Bock Water heaters ODOT200 Series Service manual

WARNING

Improper installation, adjustment, alteration,

service or maintenance can cause serious injury

or property damage. Refer to this manual. For

assistance or additional information, consult a

qualified installer or service agency.

WARNING

Install in accordance with all local codes. In the

absence of local codes, refer to NFPA 54

CAUTION

The recommended temperature for normal

residential use is 120°F. The dial on the aquastat

does not always reflect the out-coming water

temperature and it could occasionally exceed

120°F. Variation in out-coming temperature could

be based on factors including but not limited to

usage patterns and type of installation. Test water

at the tap nearest to the water heater. See page 37

for measuring the out-coming water temperature.

WARNING

Hotter water increases the risk of scald injury.

Before adjusting the water temperature setting,

read this instruction manual. Temperatures at

which injury occurs vary with the person’s age

and the length of exposure. The slower reaction

time of children, elderly or physically or mentally

challenged persons increases the scalding hazard

to them. It is recommended that lower water

temperatures be used where these exposure hazards

exist. Households with small children or invalids

may require a temperature setting less than 120°F

to prevent accidental contact with hot water.

To produce less than 120°F, use point-of-use

temperature limiting devices.

If higher water temperature is needed in part of

the water system, automatic temperature limiting

devices must be used on all lines to water taps.

WARNING

Water heater blankets may restrict air flow to the

water heater and cause fire, asphyxiation, personal

injury or death.

THIS MANUAL HAS BEEN PREPARED TO

ACQUAINT YOU WITH THE INSTALLATION,

OPERATION, AND MAINTENANCE OF YOUR

WATER HEATER AND TO PROVIDE IMPORTANT

SAFETY INFORMATION.

Read all instructions thoroughly before attempting

installation or operation of your water heater. Keep

these instructions for future reference.

Local plumbing and electrical codes must be

followed in the installation of this water heater.

In the absence of a local code use the UNIFORM

PLUMBING CODE and the NFPA Code. Local codes

may supersede instructions in this installation

manual.

These instructions are a guide for the correct

installation of the water heater. The manufacturer

will not be liable for damages caused by failure to

comply with the installation and operating instruc-

tions outlined on the following pages.

FAILURE TO FOLLOW THESE INSTRUCTIONS OR

ALL APPLICABLE BUILDING CODES

AND REGULATIONS VOIDS THE WARRANTY ON

THIS WATER HEATER.

Warranty, Registration Card and Parts List are included.

Owner: Please remember to return the Registration Card!

To the Consumer:

Please read these instructions and keep for future

reference.

To the Installer:

Please read these instructions and deliver to

consumer when installation is complete.

Rev3 2/2021

23447

— Do not store or use gasoline or other flammable

vapors and liquids in the vicintiy of this or any

other appliance.

—WHAT TO DO IFYOU SMELL GAS

- Do not try to light any appliance.

- Do not touch any electrical switch; do not use any

phone in your building.

WARNING: If the information in these instructions is not followed exactly, a

fire or explosion may result causing property damage, personal injury or death.

Installation and Operation Instructions Manual

Models: ODOT200, ODOT250, ODOT299, ODOT300*2, ODOT400*2, ODOT500*2

Outdoor Commercial Gas Water Heater

— Do not store or use gasoline or other

flammable vapors and liquids in the

vicintiy of this or any other appliance.

— WHAT TO DO IF YOU SMELL GAS

• Do not try to light any appliance.

• Do not touch any electrical switch; do

not use any phone in your building.

• Immediately call your gas supplier

from a neighbor’s phone. Follow the

gas supplier’s instructions.

• If you cannot reach your gas supplier,

call the fire department.

— Installation and service must be

perfomred by a qualified installer,

service agency or the gas supplier.

IMPORTANT SAFETY INSTRUCTIONS

The proper installation, use and servicing of this water heater is very

important to your safety and the safety of others.

This is the safety alert symbol. Statements following this symbol contain

important safety information. Obey all safety messages that follow this

symbol to avoid possible injury or death.

Important safety information will be preceded by the safety alert symbol

and the words DANGER, WARNING, CAUTION, OR NOTICE.

DANGER indicates an imminently hazardous situation which, if not

avoided, will result in serious injury or death.

WARNING indicates a potentially hazardous situation which, if not

avoided, could result in serious injury or death.

CAUTION indicates a hazardous situation which, if not avoided, could

result in minor or moderate injury.

NOTICE calls attention to observe a specified procedure.

SAVE THESE INSTRUCTIONS

DANGER

Water heaters utilizing Liquefied Petroleum gas (LP) are different from

natural gas models. A natural gas heater will not function safely on LP gas

and vice versa. To avoid possible equipment damage, personal injury or

fire: DO NOT connect this water heater to a fuel type not in accordance

with the rating label. These units are only certified for a single fuel type.

DANGER

Failure to properly install the vent and combustion air intake system as

outlined in this manual can result in unsafe operation of the water heater.

To avoid the risk of fire, explosion, or asphyxiation from carbon monoxide,

never operate this water heater unless it is properly vented and has

adequate air supply for combustion and dilution of flue gas. Be sure to

inspect the system for proper installation at initial start-up; and at least

annually thereafter. See the Maintenance section for more information.

Page 2

TABLE OF CONTENTS

Section I: Specifications .............................................4

Section II: General Information ........................................5

Section III: Pre-Installation ............................................9

Section IV: Installation ..............................................13

Section V: Operation ...............................................23

Section VI: Maintenance ............................................27

Section VII: Troubleshooting .........................................31

Section VIII: Parts List ...............................................36

Section IX: Warranty ...............................................40

Page 3

Model

Rated Storage Capacity,

GAL (L)

Rated Maximum Input,

Btu/hr (kW)

Thermal Efficiency (%)

@ Max. Input

Recovery @ 100°F

rise, GAL/HR (L/HR)

A

C

E

G

HOT (NPT)

Rated Minimum Input,

Btu/hr (kW)

Thermal Efficiency (%) @

Min. Input

1st Hr. Delivery @

100°F rise, GAL (L)

B

D

F

COLD (NPT)

Gas (NPT)

