Boart Longyear S250 Quick start guide

S250 ROCKDRILL

PARTS & SERVICE MANUAL

S250 ROCKDRILL | PARTS & SERVICE MANUAL January, 2021

1

Certificate of Conformance

Each drill is supplied with a certificate of conformance, signed by

the assembly mechanic. It lists the drill’s actual test results at

the time of assembly. The certificate also describes the start-up

and lubrication procedures, and provides a brief health and

safety notice.

Important Safety Information

DO NOT START or OPERATE THE MACHINE until you have

READ this manual and UNDERSTAND the contents.

Non-authorised personnel MUST NOT under any circumstances

attempt to operate or repair the machine. This is a violation of

warranty.

Safety precautions listed in the manual are intended to alert the

operator and mechanics to physical dangers inherent in various

phases of operating and maintaining drilling equipment of this

kind.

Safe work procedures must always be the primary consideration

of all personnel when operating or maintaining the drill rig for

intended applications. Do not use in awkward or un-intended

applications. The Safety Precautions listed herein are not

intended to be exhaustive.

Operation of hand-held vibratory equipment should be restricted

to short intervals. For extended drilling applications, drill-rig-

mounted rockdrills are recommended.

HAZARD SIGNAL WORDS AND WARNINGS:

Hazard signal words are used throughout this manual. They

appear in the narrow left-hand column of several pages, and

with their additional text description, are intended to alert the

reader to the existence and relative degree of the hazard.

The signs DANGER, WARNING, CAUTION, and NOTICE are

defined as follows:

Indicates an imminently hazardous situation,

which if not avoided, will result in serious

injury.

The safety alert symbol is used to warn of

potential personal injury hazards.

S250 ROCKDRILL | PARTS & SERVICE MANUAL January, 2021

2

Indicates a potentially hazardous situation,

which if not avoided, could result in serious

injury.

Indicates a potentially hazardous situation,

which if not avoided, may result in minor or

moderate injury.

Is used to make people aware of situations, and

gives hints for operation and maintenance,

which are important, but not hazard related. It

generally indicates an Operational Aid.

•The purchaser must provide proper training to ensure the

safety of all operators. Failure to provide training may result

in serious injury or death.

•Use only qualified service technicians. Failure to do so could

cause severe damage to the machine or the operator and

will void your warranty.

•Operating this piece of equipment without proper Personal

Protective Equipment could result in personal injury. Always

wear Personal Protective Equipment –i.e. hard hat,

industrial safety glasses, hearing protection, steel-toed

boots, and gloves. Heavy-use cut and impact, vibration

resistant gloves are recommended when working on or

operating the rockdrill.

•Operating this piece of equipment without proper hearing

protection may result in permanent hearing loss (dependent

on duration of exposure). For best protection from noise,

use both ear plugs and earmuffs simultaneously. A proper

hearing conservation program is the only effective means of

avoiding hearing damage when operating drills with

percussive power greater than 1 kW.

•Drilling can result in flying particles that may cause eye

injuries (always wear industrial safety glasses).

•ISOLATE all energy sources before servicing equipment.

•Apply safe lifting procedures and two-person lifts when

manually handling the rockdrill.

•Ensure that the drill, accessories, and all actions always

comply with applicable site and local health and safety

regulations.

S250 ROCKDRILL | PARTS & SERVICE MANUAL January, 2021

3

•Never climb on top of the machine.

•Keep clear of rotating drill steel. Never wear any loose

clothing that could become entangled with the machine.

•Be aware that sliding and tilting parts can cause pinch and

crush points.

•Do not operate this piece of equipment while under the

influence of drugs, alcohol, or medication.

•Always keep your work area clean. Avoid dangerous

working environments.

•Be aware of the operating zones and recommended areas

for safe operation. Keep visitors a safe distance away from

the work area.

•Prepare proper tools and equipment. Always use the correct

tool for the job. Improper or homemade tools can cause

injury or machine damage and will void your warranty.

•Use only Boart Longyear replacement parts. Failure to do

so could cause severe damage to the machine or the

operator and will void your warranty.

•Do not change or alter the drill, its components, optional

equipment, or accessories without prior approval from Boart

Longyear. Unauthorized alterations will void the warranty,

render the equipment unsafe, or result in decreased

performance.

•Prolonged hand contact with vibrating machines may cause

Hand Arm Vibration Syndrome (HAVS or “white knuckle”

disease). Anti-Vibration gloves are recommended.

Dependent on vibration level and duration of exposure.

