Bodor BCL-X series User manual

User Manual for BCL-X Series Laser Machine

1

Laser Engraving and Cutting Machine

User Manual for BCL-X

Series

Jinan Bodor CNC Machine Co., Ltd

Adress: Huaya Industrial Park, Kanghong Road, High-Tech Zone, Jinan,

Shandong, China

ZIP: 250101

TEL: 0086-531-88690020

FAX: 0086-531-88690199

After-sales service:0086-531-88270377

Website:www.bodorcnc.com

User Manual for BCL-X Series Laser Machine

2

Brief Introduction of Laser Engraving Cutting Machine.................................................... 4

I Safety Knowledge..................................................................................................... 4

1.1 Basic Information.................................................................................................. 4

1.2 Optical Security............................................................................................. 4

1.3 Electricity Security........................................................................................ 4

II Equipment Brief Introduction............................................................................... 5

2.1 Instruction of Machine Model&Nameplate...................................................5

1. Model Instruction............................................................................................ 5

............................................................................................................................. 5

............................................................................................................................. 5

2. Nameplate Instruction......................................................................................6

2.2 Equipment Composition................................................................................ 6

2.3 Power Strip.................................................................................................. 15

III Equipment Installation..........................................................................................16

3.1 Installation Preparation................................................................................16

3.2 Installation procedure.................................................................................. 16

3.3 Grounding Connection................................................................................ 20

IV Test Equipment.....................................................................................................20

4.1 Inspect before powering on......................................................................... 20

4.2 Adjust light path...........................................................................................21

V Rotation axis processing........................................................................................ 28

VI Simple operation instruction................................................................................ 36

6.1 Software installation.................................................................................... 36

6.2 Data line using operation.............................................................................38

6.3 U disk operation...........................................................................................49

VII Equipment's maintenance....................................................................................52

7.1 Daily maintenance....................................................................................... 52

7.2 Water tank’s change and clean.....................................................................52

7.3 Exhaust fan’s clean...................................................................................... 52

7.4 Reflector’s and lens’ clean...........................................................................52

7.5 Guide rail's clean......................................................................................... 53

7.6 Light path's examination..............................................................................53

VIII CO2 glass laser tube's precautions for use.........................................................53

IX Common Breakdown Maintenance...................................................................... 54

Appendix 1................................................................................................................ 56

《After-sale warranty of Laser Engraving Cutting Machine》........................ 56

Appendix 2................................................................................................................ 59

Cutting and engraving parameters of laser tubes...............................................59

Postscript................................................................................................................... 62

《After-sale warranty of Laser Engraving Cutting Machines》.......................................62

User Manual for BCL-X Series Laser Machine

3

Preface

Thank you very much for your trust and purchasing our Products. We can provide perfect

after-sale service and solutions. Please keep this manual and other attachments carefully,

in order to guarantee the equipments safe running.

This manual is only applied to our company’s standard machines. With regard to special

customized machines, please read other reference material carefully.

This manual is written to demonstrate the issues about working principle, installation,

operation, failure removal, transport,storage, maintenance etc. Please read the manual

carefully, if you use the equipment the first time.

For quick and efficient using this equipment, the user should have qualifications as

below:

1. The user needs to know basic computer professional knowledge, and can operate

related editing and drawing software, such as Coreldraw, Photoshop, Autocad and so on.

2. The user should have basic optical knowledge and related electromechanical device's

maintenance knowledge.

3. Before starting the equipment, make sure this equipment's operation procedure is

known well and operate accordingly.

Because of equipments continuous updates, there may be some difference between your

equipments and equipments shown in the manual in some aspects. We apologize for the

convenience.

If you have any good suggestions or doubts, please log in our website

www.bodorcnc.com to leave a message or call us directly.

After-sales' Service:0086-531-88270377

User Manual for BCL-X Series Laser Machine

4

Brief Introduction of Laser Engraving Cutting

Machine

ISafety Knowledge

1.1 Basic Information

Make sure that the operator is being trained before operating the machine.

Operator must be aside the machine during machine working. Never leave the

machine alone in case to cause unnecessary loss.