Table 1: Dimensions

Page 4

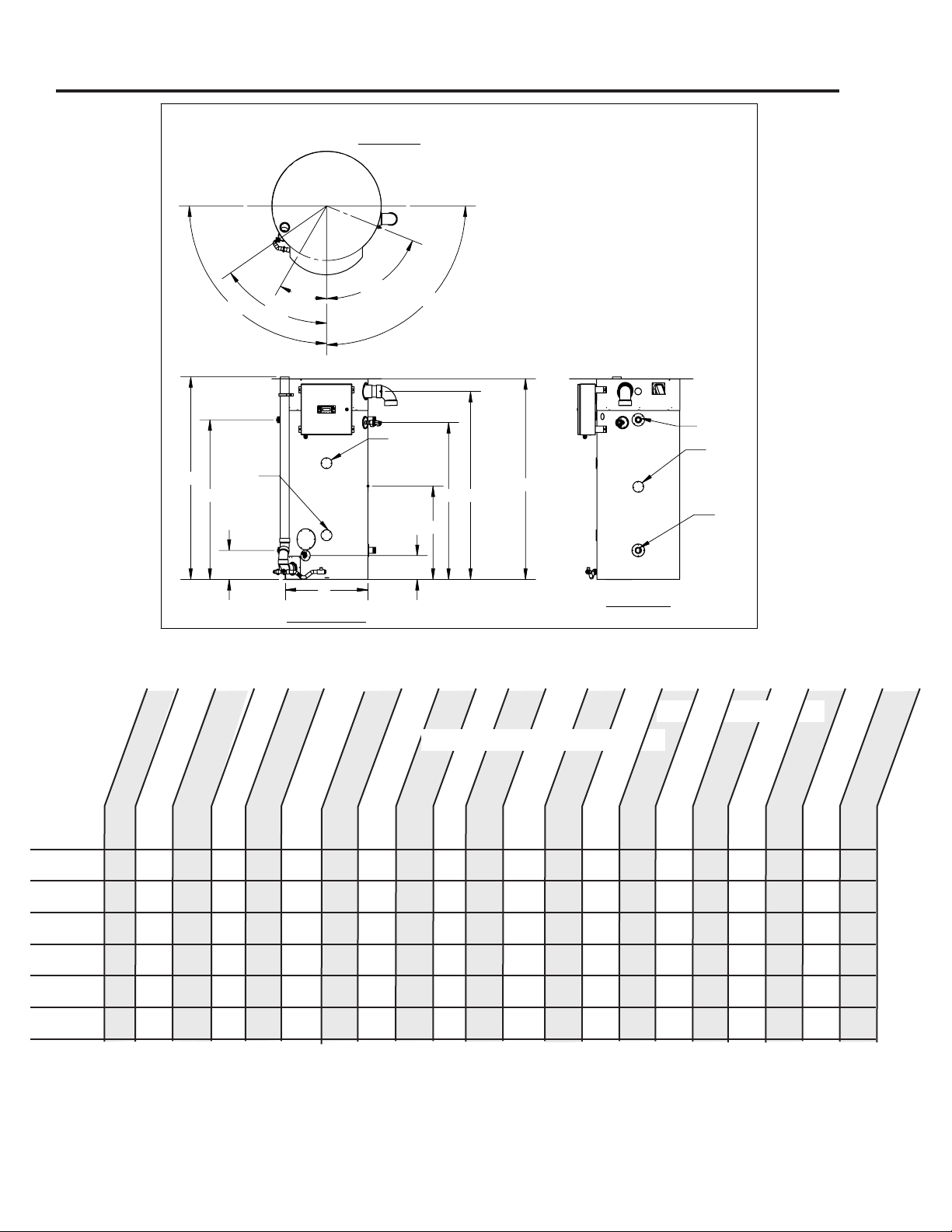

SECTION I: SPECIFICATIONS

B

H

E

F

A

G

D

I

C

RETURN

COLD

COMBUSTION INTAKE

GAS CONN.

TI Anode

Cover

ASME

Plate

COLD

RETURN

HOT

30° 68°

90° 90°

55°

TOP VIEW

HOT/COLD HOT/COLD

GAS CONN.

DRAIN

T&P VALVE

EXHAUST

DRAIN

FRONT VIEW

SIDE VIEW

Model

Dimensions in Inches (cm)

Cold

NPT

Hot

NPT

Recirc.

Return

NPT

Gas

NPT

Air

Intake

PVC

Exhaust

Vent

PVC

Shipping Weight

LBS (kg)

A

B

C

D

E

F

G

H

I

ODOT300*2 -(A)

78.8

(200)

32.5

(82)

62.75

(159)

11.4

(29)

9.4

(24)

61.7

(156)

74.0

(188)

36.3

(92)

79.66

(202)

2" 2" 1"

1-1/2"

4" 4"

1185 (539)

ODOT400*2 -(A)

78.8

(200)

32.5

(82)

62.75

(159)

11.4

(29)

9.4

(24)

61.7

(156)

74.0

(188)

36.3

(92)

79.66

(202)

2" 2" 1"

1-1/2"

4" 4"

1185 (539)

ODOT500*2 -(A)

78.8

(200)

32.5

(82)

62.75

(159)

11.4

(29)

9.4

(24)

61.7

(156)

74.0

(188)

36.3

(92)

79.66

(202)

2" 2" 1"

1-1/2"

4" 4"

1185 (539)

Figure 1: All Models

DIMENSIONS, INCHES (cm)

NOTE: * denotes fuel type, N or LP, and sux “-A” denotes ASME version.

Replace * in Model with fuel type abbreviation. Natural Gas (N) or Propane Gas (LP).

For HIGH ALTITUDE models, the following additional suxes are dened as:

“-H25” = Approved for altitudes greater than 2,000 up to 5,400 FT

For natural gas: �

MINIMUM GAS SUPPLY PRESSURE (at gas control) = 3.5” W.C. (dynamic)

MAXIMUM GAS SUPPLY PRESSURE (at gas control) = 14” W.C. (static or dynamic)

100 199,999 76,000 95 98 228 298 67.25 32.00 51.53 11.43 9.43 50.18 62.75 69.50 N/A 2” 2” NA 1 1,195

(378) (58.6) (22.3) (863) (1,128) (171) (81) (131) (29) (24) (127) (159) (177) (542)

100 250,000 76,000 94 98 282 352 67.25 32.00 51.53 11.43 9.43 50.18 62.75 69.50 N/A 2” 2” N/A 1” 1,195

(378) (73.3) (22.3) (1,067) (1,332) (171) (81) (131) (29) (24) (127) (159) (177) (542)

100 299,999 76,000 93 98 334 404 67.25 32.00 51.53 11.43 9.43 50.18 62.75 69.50 N/A 2” 2” N/A 1” 1,195

(378) (87.9) (22.3) (1,264) (1,529) (171) (81) (131) (29) (24) (127) (159) (177) (542)

125 300,000 80,000 99 99 357 480 78.8 32.5 62.75 11.4 9.4 61.7 74.0 80.75” 36.3” 2” 2” 1” 1-1/2” 1,185

(473) (87.9) (23.4) ( 1,351) (1,817) (200) (82) (159) (29) (24) (156) (188) (205) (92) (539)

125 399,999 80,000 97 99 465 587 78.8 32.5 62.75 11.4 9.4 61.7 74.0 80.75” 36.3” 2” 2” 1” 1-1/2” 1,185

(473) (117.2) (23.4) (1,760) (2,222) (200) (82) (159) (29) (24) (156) (188) (205) (92) (539)

125 500,000 80,000 96 99 576 696 78.8 32.5 62.75 11.4 9.4 61.7 74.0 80.75” 36.3” 2” 2” 1” 1-1/2” 1,185

(473) (146.5) (23.4) ( 2,180) (2,635) (200) (82) (159) (29) (24) (156) (188) (205) (92) (539)

ODOT200*(-A)

ODOT250*(-A)

ODOT299*(-A)

ODOT300*2(-A)

ODOT400*2(-A)

ODOT500*2(-A)

Shipping Weight,

LBS (kg)

For LP gas:

MINIMUM GAS SUPPLY PRESSURE (at gas control) = 8” W.C. (dynamic)

MAXIMUM GAS SUPPLY PRESSURE (at gas control) = 14” W.C. (static or dynamic)

Note: Dynamic pressure is measured while gas is owing and static pressure is measured while gas is

not owing.

All Bock products meet or exceed current ASHRAE standards

These products are design certied by UL (Underwriters Laboratories) and meet ANSI Z21.10.3/CSA 4.3

requirements for operation up to 180°F (82°C) as a Category IV water heater.

Approved as an outdoor automatic storage water heater.

H

I

RECIRC (NPT)

CONNECTION SIZES

Page 5

APPROXIMATE

TEMPERATURE/TIME

RELATIONSHIPS TO

SCALDING

120°F (49°C) More than 5 minutes

125°F (52°C) 1 1⁄2 to 2 minutes

130°F (54°C) About 30 seconds

135°F (57°C) About 10 seconds

140°F (60°C) Less than 5 seconds

145°F (63°C) Less than 3 seconds

150°F (66°C) About 1 1⁄2 seconds

155°F (68°C) About 1 second

Table 2: Scald Temperature/Time Relationships

SECTION II: GENERAL INFORMATION

WHEN YOU RECEIVE YOUR NEW WATER HEATER

Check the new equipment to see if all components are in good condition. If damage is

observed or parts appear to be missing, contact your wholesaler.

WATER TREATMENT/FILTRATION

In areas where poor water conditions are suspected (i.e. lime, iron, and other minerals), it is

essential that the water be tested and appropriate action taken to prevent damage to the

water heater and ensure the quality of the water.

TEMPERATURE CONTROL

The water heater is equipped with a main operating control that manages the temperature

regulating and limiting functionality. For domestic hot water, the proper temperature setpoint

is 120°F. For commercial applications, the maximum approved temperature setpoint is 180°F.

Sensors in the top of the tank measure water temperature. The control constantly compares

the sensor values to the temperature setpoint and controls the burner power (on/off) and

modulation accordingly.

The manual reset, temperature limiting safety function is managed by the main operating

control. In the event that the tank temperature sensor reads 190°F the control will shut off

all gas to the water heater. Manually reset the control to allow the heater to resume normal

operation. Should over heating occur, and the gas supply fails to automatically lockout,

manually turn off the power switch.

The temperature setpoint is factory set at 120°F. If hotter water is required a tempering device

or anti-scald device must be installed at the domestic hot water outlet of the heater or at the

point of use. Table 2 details the approximate relationship of water temperature and time with

regard to scald injury. It is important for the user to understand the necessity of tempering or

anti-scald devices when using hotter water in domestic water heating systems.

CAUTION: Hot water in excess of 120°F can cause scalding!

Bock recommends a tempering valve or anti-scald valve be installed and used according to

the manufacturer’s directions to prevent scalding. Many state and local codes now require

installation of these devices. Point of use temperature may be hotter than the setting on the

water heater thermostat. The tempering valve or anti-scald valve will ensure potable

water temperatures at the desired set point with a higher degree of accuracy.