HAVS may cause:

1. Painful fingers, triggered by cold or wet conditions

2. Loss of sense of touch and temperature

3. Numbness and tingling

4. Loss of grip strength

5. Loss of manual dexterity

•The purchaser must ensure safe application of this

equipment for all users, based on total daily exposure to a

vibration magnitude of 20-25 m/s2. This includes but is not

limited to:

1. Limited daily operating time for each operator of this

equipment, based on the vibration magnitude above

S250 ROCKDRILL | PARTS & SERVICE MANUAL January, 2021

4

and all relevant regional regulations and guidelines

for vibratory equipment.

2. Regular or daily health assessments of each operator

including challenging for HAVS symptoms.

Affirmative responses to any of the following

questions may indicate a risk and requires

eliminating exposure and immediate medical referral:

i. Have your fingers gone white on exposure to

cold?

ii. Have you had any tingling or numbness in

your fingers after using vibrating equipment?

iii. Are you experiencing any problems with

muscles or joints in your hand or arms?

iv. Do you have any difficulty picking up small

objects such as screws or nails?

Operating a rockdrill without lubricant or with incorrect lubricant

can cause EXTENSIVE DAMAGE to the working parts of this

machine. NO CLAIM AGAINST PRODUCT WARRANTY will be

considered by the manufacturer if these procedures have not

been followed. NO CLAIM AGAINST PRODUCT WARRANTY

will be considered by the manufacturer if Boart Longyear

replacement parts are not used in repair. All rockdrill repairs

should be performed by properly trained and equipped service

technicians. Failure to adhere to these requirements will void

your warranty.

S250 ROCKDRILL | PARTS & SERVICE MANUAL January, 2021

5

WARNING SIGNS AND SAFETY LABELS:

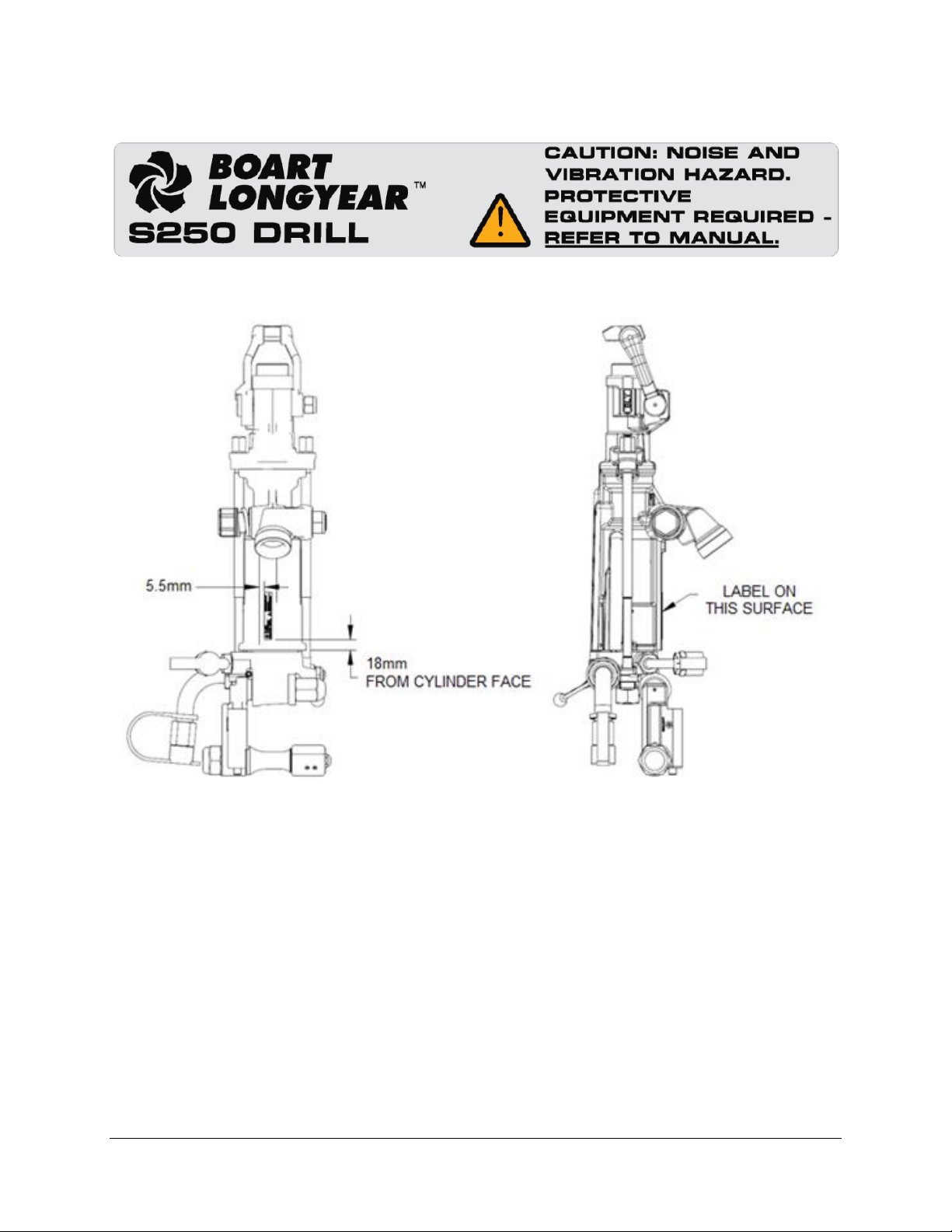

Figure 1. Caution Label

Figure 2. S250 Standard Caution Label Location

S250 ROCKDRILL | PARTS & SERVICE MANUAL January, 2021

6

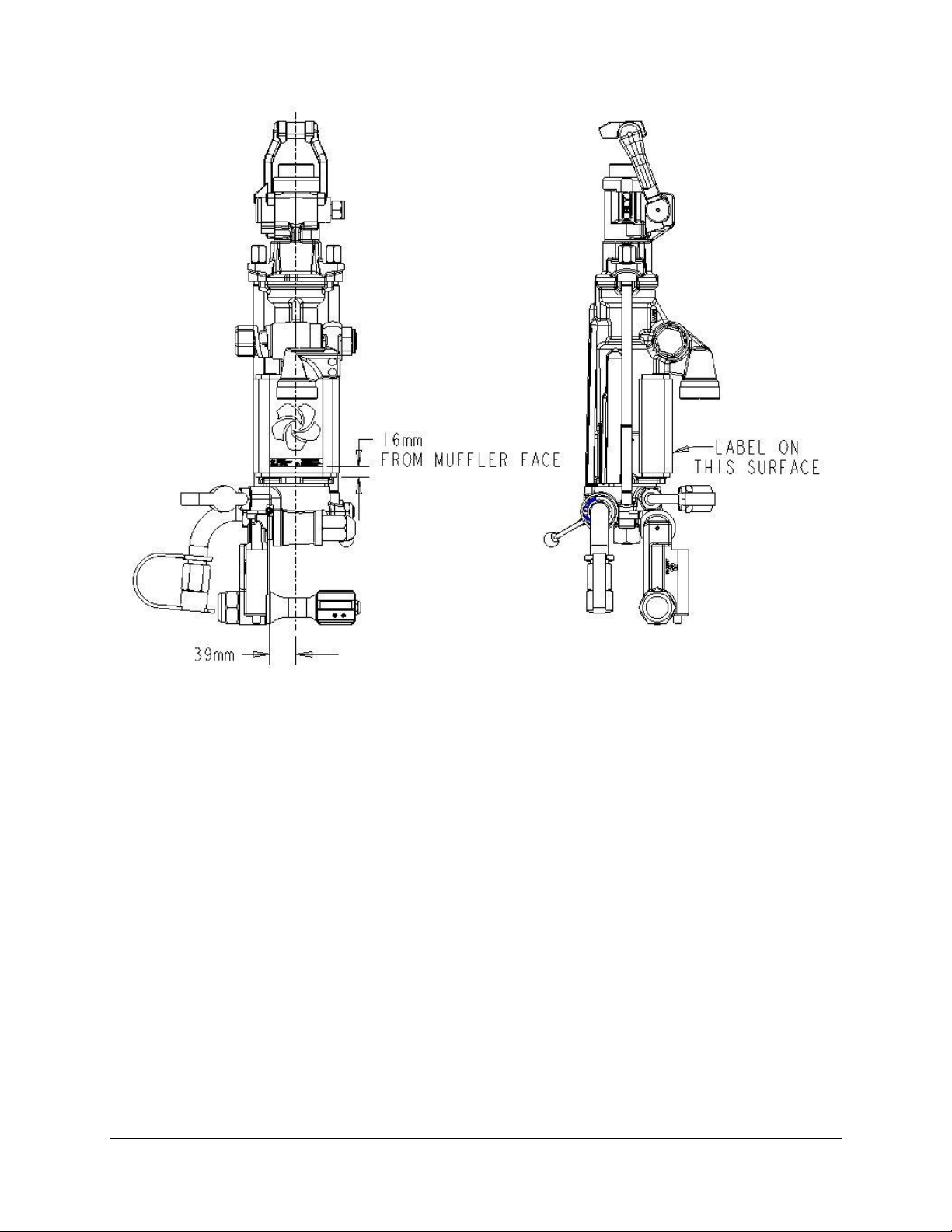

Figure 3. S250 Muffled Caution Label Location

S250 ROCKDRILL | PARTS & SERVICE MANUAL January, 2021

7

TABLE OF CONTENTS

Chapter 1: Introduction and General Information....................................................................... 9

1.1 Introduction.............................................................................................................. 9

1.2 Standard Warranty Policy .......................................................................................10

1.3 Ordering Parts.........................................................................................................12

