_1 _

Foreword

This Owner’s/ Operator’s Manual is designed to familiarize the operator with the various features and com-

ponent parts of the equipment and to assist you with the assembly, operation and maintenance of your new

Multi-cutter.

It is essential that any operator of this Multi-cutter reads and understands the contents this manual before

using the Multi-cutter.

For additional assistance, contact any local authorized BUSHRANGER dealer.

Important Notice

The benets to the consumer given by this warranty are in addition to other rights and remedies of the con-

sumer under a law in relation to the goods or services to which this warranty relates. Our goods come with

guarantees that cannot be excluded under the Australian consumer law. You are entitled to a replacement

or refund for a major failure and for compensation for any reasonable foreseeable loss or damage. You are

also entitled to have the goods repaired or replaced if the goods fail to be of acceptable quality and the

failure does not amount to a major failure.

Contents

Page

Foreword ......................................................... 1

Contents .......................................................... 1

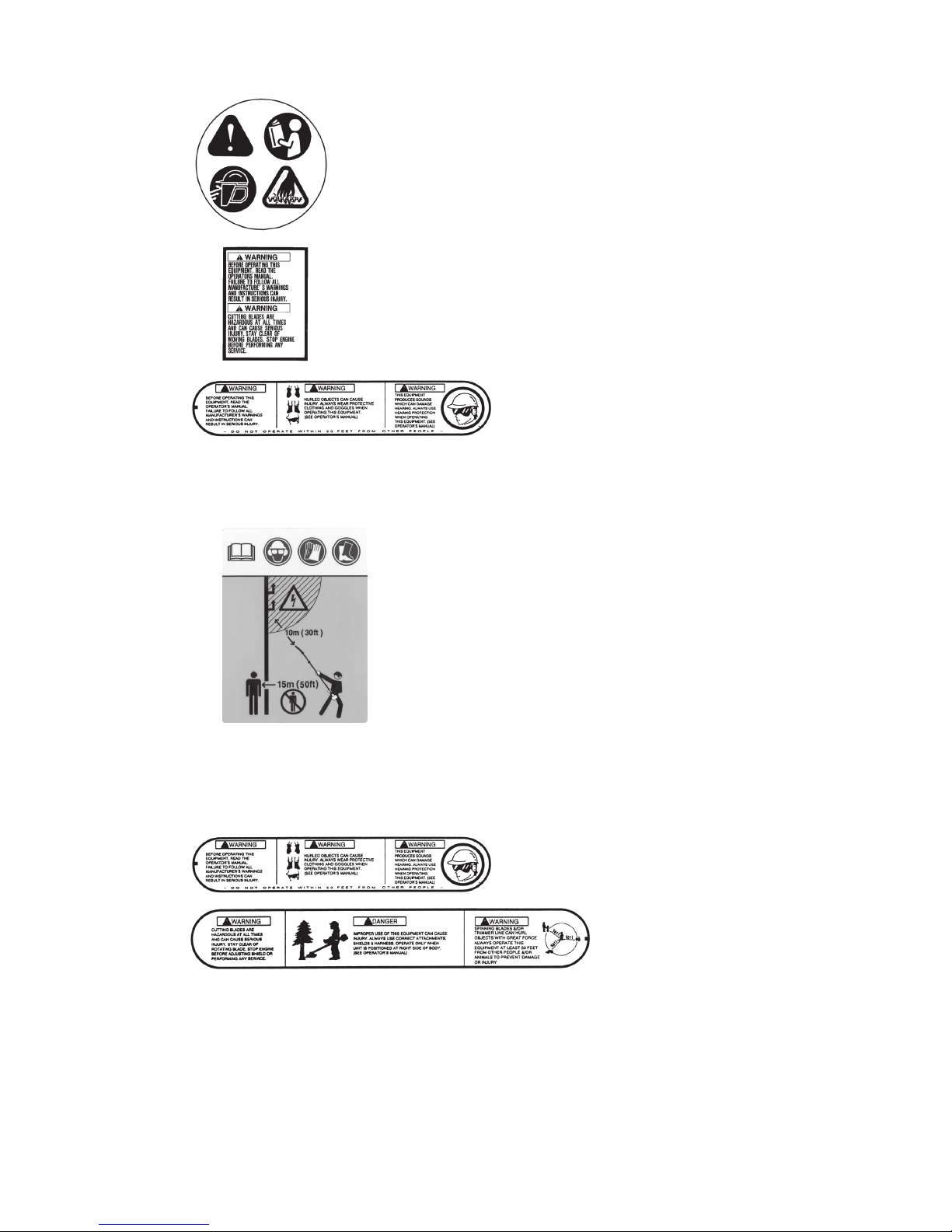

Safety Instructions........................................... 2

Operator safety............................................ 2

Multi-cutter safety ........................................ 2

Fuel safety ................................................... 3

Multi-cutter Operating Safety....................... 3

Safety and Instruction Decals ..................... 4

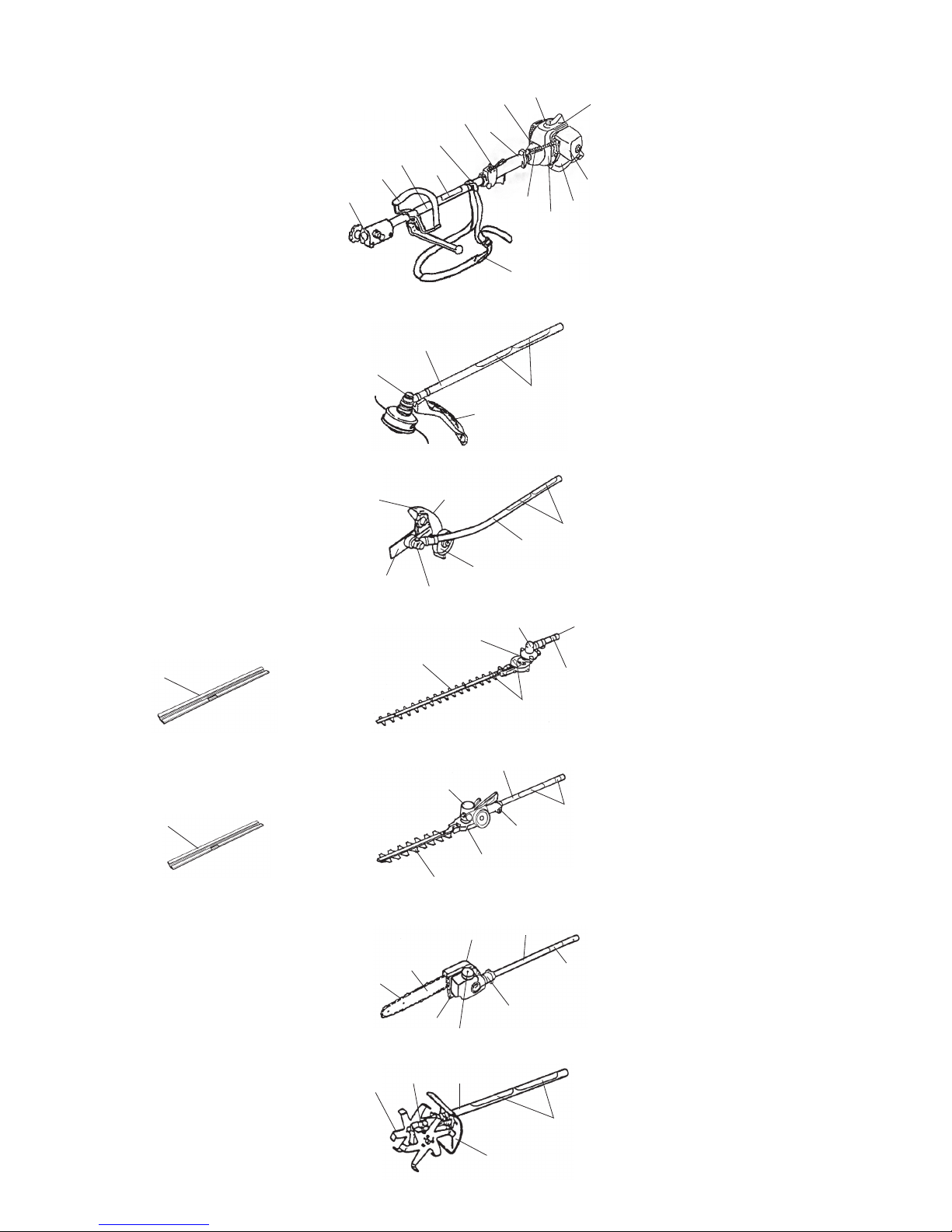

Product Description… ..................................... 6

Assembly......................................................... 7

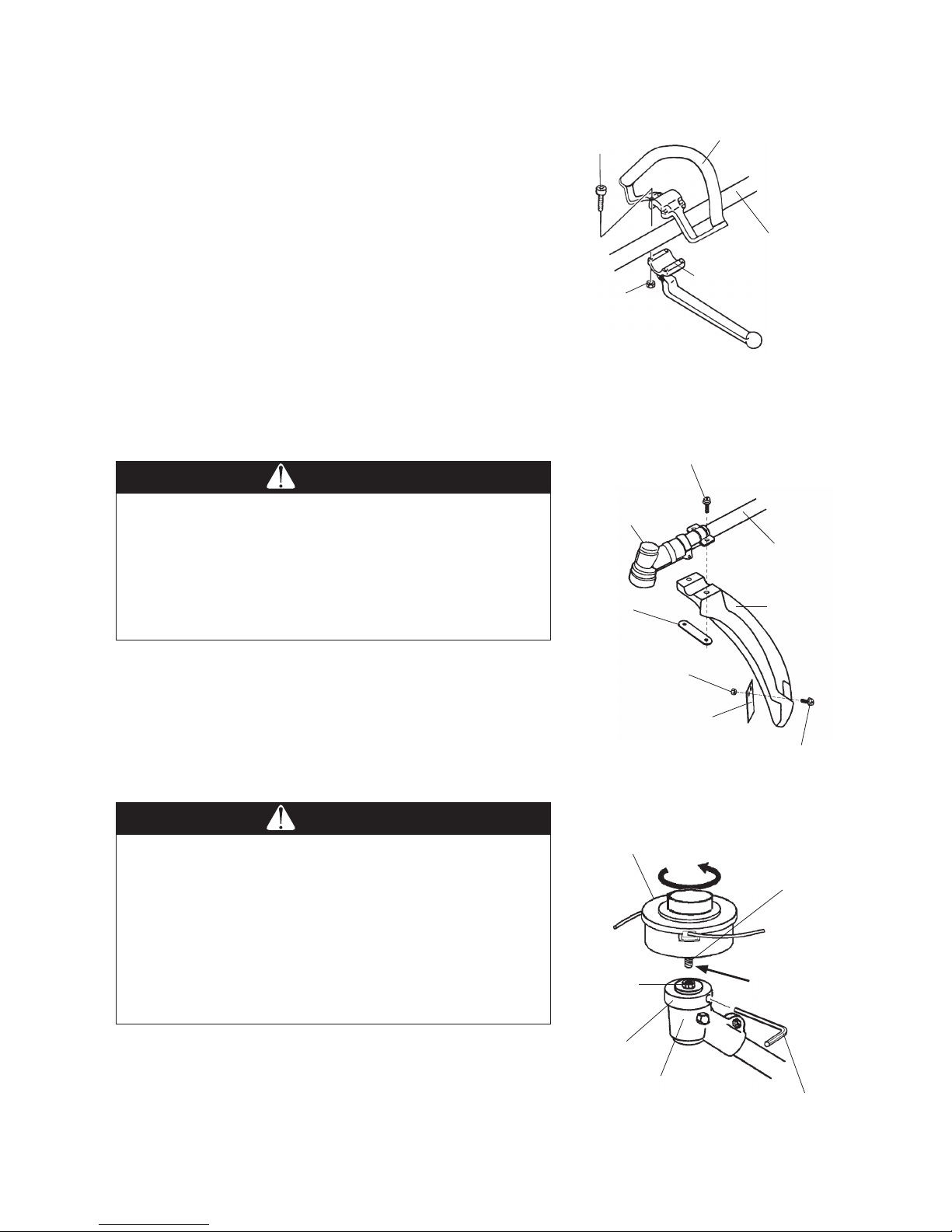

Loop Handle Installation ............................ 7

MC-S (Straight Shaft Attachment) .............. 7