SECTION II: GENERAL INFORMATION

ANODE RODS

The water heater is supplied with a factory installed powered anode system to prevent corrosion

of internal tank components. Specifically, the type of anode system that is used is an impressed-

current anode system. This system uses a power supply that regulates the protective current output

based on actual conditions inside the tank. The anode rods in the tank are not consumed over time

and, therefore, do not need to be removed and inspected. Refer to the Maintenance section of this

manual for periodic inspection instructions for the powered anode system.

NOTICE TO THE OWNER: The water heater must be connected to the power supply for the

powered anode system to operate. DO NOT DISCONNECT THE WATER HEATER FROM THE

POWER SUPPLY FOR AN EXTENDED PERIOD OF TIME. WITHOUT POWER, THE ANODE SYSTEM

WILL NOT BE CAPABLE OF PROVIDING CORROSION PROTECTION. When the power switch to

the right of the display is OFF and there is a connection to the power supply, the powered

anode system will still function. If the water heater must be disconnected from the power

supply for an extended period, the tank must be drained. Refill the tank prior to reconnect-

ing the water heater to the power supply.

CAUTION

Hydrogen gas is produced in a hot water system served by the heater that has not been

used for a long period of time (2 weeks or more). Hydrogen gas is extremely flammable.

To reduce the risk of injury under these conditions, it is recommended that a hot water

faucet be opened for several minutes before using any electrical appliance connected

to the hot water system. When hydrogen is present, there will probably be an unusual

sound such as air escaping through the pipe as the water begins to flow. There should be

no smoking or open flame near the faucet at the time it is open.

TEMPERATURE AND PRESSURE RELIEF VALVE (T&P)

CAUTION

To reduce the risk of excessive pressures and temperatures in this water heater, install

temperature and pressure protective equipment required by local codes and no less than

a combination temperature and pressure relief valve certified by a nationally recognized

testing laboratory that maintains periodic inspection of production of listed equipment

or materials, as meeting the requirements for Relief Valves and Automatic Gas Shutoff

Devices for Hot Water Supply Systems, ANSI Z21.22. This valve must be marked with a

maximum set pressure not to exceed the marked maximum working pressure of the

water heater. Install the valve in an opening provided and marked for this purpose in the

water heater, and orient it or provide tubing so that any discharge from the valve exits

only within 6 inches above, or at any distance below, the structural floor, and does not

contact any live electrical part. The discharge opening must not be blocked or reduced

in size under any circumstances. No valve is to be added between the relief valve and

tank.

CAUTION

Scalding injury and/or water damage can occur from either the manual lifting of the lever

or the normal operation of the T&P valve if it is not piped to a proper drain. If the valve fails

to flow water or reseat, call your plumber.

The T&P valve is factory installed. A discharge drain tube must be installed (responsibility of the

installer) and shall terminate plain, not threaded, 6 inches above the floor drain. The drain tube material

must be approved for temperatures of 120o F or greater and a pressure of 150 PSI or greater.

Page 6

SECTION II: GENERAL INFORMATION

BACKFLOW PREVENTER (CLOSED SYSTEM)

Some local municipal codes and ordinances require the use of these devices on potable

(domestic) water lines. Where backflow preventers, check valves, or pressure regulating valves

are required, it will be necessary to install a thermal expansion tank (designed for use with

potable water) in order to prevent pressure build up in the water heater and associated piping,

which could cause the T&P valve to discharge. Follow the expansion tank manufacturer’s

recommendations when selecting a tank for your hot water system. The expansion tank pressure

shall equal the water heater system pressure prior to initial warm up.

Periodic relieve valve discharges may be a result of thermal expansion in a closed water supply

system. Contact the water supplier or local plumbing inspector for information about thermal

expansion tanks.

Note: Working pressure of the water heater is 150 PSI. Do not exceed 150 PSI.

CONDENSATION

Condensation of flue gases will occur in the exhaust vent and portions of the heat exchanger

during burner operation. Condensate is considered acidic based on its typical pH range of 3.5

to 3.8 on a scale of 0 to 14 (a pH of 7 is neutral). Some installations may require the use of a

condensate neutralizer kit to reduce the acidity of the condensate prior to it entering the building’s

drainage system. When possible, locate a drain in close proximity to the water heater to minimize

the length of the drain line. The water heater is supplied with a condensate elbow assembly that

must be installed to the water heater before the exhaust vent is connected.

HIGH ALTITUDE

The water heaters covered in this manual are approved for altitudes up to 5,400 feet. For high

altitude applications (i.e. installations at altitudes greater than 2,000 feet), models that are

designated with a suffix “-H25” must be used.

Following installation at high altitudes, verify that O2readings and CO levels in the exhaust

vent are within the specified ranges given in Section VI: Maintenance, “Check the Combustion

System”.

Due to the natural reduction in input rate at higher altitudes, the actual hot water output of

the heater is gradually reduced as altitude is increased. Expect a 2.8% input rate reduction

per 1,000 feet altitude. However, all high altitude models are factory adjusted to maintain the

rated sea-level minimum input at minimum fan speed.

Page 7

Page 8

SECTION II: GENERAL INFORMATION

SEISMIC RESTRAINT

Regions of the United States that are considered earthquake zones require that the water

heater(s) is properly braced to avoid movement or falling during a seismic event. Bock

recommends the Holdrite Quick Strap® QS-120 or equivalent strapping system. The Holdrite

QS-120 is approved by the California Division State Architect and is UPC/IPC/IAPMO listed.

Figure 2 shows the water heater strapped to a (field supplied) support frame. The frame can

be positioned on the front/right/back of the water heater. If the water heater must be located

adjacent to an outside wall, the straps may be installed to the wall if spacers (standoffs) are

located between the wall and the water heater. The standoffs may be field supplied or a kit

may be purchased from Bock Water Heaters, Inc. One kit per water heater is required. Figure

3 shows the seismic strapping secured to an outside wall.

SUPPORT FRAMING

(FIELD SUPPLIED)

UPPER STRAP

LOWER STRAP

LOWER STRAP

UPPER STRAP

STANDOFF

(KIT AVAILABLE

FROM FACTORY)

FIGURE 3: SEISMIC RESTRAINGS TO WALL.

OUTSIDE WALL

NOTE: SECURE STANDOFFS

AND STRAPS TO OUTSIDE

WALL WITH FASTENERS

WHICH ARE APPROPRIATE

FOR WALL MATERIAL.

FIGURE 2: SEISMIC RESTRAINTS

TO SUPPORT FRAME.

BOCK WATER HEATERS, INC.

110 S. DICKINSON ST. MADISON, WI 53703

SCALE:1:32

SIZE

DWG. NO.

A

REV.

MATERIAL

FINISH

DO NOT SCALE DRAWING

DIMENSIONS ARE IN INCHES

TOLERANCES:

FRACTIONAL

ANGULAR: MACH

0.1 BEND

TWO PLACE DECIMAL

0.05

THREE PLACE DECIMAL

0.005

NAME

DATE

DRAWN

CHECKED

ENG APPR.

MFG APPR.

Q.A.

SHEET 2 OF 5

WEIGHT:

COMMENTS:

THE INFORMATION CONTAINED IN THIS

DRAWING IS THE SOLE PROPERTY OF

BOCK WATER HEATERS, INC. ANY

REPRODUCTION IN PART OR AS A WHOLE

WITHOUT THE WRITTEN PERMISSION OF

BOCK WATER HEATERS, INC. IS PROHIBITED.

PROPRIETARY AND CONFIDENTIAL

1/1/1901

-

Drawing Template

X

DrwBy

1/1/1901

Chk

Figure 2: Seismic Restraints to Support Frame

SUPPORT FRAMING

(FIELD SUPPLIED)

UPPER STRAP

LOWER STRAP

LOWER STRAP

UPPER STRAP

STANDOFF

(KIT AVAILABLE

FROM FACTORY)

FIGURE 3: SEISMIC RESTRAINGS TO WALL.

OUTSIDE WALL

NOTE: SECURE STANDOFFS

AND STRAPS TO OUTSIDE

WALL WITH FASTENERS

WHICH ARE APPROPRIATE

FOR WALL MATERIAL.

FIGURE 2: SEISMIC RESTRAINTS

TO SUPPORT FRAME.

BOCK WATER HEATERS, INC.

110 S. DICKINSON ST. MADISON, WI 53703

SCALE:1:32

SIZE

DWG. NO.

A

REV.