1.4 Returning Parts.......................................................................................................12

1.5 General Description ................................................................................................13

1.6 Features..................................................................................................................13

Chapter 2: Maintenance Procedures........................................................................................14

2.1 Rockdrill Repair Shop .............................................................................................14

2.1.1 Recommended Workshop Set-Up....................................................14

2.1.2 Recommended Tools and Equipment..............................................14

2.2 S250 Tool Kit..........................................................................................................15

2.3 General Maintenance Overview..............................................................................17

Chapter 3: S250 Jackleg/Sinker Drill Maintenance..................................................................18

3.1 Disassembly Procedures ........................................................................................18

3.1.1 Clevis Body......................................................................................18

3.1.2 Control Handle.................................................................................20

3.1.3 Water Valve & Water Tube...............................................................25

3.1.4 Water Valve.....................................................................................26

3.1.5 Water Inlet .......................................................................................28

3.1.6 Air Inlet ............................................................................................29

3.1.7 Throttle Valve Assembly ..................................................................30

3.1.8 Steel Retainer..................................................................................31

3.1.9 Side Rods........................................................................................33

3.1.10 Ratchet Ring & Rifle Bar..................................................................35

3.1.11 Piston...............................................................................................36

3.1.12 Valve Box.........................................................................................38

3.1.13 Cylinder Lug Bushing.......................................................................39

3.1.14 Front Cylinder Assembly..................................................................41

3.1.15 Chuck Insert.....................................................................................43

3.1.16 Rifle Nut...........................................................................................44

3.1.17 Chuck Nut........................................................................................45

3.2 Assembly Procedures.............................................................................................47

3.2.1 Clevis Body......................................................................................47

S250 ROCKDRILL | PARTS & SERVICE MANUAL January, 2021

8

3.2.2 Control Handle.................................................................................48

3.2.3 Water Control & Water Tube............................................................50

3.2.4 Water Inlet .......................................................................................50

3.2.5 Throttle Valve Assembly ..................................................................51

3.2.6 Steel Retainer..................................................................................52

3.2.7 Side Rods & Fronthead....................................................................54

3.2.8 Ratchet Ring & Rifle Bar..................................................................55

3.2.9 Piston...............................................................................................57

3.2.10 Valve Box.........................................................................................57

Chapter 4: S250 Stoper Drill Maintenance...............................................................................58

4.1 Disassembly Procedures ........................................................................................58

4.1.1 Drill ..................................................................................................58

4.1.2 Stoper Air Leg..................................................................................63

4.2 Assembly Procedures.............................................................................................66

4.2.1 Drill and Stoper Air Leg....................................................................66

Chapter 5: Critical Part Inspection Criteria ...............................................................................71

5.1 Cylinder..................................................................................................................71

5.2 Piston.....................................................................................................................71

5.3 Valve Box...............................................................................................................71

5.4 Rifle Nut.................................................................................................................71

5.5 Chuck Nut..............................................................................................................71

5.6 Rifle Bar.................................................................................................................71

5.7 Chuck Insert...........................................................................................................71

Chapter 6: Testing Procedures ................................................................................................72

6.1 Break-in Period......................................................................................................72

6.2 Start-Up and Lubrication........................................................................................72

6.3 Jackleg/Stoper/Sinker Testing................................................................................73

6.4 Water Testing.........................................................................................................74

Chapter 7: Troubleshooting Guide ...........................................................................................75

S250 ROCKDRILL | PARTS & SERVICE MANUAL January, 2021

9

Chapter 1:

Introduction and General Information

1.1 Introduction

The purpose of this manual is to furnish the Service Technician

with detailed information to achieve the maximum operating

performance of the drill. A Wall Chart with a comprehensive

parts list and views to aid in ordering parts is available at

www.boartlongyear.com.

Boart Longyear is backed by over 125 years of experience in the

design, manufacture, and operation of Percussive Drilling

equipment. Many of the accepted practices in use today were

pioneered by Boart Longyear.

To obtain the utmost in performance and life of the equipment, it

should be given regular care and operated in accordance with

the instructions.

Ensure a quality rockdrill lubricant is used,

preferably mineral-based or Pneuma-ToolTM, and

that consumption amounts are sufficient.

Inspect and replace worn front end and chuck parts

promptly.

Ensure the drill is being operated correctly to avoid

steel and drill rod misalignment.

Check conditions of hoses and connections for fit

and keep the bolts on the drill tight.

Read the manual carefully before attempting to

operate this equipment and keep this book handy

at all times for reference when any questions arise.

This manual is a general description of the operation and

maintenance requirements for all S250 rockdrills. Pictures,

descriptions, and technical data may not match the drill in every

aspect.

