Page 4

I. Introduction

The Bock OptiTherm Common Vent Kit can be used to direct vent up to three appliances in the

model category OT125-OT199 provided they use the same fuel type and are not high altitude

versions. This document describes two heater direct vent, and three heater direct vent kits.

These kits are intended to combine the intake and exhaust vents of two or three OptiTherm

water heaters with the maximum input rates between 125,000 and 199,000 BTU/hr for the

purpose of reducing the number of wall terminations required.

Combining heaters which have different input rates is permissible, but it is not permissible to

combine fuel types in a common vent system. For example, it is permissible to combine the

vents of an OT125N, OT150N, and OT199N because they all use the same fuel type, but it is not

permissible to combine the vents of an OT125LP, OT150LP, and OT199N because they don’t all

share the same fuel type.

This manual was supplied with the Common Vent Kit in an adhesive backed sleeve. Once

installation is complete, remove the paper adhesive cover and attach the sleeve with this

manual inside to one of the water heaters underneath the standard installation manual sleeve.

II. Supplemental Information

This installation manual supplements the standard installation manual provided with each

OptiTherm water heater. The installation of a water heater with a Polypropylene Common Vent

Kit must satisfy all the requirements in the standard installation manual and the requirements

in this document. Additionally, installation of these kits shall comply with all local codes. In the

absence of local codes, refer to the latest edition of NFPA 54/ANSI Z223.1 or CSA B149. It is permissible

to switch to a different approved vent material after the manifold is constructed with the

supplied polypropylene components given the installation complies with applicable codes.