MATERIAL

FINISH

DO NOT SCALE DRAWING

DIMENSIONS ARE IN INCHES

TOLERANCES:

FRACTIONAL

ANGULAR: MACH

0.1 BEND

TWO PLACE DECIMAL

0.05

THREE PLACE DECIMAL

0.005

NAME

DATE

DRAWN

CHECKED

ENG APPR.

MFG APPR.

Q.A.

SHEET 2 OF 5

WEIGHT:

COMMENTS:

THE INFORMATION CONTAINED IN THIS

DRAWING IS THE SOLE PROPERTY OF

BOCK WATER HEATERS, INC. ANY

REPRODUCTION IN PART OR AS A WHOLE

WITHOUT THE WRITTEN PERMISSION OF

BOCK WATER HEATERS, INC. IS PROHIBITED.

PROPRIETARY AND CONFIDENTIAL

1/1/1901

-

Drawing Template

X

DrwBy

1/1/1901

Chk

Figure 3: Seismic Restraints to Wall

Page 9

SECTION III: PRE-INSTALLATION

LOCATION

To avoid cross-contamination of combustion air, do not locate the water heater in close proximity to

other fuel burning equipment exhaust vent terminals. Maintain at least 2 feet of separation between

any exhaust vert terminal and the air intake on the water heater. If an exhaust vent terminal is within

10 feet of the water heater, it shall be raised to an equal or greater height than the combustion air

intake on the water heater. In addition to maintaining minimum spacing from fuel burning

equipment exhaust it is necessary to confirm that no cross-contamination is occurring due to various

other conditions that may be present.

Do not install this water heater in an enclosed area that prohibits wind movement around the unit.

Wind around the water heater allows combustion exhaust to be carried away and provides fresh

combustion air. Avoid installations in corners where an eddy may develop. Eddies can lead to cross-

contamination of combustion air and lead to nuisance lockouts and increase maintenance on parts.

NOTICE

If possible, in climates of consistent extreme heat (ambient temperature > 100°F), select a location

that minimizes extensive exposure to the sun.

NOTICE

If a condensate line must be routed to a drain, locate the heater to minimize the distance to the drain.

Adequate downward pitch is required on the condensate line for proper flow.

This water heater must be installed outdoors and shall use the venting configuration as

supplied by the manufacturer. All supplied parts, such as cover plates, doors, and the

top pan must be properly installed for proper operation and to prevent a hazardous

condition.

This water heater is only approved for installation in areas that experience sustained

temperatures above 32°F and below 120°F. An overnight low or daytime high

temperature can only temporarily (<2 hours) be outside of this range. Personal injury or

product damage could result under other conditions.

Avoid locating the unit where it is subjected to rain from building runoff drains or water

spraying out of hoses or sprinklers. Water may enter vents and damage electrical

components.

Locate the heater so it is not subject to physical damage from moving vehicles or flooding.

This water heater cannot be installed directly on the ground. A level platform, made from

concrete, brick, or treated wood shall be used underneath this water heater.

Do not install this water heater under a deck or in a well, stairwell, alcove or other

recessed area.

This water heater is not approved for installation in areas that experience sustained

temperatures above 120°F. Personal injury or product damage could result under these conditions.

WARNING

WARNING

WARNING

WARNING

CAUTION

CAUTION

CAUTION

CAUTION

This water heater must be located in an area where leakage of the tank, water line

connections, or the temperature and pressure relief valve will not result in damage

to the area adjacent to the water heater or to lower floors of the structure. When

such location cannot be avoided, a suitable drain pan must be installed under

the water heater. The drain pan depth must be suitable for draining and collecting

water. The drain pan can be purchased from your plumbing professional. The drain

pan must be piped to an adequate drain and all drain piping must be at least 0.75”

in diameter and pitched for proper drainage.

CAUTION

DO NOT store or use gasoline or other flammable, combustible, or corrosive vapors

and/or liquids in the vicinity of the water heater or any other appliance.

IF YOU SMELL GAS:

• DO NOT try to light any appliance.

• DO NOT touch any electric switch; do not use any telephone in your building.

• Immediately call your gas supplier from a telephone in another building. Follow

your gas supplier’s instructions.

• If you cannot reach your gas supplier, call the fire department.

DO NOT OPERATE THE APPLIANCE UNTIL THE LEAKAGE IS CORRECTED!

CAUTION

Do not drop water heater or lay heater down on its side. Move the water heater

into position by sliding or using an appropriately sized hand truck.

Page 10

SECTION III: PRE-INSTALLATION

To avoid cross-contamination of combustion air, do not locate the water heater in close proximity to

other fuel burning equipment exhaust vent terminals. Maintain at least 2 feet of separation between

any exhaust vert terminal and the air intake on the water heater. If an exhaust vent terminal is within

10 feet of the water heater, it shall be raised to an equal or greater height than the combustion air

intake on the water heater. In addition to maintaining minimum spacing from fuel burning

equipment exhaust it is necessary to confirm that no cross-contamination is occurring due to various

other conditions that may be present.

Do not install this water heater in an enclosed area that prohibits wind movement around the unit.

Wind around the water heater allows combustion exhaust to be carried away and provides fresh

combustion air. Avoid installations in corners where an eddy may develop. Eddies can lead to cross-

contamination of combustion air and lead to nuisance lockouts and increase maintenance on parts.

NOTICE

If possible, in climates of consistent extreme heat (ambient temperature > 100°F), select a location

that minimizes extensive exposure to the sun.

NOTICE

If a condensate line must be routed to a drain, locate the heater to minimize the distance to the drain.

Adequate downward pitch is required on the condensate line for proper flow.

CAUTION

To avoid cross-contamination of combustion air, do not locate the water heater in close proximity to

other fuel burning equipment exhaust vent terminals. Maintain at least 2 feet of separation between

any exhaust vert terminal and the air intake on the water heater. If an exhaust vent terminal is within

10 feet of the water heater, it shall be raised to an equal or greater height than the combustion air

intake on the water heater. In addition to maintaining minimum spacing from fuel burning

equipment exhaust it is necessary to confirm that no cross-contamination is occurring due to various

other conditions that may be present.

Do not install this water heater in an enclosed area that prohibits wind movement around the unit.

Wind around the water heater allows combustion exhaust to be carried away and provides fresh

combustion air. Avoid installations in corners where an eddy may develop. Eddies can lead to cross-

contamination of combustion air and lead to nuisance lockouts and increase maintenance on parts.

NOTICE

If possible, in climates of consistent extreme heat (ambient temperature > 100°F), select a location

that minimizes extensive exposure to the sun.

NOTICE

If a condensate line must be routed to a drain, locate the heater to minimize the distance to the drain.

Adequate downward pitch is required on the condensate line for proper flow.

Page 11

SECTION III: PRE-INSTALLATION

LOCATION

CAUTION

Do not install this water heater under an overhang less than 3 ft (91.4 cm) from its top. The

top of the water heater is defined as the highest point of the exhaust vent termination. The

area under the overhang must be open on 3 sides.

This water heater is approved for installation on combustible flooring with 0” clearances to

combustibles at the rear and sides. Maintain a 24” clearance at the front of the unit for access

to the control panel. For maintenance and troubleshooting, maintain enough sufficient

clearance at the sides to access the T&P valve and condensate drain clean out port. Clearance

from the top of the exhaust terminal to any overhang above the water heater must be at least

3 feet. Maintain clearances specified in this manual and in accordance with the National Fuel

Gas Code (NFPA 54, ANSI Z223.1) unless otherwise directed by state and local code require-

ments.

