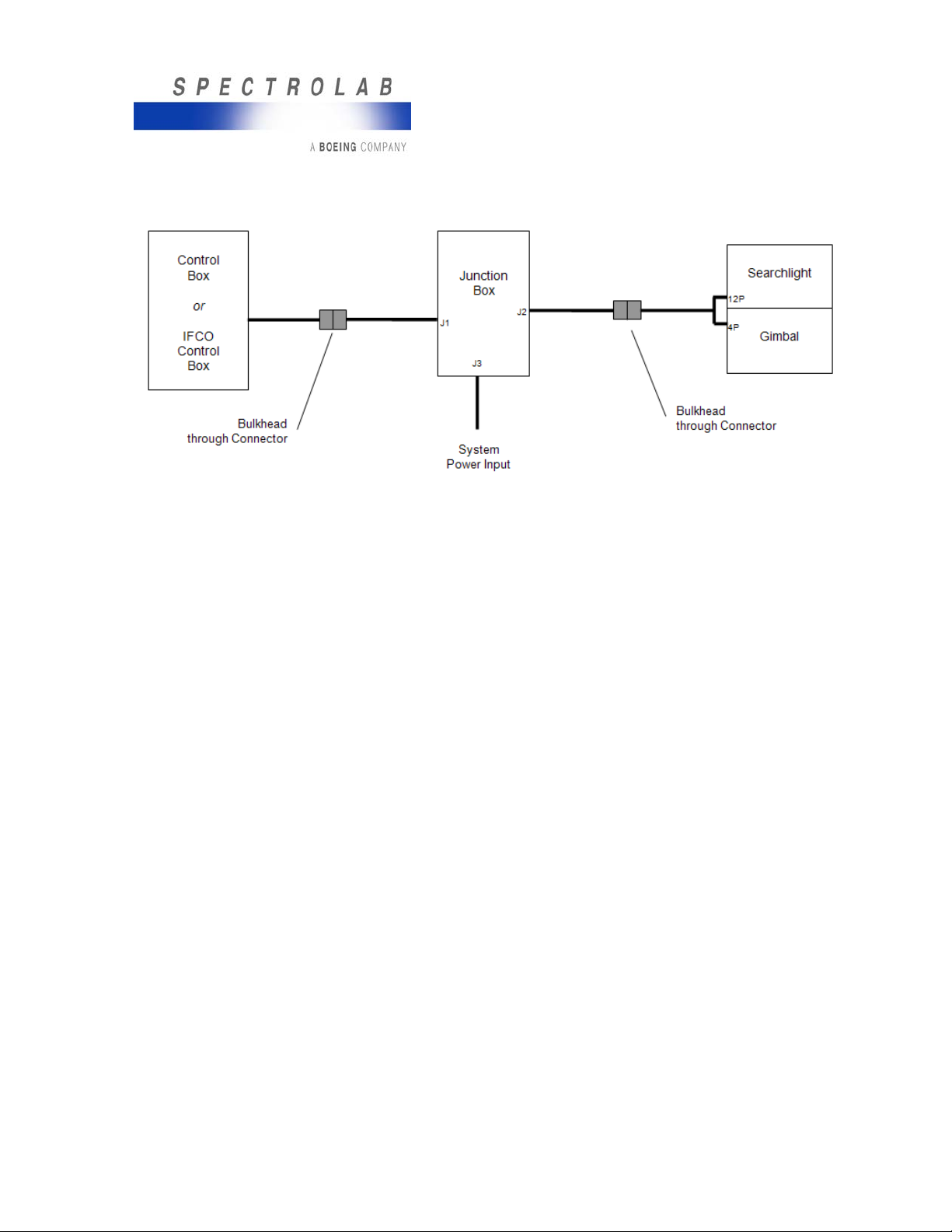

SX-16 Nightsun®Searchlight System

Maintenance Manual

Document 031734-1/Revision A 031734-1 Revision B

January 27, 2014

2.0 SAFETY

2.1 Product Safety

SX-16 Nightsun®poses the following hazards that can cause fatal or serious personal injury or

damage to nearby property, including the aircraft:

•The Searchlight generates high-voltages that can cause electrical shock.

•The Searchlight generates high temperatures that can cause a serious burn to a victim or

start a fire.

•The Searchlight generates a high-intensity light that can cause blindness or start a fire.

•The Searchlight has a pressurized xenon gas arc lamp that poses an explosion hazard.

Obey the safety precautions in this section and the precautions displayed in each section at all times.

Although the SX-16 Nightsun®is designed and manufactured to provide years of safe operation, you

are responsible for using this product properly and safely. You also are responsible for training others

to use and maintain this product safely. Do not take chances; contact Spectrolab with any questions.

2.1.1 High-voltage Electrical Shock

The SX-16 Nightsun®generates voltages in the range of 125 to 150 volts DC and up to 25,000 volts

AC. These voltages are present in both the Searchlight and Junction Box during the start cycle. To

reduce the risk of serious injury from electrical shock:

•Never work alone when working on exposed electrical components.

•During close up inspection activities, remove the Control Box or its cable, or disconnect the

Searchlight cable (power) so that the Searchlight cannot be turned on accidentally.

•High Searchlight voltages normally discharge a few seconds after the start cycle ends. Under

certain malfunction or fault conditions, however, they may remain in the 25,000 VAC range.

oUse a voltmeter to verify that voltage in the Junction Box’s large Capacitor has

discharged from its 125 to 150 VDC level before touching its terminals.

oSimilarly, use a voltmeter to verify that the start signal to the Junction Box terminal

strip is zero. This indicates that all power to the start circuit is off.

2.1.2 Lamp Explosion Hazard

The arc lamp contains xenon gas under pressure. Because the gas inside the lamp is pressurized,

the lamp can explode without warning, especially when it is hot. If it explodes, it may shoot quartz

particles in every direction. Always handle the Searchlight and lamp with caution, and ensure the

safety of others.

•Never operate the Searchlight with the front window or rear cover removed.

•The Searchlight must be cooled to ambient temperature before you work on it.

•If you must handle the arc lamp or work on the Searchlight head with the front lens removed,

wear protective clothing that includes a face shield, a long-sleeve heavy (leather) jacket, and

leather gloves.

•Never leave an exposed xenon lamp unattended.

2.1.3 High Temperature, High-intensity Light

The light from the SX-16 Nightsun®is very powerful; the intense beam can cause serious eye injury

or blindness, and the high temperatures pose a fire hazard. The Searchlight beam is hazardous to

people and certain materials at close range, particularly at distances within 10 feet of the Searchlight.

At a 10 foot distance, the beam intensity can be 100 times as powerful as direct sunlight, and its

reflection can be more intense.

•Do not look into the Searchlight beam, and never shine the light at anyone within 125 feet of

the Searchlight.

•At distances of less than 10 feet, flammable materials (such as human hair, clothing, wiping

rags, paper, cardboard, wood boxes, electrical insulation, and most plastics) can and will be

set on fire.

Source: Spectrolab, Inc. 2

The document reference is online, please check the correspondence between the online documentation and the printed version.