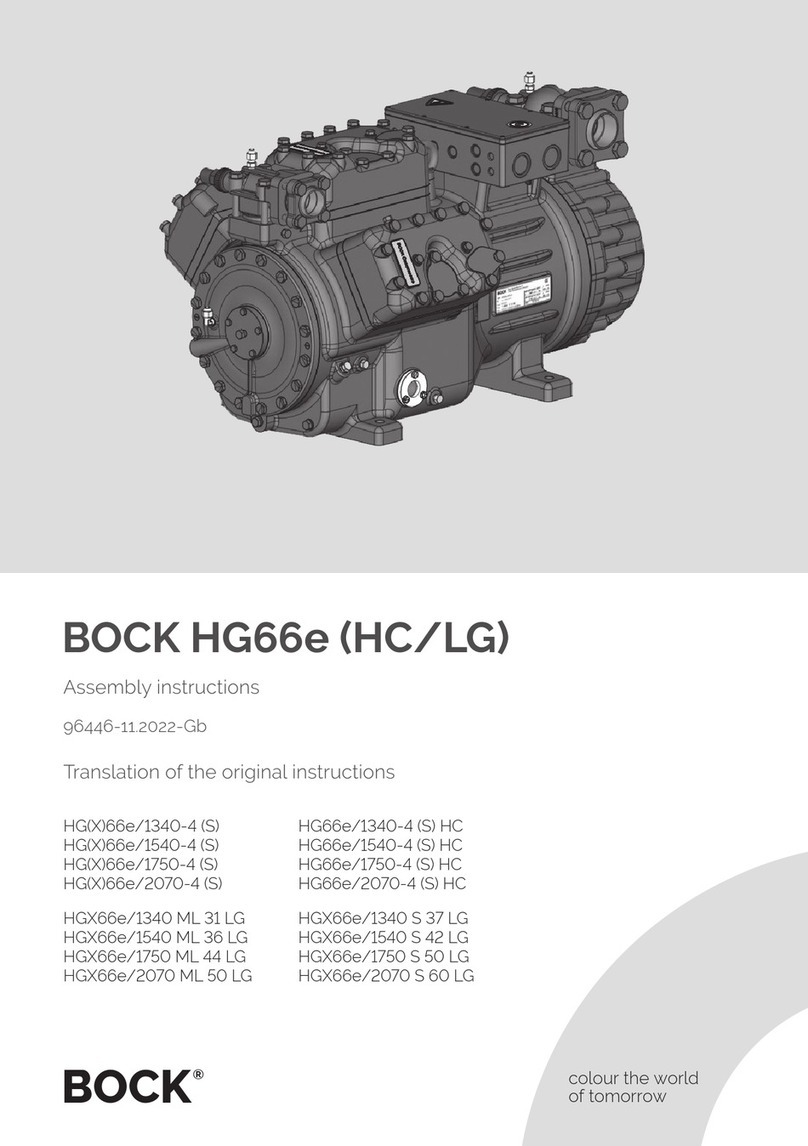

BOCK FK50 User manual

This manual suits for next models

32

Table of contents

Other BOCK Air Compressor manuals

BOCK

BOCK HG66e/1340-4 User manual

BOCK

BOCK FK40 Series User manual

BOCK

BOCK HGX24/55 MLP 6 CO2 T User manual

BOCK

BOCK HGX24 CO2 T Series User manual

BOCK

BOCK HGX24e CO2 LT Series User manual

BOCK

BOCK HGX34e S CO2 Series User manual

BOCK

BOCK HGX34/110-4 ML CO2 T User manual

BOCK

BOCK FK40 Seroes User manual

BOCK

BOCK UL-HGX22e Series User manual

BOCK

BOCK HG6 User manual

BOCK

BOCK HGX22e S CO2 Series User manual

BOCK

BOCK HG44e User manual

BOCK

BOCK HGX44e CO2 User manual

BOCK

BOCK HGX22e S CO2 Series User manual

BOCK

BOCK FK30 User manual

BOCK

BOCK Pluscom HG34P Series User manual

BOCK

BOCK UL-HGX66e/1340 ML 31 User manual

BOCK

BOCK HA44e User manual

BOCK

BOCK HG34e User manual