1.2 Optical Security

Our laser equipment adopts the forth laser tube.Length of laser beam is 10.6μm. During

machine working, we recommend people related to wear authorized laser safety goggles.

Do not stare at the laser beam or anything beam reflected.

1.3 Electricity Security

Before connecting electricity, please check carefully the requirements on the

equipment's name plate, such as power,working voltage and so on.

Without our permission, please don't dismantle electrical apparatus elements on the

equipment, especially do not touch laser power and laer tube during machine

working. Because the equipment has fatal voltage when working, and danger can

still exist after disconnecting electricity.

1 Harm

Various potentially dangerous substance can be eliminated through ventilation system

during plastic material cutting. If smog or smell is too heavy, gas mask is needed.

2 Other Harm

Out of security consideration, equipment modification is forbidden without the

permission from the Manufacturer.

User Manual for BCL-X Series Laser Machine

5

II Equipment Brief Introduction

2.1 Instruction of Machine Model&Nameplate

1.Model Instruction

※※※一※※※※一※※

BCL1309X means standard serial laser cutting machines with 1300mm x 900mm

working area and up-down working table.

Machine Serial

BCL:

Bodor Cutting

Laser

BML:

Bodor Marking

Laser

Machine Working Area:

0503: 500mm×300mm

0605:600mm ×500mm

1006:1000mm×600mm

1309: 1300mm×900mm

1610: 1600mm×1000mm

… ……

Model Introduction:

M: Mini Machine Serial

X: Standard Machine Serial

B: Bed Machine Serial

FB: Fiber Laser Cutting

Machine Serial

YB/YT: High Power Metal

Cutting Machine Serial

FP/BM: Fiber Laser Marking

Machine Serial

Other Attachments:

U- with up-down working

table

F- automatic focus/fiber

generator

H- high speed guid rail

V- vac-sorb

A- auto feed

CCD- automatic logo

positioning cutting machine

P- separable style stone

engraving machine

S- screw machine

R-RF tube

G-glass engraving machine

D-die board cutting machine

User Manual for BCL-X Series Laser Machine

6

2.Nameplate Instruction

This serial equipment is vertically installed in the middle of the transmission shaft, which

can make speedy and stable cutting and engraving.The nameplate of machine is in the

right-back side. You can read the relevant information on it. It is not accepted for

anybody to change or remove this nameplate.

2.2 Equipment Composition

Declaration: Due to different models or new updates in products, there may be some

difference in appearance or some partial detail. Specific equipment is subject to

final product.

2.2.1 Composition of full set machine

A.Machine Shell B.Drive System C.Optical System D.Control System E.Spare Parts F. Tool

Box

Laser

Machine

Machine

Shell

Drive

System

Optical

System

Control

System

Spare

Parts

Tool

Box

This number is only for each machine

User Manual for BCL-X Series Laser Machine

7

2.2.2 Machine Shell

Right/Left Shield; Side Door; Up Cover; Transom(X Axis); Carling (Y Axis);

Working Table.

Working

Side

Front Door

Transom

Carling

User Manual for BCL-X Series Laser Machine

8

2.2.3 Drive System:

Y Axis:

Back

Smoke

Entrance

Name

Universal

Wheel

Foot

USB Flash Interface

Computer Interface

User Manual for BCL-X Series Laser Machine

9

X Axis:

Guide Rail

Girdle

48 tooth

Synchronizin

g Wheel

Motor

Transmissio

n

24 tooth

Synchronizing Wheel

belt

Guide Rail

Belt

Mot

or

Pinion Stand

Endless-belt

Couple

r

24 tooth

Synchronizing

Wheel

48 tooth Synchronizing

Wheel

User Manual for BCL-X Series Laser Machine

10

2.2.4 Optical System

Attention:

The laser tube is fragile. It should be taken slightly. Water inlet of the laser tube should be

in the lower place, and water outlet be in the higher place(reci laser tube), so there won't

be any bubble. The laser tube socket should be installed with even force which can just

make the tube secure. Do not overexert, it may crush the laser tube.