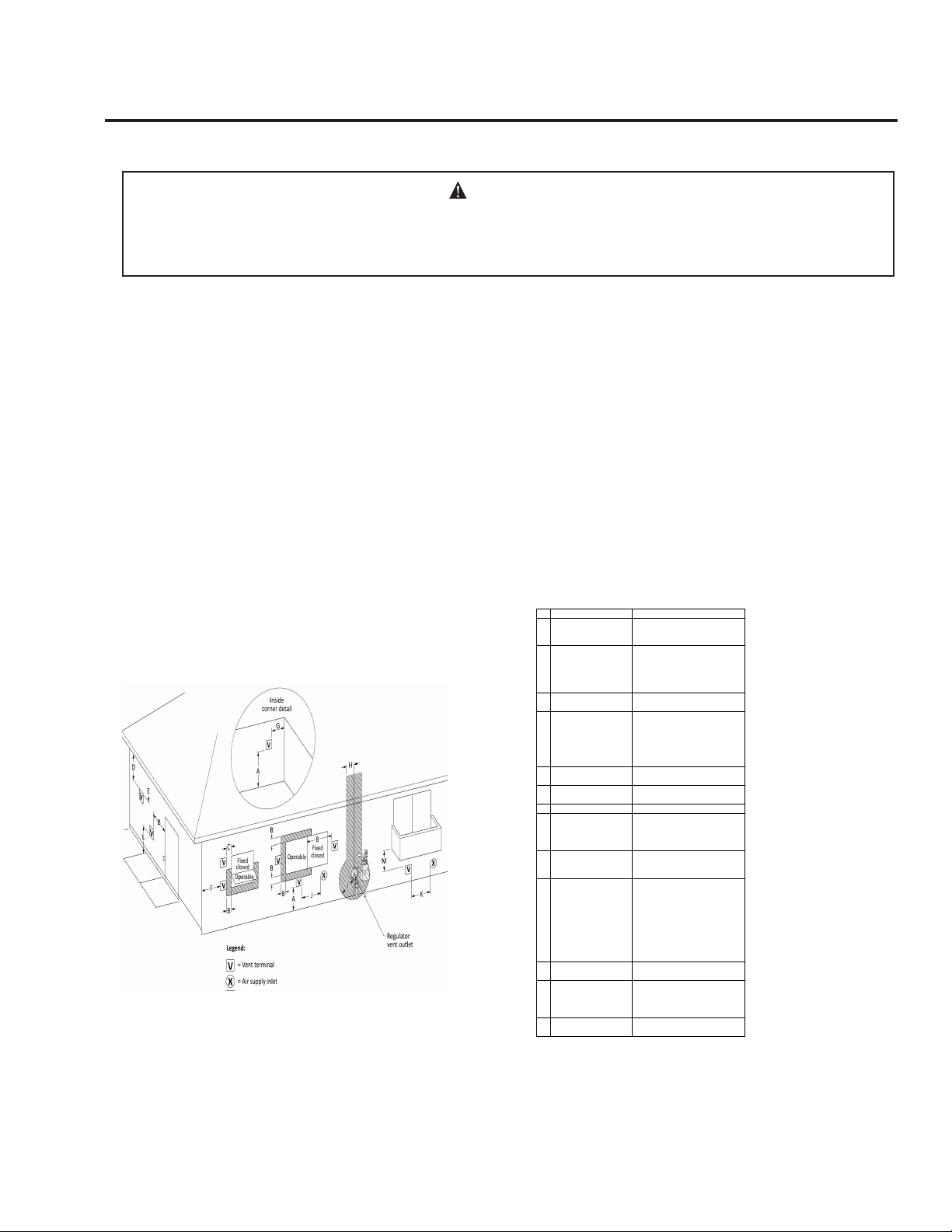

The vent pipe supplied with the water heater shall be installed as specified in this manual.

Due to the close proximity of the exhaust vent and intake air terminations to the unit itself,

attention must be given to clearances to other exhaust terminals, air supply inlets, and other

features around the building when locating this water heater. All clearances must comply

with local codes or the latest edition of NFPA 54 / ANSI Z223.1. See Figure 4 and Table 3 for

terminal clearance.

Figure 4: Vent Terminal Clearances

US Installations

A=

Clearance above grade,

veranda, porch, deck, or

balcony

12 in (30 cm)

B=

Clearance to window or

door that may be opened

6 in (15 cm) for appliances ≤ 10,000

Btuh (3 kW), 9 in (23 cm) for

appliances > 10,000 Btuh (3 kW) and ≤

50,000 Btuh (15 kW), 12 in (30 cm) for

appliances > 50,000 Btuh (15 kW)

C=

Clearance to Permanently

closed window

12 in (30 cm)*

D=

Vertical Clearance to

ventilated soffit located

above the terminal within a

horizontal distance of 2 ft

(61 cm) from the center

line of the terminal.

12 in (30 cm)*

E=

Clearance to unventilated

soffit

12 in (30 cm)*

F= Clearance to outside corner

2 ft (60 cm)*

G= Clearance to inside corner 18 in (45 cm)*

H=

Clearance to each side of

center line extended above

meter/regulator assembly

Clearance in accordance with local

installation codes and the

requirements of the gas supplier.

I=

Clearance to service

regulator vent outlet

Clearance in accordance with local

installation codes and the

requirements of the gas supplier.

J=

Clearance to

nonmechanical air supply

inlet to building or the

combustion air inlet to any

other appliance

- 6 in (15 cm) for appliances ≤ 10,000

Btuh (3kW),

- 9 in (23 cm) for appliances > 10,000

Btuh (3kW) and ≤ 500,000 Btuh (15

kW),

-12 in (30 cm) for appliances >

500,000 Btuh (15 kW)

K=

Clearance to a mechanical

air supply inlet

3 ft (91 cm) above if within 10 ft (3 m)

horizontally

L=

Clearance above paved

sidewalk or paved driveway

located on public property

Canot be located above public

walkways or other areas where

condensate or vapor can cause a

nusisance or hazard

M=

Clearance under veranda,

porch deck, or balcony

12 in (30 cm)‡

Table 3: Vent Terminal Clearances

1 In accordance with with the current CSA B149.1 Natural Gas and Propane Installation

Code.

2 In accordance with the current ANSI Z223.1 / NFPA 54 National Fuel Gas Code.

3 If locally adopted installation codes specify clearances different than those illustrated,

then the most stringent clearance shall prevail.

†A vent shall not terminate directly above a sidewalk or paved driveway that is located

between two single family dwellings and serves both dwellings.

‡Permitted only if veranda, porch, deck, or balcony is fully open on a minimum of two

sides beneath the floor.

Page 12

SECTION III: PRE-INSTALLATION (CONT)

GAS SUPPLY LINE

Prior to installation, contact your local gas utility to confirm that sufficient gas service is available

for the water heater. The gas meter must have adequate capacity to supply the rated maximum gas

input of the water heater in addition to other gas fired equipment connected to the meter.

Minimum Gas Supply Pressure

The gas supply must be capable of maintaining a minimum pressure at the inlet of the gas control

during water heater operation at maximum input. The pressure will be lowest at the gas control

during water heater operation (i.e. gas is flowing) at maximum input. For natural gas models,

during operation at maximum input, the supply pressure at the gas control must be at least 3.5”

W.C. For LP gas models, during operation at maximum input, the supply pressure at the gas

control must be at least 8” W.C.

Refer to Table 4 for gas supply line sizing. The table shows maximum input in thousands of BTU’s

per hour for various pipe sizes and lengths. The table assumes gas supply pressures of 14” W.C. or

less and a pressure drop of 0.3” W.C.

Table 4: Gas Supply Line Capacity

Minimum gas supply pipe sizes: for models ODOT200 & 250 - 3/4”; model ODOT299 - 1”;

models ODOT300*2 & 400*2 - 1-1/4”; model ODOT500*2 - 1-1/2”.

Maximum Gas Supply Pressure

The gas supply pressure shall never be greater than 14” W.C. Pressures greater than 14” W.C. may

damage the gas control which could cause a fire or explosion.

Refer to Section IV: Installation / Gas Connections for further installation instructions

Nominal

Iron Pipe

Size

(inches)

Internal

Diameter

(inches)

Length of Pipe (feet)

10 20 30 40 50 60 70 80 90 100 125 150 175 200

3/4 0.824 278 190 152 130 115 105 96 90 84 79 72 64 59 55

1 1.049 520 350 285 245 215 195 180 170 160 15 130 120 110 100

1-1/4 1.380 1,050 730 590 500 440 400 370 350 320 305 275 250 225 210

1 1/2 1.610 1,600 1,100 890 760 670 610 560 530 490 460 410 380 350 320

2 2.067 3,050 2,100 1,650 1,450 1,270 1,150 1,050 990 930 870 780 710 650 610

2 1/2 2.469 4,800 3,300 2,700 2,300 2,000 1,850 1,700 1,600 1,500 1,400 1,250 1,130 1,050 980

3 3.068 8,500 5,900 4,700 4,100 3,600 3,250 3,000 2,800 2,600 2,500 2,200 2,000 1,850 1,700

4 4.026 17,500 12,000 9,700 8,300 7,400 6,800 6,200 5,800 5,400 5,100 4,500 4,100 3,800 3,500

SECTION IV: INSTALLATION

VENT & COMBUSTION AIR INTAKE

DANGER

Failure to properly install the vent and combustion air intake system as outlined in

this manual can result in unsafe operation of the water heater. To avoid the risk of

fire, explosion, or asphyxiation from carbon monoxide, never operate this water

heater unless it is properly vented and has adequate air supply for combustion.

Be sure to inspect the system for proper installation at initial start-up; and at least

annually thereafter. See the Maintenance section for more information.