BOCK

BOCK HGX12e S CO2 User manual

Popular Air Compressor manuals by other brands

Grizzly

Grizzly H3272 instruction manual

Ingersoll-Rand

Ingersoll-Rand P425AWIR Operating, Maintenance & Parts Manual

Coleman

Coleman PMC9610 owner's manual

Rolair

Rolair V5160PT03XB instruction manual

DeVilbiss Air Power Company

DeVilbiss Air Power Company Ex-Cell E7540 Operation manual

Kobalt

Kobalt 200382 manual

Craftsman

Craftsman 919.7243 owner's manual

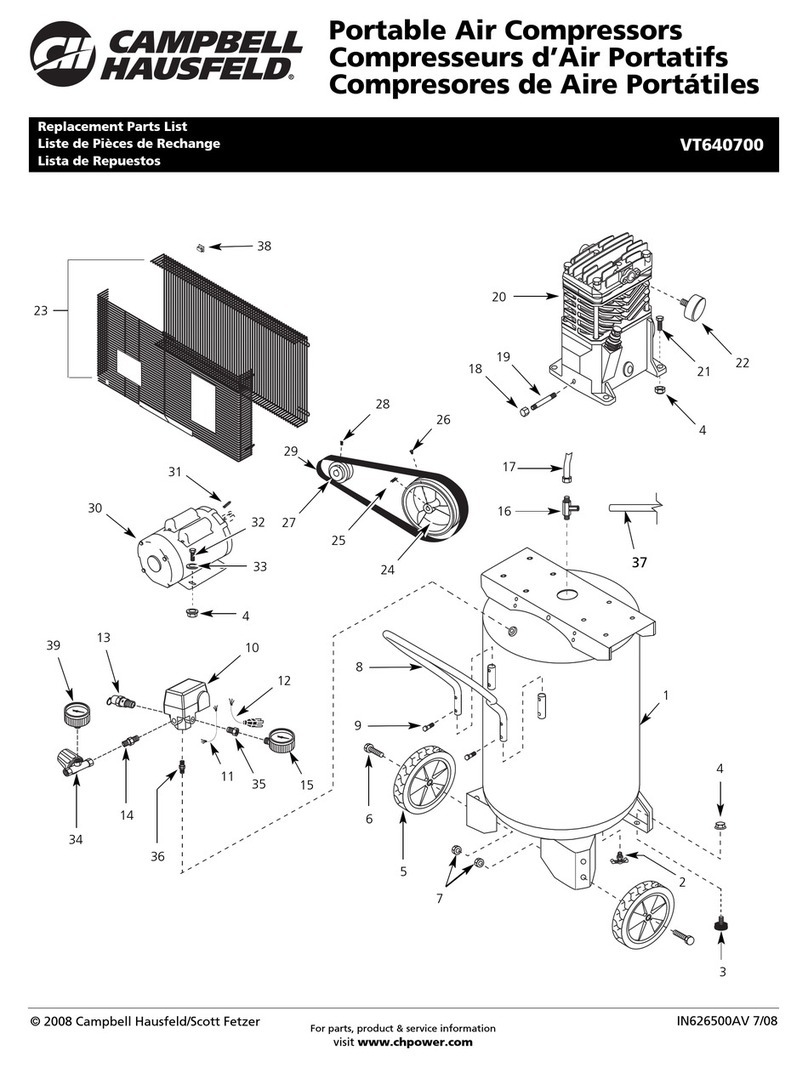

Campbell Hausfeld

Campbell Hausfeld VT640700 Replacement parts list

American Eagle

American Eagle V230 STANDARD OPERATION & PARTS MANUAL

Stanley

Stanley FATMAX FMXCMD156HE Instruction manual for owner's use

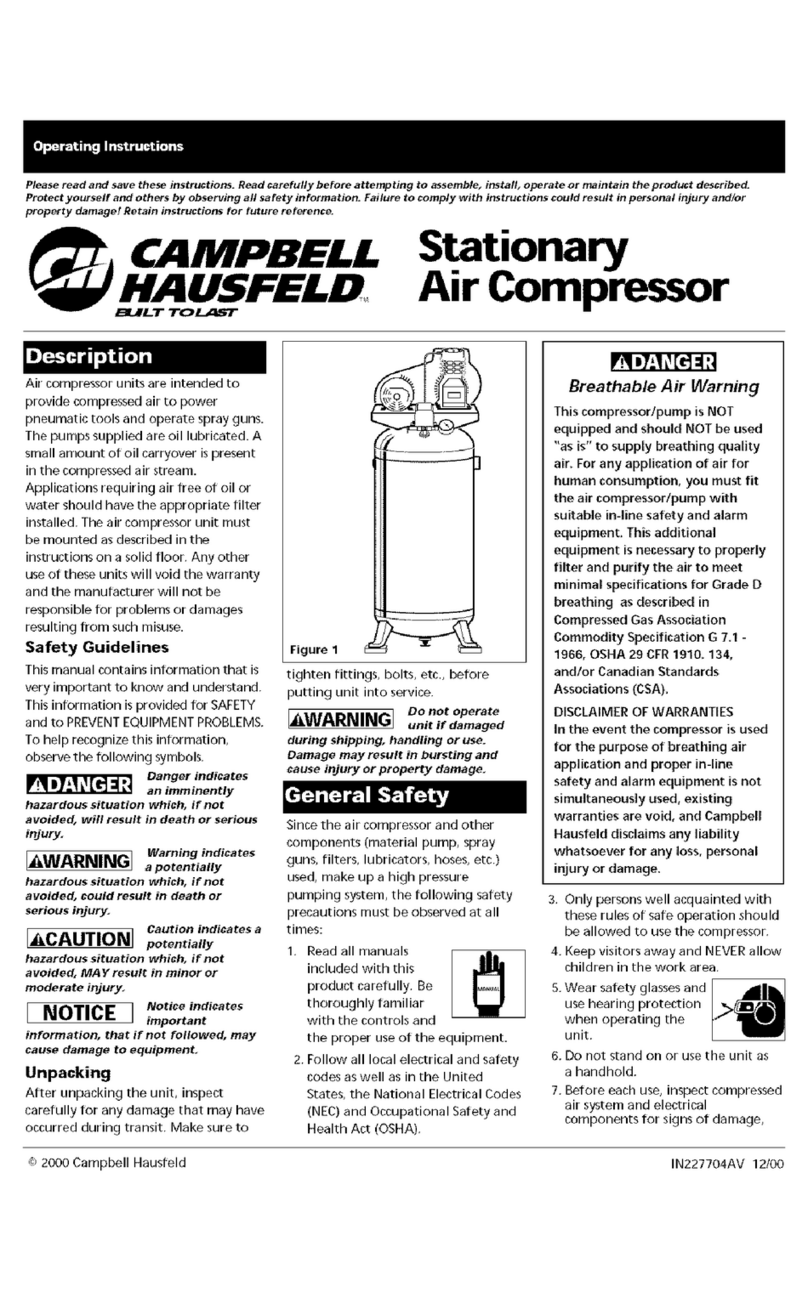

Campbell Hausfeld

Campbell Hausfeld Portable Air Compressor operating instructions

Sealey

Sealey SSC11003 instructions