Attention:

The front surface of reflection mirror should be faced to the laser outlet.

Laser Tube

Reflection Mirror

Laser outlet

Cathode rays

Reflection Mirror frame

Laser Tube Socket

User Manual for BCL-X Series Laser Machine

11

Attention:

The working-voltage of high-tension cable can be higher than 100,000V.There can be

strong static electricity even when the power was cut-off in short time. Please do not

touch the cable directly.

Installation picture of RECI laser tube

Attention:

Before working, please adjust the focal length. Put the focal length in the middle of

working material and laser outlet before working. Convex surface should be faced to working

material when installing focus lens.

High-tension cable

High-voltage insulation protective jacket

Water-in

Water flow direction

Red dot position

Air compressor

control valve

Focus Lens

3rd Reflection

Mirror

Focal length adjusting

tool

User Manual for BCL-X Series Laser Machine

12

2.2.5 Control System

There are some difference in the control system for different models.Specific product is

subject to real object.

Bodor's control system is as below:

Leetro control system;

Ruida control system;

Bodor control system.

Leetro control panel Ruida control panle

Leetro control board Ruida Control Board

User Manual for BCL-X Series Laser Machine

13

2.2.6 Spare parts

Water Chiller Exhaust fun Air compressor

Filter

48V Switch power

X Axis Motor Drive

Y Axis Motor Drive

Z Axis Motor Drive

System card board

Relay

DC24V and 5V

Power

Laser

Power

Emergency

Switch

Ammeter

Potentiometer

Start Button

User Manual for BCL-X Series Laser Machine

14

2.2.7 Tool Box

Attention: There can be some difference in toolbox for different models. Specific parts

are subject to real objects.