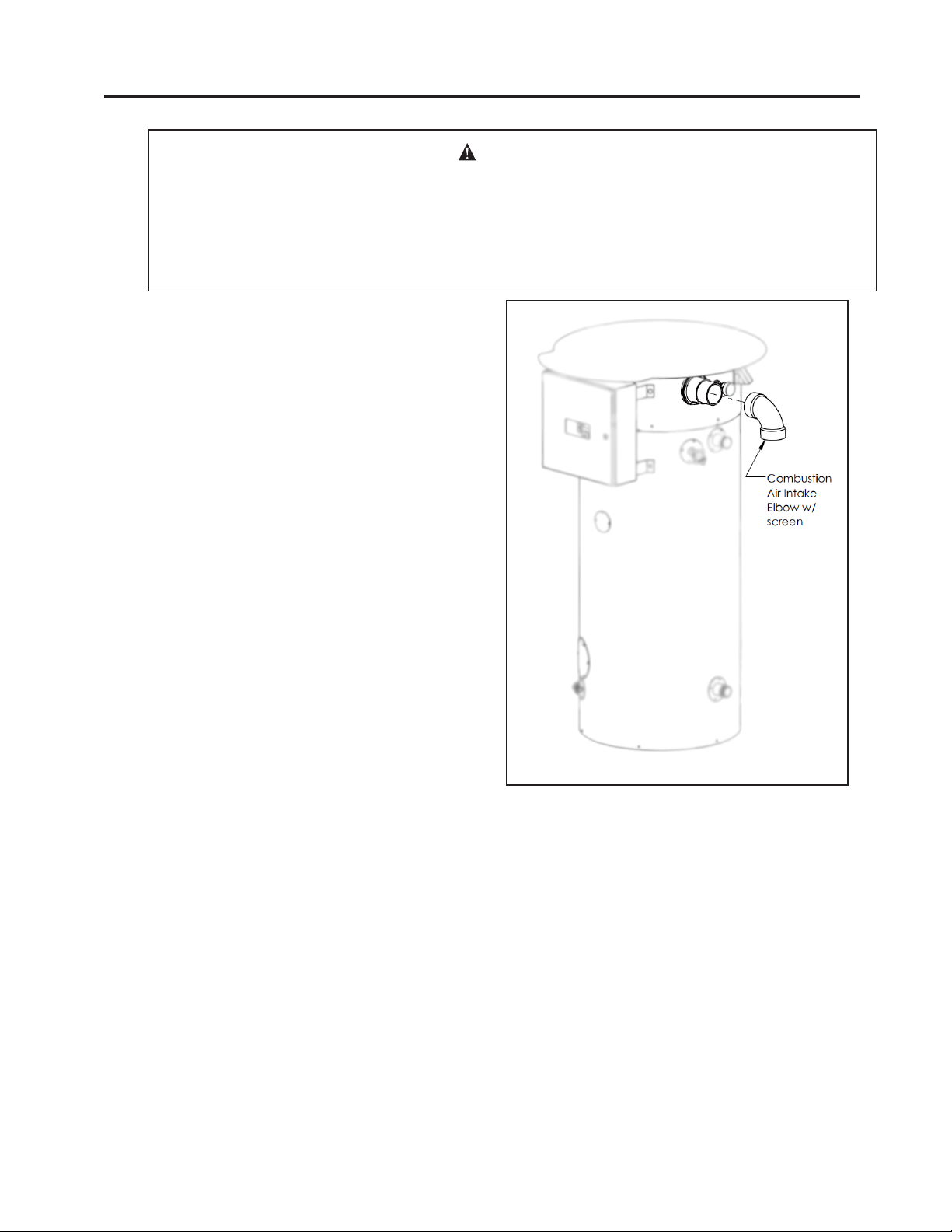

All of the vent pipe and fittings supplied

with this water heater must be used. The

exhaust vent is factory supplied and

installed. No additional vent pipes or

fittings shall be installed. Connect the

supplied elbow to the combustion air

intake as shown in Figure 5. Cementing

this connection is not required.

Page 13

Figure 5: Vent Assembly

Figure 7: Orientation of the Condensate Trap

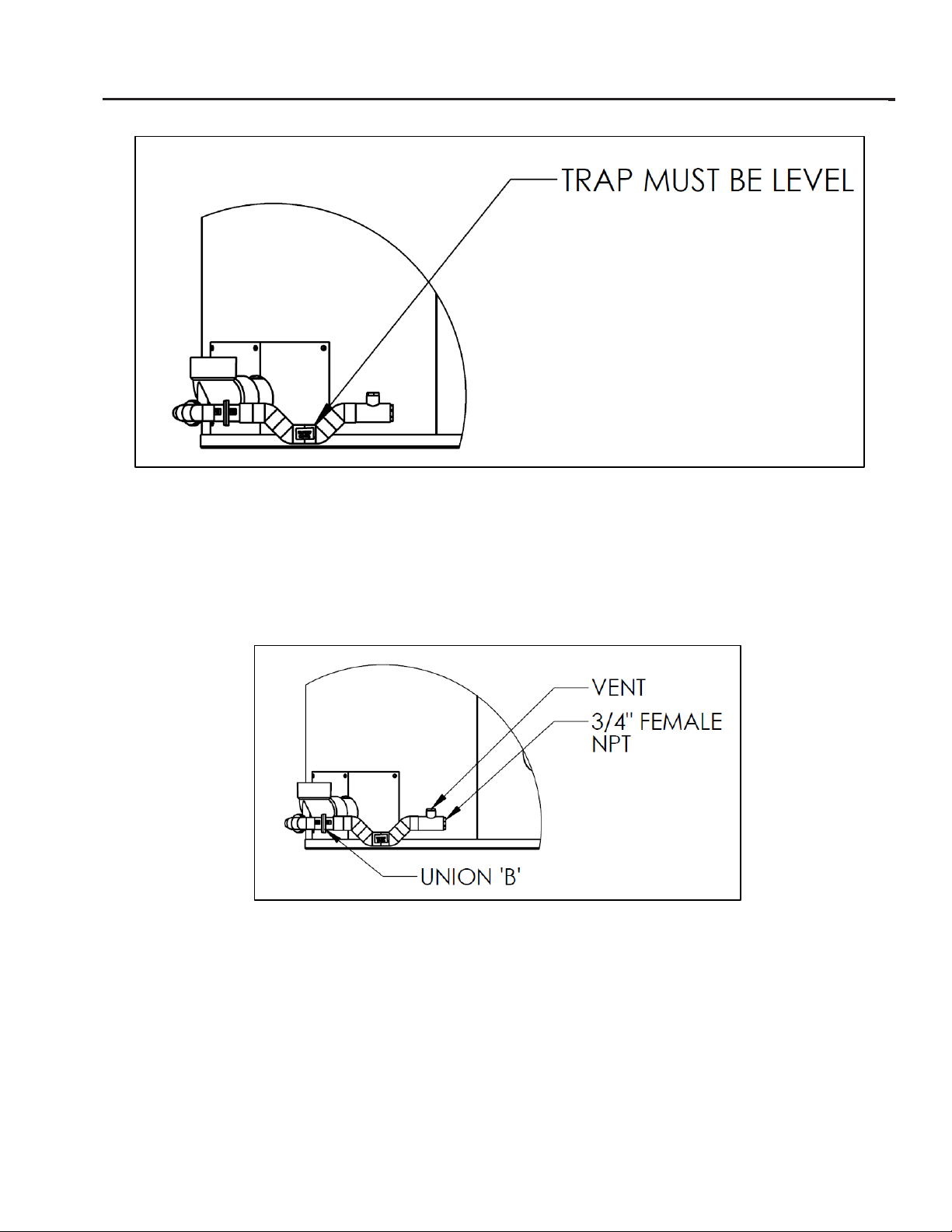

Condensate Trap Assembly

This heater comes with the exhaust vent factory installed. Before operation the condensate trap and drain

must be installed along with a suitable drain line.

The condensate trap is made up of three parts and connected by two unions, labeled ‘A’and ‘B’. The drain

elbow is factory installed. There are two orienters included; one with an angle of 135° and another with an

angle of 90°, choose whichever one minimizes the number of fittings required for proper drainage. Figure 6

shows the difference between the two options. Install the orienter of your choice by connecting the union

portions labeled ‘A’.

Figure 6: 135° and 9

0° orienter

Determine which direction minimizes the length of the condensate drain line, and point the orienter in that

direction. Install the trap portion by connecting the union parts labeled ‘B’ so that it is pointing in the

proper direction. See Figure 7 for the top view of both orientation options.