MC-E (Edger Attachment) ......................... 9

MC-HTS(Hedge Trimmer Attachment) ....... 9

MC-PX/PS/PL (Pruner Attachment) ......... 10

MC-T (Cultivator Attachment) .................. 11

Attaching Shoulder Strap.......................... 12

Connecting the Tool Attachment

to the Power Unit ..... 12

Before Operation ........................................... 13

Chain Oil (Pruner Attachment).................. 13

Engine Oil and Fuel ………………………..14

Mixing Petrol and Oil................................. 15

Starting and Stopping ............................... 16

Idle Speed Adjustment.............................. 17

Page

Operation ...................................................... 18

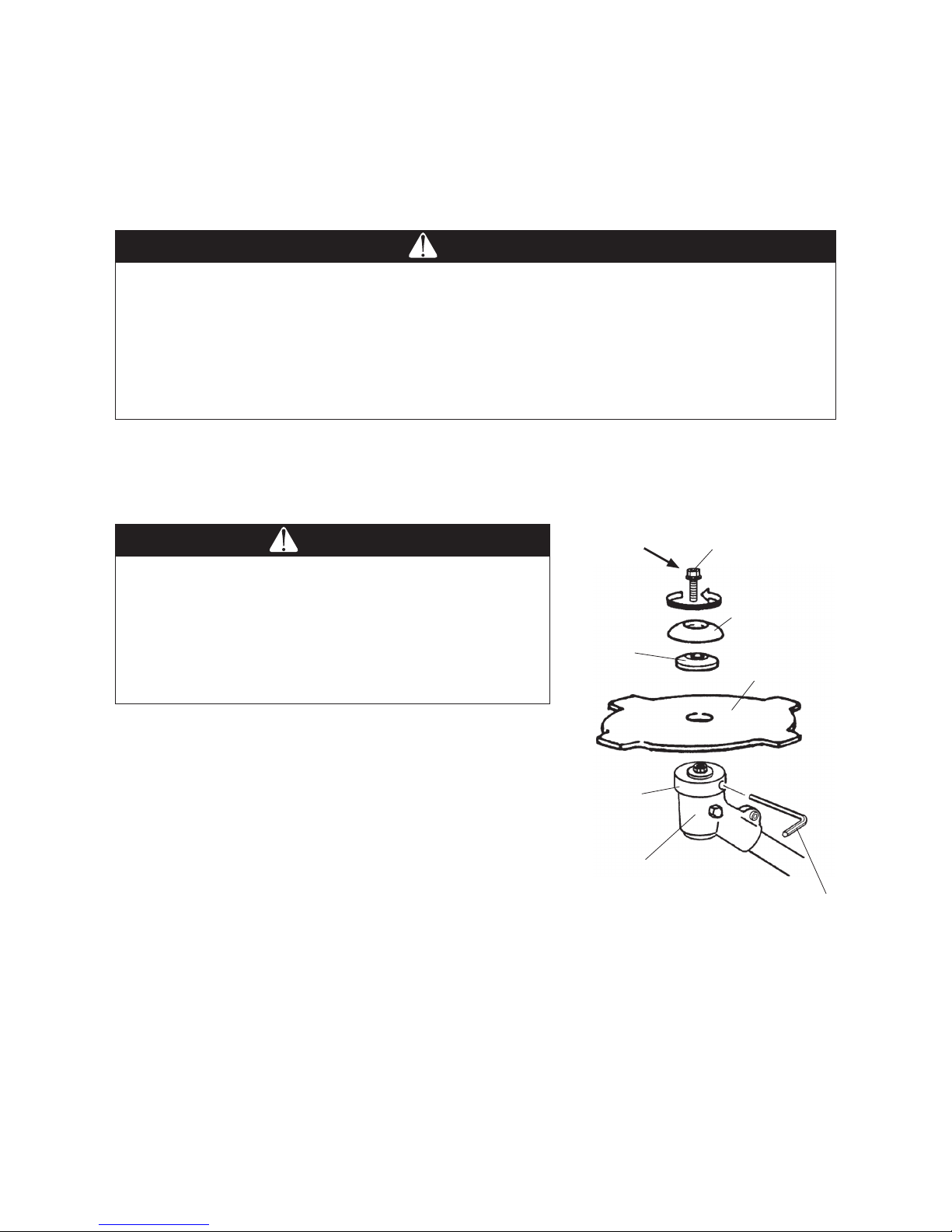

MC-S (Straight Shaft Attachment) ............ 18

MC-E (Edger Attachment) ....................... 21

MC-HT/MC-HTS

(Hedge Trimmer Attachment) ............... 22

MC-PX/PS/PL (Pruner Attachment) ......... 24

MC-T (Cultivator Attachment) .................. 26

Maintenance ................................................. 27

Air Filter ................................................... 27

Fuel Filter.................................................. 27

Spark Plug ............................................... 28

Cylinder Cooling Fins................................ 28

Spark Arrester .......................................... 28

MC-S (Straight Shaft Attachment) ............ 29

MC-E (Edger Attachment) ....................... 29

MC-HT/MC-HTS

(Hedge Trimmer Attachment) ............... 30

MC-PX/PS/PL (Pruner Attachment) ......... 31

MC-T (Cultivator Attachment) ................... 33

General Cleaning and Tightening ................. 33

Storage.......................................................... 33

Troubleshooting............................................. 34

Specifications ................................................ 34