Proximity Switch&Inching Switch

Shovel Blade Usage Focus Block Usage

Certificate

Approval

Data

Power

Limit Swith

Double-sided

Adhesive Tape

High-tension

Adhesive

Tape

U Disk

CD

Water/Air Tube

Fork

Wrench

Hexwrenc

Shove

l

Focus

Block

Dimming

Block

User Manual for BCL-X Series Laser Machine

15

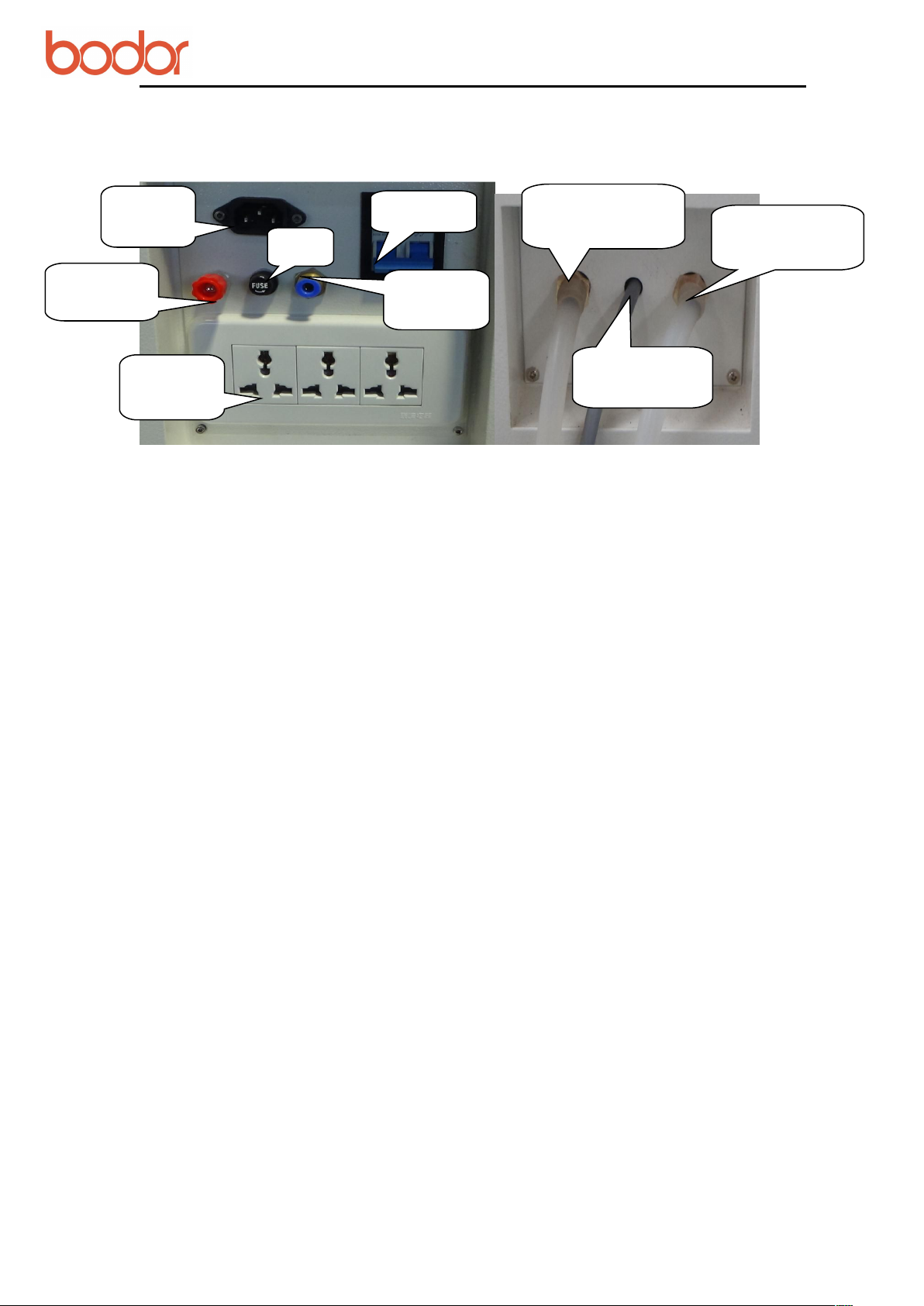

2.3 Power Strip

Air Switch

Power

Interface

Abalone

Socket

Ground

Line

Air-tube

Interface

Fuse

Water Chiller

Signal Line

Outlet Connecting

Water Chiller

Inlet Connecting

Water Chiller

User Manual for BCL-X Series Laser Machine

16

III Equipment Installation

3.1 Installation Preparation

3.1.1 Preparation for workplace

Make sure the working area is dry enough. And any electromagnetism, strong power,

pollution is forbidden. Temperature of working environment should be 10℃to 38℃,

humidity should be 10- 90%. AC 220V±10%, 50HZ, resistance to ground less than 5Ω.

3.1.2 Preparation for operator

We demand the operator must be professional technician. If the users want to install the

equipment on their own, they need to have training from our technicians and completely

master the knowledge of installation.

3.1.3 Preparation for tools

There is already a tool box with this machine. Besides, multimeter and screwdriver and

other detection tools are needed.

3.1.4 Other preparation

The users need to prepare relevant material,including purified water or distilled water for

water chiller, power strip, computer,pipe for discharge smoke, sample material, etc.

Attention: The users need to accompany all the time when our technicians install the

equipment. The users need to grasp the skills of installation and commissioning which

are the part of training.

3.2 Installation procedure

3.2.1 Package of laser tube

Laer tube package:

In case of damage during transportation or outside force, the tube is packed with sponge.

And two ends of tube are sealed with zip lock bag to prevent the mirror from pollution or

scratch. Finally, the tube is built up with sponge supports to prevent tube have direct

contact with surrounding.

User Manual for BCL-X Series Laser Machine

17

Laser tube devanning:

Open the carton box, take out the laser tube. Both hands hold the middle of the tube; take

off the sponge supports; take off the packing sponge; take off the zip lock bag. Then

inspect whether the tube is intact.

Attention: It needs as least two persons when unboxing. Handle the tube with care.

3.2.2 Installation of Laser tube

Move the equipment to the back place, so as to install the laser tube easily.

The laser tube is installed in the back of crossbeam.Open the laser tube protective cover.