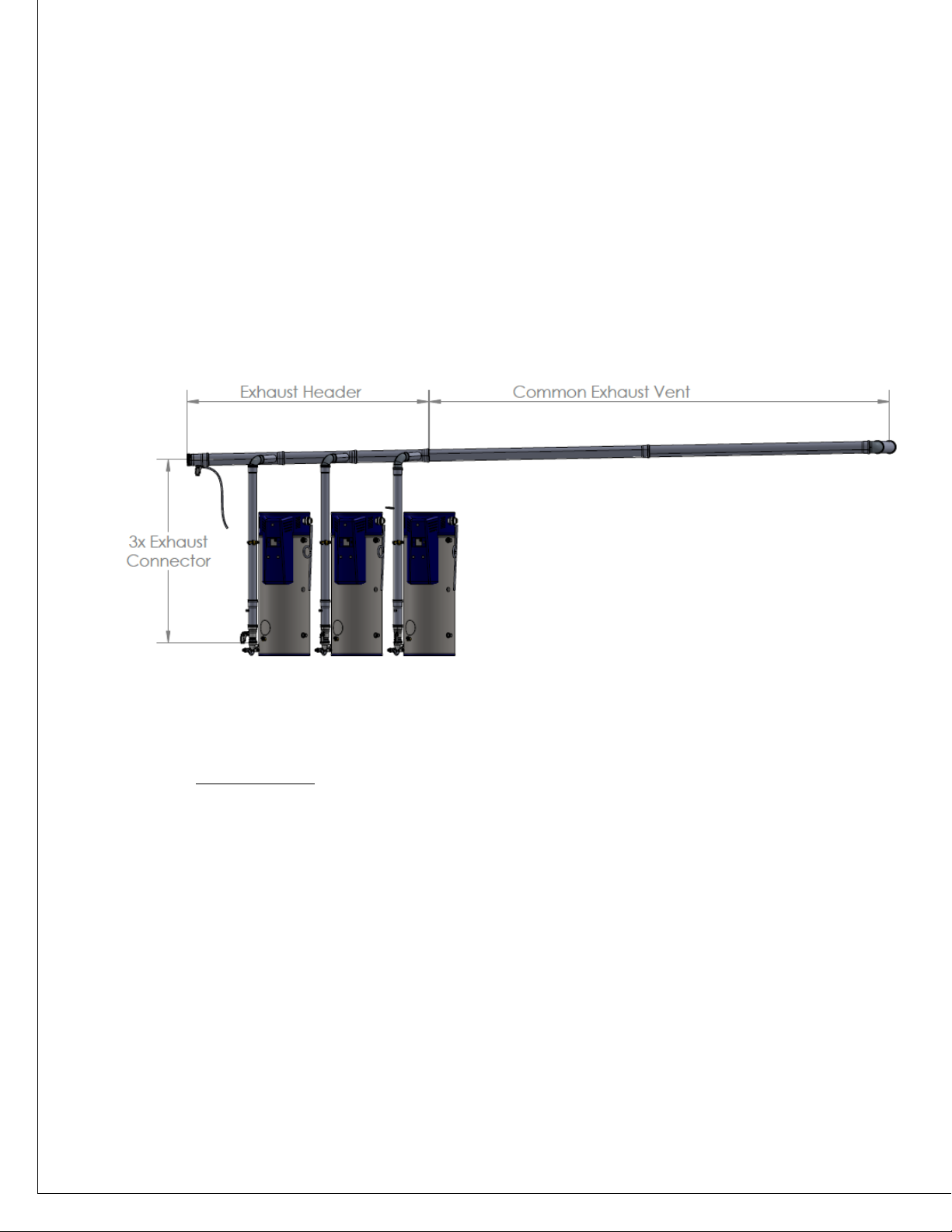

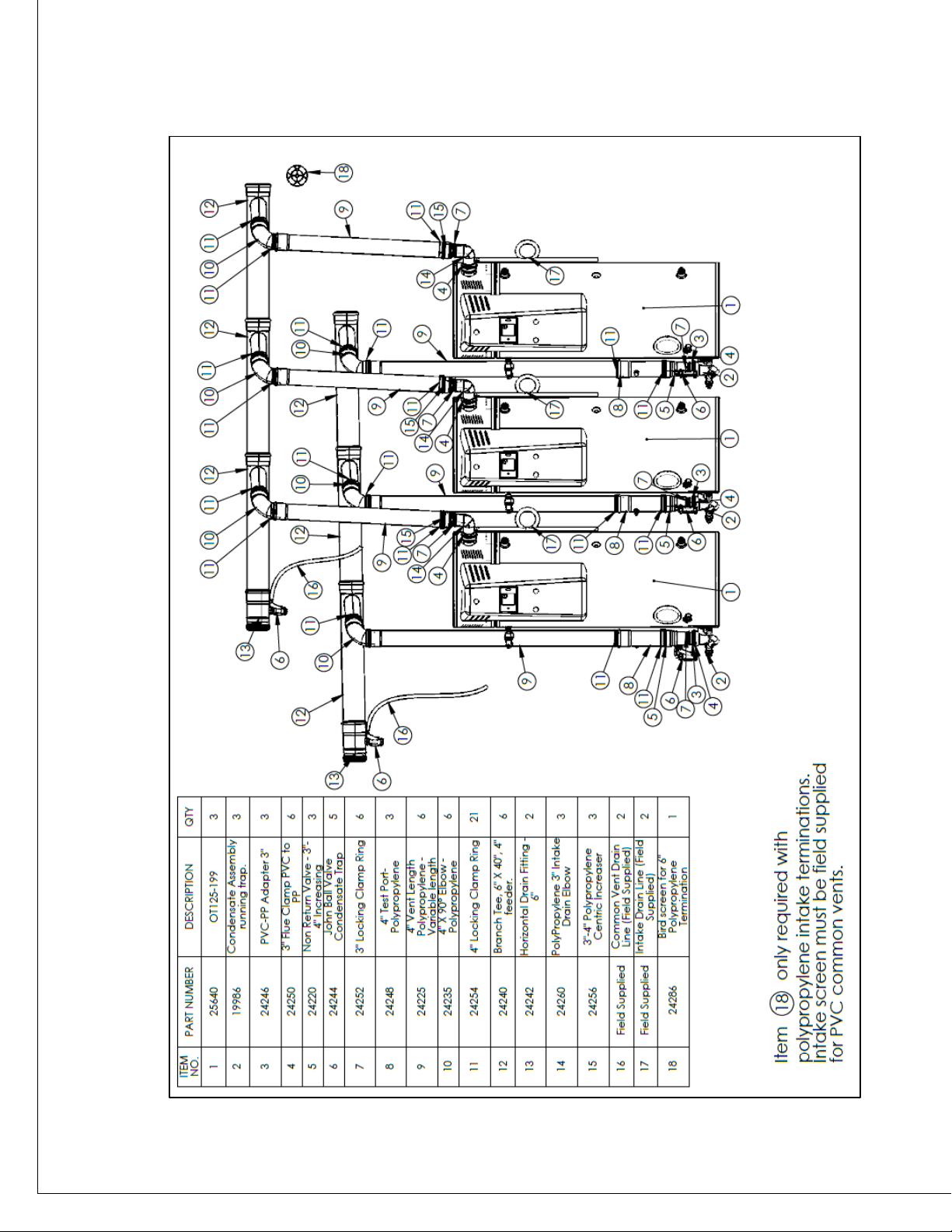

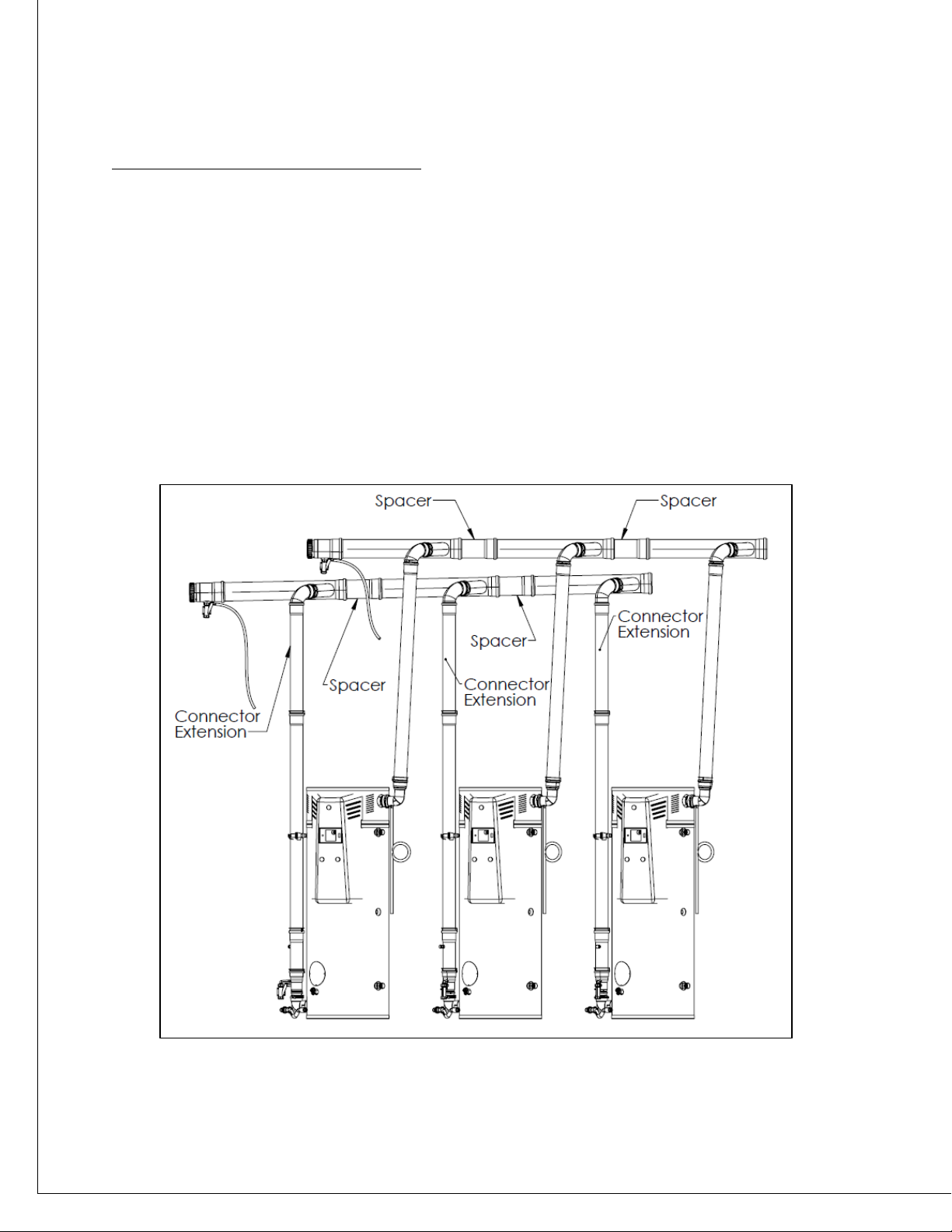