The purchaser must ensure safe application of this equipment

for all operators. This manual is only a general guide to

Ensure proper safety apparel is worn when

servicing the equipment

S250 ROCKDRILL | PARTS & SERVICE MANUAL January, 2021

10

essential operating and maintenance procedures, safety

precautions, etc. The procedures described in this manual do

not relieve the purchaser and all operators of their responsibility

to exercise caution and work safely. It is essential to comply

with all safe working procedures and instructions relevant to the

drill site at all times.

1.2 Standard Warranty Policy

A. Consumables

Boart Longyear warrants for a period of one (1) year after the

date of shipment of the consumable products manufactured by

it, or the performance of related services, under the Contract,

that such consumable products are free from defects in

materials and workmanship, and such services are performed in

a professional and workmanlike manner; provided, however,

with respect to consumable products purchased through an

authorized Boart Longyear distributor, the warranty period shall

commence on the date of purchase by the end-user.

B. Capital Equipment

Boart Longyear warrants that its capital equipment is free from

defects in materials and workmanship for a period equal to the

lesser of: (i) one (1) year after the date of shipment, or (ii) the

initial 1,000 operating hours. Boart Longyear warrants for a

period of six (6) months after the performance of related

services that such services are performed in a professional and

workmanlike manner.

C. General Terms

Boart Longyear further warrants that, to the extent applicable, as

of the date of shipment or performance, all goods manufactured

by it and services performed shall conform to the written

specifications agreed between the parties. THIS IS BOART

LONGYEAR’S ONLY WARRANTY. BOART LONGYEAR

MAKES NO OTHER WARRANTY, INCLUDING WITHOUT

LIMITATION, ANY WARRANTY OF MERCHANTABILITY OR

FITNESS FOR A PARTICULAR PURPOSE. As a condition to

Boart Longyear’s warranty obligations, the Purchaser must:

a. Contact Boart Longyear and request authorization to

return any goods claimed to be defective promptly upon

the Purchaser’s discovery of the alleged defect,

b. Upon receipt of an approved authorization code from

Boart Longyear, return any goods claimed to be defective

under the foregoing warranty, at the Purchaser’s expense,

to the facility designated by Boart Longyear, and

S250 ROCKDRILL | PARTS & SERVICE MANUAL January, 2021

11

c. With respect to consumable products purchased through

an authorized Boart Longyear distributor, the party making

the warranty claim must also deliver to Boart Longyear

reasonable evidence of the date of purchase. Boart

Longyear shall perform its examination of the goods so

returned by the Purchaser and shall report the results of its

examination to the Purchaser within thirty (30) days,

following its receipt of such goods from the Purchaser, or,

if longer time is required to complete such examination,

within such time as would be required through the exercise

of reasonable diligence. As a further condition to Boart

Longyear’s obligations hereunder for breach of warranty,

the Purchaser shall offer its reasonable cooperation, and

assist Boart Longyear in the course of Boart Longyear’s

review of any warranty claim. If requested by the

Purchaser, Boart Longyear will promptly repair or replace,

at Boart Longyear’s expense, goods that are confirmed to

be non-conforming as a result of Boart Longyear’s

examination and according to Boart Longyear’s warranty

as set forth herein. All removal and installation of goods

shall be at the Purchaser’s expense; provided, however,

Boart Longyear will reimburse the Customer for an amount

equal to the reasonable expenses incurred by the

Customer and attributable to the removal and shipment of

any defective goods. Boart Longyear reserves the right to

reimburse the Purchaser for an amount equal to the

purchase price of any defective goods in lieu of providing

repaired or replacement goods. Anything contained herein

to the contrary notwithstanding, in no event shall Boart

Longyear be liable for breach of warranty or otherwise in

any manner whatsoever for:

(i) normal wear and tear;

(ii) corrosion, abrasion or erosion;

(iii) any goods, components, parts, software or

services which, following delivery or performance

by Boart Longyear, has been subjected to accident,

abuse, misapplication, modification, improper

repair, alteration, improper installation or

maintenance, neglect, or excessive operating

conditions;

(iv) defects resulting from the Purchaser’s

specifications or designs or those of its contractors

or subcontractors other than Boart Longyear;

(v) defects associated with consumable parts or

materials, the lifetime of which is shorter than the

warranty period set forth in this Section;

S250 ROCKDRILL | PARTS & SERVICE MANUAL January, 2021

12

(vi) defects associated with Purchaser’s

specifications or designs or those of its contractors

or subcontractors other than Boart Longyear;

(vii) defects resulting from the manufacture,

distribution, promotion, or sale of Purchaser’s own

products; or

(viii) accessories of any kind used by the Purchaser

which are not manufactured by or approved by

Boart Longyear;

(ix) any indirect, incidental, special, consequential,

punitive, or similar damages, or any actual or

alleged lost profits, loss of data or business

interruption losses.

