (HRB) and Shore (HSD) hardness testing scales —by means of measurement results automatic conversion

from main hardness scale units into respective hardness units according to user’s or manufacturer’s Tables.

The hardness tester is designed to perform (referential) checking of ultimate tensile strength (МPа) of pearlitic

structural carbon steels –be means of measurement results automatic conversion from Brinell (HB) hardness scale

into respective units according to Table.

The hardness tester is designed to perform hardness check of metals and alloys which differ in properties from carbon

structural steels.

The hardness tester may be used to perform hardness check of:

Heat-resistant, corrosion-resistant, stainless, tool and other types of steels;

Non-ferrous metals and alloys;

Process-specific cast irons;

Strengthening and other layers which are coating the steel articles (cementation, nitrogenation, HFC hardening etc.)

Surface deposits and galvanic coatings (chrome etc.);

Articles made of fine-grained materials (during local investigation of materials properties).

If mechanical-and-physical properties of material under check differ from carbon structural steel properties it is

supposed that measurements will be performed after set up of additional calibration (or additional scale) made by the

device user with hardness samples made of respective material or at manufacturer’s production facilities on user’s

request.

The hardness tester is intended for use in laboratory, shop and field environment.

1.2Hardness Tester Operating Principle

Hardness tester operating principle is based on UCI (ultrasonic contact impedance) method.

Basic components of the hardness tester are: sensor and electronic sensor data conversion and measurement data

processing unit.

The metal shaft forming a part of the hardness tester has a diamond pyramid fixed on its and. The shaft is oscillating

with its own resonance frequency. Load created by the user’s hand enables the diamond pyramid to penetrate the

material and to change the shaft’s resonance frequency. Variation of shaft’s own resonance frequency is proportional

to shaft-into-material penetration depth. Since shaft-into-material penetration depth is the hardness factor one can see

dependence between F (variation of shaft’s resonance frequency) and H (material hardness): H = f (F)

The hardness tester electronic unit receives frequency signal from the sensor, converts it into hardness units,

withdraws measurement results to the display and performs statistical processing and other functions of particular

hardness tester.

1.3Hardness Tester Functions

Execution of checking:

-With main scales: Rockwell (HRC), Brinell (HB) and Vickers (HV) to measure hardness of carbon structural steels;

-With reference scales: Rockwell (HRA), Rockwell (HRB), and Shore (HSD) to perform carbon structural steels

hardness check;

-With reference scale: yield strength (MPa) of perlitic carbon structural steels;

-With the use of additional calibrations for hardness tester scales: cases where mechanical-and-physical properties of

material under check differ from carbon structural steel properties (high-alloy steels, process-specific cast irons, non-

ferrous metals and alloys etc.);

-With additional scales put into service (preset) by the user or by the manufacturer on user’s request enabling the user

to perform check of required characteristics of articles under check provided that primary signal of hardness tester

sensor and required characteristic are interrelated.

Calibration of the main scales in the event of additional error arising from long-lasting operation.

The hardness tester has and intense colored display and a shock-proof casing to provide dust and moisture

protection.