The orientation of the trap portion of the drain is critical for proper venting of gas and drainage of

condensate. This portion must be level after both unions are fully tightened. See Figure 8 for proper final

orientation of the assembly.

SECTION IV: INSTALLATION

CONDENSATE TRAP AND DRAIN

Page 14

Figure 7: Orientation of the Condensate Trap

Condensate Trap Assembly

This heater comes with the exhaust vent factory installed. Before operation the condensate trap and drain

must be installed along with a suitable drain line.

The condensate trap is made up of three parts and connected by two unions, labeled ‘A’and ‘B’. The drain

elbow is factory installed. There are two orienters included; one with an angle of 135° and another with an

angle of 90°, choose whichever one minimizes the number of fittings required for proper drainage. Figure 6

shows the difference between the two options. Install the orienter of your choice by connecting the union

portions labeled ‘A’.

Figure 6: 135° and 9

0° orienter

Determine which direction minimizes the length of the condensate drain line, and point the orienter in that

direction. Install the trap portion by connecting the union parts labeled ‘B’ so that it is pointing in the

proper direction. See Figure 7 for the top view of both orientation options.

The orientation of the trap portion of the drain is critical for proper venting of gas and drainage of

condensate. This portion must be level after both unions are fully tightened. See Figure 8 for proper final

orientation of the assembly.

Figure 6: 90° and 135° Orienter

This heater comes with the exhaust vent factory installed. Before operation the condensate trap

and drain must be installed along with a suitable drain line.

The condensate trap is made up of three parts and connected by two unions, labeled ‘A’ and ‘B’.

The drain elbow is factory installed. There are two orienters included; one with an angle of 135°

and another with an angle of 90°, choose whichever one minimizes the number of fittings required

for proper drainage. Figure 6 shows the difference between the two options. Install the orienter of

your choice by connecting the union portions labeled ‘A’.

Figure 7: Orientation of the Condensate Trap

Determine which direction minimizes the length of the condensate drain line, and point the

orienter in that direction. Install the trap portion by connecting the union parts labeled ‘B’ so that

it is pointing in the proper direction. See Figure 7 for the top view of both orientation options.

The orientation of the trap portion of the drain is critical for proper venting of gas and drainage of

condensate. This portion must be level after both unions are fully tightened. See Figure 8 for proper

final orientation of the assembly.

Page 15

A detailed view of the condensate trap is shown in Figure 9. The discharge portion of the trap is designed

with a vent and threaded ¾” female NPT connection. The trap may be cleaned by disconnecting union B and

the threaded connection, then running water through the trap. Use rigid PVC pipe for the condensate drain

line. The line must slope down, 1/8” per foot, away from the point of connection towards the drain. If there is

insufficient clearance between the connection point and the floor to maintain slope, the heater should be

installed on a concrete slab or use a low-profile condensate pump.

Figure 8: Levelness of Trap

Figure 10: Detailed View

SECTION IV: INSTALLATION

CONDENSATE TRAP AND DRAIN

A detailed view of the condensate trap is shown in Figure 9. The discharge portion of the trap is designed

with a vent and threaded ¾” female NPT connection. The trap may be cleaned by disconnecting union B and

the threaded connection, then running water through the trap. Use rigid PVC pipe for the condensate drain

line. The line must slope down, 1/8” per foot, away from the point of connection towards the drain. If there is

insufficient clearance between the connection point and the floor to maintain slope, the heater should be

installed on a concrete slab or use a low-profile condensate pump.

Figure 8: Levelness of Trap

Figure 10: Detailed View

Figure 8: Levelness of Trap

Figure 9: Detailed View

A detailed view of the condensate trap is shown in Figure 9. The discharge portion of the trap

is designed with a vent and threaded 3/4” female NPT connection. The trap may be cleaned by

disconnecting union B and the threaded connection, then running water through the trap. Use

rigid PVC pipe for the condensate drain line. The line must slope down, 1/8” per foot, away

from the point of connection towards the drain. If there is insufficient clearance between the

connection point and the floor to maintain slope, the heater should be installed on a concrete

slab or use a low-profile condensate pump.

Page 16

SECTION IV: INSTALLATION

CONDENSATE TRAP AND DRAIN

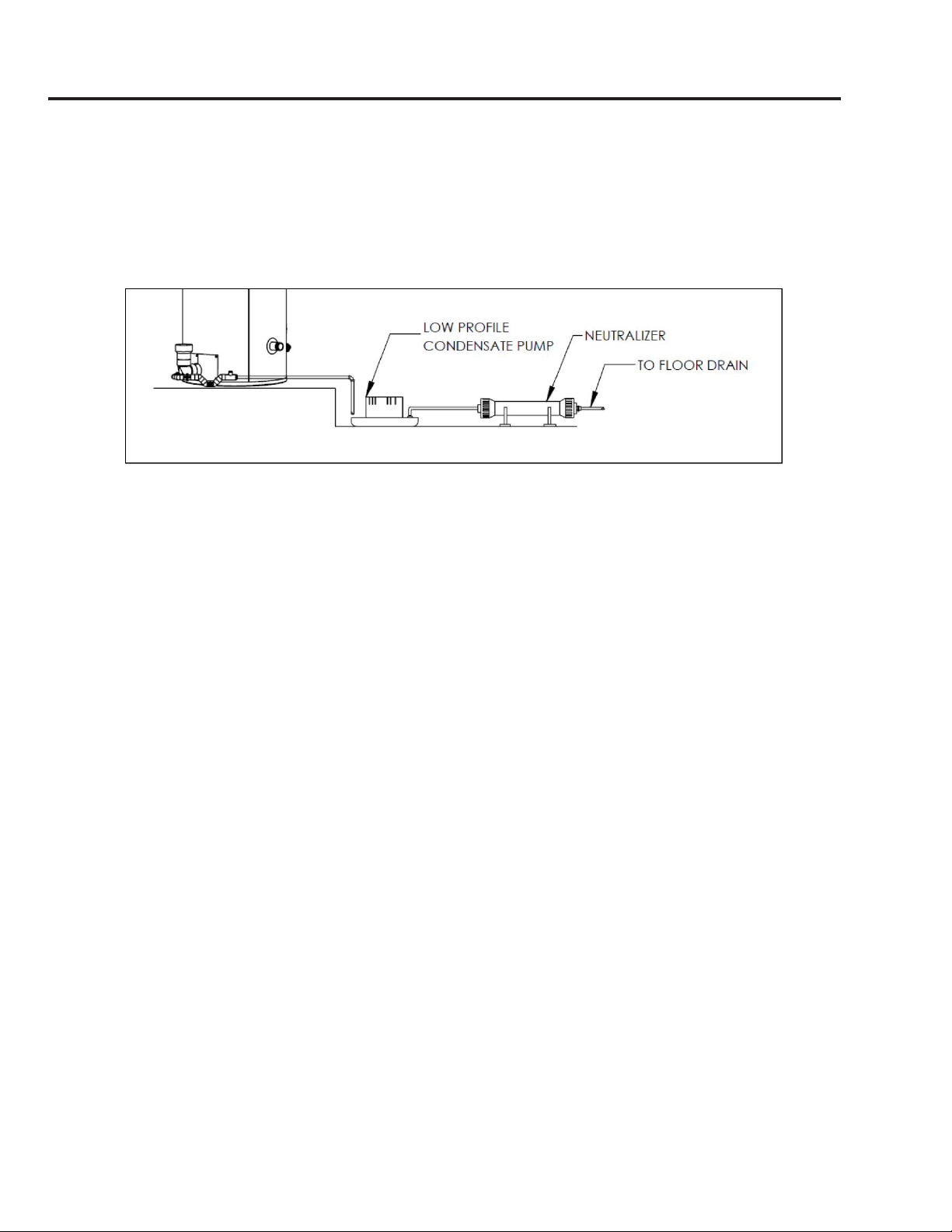

Figure 10: Pump and Neutralizer

Some installations require the use of a condensate neutralizer to reduce the acidity of the

condensate prior to reaching the drain. Figure 10 shows the connection of a condensate

line to a neutralizer. It is recommended that a low profile condensate pump is installed

between the heater and neutralizer to facilitate flow through the neutralizer. For further

details, refer to the instructions provided with the pump and neutralizer.

Page 17

SECTION IV: INSTALLATION

WATER CONNECTIONS

CAUTION

This water heater incorporates fittings that contain a nonmetallic lining. DO NOT apply

heat to these fittings when making sweat connections to the heater. Sweat tubing to

an adapter before securing adapter to any fittings on water heaters.

ALL PIPING SHOULD CONFORM TO LOCAL CODES AND ORDINANCES. It is highly

recommended that unions and shut-off valves are installed at the potable water connections

to allow for isolation and/or movement during service. All piping should be adequately

insulated with an approved material to minimize heat loss.