D. Sourced Goods

If the defective parts or components are not manufactured by

Boart Longyear, the guarantee of the manufacturer of those

defective parts or components is accepted by the Purchaser and

is the only guarantee given to the Purchaser in respect of the

defective parts or components. Boart Longyear agrees to

assign to the Purchaser, on request made by the Purchaser, the

benefit of any warranty or entitlement to the defective parts or

components that the manufacturer has granted to Boart

Longyear under any contract or by implication or operation of

the law to the extent that the benefit of any warranty or

entitlement is assignable.

Boart Longyear Global Headquarters,

2455 South 3600 West

Salt Lake City, Utah 84119,

United States of America,

www.boartlongyear.com

Tel: +1 801-972-6430

Fax: +1 801-977-3374

1.3 Ordering Parts

Please contact your local authorized spare parts dealer or

customer service representative. A schematic of parts can be

found on the S250 Rockdrill Wall Chart, available for download

at www.boartlongyear.com.

1.4 Returning Parts

If you desire to return parts, whether for repairs,

replacement, or warranty, please contact our order desk with

S250 ROCKDRILL | PARTS & SERVICE MANUAL January, 2021

13

the following information: quantity, part numbers,

model and serial number of the product, as well as

the reason for requesting return.

Boart Longyear Inc.

P.O. Box 330, 1111 Main Street West

North Bay, Ontario

Canada P1B 8H6

Phone: (705) 474-2800

Fax: (705) 474-2373

DO NOT ship parts until authorized and shipping

instructions are received.

All parts returned must be shipped prepaid.

1.5 General Description

The S250 hand-held pneumatic rockdrill is available in various

configurations, providing maximum utility for specific customer

needs. The S250 is available in the standard unmuffled and

optional muffled version to reduce operator fatigue.

1.6 Features

PREMIUM MATERIALS

The S250 uses premium materials, machined to exacting

specifications to deliver high performance and exceptional

durability.

PROVEN TECHNOLOGY

Boart Longyear’s S250 rockdrill is based on well- established,

market-leading design.

UTILITY

The S250 is available in three primary variations including

Jackleg, Stoper and Sinker, providing maximum utility for the

specific customer needs. Both muffled and standard versions

are available.

SERVICES AND TRAINING

Boart Longyear offers on-site services training, and complete

rebuild and overhaul service to ensure optimal drill performance

and extended life.

S250 ROCKDRILL | PARTS & SERVICE MANUAL January, 2021

14

Chapter 2:

Maintenance Procedures

2.1Rockdrill Repair Shop

A clean workshop area equipped with all the usual fitters’ tools,

work benches, component cleaning tanks, and a hydraulic press

is required prior to beginning any work. A steam cleaner outside

the workshop is also required.

2.1.1 Recommended Workshop Set-Up

•Work Bench - 91,4 cm x 213,4 cm (36” x 84”) c/w air

bulkhead (optional)

•15,2 cm (6”) Vice (not swivel) mounted on the corner of the

bench

•10,2 cm to 20,3 cm (4” to 8”) Chain Vice mounted on

opposite corner of bench

•Steel block for press - two 7,6 cm x 7,6 cm x 45,7 cm (3” x 3”

x 18”) and two 5,1 cm x 7,6 cm x 45,7 cm (2” x 3” x 18”) with

slider stop bars

•Cleaning Tank

•Bench Grinder (optional)

•Belt Grinder c/w piston support

•Torch Set c/w tanks

•Welder M/C (optional)

•Venmar - eight drawers

•Pin Skids

•Electric Rewind Extension Cord

•Lighting over work bench

2.1.2 Recommended Tools and Equipment

•S250 Repair Kit (refer to section 2.1)

•Torque Wrench with 12,7 mm (1/2”) drive (up to 250 ft-lbs)

•Impact Wrench 12,7 mm (1/2”) drive

•Pipe Wrench 61 cm (24”)

•Pipe Wrench 30,5 cm (12”)

•Combination Wrench 38 mm (1-1/2”)

•Drive Socket 38 mm x 12,7 mm (1-1/2” x 1/2”)

•Drive Socket 36,5 mm x 12,7 mm (1-7/16” x 1/2”)

•Pick Set

•Mechanic’s Hammer

•12,7 mm x 304,8 mm (1/2” x 12”) Plate c/w chuck nut

removal tool, rifle nut removal tool

•Gene Clamp c/w swing and dump (optional S-36 repairs)

•Guide Shell 61 cm (24”) (optional S-36 repairs)

S250 ROCKDRILL | PARTS & SERVICE MANUAL January, 2021

15

•Compressor capable of 175 cfm @ 100 psi

•35-ton press (note: blocks for the press should be made of

quality steel to withstand the forces of the press)