You can see two laser supports, two water pipes, a black color low-tension line and a red

color high-tension line.

Low-tension line High-tension line

Laser tube installation:

1.Take off the screw from the two laser support which are used for fitting the laser tube.

2.Put the outlet(low-tension part) of the laser tube on the base facing to the first reflected

mirror.

3.Buckle the upper part of the laser tube support, tighten the screw, connect the

high-tension&low-tension line and outlet&inlet water tube.

4.Fix the laser tube.

Attention:

Keep the laser tube outlet clear in case of front mirror breakdown. The broken

damage caused by improper operation, will not be in Bodor's range of protection.

Fix the laser tube with proper strength. Larger strength will broke the laser tube.

Keep the laser tube water inlet in the lower place, and the water outlet in

the higher place(in the upper section of laser tube). Come in from the bottom, out

from the top as shown in the above picture.

Water tube joints must be connect well avoiding water leaking. Water tube must be

straightened.

Handle laser tube carefully when installing.High-tension wire and cathode rays

should be fastened enough.Water inlet should be in the bottom and water outlet in the

top. Make sure there is no air bubble in the laser tube. Use even force on the two

sides when pushing laser tube sockets to fix the laser tube. Do not use too much

force avoiding the damage of laser tube.

User Manual for BCL-X Series Laser Machine

18

3.2.3 Installation of Water Chiller

▲ First take down the cover of water inlet on the top of the chiller. Pour purified water or

distilled water into the water tank until it is full.

▲ Then complete the connection of water cycle pipelin by connecting the water outlet of

the chiller with the water inlet of the machine, and the water inlet of it with the water

outlet of the machine.

▲ Finally, connect the holding wire and the water chiller power line.

Pressing the rocker switch after electrifying the chiller, you can hear sound like

"didi...".Then the water in the tube will flow from high-tension terminal to low-tension

terminal. Then the green indicator light on water chiller will be on. The system works

well if the alarm does not ring.

Attention:

When working, the water must flow from the high-tension to the low-tension.

Otherwise, it may damage the laser tube.

When the power is on, the bubble in the tube can be removed by extruding the water

pipe or turning the laser tube.

When machine is working or shut down, please do not touch the high-tension line. It

may still have high power and may threat to life.

Chiller installation: water-inlet in the top side, water-outlet under the back below side

3.2.4 Installation of Exhaust Fan and Air Pump

Installation of Exhaust Fun

Connect the air inlet of the fan with exhaust port by the air duct and screw tightly with

spanner. Then connect the outlet of the fan by the other air duct and lead it out of the

room. The installation is as shown in the below.

display

Water inlet

green indicator

light

Water-outlet

Water-in

Alarm

Power line

Ship type switch

Water-out

Alarming line

User Manual for BCL-X Series Laser Machine

19

Installation of Air Pump

Insert the silicone tube into the air-inlet by an air tube. Then connect the power and make the smooth

air-out of the air entry in the leaser head as shown in the below picture.

Air pump (air compressor) is very important in the system. High-pressure air sprays from

the light outlet of laser head through air tube. On one hand, it can keep the focus lens

clear enough. On the other hand, it can prevent working material from burning. Please

make sure the rubber tube is intact during machine working. Otherwise it may cause

burning of the materials.

Screw tightly

with spanner

User Manual for BCL-X Series Laser Machine

20

3.2.5 Installation of accessory

3.3 Grounding Connection

Grounding requirements for the equipment are very strict. Your local electric system

must meet the local electric security standard.

L : 220V Live line; Phase line

N : Zero Line, compose the electric system together with phase line

E: Grounding line, connect every grounding part of electricity consuming

accessories,resistance to ground should be less than 4 Ω

Attention:

Nonstandard grounding may lead to high failure rate and other security accidents. All

these are not in the range of Bodor's protection.

IV Test Equipment

4.1 Inspect before powering on

Before powering on, please inspect and make sure all electric wire terminals are intact.

Name Plate

Water Chiller

Air pump

Exhaust Fun

Table of contents

Other Bodor Cutter manuals