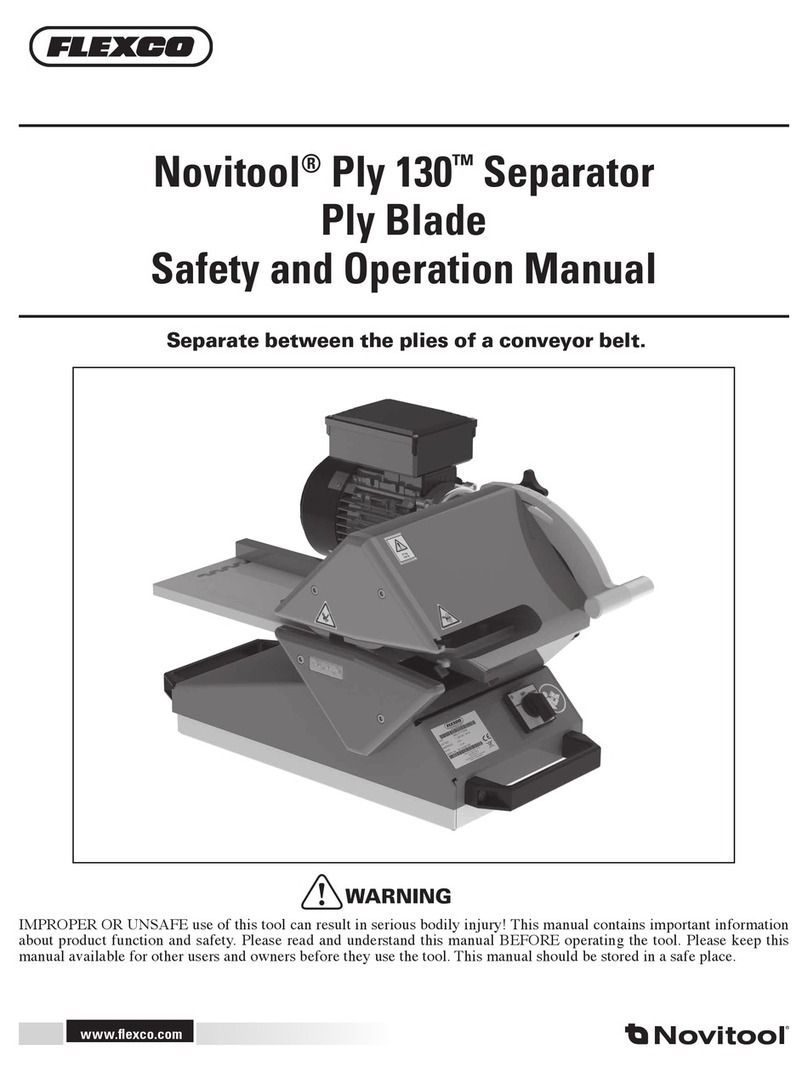

Novitool Ply 130 Guide

Ply 130™Step Cutter

Safety and Operation Manual

www.flexco.com

www.flexco.com

Preparing Stepped Belt Edges for Splicing

IMPROPER OR UNSAFE use of this tool can result in serious bodily injury! is manual contains important information

about product function and safety. Please read and understand this manual BEFORE operating the tool. Please keep this

manual available for other users and owners before they use the tool. is manual should be stored in a safe place.

WARNING

www.flexco.com

—2—

Table of Contents

Main Components Ply 130™ Step Cutter

.................................................3

Description..................................................................................................... 4

Specications.................................................................................................. 4

Tools Required for Installation....................................................................4

General Safety Rules...................................................................................... 5

Installation of New Faceplate....................................................................... 7

Installation of Scale .....................................................................................10

Installation of Step Cutting Blade..............................................................11

Installation of the Step Cutter....................................................................12

Operation of the Step Cutter......................................................................15

Troubleshooting...........................................................................................16

Warranty.......................................................................................................16

Disclaimer e Ply 130 Step Cutter has been tested successfully with the Ply 130 WB.