•Pin skids to store the rockdrills in a staging area

•Storage cabinets to store new replacement components for

the drills

•Repair Tags and Report Sheets

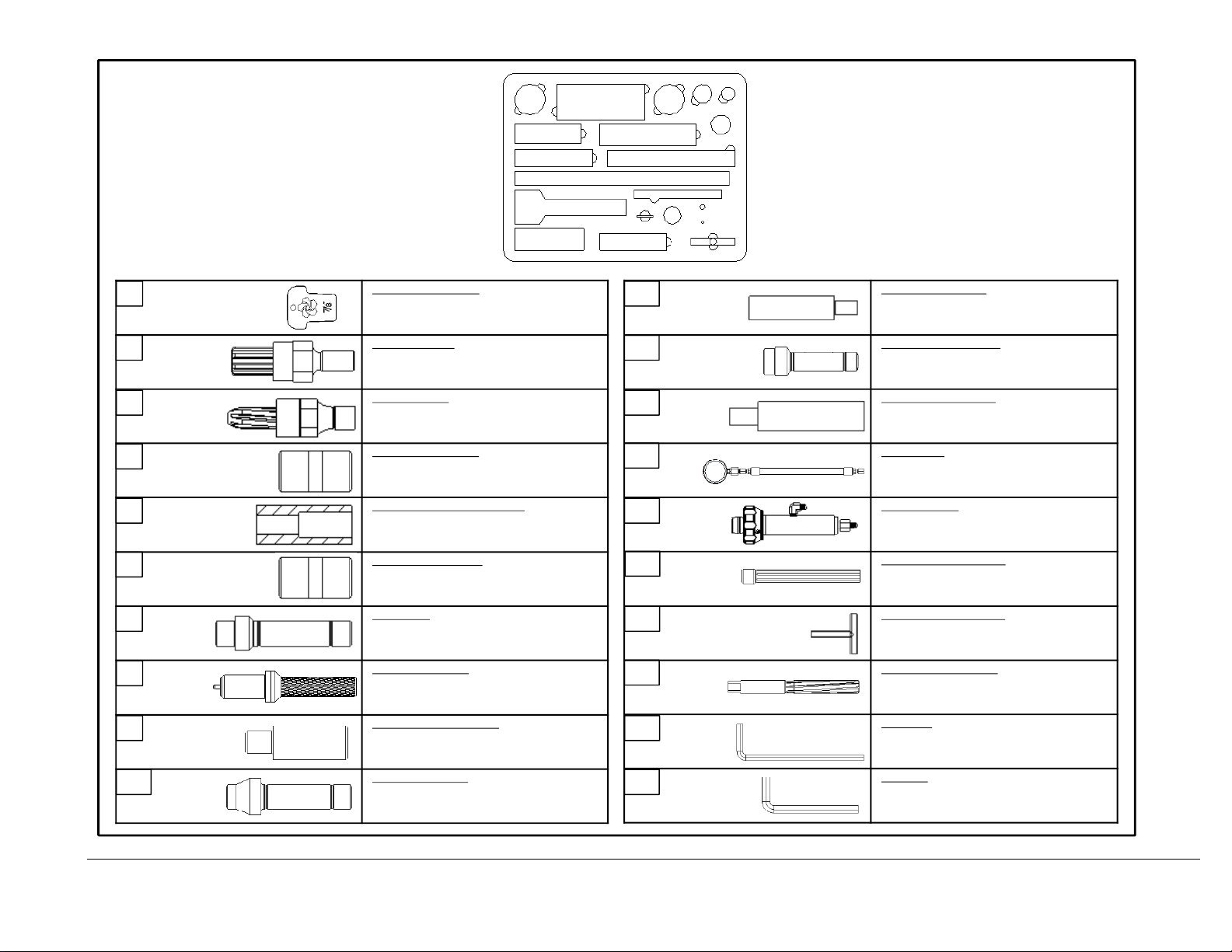

2.2 S250 Tool Kit

The S250 Tool Kit contains the full line of tools required to

service all S250 rockdrill configurations. Using Boart Longyear-

supplied equipment is essential in order to limit the potential to

damage drill parts while improving service shop efficiency.

Please see the following page for parts list and descriptions.

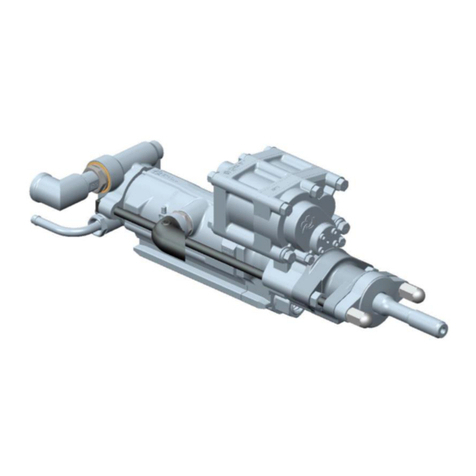

Figure 3: S250 Tool Kit –Part No. 5607146

S250 ROCKDRILL | PARTS & SERVICE MANUAL January, 2021

16

S250 Rockdrill Repair Kit

CHUCK INSERT WEAR GAUGE

Place in chuck insertacross flats.