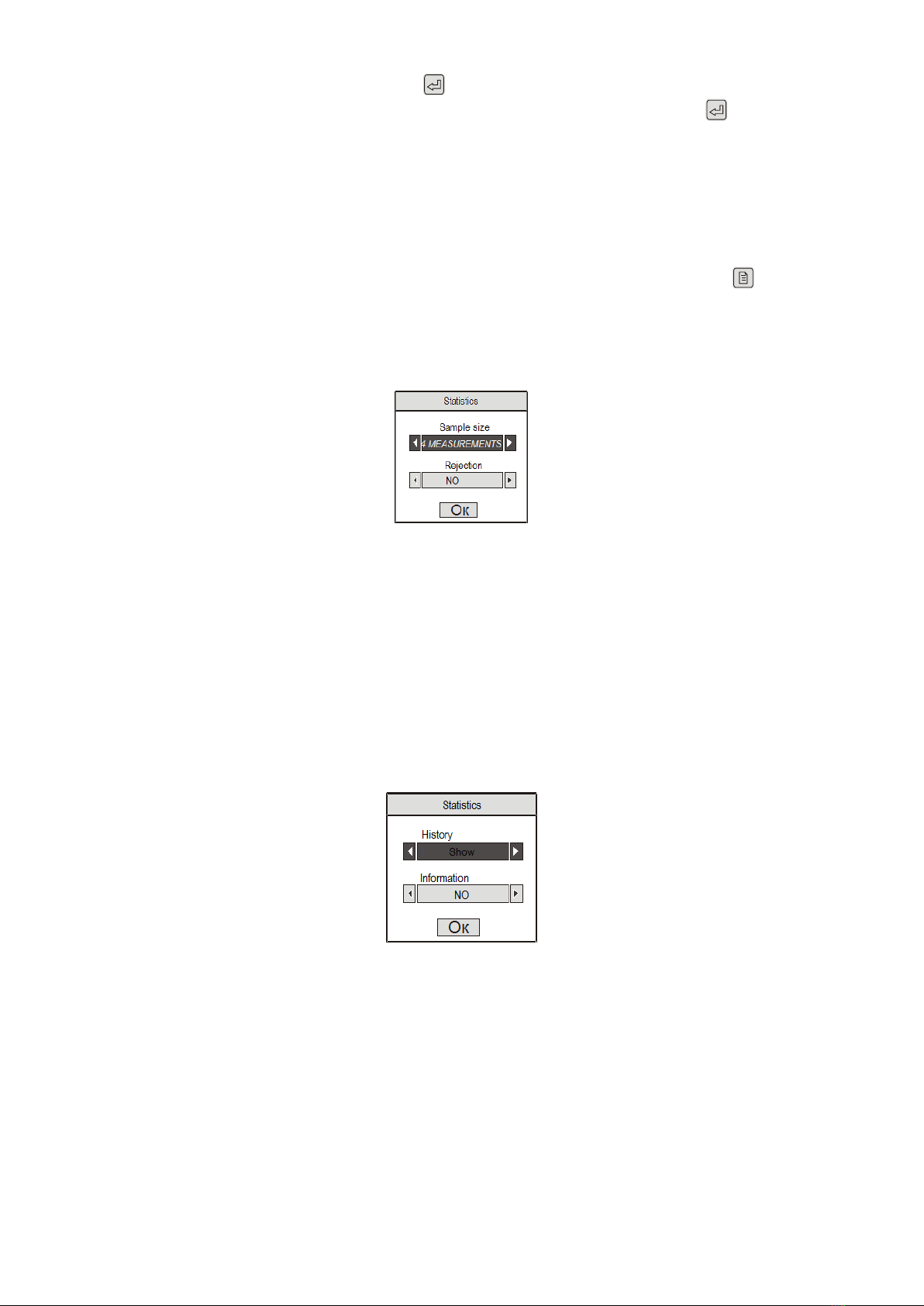

The hardness tester enables the user to perform on-line calculation of the average value of measurement series

results, inter alia, with rejection of the results of incorrectly performed measurements by user-selected algorithm.

The hardness tester enables the user to perform on-line additional statistical processing of measurement series

results, namely, retrieval of minimum, maximum values, calculation of average value and calculation of mean square

deviation from the average value.

The hardness tester enables the user to perform on-line displaying of additional information, namely, results of the

preceding measurement series.

The hardness tester enables the user to organize data storage in the form of individualized blocks of measurement

results, to store them with power off and to transfer the data to the computer.

The hardness tester enables the user to perform various types of stored measurement results analyses, to plot

various types of charts directly on display.

The hardness tester enables the user to select information additionally displayed in the course of measurements.

The hardness tester enables the user to set up checking range and to set up measurement range overrun alarm.