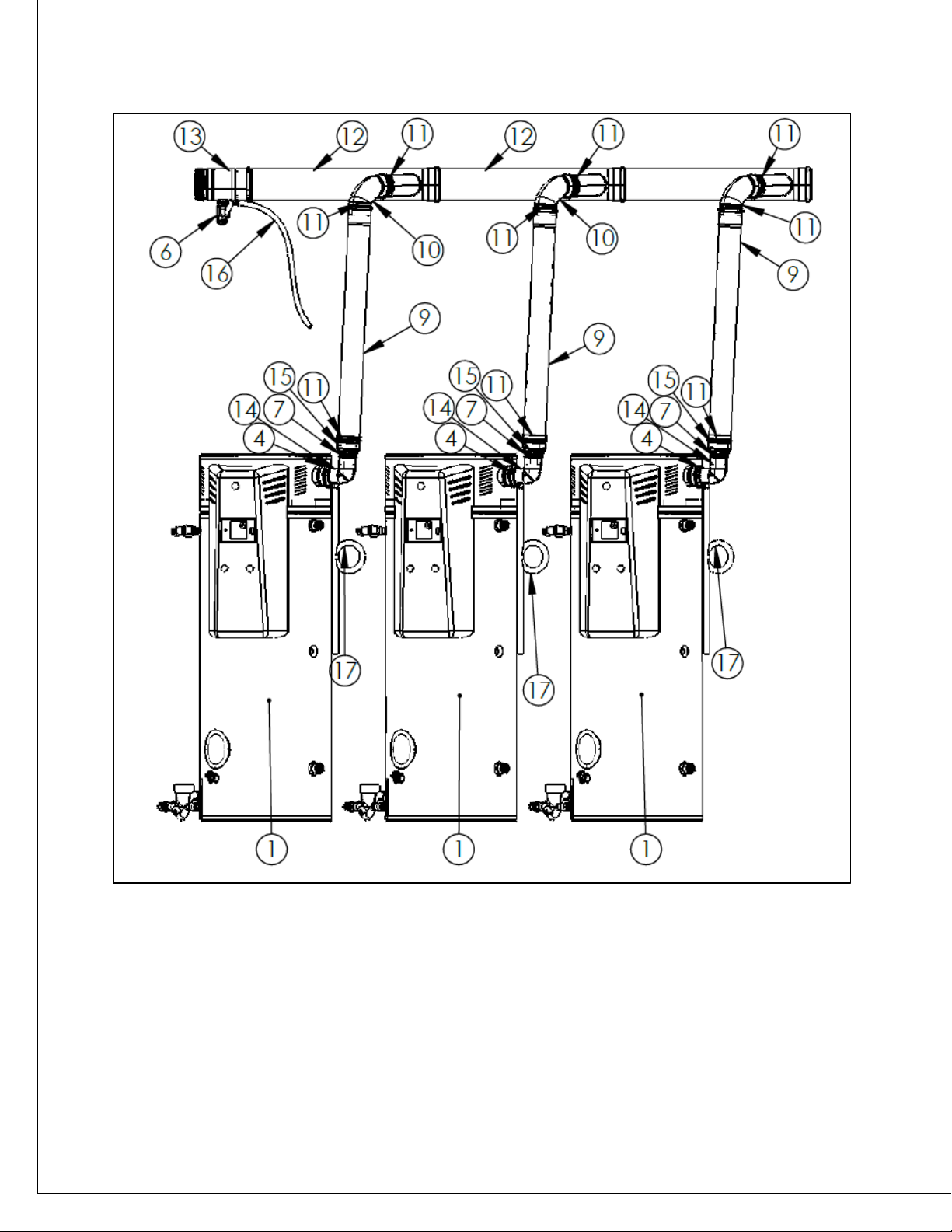

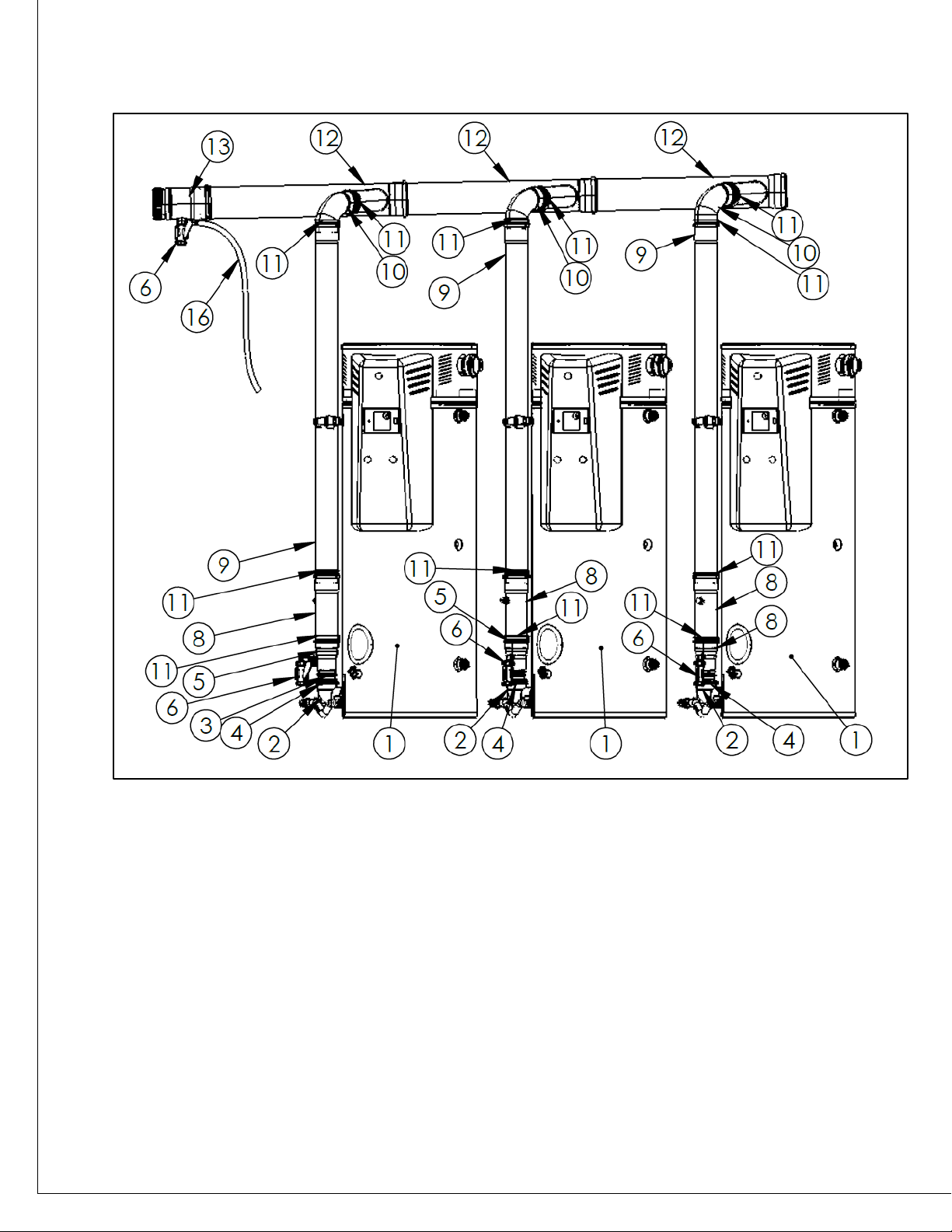

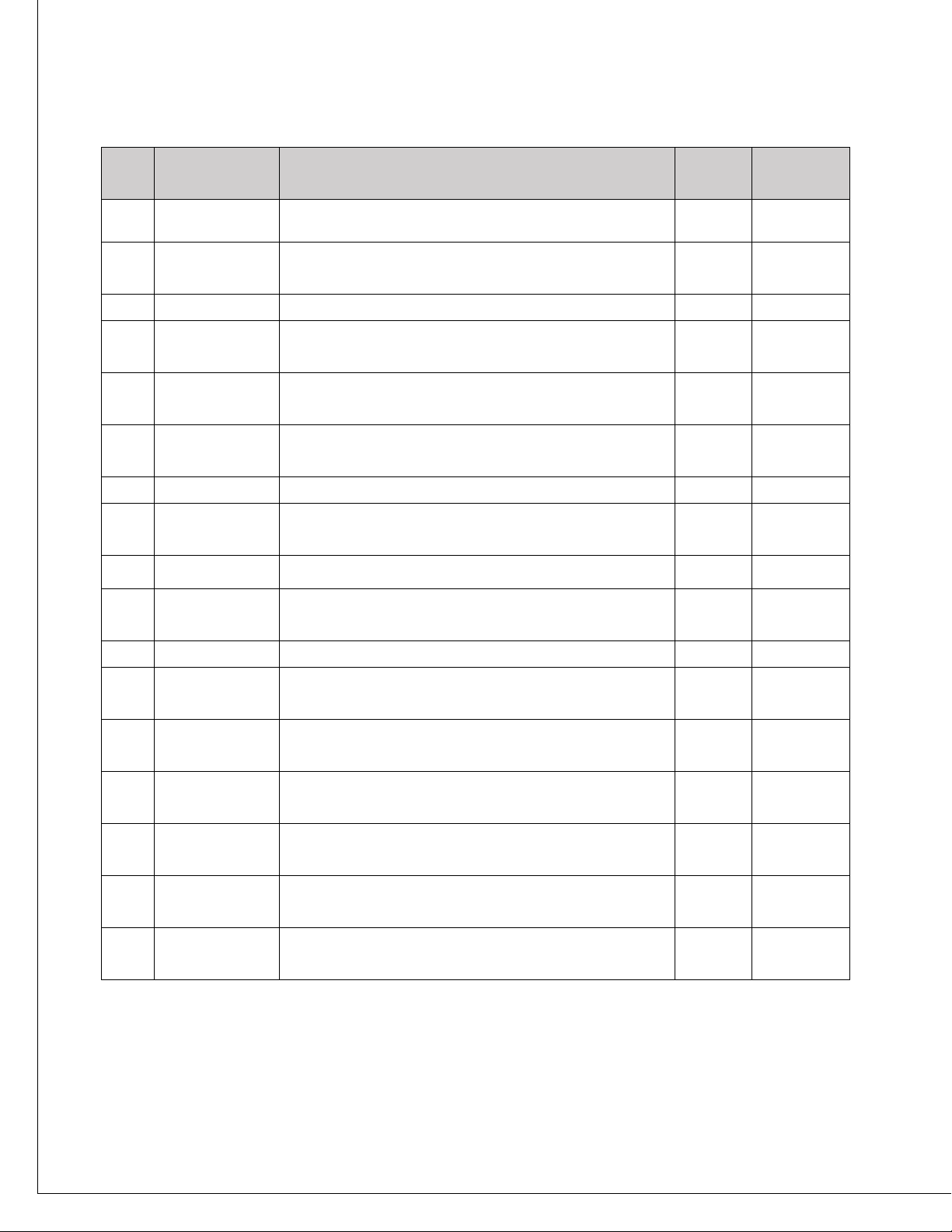