If top of insert is more than halfway up gauge,

insert should be changed.

CHUCK NUT REMOVER

Insert into Chuck Nut.

Remove with 1/2-inchsocket wrench.

RIFLE NUT REMOVER

Insert into Rifle Nut.

Remove with 1/2-inchsocket wrench.

STOPER CYLINDER MANDREL

Removes small dents from stoper leg

CHUCK INSERT REMOVAL SUPPORT TOOL

Used to remove collaredand collarless chuck insert.

Place chuck in support tool and use 5600114 chuckinsertextractor

with hydraulic press toremove.

JACKLEG CYLINDER MANDREL

Removes small dents from airleg

STOPER PUNCH

Removes stoper handle bushing from cylinder

PISTON EXTRACTOR TOOL

Removes piston and valve chest from cylinder.

Remove front head and chuck, insertpunch into pistonand hammer

out.

VALVE CHEST DISASSEMBLY TOOL

Disassembles valve chest.

Insert punch into top of valve box and hammer out.

LUG BUSHING DRIFT TOOL

Installs cylinder lug bushing on jackleg

CHUCK INSERT PUNCH TOOL

Inserts collared steelchuck insert.

Place chuck insertin chuck insert removalsupport tool5600101,

insert punch in chuck, and press with hydraulic press.

CYLINDER BUSHING EXTRACTOR

Removes brass bushing from inside cylinder and removes bushing

from stoper leg

VALVE CHEST ASSEMBLY TOOL

Used to assemble valve chestand install valve chestin cylinder

AIR HOSE GAUGE

Used to measure airleg pressure.

Attach to airgauge adaptor 5600113.

AIR GAUGE ADAPTOR

Used to measure airleg pressure.

Attach to jackleg clevis body

CHUCK INSERT EXTRACTOR TOOL

Used on collaredsteelchuck.

Place chuck in chuck insert support tool 5600101and press chuck

insert out withhydraulic press.

RETRACT VALVE ASSEMBLY TOOL

Place retractvalve inhandle and gently hammer in with retractvalve

tool

RETRACT VALVE HAND REAMER

Used to remove burrs from retract valve bore

3/16” HEX KEY

3/8” HEX KEY

5600005

5600043

5600044

5600100

5600101

5600102

5600103

5600105

5600106

5600107

5600108

5600110

5600111

5600112

5600113

5600114

5600115

5600116

5600117

5600118

ADDITIONAL TOOLS REQUIRED:

• SOCKETS: 15/16”, 1 1/16”, 1 7/16”, AND 1 1/2”

• 15” CRESCENT WRENCH

•TORQUE WRENCH

• MECHANIC’S HAMMER

1

2

3

456

7

8

9

10

11

12

13

14

15

16

17

18

19

20

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

S250 ROCKDRILL | PARTS & SERVICE MANUAL January, 2021

17

2.3 General Maintenance Overview

The maintenance routine of any rockdrill machine always follows

the same set pattern: external clean, strip down, clean parts,

inspect, replace, rebuild, and test. Sophisticated measuring

equipment used to accurately gauge the wear on components is

often not available. Consequently, wear is gauged by simple,

but effective workshop practices.

The jackleg rockdrill is similar in many respects to the stoper.

The stoper maintenance is referred to in Chapter 4.

NOTE: After the unit is completely disassembled, all

components should be cleaned prior to inspection.

S250 ROCKDRILL | PARTS & SERVICE MANUAL January, 2021

18

Chapter 3:

S250 Jackleg/Sinker Drill Maintenance

3.1 Disassembly Procedures

Before any disassembly procedure, ensure that the air and

water hoses are disconnected from the drill

3.1.1 Clevis Body

1. Place the machine upside down on a work bench with the

steel retainer in the position shown.

2. Using an adjustable wrench, unscrew the spindle nut. If the

nut is tight, compress the clevis body spindle spring by

inserting a screwdriver between the spindle lock washer and

the spindle nut.

S250 ROCKDRILL | PARTS & SERVICE MANUAL January, 2021

19

3. Remove the spindle nut, spring, lock washer, and thrust

washer. Remove the keys from the stem end of the spindle.

4. Strike the end of the spindle with a copper mallet or punch and

withdraw the spindle complete with the clevis body from the

cylinder lug bushing.

Table of contents

Other Boart Longyear Drill manuals