It is intended for use only with Ply130 ply separators manufactured by Flexco.

—3—

Main Components Ply 130™Step Cutter

No. Item No. Description

1 08501 PLY130-STEPCUT

2 08499 PLY130-STEPCUT-RETROFIT

3 08498 PLY130-STEPCUT-GUIDE-EXT

4 08500 PLY130-STEPCUT-TWRENCH

5 08497 PLY130-STEPCUT-BLADES (5)

5 4 3 2 1 0

13 12 11 10 9 8 7 6 5 4 3 2 1 0

1 2 3 4 5

www.flexco.com

—4—

Specifications

Description

With the Ply 130 Step Cutter you are in possession

of a quality Novitool® product from Flexco. e

carefully developed and built machine gives you

the option of the highest quality conveyor belting

fabrication. By adding the Step Cutter to the Ply 130

ply separator, you can now maximize productivity

with fast, repeatable creation of stepped edges in

preparation for endless or mechanical belt splicing.

e Ply 130 is able to separate belt edges. It is

normally used for preparing a stepped splice. By

means of the Step Cutter, the layer passing above the

separation blade can be cut o simultaneously with

the separation process. is operation is commonly

used for preparing stepped splices or recessed

mechanical belt fasteners.

Two Step Cutter models are available. One is a

retrot model (Item 08499) for Ply 130 separators

manufactured without a Step Cutter interface (T-slot

on inside of faceplate). For units manufactured with

this interface, the Step Cutter (Item 08501) is an

optional feature available for purchase.

Ply 130 Step Cutter Ordering Information

Item Number Description Shipping Weight

08499 PLY130-STEPCUT-RETROFIT 4.1 lbs. (1.9 kg)

08501 PLY130-STEPCUT 2.7 lbs. (1.2 kg)

Optional Items Ordering Information

08497 PLY130-STEPCUT-BLADES (5) 0.15 lbs. (0.07 kg)

08498 PLY130-STEPCUT-GUIDE-EXT 1.6 lbs. (0.7 kg)

08500 PLY130-STEPCUT-TWRENCH 0.2 lbs. (0.09 kg)

Tools Required for Installation

Item 08499 PLY130-STEPCUT-RETROFIT

• Plastic Hammer

• 5 mm Hex Wrench

• Torque Wrench

—5—

Signal words:

“DANGER” indicates an imminently

hazardous situation which, if not avoided, will

result in death or serious injury. is signal

word is limited to the most extreme situations.

“WARNING” indicates a potentially

hazardous situation which, if not avoided,

could result in death or serious injury.

“CAUTION” indicates a potentially hazardous

situation which, if not avoided, may result in

minor or moderate injury. It may also be used

to alert against unsafe practices.

Safety Symbol

!

is international safety symbol is used to

identify and call attention to specic

safety matters.

Safety Information

To Avoid Severe Personal Injury or Property

Damage, read carefully and understand the

following Safety Precautions.

General Safety Rules –Save These Instructions–

1. WORK AREA

!cAutIoN

Keep your work area clean and well lit.

Cluttered benches and dark areas

inviteaccidents.

!dANGeR

Do not operate power tools in explosive

atmospheres, such as in the presence of ammable

liquids, gases, or dust. Power tools create sparks

which may ignite the dust or fumes.

2. ELECTRICAL SAFETY

!dANGeR

e Ply Separator is a single insulated tool and

needs a multiple wire grounded power cord

and grounded power supply system. Contact

a qualied electrical installation company to

connect the right plug.

!WARNING

Do not use outdoors. is power tool is

designed for indoor use only.

3. PERSONAL SAFETY

!WARNING

Use safety equipment. Always wear eye

protection. Dust mask, non-skid safety shoes,

hard hat, or hearing protection must be used for

appropriate conditions.