III. Overview

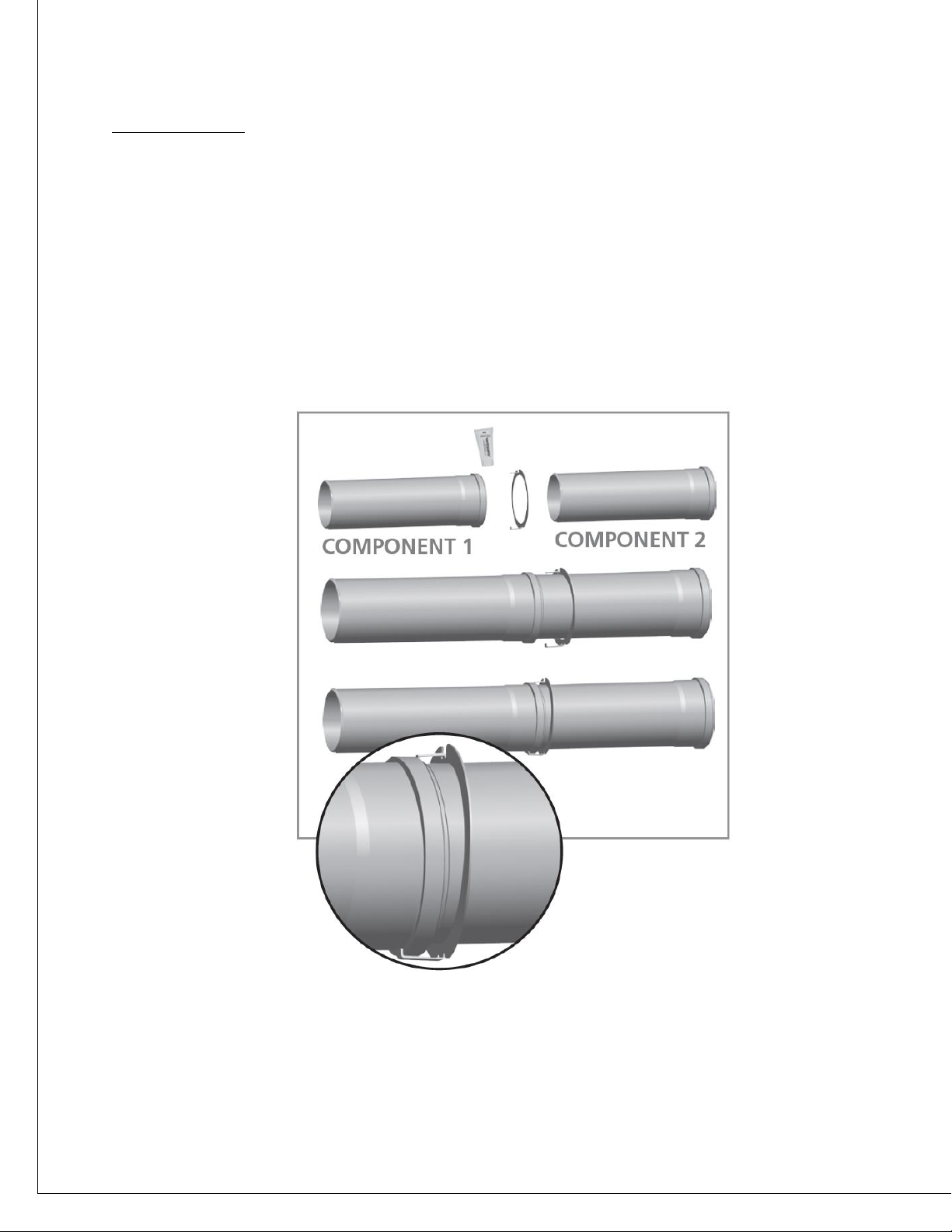

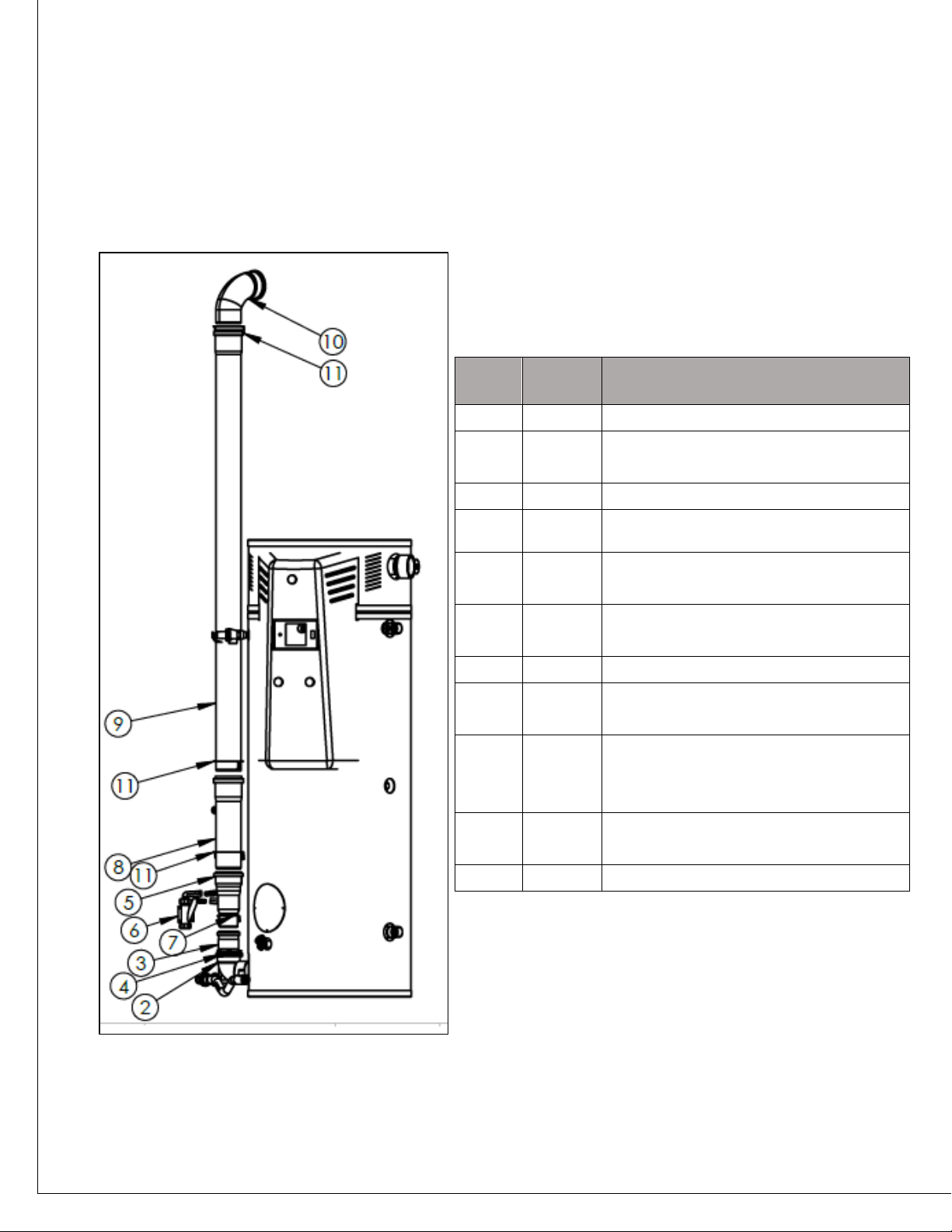

The Bock OptiTherm Common Vent Kits include all necessary parts to properly connect the vents

of two or three heaters and begin the common vent. These parts make up the vent sections

called connectors and headers.

a. Definitions

•Common vent: The section of intake/exhaust vent which carries combustion air/flue

gasses of multiple water heaters from/to outside. This section does not include the

Header section of the vent, is made up entirely of 6” vent pipes and fittings and is unique

to each installation.