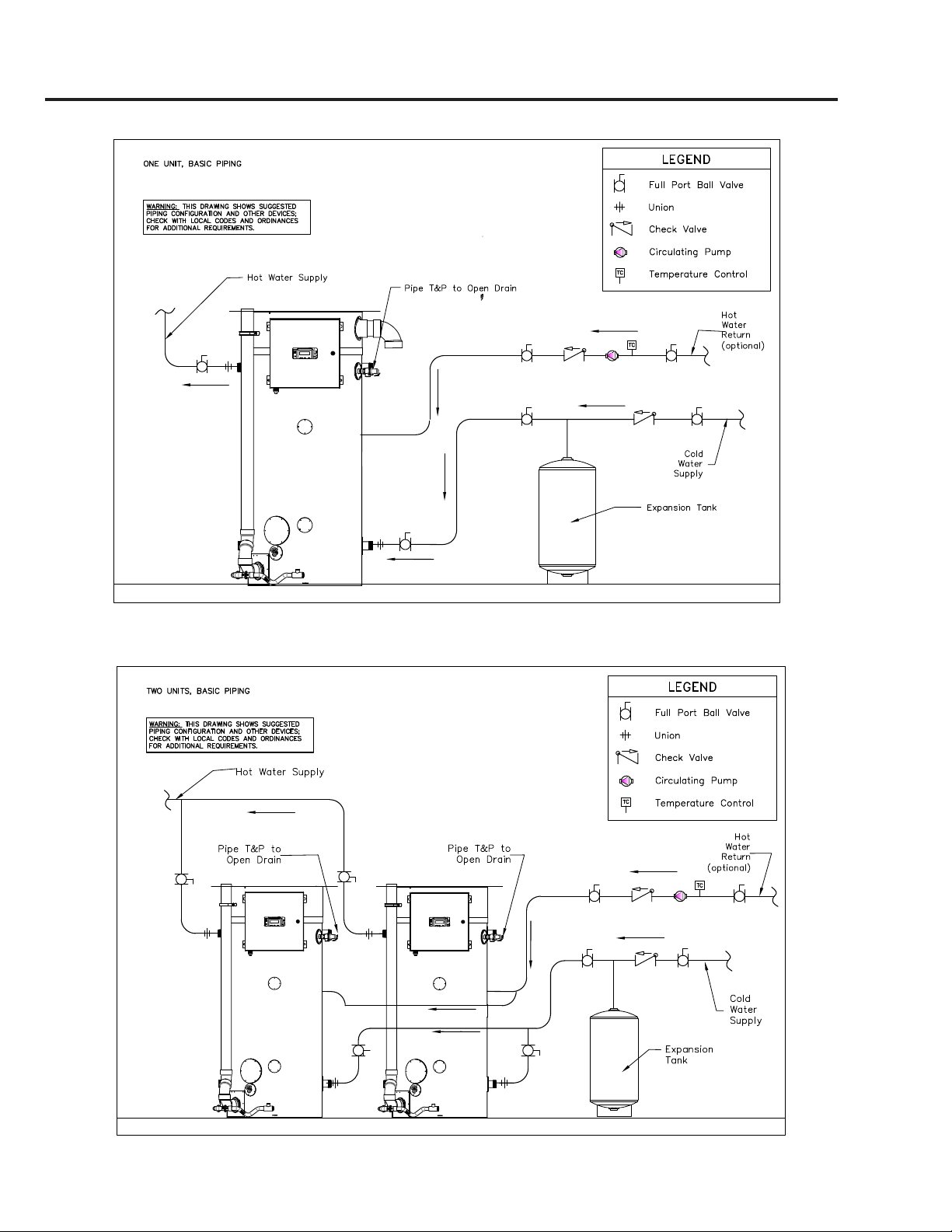

Piping diagrams are provided in Figures 12-15 for a variety of configurations.

POTABLE WATER CONNECTIONS

IMPORTANT: THE WATER HEATER MUST BE FILLED WITH WATER BEFORE

CONNECTING ELECTRIC POWER.

1) Close the main water supply valve before continuing with the installation. After the

main water supply is shut-off, relieve the water line pressure by opening a faucet. Once the

pressure has been relieved, close the faucet. The “Cold” and “Hot” potable water connections

are labeled on the water heater. Install a union and shut-off valve at both potable water

connections. A tempering valve or anti-scald valve should be installed at the potable water

outlet and used according to the manufacturer’s specifications to prevent scalding.

IMPORTANT: The water heater contains factory installed

pipe nipples at the hot outlet connections. These pipes

were tightened to proper orientation at the factory. DO

NOT ROTATE THESE PIPES WHEN CONNECTING FITTINGS

IN THE FIELD. The black indicator line on the side of the

factory installed pipe nipple must be in line with the arrow

on the label shown in Figure 11. If orientation is not correct

there will be a reduction in water heater performance.

2) If a backflow preventer, check valve, or pressure regulating valve is required in the cold

water supply, a properly sized expansion tank must be installed to control thermal expansion.

Do not operate the water heater in a closed system without installing a thermal expansion

tank. Follow the expansion tank manufacturer’s recommendations when selecting a tank for

your system.

3) Following installation of the water lines, open the main water supply valve and fill the

water heater. Open several hot water faucets to relieve air from the system. After water is

flowing through the faucets and the system is void of air, close the faucets and check for water

leaks in the system.

Note: Do not try to heat hard water as this will drastically reduce heater life. Install a water

softener or other scale reducing water treatment system if the water heater is being installed in

a hard water area (water hardness higher than seven grains).

)L

J

XUH +RW 2XWOHW 3LSH 1LSSOH 2ULHQWDWLRQ

Figure 11: Hot Outlet Pipe

Nipple Orientation

Page 18

SECTION IV: INSTALLATION

Figure 12: Piping Diagram One Unit

Figure 13: Piping Diagram Two Units

Page 19

SECTION IV: INSTALLATION

Figure 14: Piping Diagram Three Units

Figure 15: Piping Diagram One Unit with Storage Tank

Page 20

SECTION IV: INSTALLATION

GAS CONNECTIONS

CAUTION

Do not use this water heater with any gas other than the type listed on the rating label.

Check the rating label on the front of the water heater and make sure the gas to be

used matches the gas stated on the rating label. Consult your local gas company or

Bock Water Heaters with any questions.

A manual valve, union, and a sediment

trap shall be provided in front of the

gas valve. All gas piping must conform

to local codes and/or the National Fuel

Gas Code ANSI 223.1/NFPA 54 or CSA

B149.1. Figure 16 shows the installation

of a sediment trap to the gas piping on

the water heater.

The gas supply piping to the heater

must be sized such that the pressure at

the valve is sufficient when all other

appliances are operating. Undersized

gas piping will reduce water heater

performance and result in nuisance

lockouts. Refer to Section III: Pre-Instal-

lation / Gas Supply Line for pipe size requirements.

Verify that the gas service and meter are sized properly for the total load. If the gas supply

pressure is greater than 14” W.C., the water heater must have a supply gas regulator installed

in the gas supply line for each water heater. The regulator must be rated at or above the input

rating (Btu/hr) of the water heater that it serves. Inlet and outlet connections on the regulator

shall not be less than the minimum gas supply line size for the water heater. The Maxitrol

325-7 series of regulators with 1-1/4” or 1-1/2” connections is recommended.

For ease of measurement, install a tee with a pipe fitting and a manual shutoff valve between

the main manual shut-off valve to the water heater and the pressure regulator. The pipe

fitting should be adaptable to a pressure gauge for measuring incoming gas pressure. If further

measurement of gas pressure is required due to lack of adequate pressure, measurement at the

inlet of the gas control is recommended. Refer to Section III: Pre-Installation / Gas Supply Line

for minimum pressure requirements.

During pressure testing of the gas supply piping, close the manual gas shut-off valve to the

water heater. Test pressure shall not exceed 1⁄2PSIG (14” W.C). The gas control is only rated

for 1⁄2PSIG. To test at a pressure greater than 1⁄2PSIG, close the manual shut-off valve and

disconnect the gas control. Turn on gas and inspect piping for leaks by “painting” each joint

with a soapy water solution and check for bubbles.

WARNING

DO NOT use an open flame to check for leaks. Serious injury or death could result from

fire or explosion.

The pipe thread compound that is used on gas piping must be of the type resistant to

propane gas. Do not use teflon tape on gas piping.

Figure 16: Gas Piping with Sediment Trap

This manual suits for next models

11

Table of contents