Stay alert, watch what you are doing and use

common sense when operating a tool. Do not

use tool while tired or under the inuence of

drugs, alcohol, or medication. A moment of

inattention while operating tools may result in

serious personal injury.

www.flexco.com

—6—

Check for misalignment or binding of moving

parts, breakage of parts, and any other condition

that may aect the tool’s operation. If damaged,

have the tool serviced before using. Poorly

maintained tools cause many accidents.

e Ply Separator should not be used to split

other materials than thermoplastic belting

materials. e thickness of the belting material

should never exceed 10 mm.

5. SERVICE AND MAINTENANCE

!WARNING

Only qualied repair personnel must perform

tool service. Service or maintenance performed by

unqualied personnel could result in a risk of injury.

Always wear cut-proof safety gloves (according to

EN388, Coded X.5.X.X) and safety glasses.

!cAutIoN

Maintain tools with care. Keep blades sharp

and clean. Properly serviced tools and knives

with sharp edges are less likely to bind or clutter

material and are easier to control.

When servicing a tool, use only original

replacement parts. Use of unauthorized parts or

failure to follow Maintenance Instruction, may

create a risk of injury.

6. REPLACING THE BLADE

!WARNING

Always wear cut-proof safety gloves (according

to EN388, Coded X.5.X.X) and safety glasses

when replacing blade. Blade is razor sharp, treat

itaccordingly.

Safely store spare blades.

Do not attempt to re-sharpen blades. is will

aect splitting completely through belt.

General Safety Rules -Save These Instructions-

3. PERSONAL SAFETY (continued)

!WARNING

Dress properly. Do not wear loose clothing

or jewelry. Contain long hair. Keep your hair,

clothing, and gloves away from moving parts.

Loose clothes, jewelry, or long hair can be

caught in moving parts.

Never alter or remove safety devices.

4. USE AND CARE

!WARNING

Read and understand the Ply 130 Operations

Manual before using the Step Cutter with the

Ply130.

Keep your hands away from the Ply 130

traction rolls and splitting area. Always guide

the material in a way that your hands have

a minimum distance of 3.94” (10 cm) from

thisarea.

cAutIoN

Only operate the Ply 130 with it being fastened

to a level, rm surface. Splitting should be

performed operating the machine with two

hands on the material.

Disconnect the plug from the power source

before making any adjustments, changing

accessories, or storing or transporting the tool.

Such preventive safety measures reduce the risk

of starting the tool accidentally.

NEVER use a tool, which is defective or

operating abnormally. If the tool appears to be

operating unusually, making strange noises,

or otherwise appears defective, stop using it

immediately and arrange for repairs.

Do not use tool if switch does not turn it on or

o. Any tool that cannot be controlled with the

switch is dangerous and must be repaired.

!

—7—

www.flexco.com

Installation of New Faceplate - Retrofit Kit Only

A

Caution! Disconnect Ply 130 plug from the power source. Remove two

screws from existing top faceplate on Ply 130.

Lightly tap at back edge of top faceplate with a plastic hammer until a small

opening appears in between top cover plate and Ply 130 body. A small plastic

chisel may be required if the faceplate is a tight t.

A1

A2

www.flexco.com

—8—

B1

B1

Installation of New Faceplate - Retrofit Kit Only

A4

While tapping back edge of faceplate, alternate low pulling force on each side

of faceplate until removed. Discard removed faceplate. Ensure ngerguard

and dowels are installed in the Ply 130 body as shown before installing the

Step Cutter faceplate.

With traction roller and dowel pins properly aligned, mount Step Cutter

faceplate at to Ply 130 body, lightly tapping with plastic hammer if

required. Warning! Do NOT use screws to pull faceplate to Ply 130 body!

A3

—9—

Installation of New Faceplate - Retrofit Kit Only

Using a torque wrench, reinstall two screws at 2.9 -lbs (4 N-m) torque

maximum, xing retrot faceplate to Ply 130 body.

A5

www.flexco.com

—10—

Installation of Scale - Retrofit Kit Only

B

B2

Clean top surface of Ply 130 body nearest to infeed table.

Remove backing paper from scale decal and install on Ply 130 body. Align

to edge of Ply Separator body as indicated above.

B1

—11—

C

Installation of Step Cutting Blade

Loosen blade retention setscrews using 2.5 mm hex wrench. Do not loosen

the at head screw on opposite side.

Carefully insert step cutting blade into position, aligning edge of blade

even with step cutter face to ensure proper blade position. Tighten blade

retentionsetscrews.

C1

C2

www.flexco.com

—12—

Installation of the Step Cutter

D

D2

Ensure that Step Cutter blade position is adjusted ush to T-nut side of unit.

Loosen (do not remove) Step Cutter T-nut screw. Align Step Cutter T-nut with

T-groove in faceplate and insert until tab contacts faceplate. Caution! Step

Cutter should slide in T-slot with ease and not be forced.

D1

—13—

Installation of the Step Cutter

Using the T-handle hex wrench, tighten Step-Cutter T-nut screw. Reposition

Ply 130 adjustment handle if required for improved access.

If necessary, use the 2.5 mm hex wrench to loosen screw and adjust lateral

position of step-cutting blade near to, but not contacting ply separation

blade. Tighten screw to x blade position. If ply separation blade is replaced

(Refer to Ply 130 Safety and Operations Manual for instructions), correct

position of step-cutting blade should be conrmed.

D3

D4

www.flexco.com

—14—

Installation of the Step Cutter

D6

Install Guide Extension for step cutting less than 1.57” (40 mm). Loosen belt

guide xing screws.

Li belt guide and insert guide extension under guide. Position guide to

desired step cutting possition and tighten belt guide xing screws.

D5

—15—

E

Operation of the Step Cutter

Test Step Cutter using a two-ply, PVC belt. e belt material passing over the

ply separation blade should be cut from belt at step cutter blade position and

a small undercut will remain.

Near end of step cut, operator must assist nal few millimeters of belt

material through step cutting blade, taking care to guide belt straight.

E1

E2

www.flexco.com

—16—

Ply 130™Step Cutter Safety and Operation Manual

• If the material passing above the ply separation blade is not being cut at the step cutter

bladeposition:

– xation screw is loose and Step Cutter may require repositioning, or

– step cutter blade may require adjustment towards ply separation blade, or

– step cutter blade may not be seated correctly in the Step Cutter unit, or

– step cutter blade may be worn, requiring replacement.

• If the belt cover is very thin or has little stability (e.g. w/o fabric), step cut may become wavy.

is is subject to the material, machine settings, and can be dicult to avoid.

• If belt material becomes stuck in the ply separator, rotate the Ply 130 power switch to the

reverse position, to dislodge the material. Inspect step cutter blade position aer dislodging

material and making adjustments as needed.

Troubleshooting

Warranty provided is limited to defects in materials and workmanship.

e warranty has a maturity of one year from the date of delivery. In this period the necessary

parts will be made available free of charge. Any further warranty claims, damages, consequential

damages are excluded.

e above warranty shall apply exclusively and only under the following conditions:

• An expert according to the conditions and standards of the competent authorities must install

the appliance.

• Any warranty claims are forfeited when performing repairs, modications or adaptations

and or assembling unapproved components without the prior consent of Flexco. In addition,

any warranty claims are forfeited when installed by way of deviation from the national and

localregulations.

• Claims during the warranty period provide no extension of the warranty period.

Warranty

2525 Wisconsin Avenue • Downers Grove, IL 60515-4200 • USA

Tel: (630) 971-0150 • Fax: (630) 971-1180 • E-mail: info@exco.com

Visit www.flexco.com for other Flexco locations and products.

©2013 Flexible Steel Lacing Company. 09-13. For reorder: X3407

Other manuals for Ply 130

1

Table of contents

Other Novitool Cutter manuals